Non-toxic Borosilicate Glasses for Environmental Applications

JUL 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Borosilicate Glass Evolution and Objectives

Borosilicate glass has a rich history dating back to the late 19th century when German glassmaker Otto Schott first developed this versatile material. Initially prized for its thermal shock resistance and chemical durability, borosilicate glass quickly found applications in laboratory equipment and household cookware. Over the decades, its use has expanded into various industrial and environmental applications, driven by its unique properties and adaptability.

The evolution of borosilicate glass has been marked by continuous improvements in composition and manufacturing techniques. Early formulations focused on optimizing the ratio of silica to boron oxide to achieve desired properties. As research progressed, the inclusion of other oxides such as aluminum and sodium further enhanced the glass's characteristics, leading to a wide range of specialized compositions tailored for specific applications.

In recent years, the focus has shifted towards developing non-toxic borosilicate glasses for environmental applications. This trend is driven by growing concerns over the potential health and ecological impacts of traditional glass compositions, particularly those containing heavy metals or other harmful elements. The objective is to create borosilicate glasses that maintain their superior physical and chemical properties while minimizing environmental risks.

Current research aims to explore novel compositions that replace potentially toxic components with more benign alternatives. This includes investigating the use of alternative network formers and modifiers that can provide similar or enhanced properties without compromising safety. Additionally, efforts are being made to optimize the manufacturing processes to reduce energy consumption and emissions, aligning with broader sustainability goals.

The development of non-toxic borosilicate glasses for environmental applications presents several key objectives. Firstly, researchers seek to maintain or improve the glass's resistance to chemical attack, thermal shock, and mechanical stress – properties that are crucial for its use in environmental monitoring and remediation. Secondly, there is a focus on enhancing the glass's ability to encapsulate or immobilize environmental contaminants, potentially expanding its role in waste management and pollution control.

Another important objective is to improve the recyclability and end-of-life management of borosilicate glass products. This involves developing compositions that are easier to recycle or repurpose, reducing the environmental footprint of these materials throughout their lifecycle. Furthermore, researchers are exploring ways to incorporate recycled materials into new borosilicate glass formulations, contributing to a more circular economy approach in glass production.

As the field progresses, the ultimate goal is to create a new generation of borosilicate glasses that not only meet stringent performance requirements but also align with the principles of green chemistry and sustainable materials science. This evolution represents a significant step towards more environmentally responsible technologies, potentially opening up new applications in environmental monitoring, remediation, and protection.

The evolution of borosilicate glass has been marked by continuous improvements in composition and manufacturing techniques. Early formulations focused on optimizing the ratio of silica to boron oxide to achieve desired properties. As research progressed, the inclusion of other oxides such as aluminum and sodium further enhanced the glass's characteristics, leading to a wide range of specialized compositions tailored for specific applications.

In recent years, the focus has shifted towards developing non-toxic borosilicate glasses for environmental applications. This trend is driven by growing concerns over the potential health and ecological impacts of traditional glass compositions, particularly those containing heavy metals or other harmful elements. The objective is to create borosilicate glasses that maintain their superior physical and chemical properties while minimizing environmental risks.

Current research aims to explore novel compositions that replace potentially toxic components with more benign alternatives. This includes investigating the use of alternative network formers and modifiers that can provide similar or enhanced properties without compromising safety. Additionally, efforts are being made to optimize the manufacturing processes to reduce energy consumption and emissions, aligning with broader sustainability goals.

The development of non-toxic borosilicate glasses for environmental applications presents several key objectives. Firstly, researchers seek to maintain or improve the glass's resistance to chemical attack, thermal shock, and mechanical stress – properties that are crucial for its use in environmental monitoring and remediation. Secondly, there is a focus on enhancing the glass's ability to encapsulate or immobilize environmental contaminants, potentially expanding its role in waste management and pollution control.

