Neoprene as a Foundation in Modern Membrane Solutions

AUG 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Neoprene Membrane Evolution

Neoprene, a synthetic rubber developed by DuPont in 1930, has played a pivotal role in the evolution of modern membrane solutions. Initially created as an oil-resistant alternative to natural rubber, neoprene quickly found applications in various industries due to its unique properties. The evolution of neoprene membranes can be traced through several key stages, each marked by significant advancements in material science and manufacturing techniques.

In the early years, neoprene membranes were primarily used in industrial applications, such as gaskets and seals, where their resistance to oils, chemicals, and weathering was highly valued. The 1950s and 1960s saw the expansion of neoprene into the construction industry, with its introduction as a waterproofing membrane for roofing and foundation systems. This period marked a crucial turning point in the material's history, as it began to be recognized for its potential in building envelope solutions.

The 1970s and 1980s witnessed significant improvements in neoprene formulation and processing techniques. Manufacturers developed methods to enhance the material's durability, flexibility, and resistance to environmental factors. These advancements led to the creation of thinner, more efficient membranes that could be easily applied to a wider range of surfaces. During this time, neoprene membranes became increasingly popular in below-grade waterproofing applications, offering superior protection against water ingress and hydrostatic pressure.

The late 1990s and early 2000s saw a shift towards more environmentally friendly and sustainable building practices. This trend prompted researchers to explore ways to improve neoprene's environmental profile. Efforts were made to reduce the use of harmful chemicals in production and to develop recycling methods for neoprene products. These initiatives helped maintain neoprene's relevance in an increasingly eco-conscious market.

In recent years, the focus has been on enhancing neoprene's performance through composite technologies. By combining neoprene with other materials such as reinforcing fabrics or polymers, manufacturers have created hybrid membranes that offer improved strength, durability, and application versatility. These composite membranes have found applications in demanding environments, such as green roofs and plaza decks, where traditional single-ply membranes may fall short.

The latest developments in neoprene membrane technology involve the integration of smart features. Researchers are exploring ways to incorporate sensors and conductive elements into neoprene membranes, enabling real-time monitoring of structural integrity and environmental conditions. This innovation promises to revolutionize building maintenance and safety protocols, particularly in critical infrastructure projects.

In the early years, neoprene membranes were primarily used in industrial applications, such as gaskets and seals, where their resistance to oils, chemicals, and weathering was highly valued. The 1950s and 1960s saw the expansion of neoprene into the construction industry, with its introduction as a waterproofing membrane for roofing and foundation systems. This period marked a crucial turning point in the material's history, as it began to be recognized for its potential in building envelope solutions.

The 1970s and 1980s witnessed significant improvements in neoprene formulation and processing techniques. Manufacturers developed methods to enhance the material's durability, flexibility, and resistance to environmental factors. These advancements led to the creation of thinner, more efficient membranes that could be easily applied to a wider range of surfaces. During this time, neoprene membranes became increasingly popular in below-grade waterproofing applications, offering superior protection against water ingress and hydrostatic pressure.

The late 1990s and early 2000s saw a shift towards more environmentally friendly and sustainable building practices. This trend prompted researchers to explore ways to improve neoprene's environmental profile. Efforts were made to reduce the use of harmful chemicals in production and to develop recycling methods for neoprene products. These initiatives helped maintain neoprene's relevance in an increasingly eco-conscious market.

In recent years, the focus has been on enhancing neoprene's performance through composite technologies. By combining neoprene with other materials such as reinforcing fabrics or polymers, manufacturers have created hybrid membranes that offer improved strength, durability, and application versatility. These composite membranes have found applications in demanding environments, such as green roofs and plaza decks, where traditional single-ply membranes may fall short.

The latest developments in neoprene membrane technology involve the integration of smart features. Researchers are exploring ways to incorporate sensors and conductive elements into neoprene membranes, enabling real-time monitoring of structural integrity and environmental conditions. This innovation promises to revolutionize building maintenance and safety protocols, particularly in critical infrastructure projects.

Market Demand Analysis

The market demand for neoprene-based membrane solutions has been steadily growing in recent years, driven by the increasing need for durable and versatile materials in various industries. Neoprene, a synthetic rubber known for its excellent resistance to weathering, oil, and chemicals, has found widespread applications in modern membrane solutions, particularly in construction, automotive, and industrial sectors.

In the construction industry, neoprene membranes are increasingly sought after for their waterproofing properties and ability to withstand extreme weather conditions. The growing emphasis on sustainable and energy-efficient buildings has further boosted the demand for neoprene-based solutions, as they contribute to improved insulation and longevity of structures. This trend is expected to continue as urbanization accelerates and the need for resilient infrastructure grows.

The automotive sector represents another significant market for neoprene membranes. With the rising production of vehicles worldwide and the increasing focus on vehicle safety and comfort, the demand for neoprene-based components such as gaskets, seals, and vibration dampeners has surged. The material's ability to maintain flexibility across a wide temperature range makes it particularly valuable in automotive applications.

