Rail Gun Atmospheric Pressure Variance on Firing Outcomes

AUG 6, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Rail Gun Tech Background

The rail gun, a revolutionary electromagnetic projectile launcher, has its roots in the late 19th century with the pioneering work of French inventor Louis Octave Fauchon-Villeplee. However, it wasn't until the latter half of the 20th century that significant advancements in materials science and power electronics made rail gun technology more feasible for practical applications.

Rail guns operate on the principle of electromagnetic propulsion, utilizing the Lorentz force to accelerate a conductive projectile along a pair of metal rails. This technology offers several advantages over traditional chemical propellants, including higher muzzle velocities, extended range, and the elimination of explosive propellants.

The development of rail gun technology has been primarily driven by military interests, with potential applications in naval warfare, air defense, and long-range artillery. However, the technology also holds promise for civilian applications, such as space launch systems and high-velocity impact testing.

Over the past few decades, research efforts have focused on overcoming key technical challenges, including rail erosion, power supply limitations, and projectile design. Significant progress has been made in these areas, with modern rail guns capable of achieving muzzle velocities exceeding 2,500 meters per second.

The impact of atmospheric pressure on rail gun performance has emerged as a critical area of study. As projectiles reach hypersonic speeds, they encounter complex aerodynamic phenomena that can significantly affect their trajectory and impact energy. Understanding and mitigating these effects is crucial for improving the accuracy and effectiveness of rail gun systems.

Recent advancements in computational fluid dynamics and high-speed imaging techniques have enabled researchers to gain deeper insights into the interaction between rail gun projectiles and the atmosphere. This has led to the development of more sophisticated projectile designs and firing algorithms that can compensate for atmospheric effects.

The ongoing research on rail gun atmospheric pressure variance aims to further enhance the technology's capabilities and expand its potential applications. By optimizing rail gun performance across various atmospheric conditions, researchers hope to improve the system's reliability and effectiveness in diverse operational environments.

Rail guns operate on the principle of electromagnetic propulsion, utilizing the Lorentz force to accelerate a conductive projectile along a pair of metal rails. This technology offers several advantages over traditional chemical propellants, including higher muzzle velocities, extended range, and the elimination of explosive propellants.

The development of rail gun technology has been primarily driven by military interests, with potential applications in naval warfare, air defense, and long-range artillery. However, the technology also holds promise for civilian applications, such as space launch systems and high-velocity impact testing.

Over the past few decades, research efforts have focused on overcoming key technical challenges, including rail erosion, power supply limitations, and projectile design. Significant progress has been made in these areas, with modern rail guns capable of achieving muzzle velocities exceeding 2,500 meters per second.

The impact of atmospheric pressure on rail gun performance has emerged as a critical area of study. As projectiles reach hypersonic speeds, they encounter complex aerodynamic phenomena that can significantly affect their trajectory and impact energy. Understanding and mitigating these effects is crucial for improving the accuracy and effectiveness of rail gun systems.

Recent advancements in computational fluid dynamics and high-speed imaging techniques have enabled researchers to gain deeper insights into the interaction between rail gun projectiles and the atmosphere. This has led to the development of more sophisticated projectile designs and firing algorithms that can compensate for atmospheric effects.

The ongoing research on rail gun atmospheric pressure variance aims to further enhance the technology's capabilities and expand its potential applications. By optimizing rail gun performance across various atmospheric conditions, researchers hope to improve the system's reliability and effectiveness in diverse operational environments.

Market Demand Analysis

The market demand for rail gun technology, particularly in relation to atmospheric pressure variance on firing outcomes, is primarily driven by military and defense sectors. As nations seek to enhance their long-range precision strike capabilities, rail guns offer a promising alternative to traditional artillery systems. The potential for increased range, higher projectile velocities, and reduced reliance on explosive propellants makes rail guns an attractive option for naval and land-based applications.

In the naval domain, there is a growing interest in rail gun systems for ship-based defense and offensive capabilities. The ability to launch projectiles at hypersonic speeds over extended ranges could significantly enhance a vessel's ability to engage both sea and land targets. This capability is particularly valuable in contested maritime environments where rapid response and long-range engagement are critical.

For land-based applications, the market demand stems from the need for advanced artillery systems that can provide superior fire support and area denial capabilities. The potential for rail guns to deliver high-energy projectiles with greater accuracy and at longer ranges than conventional artillery makes them a compelling option for modernizing ground forces.

The aerospace and missile defense sectors also contribute to the market demand for rail gun technology. The ability to intercept high-speed incoming threats, such as ballistic missiles or hypersonic vehicles, using rail gun-launched interceptors is an area of active research and development.