Another important objective is to improve the recyclability and end-of-life management of borosilicate glass products. This involves developing compositions that are easier to recycle or repurpose, reducing the environmental footprint of these materials throughout their lifecycle. Furthermore, researchers are exploring ways to incorporate recycled materials into new borosilicate glass formulations, contributing to a more circular economy approach in glass production.

As the field progresses, the ultimate goal is to create a new generation of borosilicate glasses that not only meet stringent performance requirements but also align with the principles of green chemistry and sustainable materials science. This evolution represents a significant step towards more environmentally responsible technologies, potentially opening up new applications in environmental monitoring, remediation, and protection.

Market Demand for Eco-friendly Glass Solutions

The market demand for eco-friendly glass solutions has been steadily increasing in recent years, driven by growing environmental concerns and stricter regulations on toxic materials. Borosilicate glasses, known for their durability and chemical resistance, are gaining traction in various environmental applications due to their non-toxic nature and recyclability.

In the water treatment sector, there is a rising demand for borosilicate glass components in filtration systems and water purification equipment. These glasses offer superior resistance to chemical corrosion and thermal shock, making them ideal for handling diverse water contaminants. The global water treatment market, valued at $265 billion in 2021, is expected to grow significantly, further boosting the demand for eco-friendly glass solutions.

The renewable energy sector, particularly solar energy, presents another substantial market for non-toxic borosilicate glasses. These glasses are used in the production of solar panels and concentrated solar power systems due to their high transparency and low thermal expansion coefficient. With the solar energy market projected to reach $223 billion by 2026, the demand for environmentally friendly glass materials is set to surge.

In the field of environmental monitoring and analysis, there is an increasing need for non-toxic laboratory glassware. Borosilicate glasses are preferred for their chemical inertness and ability to withstand high temperatures, making them suitable for various analytical instruments and containment vessels used in environmental testing.

The packaging industry is also shifting towards more sustainable materials, creating opportunities for non-toxic borosilicate glasses. These glasses are being explored as alternatives to plastic packaging, especially for food and beverage containers, due to their recyclability and absence of harmful chemicals.

The construction sector is another area where eco-friendly glass solutions are gaining popularity. Green building initiatives are driving the demand for energy-efficient and environmentally friendly materials, including non-toxic glasses for windows, facades, and interior applications.

As consumers become more environmentally conscious, there is a growing market for household products made from non-toxic materials. This trend is creating opportunities for borosilicate glasses in kitchenware, storage containers, and decorative items, as consumers seek alternatives to plastic and other potentially harmful materials.

In the water treatment sector, there is a rising demand for borosilicate glass components in filtration systems and water purification equipment. These glasses offer superior resistance to chemical corrosion and thermal shock, making them ideal for handling diverse water contaminants. The global water treatment market, valued at $265 billion in 2021, is expected to grow significantly, further boosting the demand for eco-friendly glass solutions.

The renewable energy sector, particularly solar energy, presents another substantial market for non-toxic borosilicate glasses. These glasses are used in the production of solar panels and concentrated solar power systems due to their high transparency and low thermal expansion coefficient. With the solar energy market projected to reach $223 billion by 2026, the demand for environmentally friendly glass materials is set to surge.

In the field of environmental monitoring and analysis, there is an increasing need for non-toxic laboratory glassware. Borosilicate glasses are preferred for their chemical inertness and ability to withstand high temperatures, making them suitable for various analytical instruments and containment vessels used in environmental testing.

The packaging industry is also shifting towards more sustainable materials, creating opportunities for non-toxic borosilicate glasses. These glasses are being explored as alternatives to plastic packaging, especially for food and beverage containers, due to their recyclability and absence of harmful chemicals.

The construction sector is another area where eco-friendly glass solutions are gaining popularity. Green building initiatives are driving the demand for energy-efficient and environmentally friendly materials, including non-toxic glasses for windows, facades, and interior applications.