In the industrial sector, neoprene membranes are gaining traction in various applications, including chemical processing, oil and gas, and manufacturing. The material's resistance to corrosion, chemicals, and abrasion makes it an ideal choice for protective coatings, linings, and seals in harsh industrial environments. As industries continue to prioritize safety and efficiency, the demand for neoprene-based solutions is expected to grow.

The global market for neoprene membranes is also being driven by advancements in material science and manufacturing technologies. Innovations in neoprene formulations and production processes have led to improved performance characteristics and cost-effectiveness, further expanding its potential applications and market reach.

Geographically, the Asia-Pacific region is emerging as a key market for neoprene-based membrane solutions, fueled by rapid industrialization, infrastructure development, and automotive production in countries like China and India. North America and Europe continue to be significant markets, with a focus on high-performance applications and sustainable solutions.

Despite the positive market outlook, challenges such as fluctuating raw material prices and environmental concerns regarding the production and disposal of synthetic rubber products may impact the growth trajectory. However, ongoing research into more sustainable production methods and the development of bio-based alternatives are expected to address these concerns and further drive market expansion in the coming years.

In the construction industry, neoprene membranes are increasingly sought after for their waterproofing properties and ability to withstand extreme weather conditions. The growing emphasis on sustainable and energy-efficient buildings has further boosted the demand for neoprene-based solutions, as they contribute to improved insulation and longevity of structures. This trend is expected to continue as urbanization accelerates and the need for resilient infrastructure grows.

The automotive sector represents another significant market for neoprene membranes. With the rising production of vehicles worldwide and the increasing focus on vehicle safety and comfort, the demand for neoprene-based components such as gaskets, seals, and vibration dampeners has surged. The material's ability to maintain flexibility across a wide temperature range makes it particularly valuable in automotive applications.

In the industrial sector, neoprene membranes are gaining traction in various applications, including chemical processing, oil and gas, and manufacturing. The material's resistance to corrosion, chemicals, and abrasion makes it an ideal choice for protective coatings, linings, and seals in harsh industrial environments. As industries continue to prioritize safety and efficiency, the demand for neoprene-based solutions is expected to grow.

The global market for neoprene membranes is also being driven by advancements in material science and manufacturing technologies. Innovations in neoprene formulations and production processes have led to improved performance characteristics and cost-effectiveness, further expanding its potential applications and market reach.

Geographically, the Asia-Pacific region is emerging as a key market for neoprene-based membrane solutions, fueled by rapid industrialization, infrastructure development, and automotive production in countries like China and India. North America and Europe continue to be significant markets, with a focus on high-performance applications and sustainable solutions.

Despite the positive market outlook, challenges such as fluctuating raw material prices and environmental concerns regarding the production and disposal of synthetic rubber products may impact the growth trajectory. However, ongoing research into more sustainable production methods and the development of bio-based alternatives are expected to address these concerns and further drive market expansion in the coming years.

Technical Challenges

Neoprene, as a foundation in modern membrane solutions, faces several technical challenges that hinder its widespread adoption and optimal performance. One of the primary issues is the material's limited temperature resistance. While neoprene exhibits excellent flexibility and durability at room temperature, its properties degrade significantly at extreme temperatures, particularly in high-heat environments. This thermal instability restricts its application in industries requiring consistent performance across a wide temperature range.

Another significant challenge is the material's susceptibility to chemical degradation. Although neoprene demonstrates good resistance to many common chemicals, it can be vulnerable to certain solvents, oils, and aggressive chemicals. This limitation necessitates careful consideration of the operational environment and potential chemical exposures when designing neoprene-based membrane solutions.

The aging and weathering of neoprene pose additional technical hurdles. Prolonged exposure to UV radiation, ozone, and atmospheric pollutants can lead to surface cracking, discoloration, and a gradual decline in mechanical properties. This degradation process affects the long-term reliability and lifespan of neoprene membranes, particularly in outdoor applications or harsh environmental conditions.

Achieving consistent quality and performance across large-scale production remains a challenge. The manufacturing process of neoprene membranes involves complex chemical reactions and processing steps, making it difficult to maintain uniform thickness, density, and mechanical properties. These variations can lead to inconsistencies in the final product's performance and reliability.

The environmental impact of neoprene production and disposal presents another significant challenge. The manufacturing process involves the use of potentially harmful chemicals and generates substantial energy consumption. Additionally, the end-of-life disposal of neoprene products raises concerns about environmental sustainability, as the material is not biodegradable and can contribute to long-term pollution if not properly managed.

Balancing the trade-offs between different performance attributes poses a continuous challenge in neoprene membrane development. Enhancing one property, such as chemical resistance, often comes at the expense of others, like flexibility or tear strength. This necessitates careful optimization and sometimes compromises in material formulation to meet specific application requirements.