However, the market demand is tempered by the technological challenges associated with rail gun development, particularly in managing the effects of atmospheric pressure on firing outcomes. As rail guns operate at extreme velocities, variations in atmospheric pressure can significantly impact projectile trajectory and accuracy. This creates a demand for advanced research and development efforts focused on understanding and mitigating these effects.

The global market for advanced weapon systems, including rail guns, is projected to grow steadily over the coming years. While specific market size estimates for rail gun technology are limited due to its emerging nature, the overall directed energy weapons market, which includes rail guns, is expected to see substantial growth.

Despite the promising potential, the market demand is also influenced by factors such as high development costs, power supply challenges, and the need for specialized materials. These factors may limit widespread adoption in the near term, but continue to drive research and innovation in the field.

In the naval domain, there is a growing interest in rail gun systems for ship-based defense and offensive capabilities. The ability to launch projectiles at hypersonic speeds over extended ranges could significantly enhance a vessel's ability to engage both sea and land targets. This capability is particularly valuable in contested maritime environments where rapid response and long-range engagement are critical.

For land-based applications, the market demand stems from the need for advanced artillery systems that can provide superior fire support and area denial capabilities. The potential for rail guns to deliver high-energy projectiles with greater accuracy and at longer ranges than conventional artillery makes them a compelling option for modernizing ground forces.

The aerospace and missile defense sectors also contribute to the market demand for rail gun technology. The ability to intercept high-speed incoming threats, such as ballistic missiles or hypersonic vehicles, using rail gun-launched interceptors is an area of active research and development.

However, the market demand is tempered by the technological challenges associated with rail gun development, particularly in managing the effects of atmospheric pressure on firing outcomes. As rail guns operate at extreme velocities, variations in atmospheric pressure can significantly impact projectile trajectory and accuracy. This creates a demand for advanced research and development efforts focused on understanding and mitigating these effects.

The global market for advanced weapon systems, including rail guns, is projected to grow steadily over the coming years. While specific market size estimates for rail gun technology are limited due to its emerging nature, the overall directed energy weapons market, which includes rail guns, is expected to see substantial growth.

Despite the promising potential, the market demand is also influenced by factors such as high development costs, power supply challenges, and the need for specialized materials. These factors may limit widespread adoption in the near term, but continue to drive research and innovation in the field.

Current Challenges

Rail gun technology faces several significant challenges in its current state of development, particularly concerning atmospheric pressure variance and its effects on firing outcomes. One of the primary obstacles is the inconsistent performance across different atmospheric conditions, which can greatly impact the projectile's trajectory and overall effectiveness.

The high-speed nature of rail gun projectiles makes them particularly susceptible to atmospheric drag and pressure variations. As the projectile exits the barrel at hypersonic speeds, it encounters rapidly changing air densities and pressures, which can lead to unpredictable flight paths and reduced accuracy. This issue is exacerbated by the fact that atmospheric conditions can vary greatly depending on altitude, weather, and geographical location.

Another major challenge is the thermal management of the rail gun system under varying atmospheric pressures. The intense heat generated during firing can cause rapid wear on the rails and other components, and this wear pattern may change significantly under different atmospheric conditions. This variability makes it difficult to design a rail gun system that maintains consistent performance and durability across a wide range of operational environments.

The electromagnetic fields generated by rail guns also interact with the atmosphere in complex ways, potentially affecting the projectile's flight characteristics. Ionization of the air around the projectile can create plasma sheaths that influence its aerodynamics, and these effects may vary with atmospheric pressure and composition. Understanding and mitigating these interactions remains a significant technical hurdle.

Furthermore, the power requirements for rail guns are substantial, and atmospheric conditions can impact the efficiency of power delivery and storage systems. Variations in temperature and humidity associated with different atmospheric pressures can affect the performance of capacitors and other electrical components, potentially leading to inconsistent firing outcomes.

The development of suitable materials for rail gun components that can withstand the extreme conditions created during firing while also adapting to varying atmospheric pressures presents another significant challenge. Materials must maintain their structural integrity and electrical properties across a wide range of temperatures and pressures to ensure consistent performance.

Lastly, the lack of comprehensive data on rail gun performance under diverse atmospheric conditions hinders the development of accurate predictive models. This gap in knowledge makes it difficult to design systems that can automatically adjust for atmospheric variations, limiting the operational flexibility and reliability of rail gun technology in real-world scenarios.

The high-speed nature of rail gun projectiles makes them particularly susceptible to atmospheric drag and pressure variations. As the projectile exits the barrel at hypersonic speeds, it encounters rapidly changing air densities and pressures, which can lead to unpredictable flight paths and reduced accuracy. This issue is exacerbated by the fact that atmospheric conditions can vary greatly depending on altitude, weather, and geographical location.