As consumers become more environmentally conscious, there is a growing market for household products made from non-toxic materials. This trend is creating opportunities for borosilicate glasses in kitchenware, storage containers, and decorative items, as consumers seek alternatives to plastic and other potentially harmful materials.

Current Challenges in Non-toxic Borosilicate Glass

The development of non-toxic borosilicate glasses for environmental applications faces several significant challenges. One of the primary obstacles is the need to maintain the desirable properties of traditional borosilicate glasses while eliminating or reducing toxic components. Boron, a key element in these glasses, can be environmentally harmful in high concentrations, necessitating careful formulation to minimize its release.

Another challenge lies in achieving the required chemical durability and thermal resistance without compromising the glass's environmental friendliness. Non-toxic alternatives often struggle to match the performance of their conventional counterparts, particularly in harsh environmental conditions. This balance between performance and safety is crucial for applications such as waste immobilization and water purification.

The manufacturing process of non-toxic borosilicate glasses presents its own set of challenges. Traditional production methods may need to be modified to accommodate new compositions, potentially increasing production costs and complexity. Ensuring consistent quality and properties across different batches of environmentally friendly formulations can be more difficult than with well-established compositions.

Regulatory compliance and certification pose additional hurdles. As environmental standards become more stringent, manufacturers must navigate a complex landscape of regulations that vary across different regions and applications. Demonstrating the long-term safety and efficacy of new non-toxic formulations can be a time-consuming and costly process.

The economic viability of non-toxic borosilicate glasses is also a significant concern. Higher production costs and the need for extensive research and development can make these glasses less competitive in the market. Convincing industries to adopt these new materials, especially when existing options are well-established and cost-effective, remains a challenge.

Furthermore, the limited availability of certain non-toxic raw materials can impact the scalability of production. Some alternative components may be scarce or expensive, affecting the feasibility of large-scale manufacturing. This scarcity can also lead to supply chain vulnerabilities, potentially disrupting production and increasing costs.

Lastly, there is a need for more comprehensive research on the long-term environmental impact of these new glass formulations. While they may be non-toxic in their initial state, understanding their behavior over extended periods and under various environmental conditions is crucial. This includes studying their degradation patterns, potential leaching of components, and overall lifecycle assessment.

Another challenge lies in achieving the required chemical durability and thermal resistance without compromising the glass's environmental friendliness. Non-toxic alternatives often struggle to match the performance of their conventional counterparts, particularly in harsh environmental conditions. This balance between performance and safety is crucial for applications such as waste immobilization and water purification.

The manufacturing process of non-toxic borosilicate glasses presents its own set of challenges. Traditional production methods may need to be modified to accommodate new compositions, potentially increasing production costs and complexity. Ensuring consistent quality and properties across different batches of environmentally friendly formulations can be more difficult than with well-established compositions.

Regulatory compliance and certification pose additional hurdles. As environmental standards become more stringent, manufacturers must navigate a complex landscape of regulations that vary across different regions and applications. Demonstrating the long-term safety and efficacy of new non-toxic formulations can be a time-consuming and costly process.

The economic viability of non-toxic borosilicate glasses is also a significant concern. Higher production costs and the need for extensive research and development can make these glasses less competitive in the market. Convincing industries to adopt these new materials, especially when existing options are well-established and cost-effective, remains a challenge.

Furthermore, the limited availability of certain non-toxic raw materials can impact the scalability of production. Some alternative components may be scarce or expensive, affecting the feasibility of large-scale manufacturing. This scarcity can also lead to supply chain vulnerabilities, potentially disrupting production and increasing costs.

Lastly, there is a need for more comprehensive research on the long-term environmental impact of these new glass formulations. While they may be non-toxic in their initial state, understanding their behavior over extended periods and under various environmental conditions is crucial. This includes studying their degradation patterns, potential leaching of components, and overall lifecycle assessment.