Lastly, the integration of neoprene with other materials and components in complex membrane systems presents technical difficulties. Ensuring proper adhesion, compatibility, and long-term stability at material interfaces requires extensive research and testing. The development of effective bonding techniques and composite structures that leverage neoprene's unique properties while mitigating its limitations remains an ongoing challenge in the field of modern membrane solutions.

Another significant challenge is the material's susceptibility to chemical degradation. Although neoprene demonstrates good resistance to many common chemicals, it can be vulnerable to certain solvents, oils, and aggressive chemicals. This limitation necessitates careful consideration of the operational environment and potential chemical exposures when designing neoprene-based membrane solutions.

The aging and weathering of neoprene pose additional technical hurdles. Prolonged exposure to UV radiation, ozone, and atmospheric pollutants can lead to surface cracking, discoloration, and a gradual decline in mechanical properties. This degradation process affects the long-term reliability and lifespan of neoprene membranes, particularly in outdoor applications or harsh environmental conditions.

Achieving consistent quality and performance across large-scale production remains a challenge. The manufacturing process of neoprene membranes involves complex chemical reactions and processing steps, making it difficult to maintain uniform thickness, density, and mechanical properties. These variations can lead to inconsistencies in the final product's performance and reliability.

The environmental impact of neoprene production and disposal presents another significant challenge. The manufacturing process involves the use of potentially harmful chemicals and generates substantial energy consumption. Additionally, the end-of-life disposal of neoprene products raises concerns about environmental sustainability, as the material is not biodegradable and can contribute to long-term pollution if not properly managed.

Balancing the trade-offs between different performance attributes poses a continuous challenge in neoprene membrane development. Enhancing one property, such as chemical resistance, often comes at the expense of others, like flexibility or tear strength. This necessitates careful optimization and sometimes compromises in material formulation to meet specific application requirements.

Lastly, the integration of neoprene with other materials and components in complex membrane systems presents technical difficulties. Ensuring proper adhesion, compatibility, and long-term stability at material interfaces requires extensive research and testing. The development of effective bonding techniques and composite structures that leverage neoprene's unique properties while mitigating its limitations remains an ongoing challenge in the field of modern membrane solutions.

Current Neoprene Solutions

01 Composition and synthesis of neoprene

Neoprene is a synthetic rubber produced by polymerization of chloroprene. Various methods and compositions are used to synthesize neoprene with specific properties, including the use of different catalysts, additives, and polymerization techniques to control the molecular structure and characteristics of the resulting polymer.- Composition and synthesis of neoprene: Neoprene is a synthetic rubber produced by polymerization of chloroprene. It is known for its resistance to oil, heat, and weathering. The manufacturing process involves careful control of reaction conditions and may include various additives to enhance specific properties.

- Applications of neoprene in protective gear: Neoprene is widely used in the production of protective clothing and equipment due to its durability and flexibility. It is commonly found in wetsuits, diving suits, and other water-resistant garments. The material's insulating properties make it suitable for various outdoor and sports applications.

- Neoprene foam and its uses: Neoprene foam is a versatile material used in various industries. It is produced by introducing gas bubbles into the neoprene during the manufacturing process. The resulting foam offers excellent insulation, cushioning, and shock-absorbing properties, making it suitable for applications in automotive, construction, and sports equipment.

- Modifications and improvements to neoprene: Ongoing research focuses on enhancing neoprene's properties through various modifications. These improvements may include increasing its resistance to specific chemicals, enhancing its thermal stability, or improving its overall performance. Advanced manufacturing techniques and the incorporation of new additives contribute to the development of specialized neoprene variants.

- Environmental considerations and alternatives: As environmental concerns grow, efforts are being made to develop more sustainable alternatives to traditional neoprene. This includes exploring bio-based materials, improving recycling processes for neoprene products, and developing production methods with reduced environmental impact. The industry is also focusing on creating neoprene alternatives that maintain similar performance characteristics while being more eco-friendly.

02 Applications of neoprene in protective gear

Neoprene is widely used in the production of protective gear due to its excellent insulation, flexibility, and durability properties. It is commonly used in wetsuits, diving suits, and other water-resistant clothing. The material can be engineered to provide varying levels of thermal insulation and protection against environmental factors.Expand Specific Solutions03 Neoprene foam production and properties

Neoprene foam is a versatile material with applications in various industries. The production process involves the introduction of gas bubbles into the neoprene compound during polymerization or through chemical blowing agents. The resulting foam can be tailored to have specific properties such as density, cell structure, and compression resistance.Expand Specific Solutions04 Neoprene in adhesive and sealant formulations

Neoprene is used as a key component in various adhesive and sealant formulations due to its excellent bonding properties, chemical resistance, and durability. These formulations often include additional components to enhance specific properties such as tack, peel strength, and heat resistance.Expand Specific Solutions05 Modifications and blends of neoprene

To enhance its properties or create specialized materials, neoprene is often modified or blended with other polymers or additives. These modifications can improve characteristics such as flame resistance, oil resistance, or weatherability. Techniques include chemical modifications, physical blending, and the incorporation of nanoparticles or other functional materials.Expand Specific Solutions

Key Industry Players

The research on Neoprene as a foundation in modern membrane solutions is in a growth phase, with increasing market size and technological advancements. The global neoprene market is expanding due to its versatile applications in various industries. Companies like Tianjin Pengling Group Co. Ltd., Zhuzhou Times New Materials Technology Co., Ltd., and Denka Corp. are at the forefront of neoprene technology development. The technology's maturity is advancing, with research institutions such as the National Research Council of Canada and universities like Yale and Harvard contributing to innovations. Collaborations between industry players and academic institutions are driving the technology's evolution, indicating a competitive landscape with potential for further growth and innovation.