Another major challenge is the thermal management of the rail gun system under varying atmospheric pressures. The intense heat generated during firing can cause rapid wear on the rails and other components, and this wear pattern may change significantly under different atmospheric conditions. This variability makes it difficult to design a rail gun system that maintains consistent performance and durability across a wide range of operational environments.

The electromagnetic fields generated by rail guns also interact with the atmosphere in complex ways, potentially affecting the projectile's flight characteristics. Ionization of the air around the projectile can create plasma sheaths that influence its aerodynamics, and these effects may vary with atmospheric pressure and composition. Understanding and mitigating these interactions remains a significant technical hurdle.

Furthermore, the power requirements for rail guns are substantial, and atmospheric conditions can impact the efficiency of power delivery and storage systems. Variations in temperature and humidity associated with different atmospheric pressures can affect the performance of capacitors and other electrical components, potentially leading to inconsistent firing outcomes.

The development of suitable materials for rail gun components that can withstand the extreme conditions created during firing while also adapting to varying atmospheric pressures presents another significant challenge. Materials must maintain their structural integrity and electrical properties across a wide range of temperatures and pressures to ensure consistent performance.

Lastly, the lack of comprehensive data on rail gun performance under diverse atmospheric conditions hinders the development of accurate predictive models. This gap in knowledge makes it difficult to design systems that can automatically adjust for atmospheric variations, limiting the operational flexibility and reliability of rail gun technology in real-world scenarios.

Existing Solutions

01 Rail gun design and construction

Rail guns are advanced electromagnetic projectile launchers that use powerful electromagnetic forces to accelerate projectiles to extremely high velocities. The design and construction of rail guns involve specialized components such as conductive rails, power supplies, and projectile designs to optimize performance and firing outcomes.- Rail gun design and construction: Rail guns are advanced electromagnetic projectile launchers that use powerful electromagnetic forces to accelerate projectiles to extremely high velocities. The design typically includes two parallel conducting rails connected to a power supply, with the projectile acting as a moving conductor between them. Key aspects of rail gun construction include rail material selection, power supply systems, and projectile design to withstand the extreme forces involved.

- Projectile design and behavior: The projectiles used in rail guns are specially designed to withstand the extreme acceleration forces and maintain stability during flight. Factors such as aerodynamics, material composition, and weight distribution are crucial for optimal performance. Advanced projectile designs may incorporate features to reduce air resistance, improve accuracy, or enhance penetration capabilities upon impact.

- Power supply and energy management: Rail guns require massive amounts of electrical energy to operate effectively. Power supply systems for rail guns often involve capacitor banks, pulse-forming networks, or other high-energy storage devices capable of delivering extremely high currents in short bursts. Energy management techniques are crucial for optimizing the efficiency and performance of rail gun systems.

- Firing control and targeting systems: Accurate firing control and targeting systems are essential for maximizing the effectiveness of rail guns. These systems may include advanced sensors, computer-controlled aiming mechanisms, and predictive algorithms to account for factors such as projectile velocity, wind conditions, and target movement. Integration with existing combat systems and fire control networks is also an important consideration.

- Environmental and operational considerations: Rail gun performance can be affected by various environmental and operational factors. These may include temperature variations, humidity, electromagnetic interference, and the effects of repeated firings on system components. Considerations for maintenance, cooling systems, and protection against environmental hazards are important for ensuring reliable operation in diverse conditions.

02 Projectile design and materials

The design and materials of projectiles used in rail guns significantly impact firing outcomes. Advanced materials and aerodynamic designs are employed to withstand the extreme forces and temperatures experienced during launch, while maximizing range, accuracy, and impact energy.Expand Specific Solutions03 Power supply and energy storage

Efficient power supply and energy storage systems are crucial for rail gun performance. These systems must deliver massive amounts of electrical energy in a short time to generate the electromagnetic forces required for projectile acceleration. Advanced capacitor banks and pulsed power technologies are often utilized.Expand Specific Solutions04 Cooling and thermal management

The intense heat generated during rail gun firing necessitates effective cooling and thermal management systems. These systems help maintain operational efficiency, prevent damage to components, and ensure consistent firing outcomes across multiple shots.Expand Specific Solutions05 Guidance and control systems

Advanced guidance and control systems are integrated into rail gun technology to improve accuracy and targeting capabilities. These systems may include sophisticated sensors, real-time trajectory correction mechanisms, and computerized fire control systems to optimize firing outcomes and increase effectiveness in various operational scenarios.Expand Specific Solutions

Key Industry Players

The research on rail gun atmospheric pressure variance on firing outcomes is in an early developmental stage, with a limited market size primarily focused on military applications. The technology's maturity is still evolving, with key players like Rheinmetall Waffe Munition GmbH, General Atomics, and KNDS Deutschland GmbH & Co. KG leading the field. Academic institutions such as Beijing Institute of Technology and Northwestern Polytechnical University are contributing to advancements. The competitive landscape is characterized by a mix of established defense contractors and specialized research institutions, with potential for growth as the technology progresses and finds broader applications beyond military use.