Existing Non-toxic Borosilicate Formulations

01 Composition of non-toxic borosilicate glasses

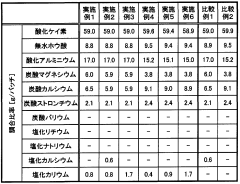

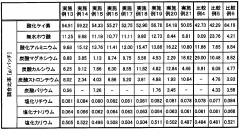

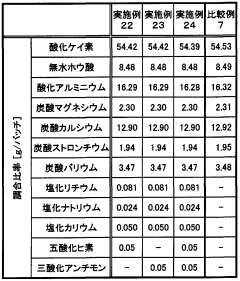

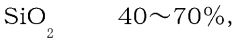

Non-toxic borosilicate glasses are formulated with specific compositions to ensure safety and desired properties. These glasses typically contain boron oxide, silica, and other oxides in carefully controlled proportions. The composition can be adjusted to achieve specific characteristics such as thermal resistance, chemical durability, and optical properties while maintaining low toxicity.- Composition of non-toxic borosilicate glasses: Non-toxic borosilicate glasses are formulated with specific compositions to ensure safety and desired properties. These glasses typically contain boron oxide, silica, and other elements in carefully controlled proportions. The composition can be adjusted to achieve specific characteristics such as thermal resistance, chemical durability, and optical properties while maintaining low toxicity.

- Manufacturing processes for non-toxic borosilicate glasses: Various manufacturing processes are employed to produce non-toxic borosilicate glasses. These may include melting raw materials at high temperatures, forming the molten glass into desired shapes, and applying specific heat treatments or annealing processes. Advanced techniques may be used to control the glass structure and properties, ensuring the final product meets safety and performance requirements.

- Applications of non-toxic borosilicate glasses: Non-toxic borosilicate glasses find applications in various fields due to their safety and unique properties. They are commonly used in laboratory glassware, pharmaceutical packaging, cookware, and optical components. These glasses are also utilized in specialized applications such as solar energy systems, electronics, and medical devices where biocompatibility and chemical resistance are crucial.

- Surface treatments and coatings for enhanced properties: Surface treatments and coatings can be applied to non-toxic borosilicate glasses to enhance their properties or add functionality. These treatments may include chemical etching, ion exchange processes, or the application of specialized coatings. Such modifications can improve characteristics like scratch resistance, hydrophobicity, or electrical conductivity while maintaining the glass's non-toxic nature.

- Testing and characterization of non-toxic borosilicate glasses: Various testing and characterization methods are employed to ensure the safety and performance of non-toxic borosilicate glasses. These may include chemical analysis, leaching tests, thermal shock resistance tests, and optical property measurements. Advanced analytical techniques such as spectroscopy and microscopy are used to study the glass structure and composition, ensuring compliance with safety standards and desired specifications.

02 Manufacturing processes for non-toxic borosilicate glasses

Various manufacturing processes are employed to produce non-toxic borosilicate glasses. These may include melting raw materials at high temperatures, forming the molten glass into desired shapes, and applying specific heat treatments. Advanced techniques such as sol-gel processes or vapor deposition methods may also be used for specialized applications, ensuring the final product maintains its non-toxic properties.Expand Specific Solutions03 Applications of non-toxic borosilicate glasses

Non-toxic borosilicate glasses find applications in various fields due to their safety and unique properties. They are commonly used in laboratory glassware, pharmaceutical packaging, cookware, and optical components. These glasses are also utilized in specialized applications such as solar energy systems, electronics, and medical devices where biocompatibility and chemical resistance are crucial.Expand Specific Solutions04 Surface treatments and coatings for enhanced properties

Surface treatments and coatings can be applied to non-toxic borosilicate glasses to enhance their properties. These treatments may include chemical etching, ion exchange processes, or the application of specialized coatings. Such modifications can improve characteristics like scratch resistance, hydrophobicity, or anti-reflective properties while maintaining the non-toxic nature of the glass.Expand Specific Solutions05 Testing and characterization of non-toxic borosilicate glasses