Denka Corp.

Technical Solution: Denka Corp. has developed advanced neoprene-based membrane solutions for various applications. Their research focuses on improving the chemical resistance and durability of neoprene membranes. They have introduced a proprietary cross-linking technology that enhances the material's resistance to oils, solvents, and extreme temperatures[1]. This innovation has led to the development of neoprene membranes with extended lifespan and improved performance in harsh industrial environments. Denka's neoprene membranes also incorporate nano-scale additives to enhance flexibility and reduce weight without compromising strength[3]. The company has successfully applied these membranes in automotive, construction, and aerospace industries, demonstrating the versatility of their neoprene-based solutions[5].

Strengths: Superior chemical resistance, enhanced durability, and versatility across multiple industries. Weaknesses: Potentially higher production costs due to advanced technologies and additives used.

Sekisui Chemical Co., Ltd.

Technical Solution: Sekisui Chemical Co., Ltd. has focused on developing neoprene-based membranes for sustainable building solutions. Their research has resulted in the creation of high-performance neoprene membranes for roofing and waterproofing applications. These membranes feature a unique layered structure that combines neoprene with other polymers to enhance UV resistance and weatherability[7]. Sekisui's neoprene membranes have demonstrated a 50% increase in lifespan compared to traditional roofing materials[9]. The company has also incorporated self-healing properties into their neoprene membranes, allowing for automatic repair of minor damages and punctures, thus reducing maintenance costs and improving long-term performance[11].

Strengths: Excellent weatherability, self-healing properties, and extended lifespan. Weaknesses: Higher initial costs compared to traditional roofing materials.