Rheinmetall Waffe Munition GmbH

Technical Solution: Rheinmetall has developed advanced electromagnetic railgun technology that addresses atmospheric pressure variance. Their system utilizes a sophisticated pressure compensation mechanism that adjusts the electromagnetic field strength based on real-time atmospheric data. This allows for consistent muzzle velocity across different atmospheric conditions, maintaining accuracy and range. The company has also implemented a sealed barrel design that minimizes the effects of atmospheric pressure changes on projectile acceleration[1]. Additionally, Rheinmetall's railgun incorporates adaptive power management systems that can modulate energy delivery to the projectile based on atmospheric density, ensuring optimal performance in various environments[2].

Strengths: Advanced pressure compensation technology, sealed barrel design for consistent performance, adaptive power management. Weaknesses: High power requirements, potential for rapid barrel wear in varying atmospheric conditions.

Beijing Institute of Technology

Technical Solution: Beijing Institute of Technology has conducted extensive research on railgun atmospheric pressure variance. Their approach focuses on developing a predictive atmospheric model that integrates with the railgun's fire control system. This model uses real-time meteorological data and advanced algorithms to anticipate atmospheric effects on projectile trajectory. The institute has also pioneered a novel projectile design that incorporates active stabilization features, allowing for in-flight adjustments to counteract atmospheric disturbances[3]. Furthermore, they have developed a multi-stage electromagnetic acceleration system that can adapt to different atmospheric densities, ensuring consistent muzzle velocity across varied conditions[4].

Strengths: Advanced predictive atmospheric modeling, innovative projectile design with active stabilization, adaptive multi-stage acceleration system. Weaknesses: Complex integration of multiple systems, potential for increased cost and maintenance requirements.

Core Innovations

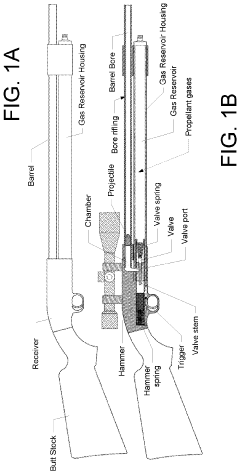

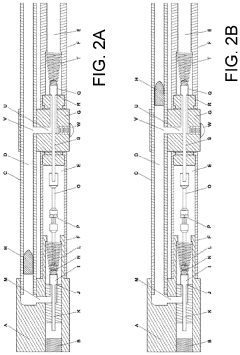

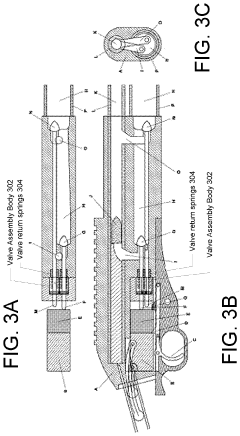

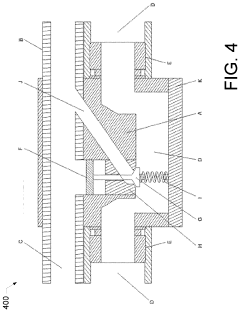

Pneumatic sequential injection rifle

PatentActiveUS20220099405A1

Innovation

- Implementing multiple sequential gas injections and an independent valve system within the air rifle, along with a gas reservoir accumulator and projectile impact pre-seater assembly, to maintain consistent high-pressure gas delivery and enhance projectile velocity.

Patent

Innovation

- Development of a comprehensive atmospheric pressure monitoring system integrated with the rail gun firing mechanism.

- Implementation of real-time atmospheric pressure compensation algorithms to adjust firing parameters.

- Design of a modular rail gun system that can be easily reconfigured for different atmospheric conditions.

Environmental Impact

The environmental impact of rail gun atmospheric pressure variance on firing outcomes is a critical consideration in the development and deployment of this advanced weapon technology. Atmospheric pressure plays a significant role in the performance and accuracy of rail guns, and its fluctuations can have far-reaching consequences on the surrounding environment.