Various testing and characterization methods are employed to ensure the non-toxic nature and desired properties of borosilicate glasses. These may include chemical analysis, leaching tests, thermal shock resistance tests, and optical property measurements. Advanced techniques such as X-ray diffraction, electron microscopy, and spectroscopic methods may also be used to analyze the glass structure and composition.Expand Specific Solutions

Key Players in Environmental Glass Industry

The research on non-toxic borosilicate glasses for environmental applications is in a growth phase, with increasing market demand driven by environmental concerns and sustainability initiatives. The global market for specialized glass products is expanding, with projections indicating significant growth in the coming years. Technologically, the field is moderately mature, with established players like SCHOTT AG, Corning, Inc., and Nippon Electric Glass Co., Ltd. leading innovation. These companies have extensive experience in developing high-performance glass solutions. Emerging players such as Hunan Kibing Pharmaceutical Material Technology Co., Ltd. and Sunshine Lake Pharma Co., Ltd. are also contributing to advancements in this area, particularly in pharmaceutical and medical applications of borosilicate glasses.

SCHOTT AG

Technical Solution: SCHOTT AG has developed eco-friendly borosilicate glasses for environmental applications, focusing on reducing toxic elements while maintaining high performance. Their DURAN® borosilicate glass 3.3 is lead and arsenic-free, offering excellent chemical and thermal resistance[1]. SCHOTT has also introduced NEXTREMA®, a glass-ceramic with improved mechanical properties and temperature resistance up to 950°C[2]. For environmental monitoring, they've created specialized optical glasses with high transmission in specific wavelengths, crucial for spectroscopic analysis of pollutants[3]. SCHOTT's ongoing research includes developing borosilicate glasses with enhanced durability for long-term environmental exposure and exploring new compositions to further reduce environmental impact while improving functional properties.

Strengths: Extensive experience in borosilicate glass production, strong R&D capabilities, and a wide range of specialized products. Weaknesses: Higher production costs compared to standard glass, limited flexibility in rapid composition changes due to established production processes.

Nippon Electric Glass Co., Ltd.

Technical Solution: Nippon Electric Glass (NEG) has made significant advancements in non-toxic borosilicate glasses for environmental applications. Their E-glass fibers, made from borosilicate glass, are used in environmental filtration systems and offer improved chemical resistance and durability[7]. NEG has developed specialized borosilicate glass compositions for solar panels, enhancing their efficiency and lifespan in various environmental conditions[8]. Their research includes the development of ultra-thin borosilicate glass for advanced sensors used in environmental monitoring, offering improved sensitivity and reliability[9]. NEG is also exploring the use of borosilicate glass in water purification systems, leveraging its chemical stability and non-toxicity to create more efficient and environmentally friendly filtration media.

Strengths: Strong presence in Asian markets, diverse product range, and expertise in specialty glass manufacturing. Weaknesses: Potential challenges in global market expansion, relatively lower brand recognition in Western markets compared to some competitors.

Innovations in Eco-friendly Glass Composition

Glass composition and process for producing glass composition

PatentWO2007020824A1

Innovation

- An aluminoporosilicate-based glass composition with a reduced amount of alkali metal oxide and chloride, specifically using potassium chloride as a refining agent to enhance fining and reduce environmental load, while maintaining glass clarity and chemical durability.

Aluminum-free borosilicate glass and applications thereof

PatentInactiveUS20040113237A1

Innovation

- Development of an aluminum-free borosilicate glass with a composition ranging from 60-78% SiO2, 7-20% B2O3, and varying amounts of Li2O, Na2O, K2O, MgO, CaO, BaO, ZnO, ZrO2, TiO2, and CeO2, which reduces thermal expansion, melting point, and improves chemical resistance while avoiding aluminum oxide.