Core Neoprene Innovations

Flexible membranes

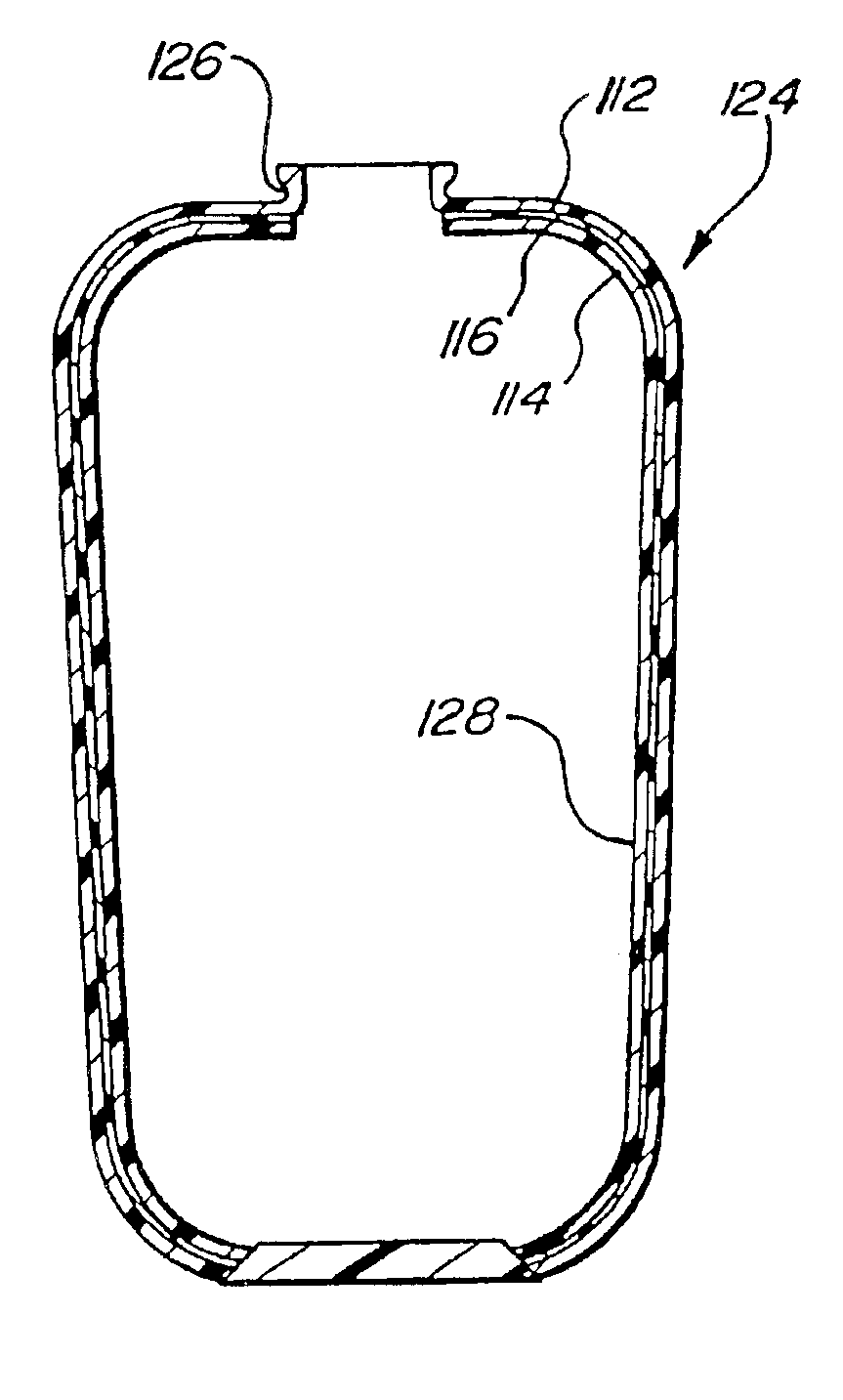

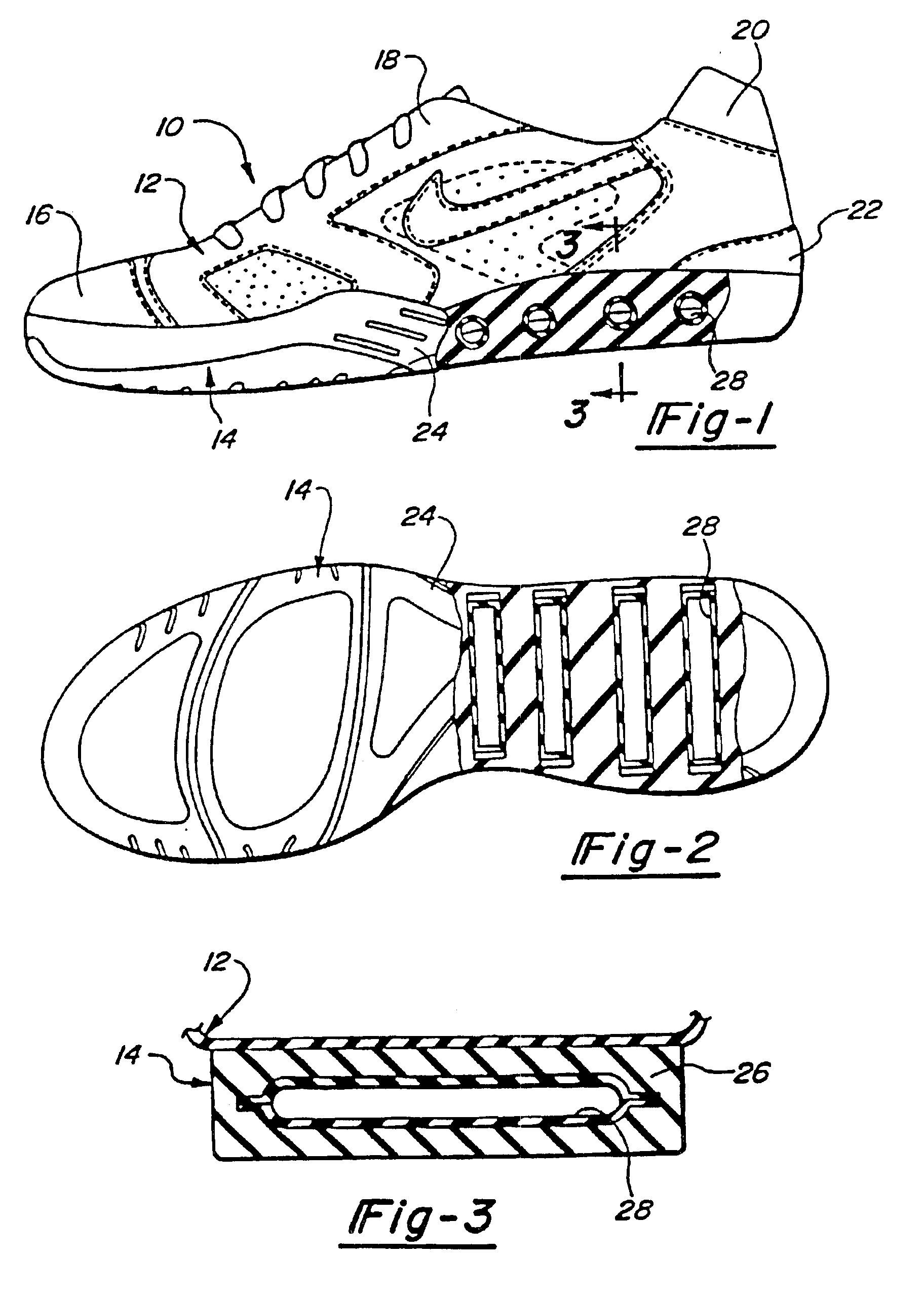

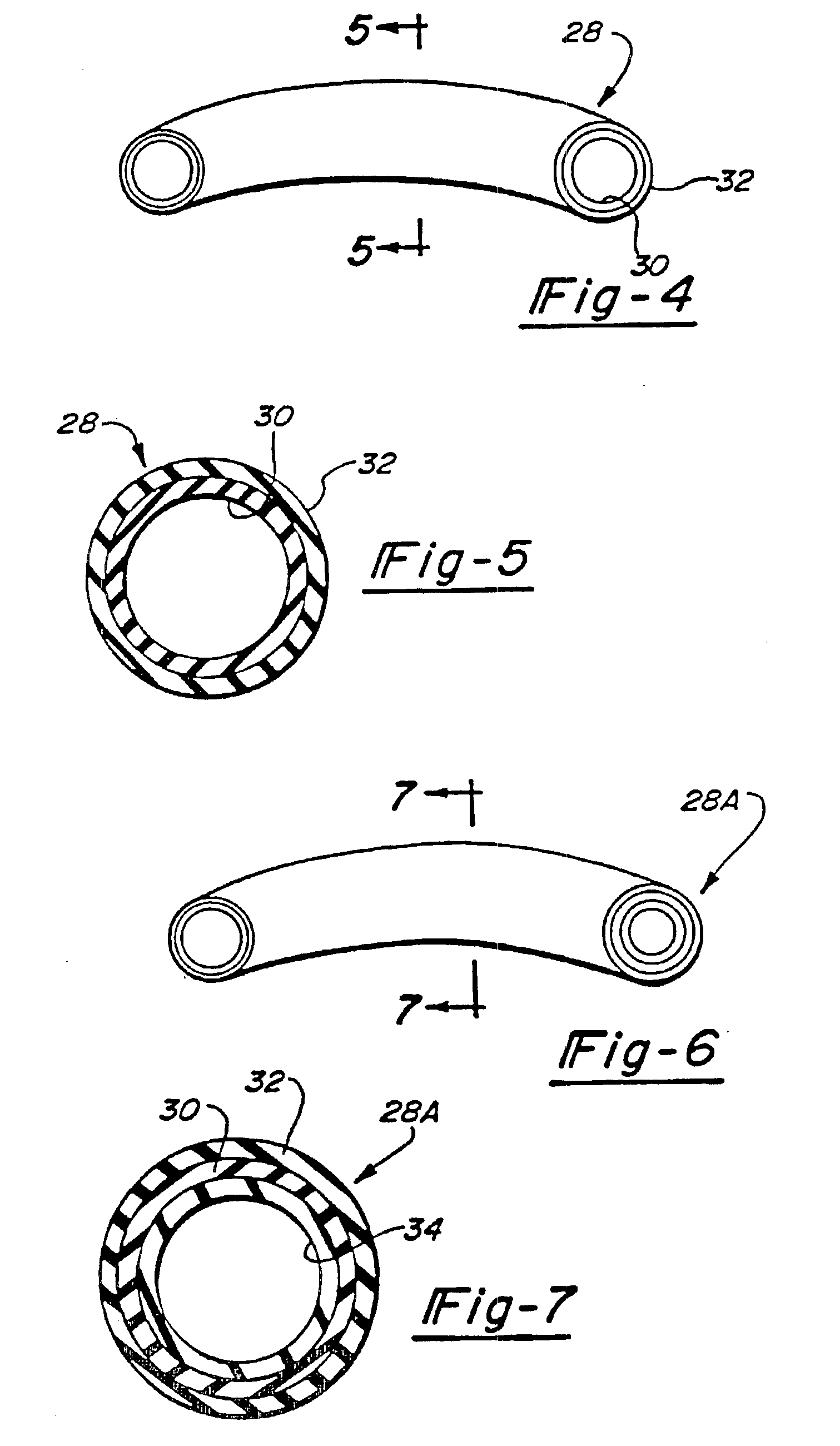

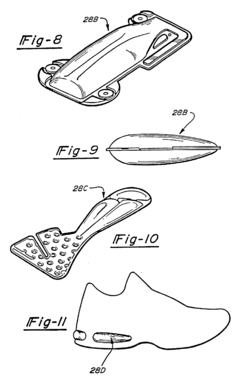

PatentInactiveUS6846534B2

Innovation

- The development of microlayer polymeric composites with alternating thin layers of elastomeric and fluid barrier materials, which provide enhanced flexibility, resistance to gas transmission, and improved durability, allowing for the creation of membranes with low nitrogen gas transmission rates suitable for long-lasting inflation without frequent re-pressurization.