Environmental Impact Assessment

The environmental impact assessment of non-toxic borosilicate glasses for environmental applications reveals both positive and negative effects on ecosystems and human health. These glasses, designed to be environmentally friendly, offer significant advantages over traditional glass materials in terms of reduced toxicity and improved sustainability.

One of the primary benefits of non-toxic borosilicate glasses is their minimal leaching of harmful substances into the environment. Unlike conventional glasses that may contain heavy metals or other toxic components, these advanced materials are engineered to be chemically stable and resistant to degradation. This characteristic significantly reduces the risk of contaminating soil, water, and air during their lifecycle, from production to disposal.

The production process of non-toxic borosilicate glasses also demonstrates improved environmental performance compared to traditional glass manufacturing. The use of less hazardous raw materials and optimized production techniques results in lower emissions of greenhouse gases and other pollutants. This contributes to a reduced carbon footprint and helps mitigate the industry's impact on climate change.

Furthermore, the durability and recyclability of non-toxic borosilicate glasses play a crucial role in waste reduction. These glasses exhibit enhanced resistance to thermal shock, mechanical stress, and chemical corrosion, leading to extended product lifespans. When they do reach the end of their useful life, they can be efficiently recycled without the need for complex separation processes, thus minimizing landfill waste and conserving natural resources.

However, the environmental impact assessment also identifies potential challenges. The production of non-toxic borosilicate glasses may require specialized equipment and processes, potentially leading to increased energy consumption during manufacturing. This could offset some of the environmental benefits if not carefully managed through the use of renewable energy sources and energy-efficient technologies.

Additionally, the extraction and processing of specific raw materials needed for non-toxic borosilicate glasses may have localized environmental impacts. These could include habitat disruption, water usage concerns, and potential soil erosion at mining sites. Responsible sourcing practices and rehabilitation efforts are essential to mitigate these effects.

In conclusion, the environmental impact assessment of non-toxic borosilicate glasses for environmental applications demonstrates a net positive effect on ecosystem health and sustainability. The reduced toxicity, improved durability, and enhanced recyclability of these materials offer significant environmental advantages. However, ongoing research and development efforts should focus on further optimizing production processes and sourcing practices to maximize the environmental benefits of these innovative glass materials.

One of the primary benefits of non-toxic borosilicate glasses is their minimal leaching of harmful substances into the environment. Unlike conventional glasses that may contain heavy metals or other toxic components, these advanced materials are engineered to be chemically stable and resistant to degradation. This characteristic significantly reduces the risk of contaminating soil, water, and air during their lifecycle, from production to disposal.

The production process of non-toxic borosilicate glasses also demonstrates improved environmental performance compared to traditional glass manufacturing. The use of less hazardous raw materials and optimized production techniques results in lower emissions of greenhouse gases and other pollutants. This contributes to a reduced carbon footprint and helps mitigate the industry's impact on climate change.

Furthermore, the durability and recyclability of non-toxic borosilicate glasses play a crucial role in waste reduction. These glasses exhibit enhanced resistance to thermal shock, mechanical stress, and chemical corrosion, leading to extended product lifespans. When they do reach the end of their useful life, they can be efficiently recycled without the need for complex separation processes, thus minimizing landfill waste and conserving natural resources.

However, the environmental impact assessment also identifies potential challenges. The production of non-toxic borosilicate glasses may require specialized equipment and processes, potentially leading to increased energy consumption during manufacturing. This could offset some of the environmental benefits if not carefully managed through the use of renewable energy sources and energy-efficient technologies.

Additionally, the extraction and processing of specific raw materials needed for non-toxic borosilicate glasses may have localized environmental impacts. These could include habitat disruption, water usage concerns, and potential soil erosion at mining sites. Responsible sourcing practices and rehabilitation efforts are essential to mitigate these effects.

In conclusion, the environmental impact assessment of non-toxic borosilicate glasses for environmental applications demonstrates a net positive effect on ecosystem health and sustainability. The reduced toxicity, improved durability, and enhanced recyclability of these materials offer significant environmental advantages. However, ongoing research and development efforts should focus on further optimizing production processes and sourcing practices to maximize the environmental benefits of these innovative glass materials.

Regulatory Framework for Green Materials

The regulatory framework for green materials plays a crucial role in shaping the development and adoption of non-toxic borosilicate glasses for environmental applications. As governments and international organizations increasingly prioritize sustainability and environmental protection, the regulations surrounding green materials have become more stringent and comprehensive.

At the global level, the United Nations Environment Programme (UNEP) has established guidelines for sustainable production and consumption, which influence the development of green materials, including non-toxic borosilicate glasses. These guidelines emphasize the importance of life cycle assessments, resource efficiency, and waste reduction in material production and use.

In the European Union, the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation sets strict standards for the use of chemicals in various products, including glass materials. This regulation has a significant impact on the development of non-toxic borosilicate glasses, as it requires manufacturers to assess and manage the risks associated with the substances used in their production processes.

The United States Environmental Protection Agency (EPA) has implemented the Toxic Substances Control Act (TSCA), which regulates the introduction of new or already existing chemicals in the market. This act has implications for the development and use of non-toxic borosilicate glasses, as it requires manufacturers to provide data on the environmental and health effects of their products.

Many countries have also introduced specific regulations targeting the recycling and disposal of glass materials. These regulations often include requirements for the collection, sorting, and processing of glass waste, which can influence the design and composition of borosilicate glasses to ensure their recyclability and environmental compatibility.

In addition to government regulations, various industry standards and certification programs have emerged to promote the use of green materials. For instance, the Leadership in Energy and Environmental Design (LEED) certification system awards points for the use of environmentally friendly materials in building construction, which can incentivize the adoption of non-toxic borosilicate glasses in architectural applications.

The regulatory landscape for green materials is continually evolving, with new policies and standards being introduced to address emerging environmental concerns. This dynamic regulatory environment presents both challenges and opportunities for researchers and manufacturers working on non-toxic borosilicate glasses. Staying compliant with these regulations while innovating to meet environmental goals requires ongoing research and development efforts in the field of green materials.

At the global level, the United Nations Environment Programme (UNEP) has established guidelines for sustainable production and consumption, which influence the development of green materials, including non-toxic borosilicate glasses. These guidelines emphasize the importance of life cycle assessments, resource efficiency, and waste reduction in material production and use.

In the European Union, the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation sets strict standards for the use of chemicals in various products, including glass materials. This regulation has a significant impact on the development of non-toxic borosilicate glasses, as it requires manufacturers to assess and manage the risks associated with the substances used in their production processes.

The United States Environmental Protection Agency (EPA) has implemented the Toxic Substances Control Act (TSCA), which regulates the introduction of new or already existing chemicals in the market. This act has implications for the development and use of non-toxic borosilicate glasses, as it requires manufacturers to provide data on the environmental and health effects of their products.

Many countries have also introduced specific regulations targeting the recycling and disposal of glass materials. These regulations often include requirements for the collection, sorting, and processing of glass waste, which can influence the design and composition of borosilicate glasses to ensure their recyclability and environmental compatibility.

In addition to government regulations, various industry standards and certification programs have emerged to promote the use of green materials. For instance, the Leadership in Energy and Environmental Design (LEED) certification system awards points for the use of environmentally friendly materials in building construction, which can incentivize the adoption of non-toxic borosilicate glasses in architectural applications.

The regulatory landscape for green materials is continually evolving, with new policies and standards being introduced to address emerging environmental concerns. This dynamic regulatory environment presents both challenges and opportunities for researchers and manufacturers working on non-toxic borosilicate glasses. Staying compliant with these regulations while innovating to meet environmental goals requires ongoing research and development efforts in the field of green materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!