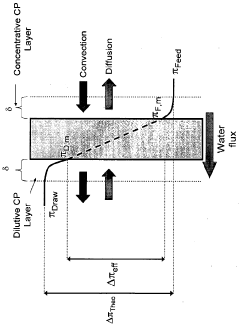

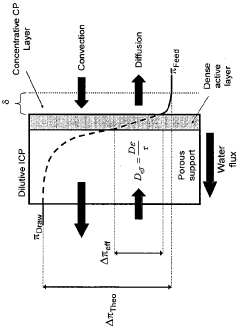

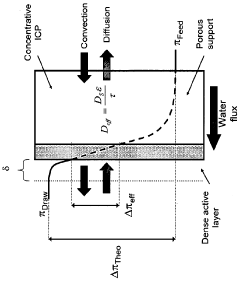

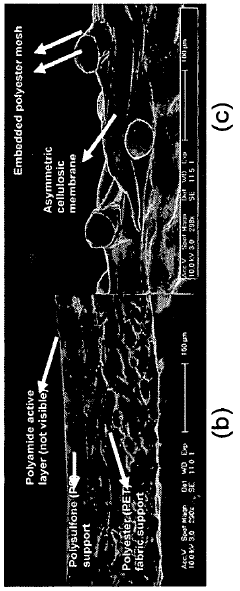

Method for designing membranes for osmotically driven membrane processes

PatentWO2008137082A1

Innovation

- Designing composite membranes with hydrophilic support layers of high porosity, low tortuosity, and minimal thickness, and using polymer blends or nanofiber webs to enhance osmotic flux, while ensuring chemical compatibility with draw and feed solutions, to reduce internal concentration polarization and improve water transport efficiency.

Environmental Impact

The environmental impact of neoprene as a foundation in modern membrane solutions is a critical consideration in the development and application of this material. Neoprene, a synthetic rubber produced through polymerization of chloroprene, has both positive and negative environmental implications throughout its lifecycle.

From a production standpoint, the manufacturing process of neoprene involves the use of petrochemicals and energy-intensive procedures, contributing to carbon emissions and potential environmental pollution. The chloroprene monomer used in neoprene production is derived from fossil fuels, raising concerns about resource depletion and greenhouse gas emissions associated with extraction and processing.

However, neoprene's durability and resistance to degradation offer potential environmental benefits in terms of product longevity. Membrane solutions incorporating neoprene often have extended lifespans compared to alternative materials, potentially reducing the frequency of replacement and associated waste generation. This durability can lead to a lower overall environmental footprint when considering the full lifecycle of membrane applications.

In terms of end-of-life considerations, neoprene presents challenges for recycling and disposal. While some recycling processes for neoprene exist, they are not widely available or economically viable on a large scale. The material's resistance to degradation, while beneficial during use, becomes problematic when neoprene products reach the end of their useful life, potentially contributing to long-term waste accumulation in landfills.

Water pollution is another environmental concern associated with neoprene production and use. The manufacturing process can release harmful chemicals into waterways if not properly managed, and the material itself may leach compounds over time when exposed to aquatic environments. This potential for water contamination necessitates careful consideration in applications where neoprene-based membranes come into contact with water resources.

On the positive side, neoprene's chemical resistance and impermeability make it an effective barrier material in environmental protection applications. Neoprene-based membranes can be used to contain hazardous materials, prevent soil and groundwater contamination, and protect sensitive ecosystems from pollutants. This protective capability contributes to environmental preservation efforts in various industries.

As environmental awareness grows, research into more sustainable alternatives and production methods for neoprene is ongoing. Efforts to develop bio-based precursors for neoprene production, improve recycling technologies, and enhance the material's biodegradability are areas of active investigation. These advancements aim to mitigate the environmental impact of neoprene while maintaining its beneficial properties for membrane solutions.

From a production standpoint, the manufacturing process of neoprene involves the use of petrochemicals and energy-intensive procedures, contributing to carbon emissions and potential environmental pollution. The chloroprene monomer used in neoprene production is derived from fossil fuels, raising concerns about resource depletion and greenhouse gas emissions associated with extraction and processing.

However, neoprene's durability and resistance to degradation offer potential environmental benefits in terms of product longevity. Membrane solutions incorporating neoprene often have extended lifespans compared to alternative materials, potentially reducing the frequency of replacement and associated waste generation. This durability can lead to a lower overall environmental footprint when considering the full lifecycle of membrane applications.

In terms of end-of-life considerations, neoprene presents challenges for recycling and disposal. While some recycling processes for neoprene exist, they are not widely available or economically viable on a large scale. The material's resistance to degradation, while beneficial during use, becomes problematic when neoprene products reach the end of their useful life, potentially contributing to long-term waste accumulation in landfills.

Water pollution is another environmental concern associated with neoprene production and use. The manufacturing process can release harmful chemicals into waterways if not properly managed, and the material itself may leach compounds over time when exposed to aquatic environments. This potential for water contamination necessitates careful consideration in applications where neoprene-based membranes come into contact with water resources.

On the positive side, neoprene's chemical resistance and impermeability make it an effective barrier material in environmental protection applications. Neoprene-based membranes can be used to contain hazardous materials, prevent soil and groundwater contamination, and protect sensitive ecosystems from pollutants. This protective capability contributes to environmental preservation efforts in various industries.

As environmental awareness grows, research into more sustainable alternatives and production methods for neoprene is ongoing. Efforts to develop bio-based precursors for neoprene production, improve recycling technologies, and enhance the material's biodegradability are areas of active investigation. These advancements aim to mitigate the environmental impact of neoprene while maintaining its beneficial properties for membrane solutions.

Regulatory Compliance

Regulatory compliance plays a crucial role in the development and application of neoprene-based membrane solutions. As these materials are widely used in various industries, including construction, automotive, and healthcare, adherence to regulatory standards is essential to ensure safety, performance, and environmental sustainability.

In the construction industry, neoprene membranes must comply with building codes and standards set by organizations such as the International Code Council (ICC) and the American Society for Testing and Materials (ASTM). These regulations often focus on fire resistance, water resistance, and durability. For instance, ASTM D6134 provides standard specifications for vulcanized rubber sheets used in roofing and waterproofing applications, which neoprene membranes must meet.

The automotive sector imposes strict regulations on neoprene-based components, particularly concerning safety and environmental impact. Compliance with standards set by the National Highway Traffic Safety Administration (NHTSA) and the Environmental Protection Agency (EPA) is mandatory. These regulations address issues such as flammability resistance, off-gassing, and recyclability of materials used in vehicle manufacturing.

In healthcare applications, neoprene-based products must adhere to regulations set by the Food and Drug Administration (FDA) and other relevant health authorities. These regulations ensure the biocompatibility and safety of materials used in medical devices, prosthetics, and other healthcare-related applications. Compliance with ISO 10993, which outlines the biological evaluation of medical devices, is often required for neoprene-based products in this sector.

Environmental regulations also significantly impact the production and use of neoprene membranes. The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation and similar laws in other regions require manufacturers to assess and manage the risks associated with chemicals used in neoprene production. This includes monitoring and reporting on potentially harmful substances and finding alternatives when necessary.

As sustainability becomes increasingly important, regulations promoting the use of eco-friendly materials and manufacturing processes are emerging. These regulations may influence the development of neoprene alternatives or drive innovations in recycling and disposal methods for neoprene-based products. Manufacturers must stay informed about evolving regulations and adapt their products and processes accordingly to maintain compliance and market competitiveness.

Compliance with these diverse regulatory requirements necessitates ongoing research and development efforts in neoprene-based membrane solutions. This includes improving material properties, developing new formulations, and enhancing manufacturing processes to meet evolving standards across different industries and regions. As regulatory landscapes continue to change, the ability to adapt and innovate will be crucial for companies working with neoprene-based membrane solutions.

In the construction industry, neoprene membranes must comply with building codes and standards set by organizations such as the International Code Council (ICC) and the American Society for Testing and Materials (ASTM). These regulations often focus on fire resistance, water resistance, and durability. For instance, ASTM D6134 provides standard specifications for vulcanized rubber sheets used in roofing and waterproofing applications, which neoprene membranes must meet.

The automotive sector imposes strict regulations on neoprene-based components, particularly concerning safety and environmental impact. Compliance with standards set by the National Highway Traffic Safety Administration (NHTSA) and the Environmental Protection Agency (EPA) is mandatory. These regulations address issues such as flammability resistance, off-gassing, and recyclability of materials used in vehicle manufacturing.

In healthcare applications, neoprene-based products must adhere to regulations set by the Food and Drug Administration (FDA) and other relevant health authorities. These regulations ensure the biocompatibility and safety of materials used in medical devices, prosthetics, and other healthcare-related applications. Compliance with ISO 10993, which outlines the biological evaluation of medical devices, is often required for neoprene-based products in this sector.

Environmental regulations also significantly impact the production and use of neoprene membranes. The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation and similar laws in other regions require manufacturers to assess and manage the risks associated with chemicals used in neoprene production. This includes monitoring and reporting on potentially harmful substances and finding alternatives when necessary.

As sustainability becomes increasingly important, regulations promoting the use of eco-friendly materials and manufacturing processes are emerging. These regulations may influence the development of neoprene alternatives or drive innovations in recycling and disposal methods for neoprene-based products. Manufacturers must stay informed about evolving regulations and adapt their products and processes accordingly to maintain compliance and market competitiveness.

Compliance with these diverse regulatory requirements necessitates ongoing research and development efforts in neoprene-based membrane solutions. This includes improving material properties, developing new formulations, and enhancing manufacturing processes to meet evolving standards across different industries and regions. As regulatory landscapes continue to change, the ability to adapt and innovate will be crucial for companies working with neoprene-based membrane solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!