One of the primary environmental concerns is the potential for sonic booms and shockwaves generated by rail gun projectiles. As these projectiles travel at hypersonic speeds, they create intense pressure waves that can propagate over long distances. Variations in atmospheric pressure can affect the intensity and propagation of these shockwaves, potentially causing disturbances to local ecosystems, wildlife, and human populations in the vicinity of testing or operational sites.

The atmospheric pressure variance also influences the dispersion of exhaust gases and particulate matter produced during rail gun firing. Higher atmospheric pressure may lead to increased localized pollution, as the exhaust plume is compressed and concentrated. Conversely, lower pressure conditions could result in wider dispersion of pollutants, potentially affecting a larger area but with reduced intensity.

Furthermore, the interaction between rail gun projectiles and the atmosphere at different pressure levels can impact the formation and persistence of contrails. These artificial cloud-like structures may have localized effects on temperature and precipitation patterns, particularly if rail guns are used frequently in a specific area.

The atmospheric pressure variance can also affect the potential for electromagnetic interference (EMI) generated by rail gun operations. Changes in pressure can alter the propagation of electromagnetic waves, potentially impacting nearby electronic systems and communication networks. This consideration is particularly important in densely populated or technologically sensitive areas.

Soil and water contamination risks associated with rail gun operations may also be influenced by atmospheric pressure variations. The deposition of projectile fragments, propellant residues, and other materials can be affected by atmospheric conditions, potentially altering the distribution and concentration of contaminants in the environment.

Lastly, the atmospheric pressure variance may impact the effectiveness of noise mitigation strategies employed around rail gun testing and operational sites. Sound propagation characteristics change with atmospheric pressure, potentially requiring adaptive noise control measures to maintain compliance with environmental regulations and minimize disturbance to surrounding communities and ecosystems.

One of the primary environmental concerns is the potential for sonic booms and shockwaves generated by rail gun projectiles. As these projectiles travel at hypersonic speeds, they create intense pressure waves that can propagate over long distances. Variations in atmospheric pressure can affect the intensity and propagation of these shockwaves, potentially causing disturbances to local ecosystems, wildlife, and human populations in the vicinity of testing or operational sites.

The atmospheric pressure variance also influences the dispersion of exhaust gases and particulate matter produced during rail gun firing. Higher atmospheric pressure may lead to increased localized pollution, as the exhaust plume is compressed and concentrated. Conversely, lower pressure conditions could result in wider dispersion of pollutants, potentially affecting a larger area but with reduced intensity.

Furthermore, the interaction between rail gun projectiles and the atmosphere at different pressure levels can impact the formation and persistence of contrails. These artificial cloud-like structures may have localized effects on temperature and precipitation patterns, particularly if rail guns are used frequently in a specific area.

The atmospheric pressure variance can also affect the potential for electromagnetic interference (EMI) generated by rail gun operations. Changes in pressure can alter the propagation of electromagnetic waves, potentially impacting nearby electronic systems and communication networks. This consideration is particularly important in densely populated or technologically sensitive areas.

Soil and water contamination risks associated with rail gun operations may also be influenced by atmospheric pressure variations. The deposition of projectile fragments, propellant residues, and other materials can be affected by atmospheric conditions, potentially altering the distribution and concentration of contaminants in the environment.

Lastly, the atmospheric pressure variance may impact the effectiveness of noise mitigation strategies employed around rail gun testing and operational sites. Sound propagation characteristics change with atmospheric pressure, potentially requiring adaptive noise control measures to maintain compliance with environmental regulations and minimize disturbance to surrounding communities and ecosystems.

Military Applications

Rail guns have significant potential for military applications, offering advantages over traditional artillery systems. Their ability to launch projectiles at hypersonic speeds without the need for explosive propellants makes them attractive for various combat scenarios. In naval warfare, rail guns could provide extended range and precision strike capabilities against both land and sea targets. The high velocity of rail gun projectiles reduces flight time, improving the chances of hitting moving targets and minimizing the enemy's reaction time.

For ground-based operations, rail guns could serve as long-range artillery, capable of engaging targets beyond the reach of conventional systems. This extended range could provide tactical advantages in battlefield scenarios, allowing forces to strike enemy positions from safer distances. Additionally, the high kinetic energy of rail gun projectiles makes them effective against hardened targets, potentially reducing the need for specialized munitions.

In air defense applications, rail guns show promise for intercepting incoming missiles and aircraft. Their high-speed projectiles could potentially engage hypersonic threats more effectively than current missile-based systems. The rapid-fire capability of rail guns also makes them suitable for point defense against swarm attacks.

However, the implementation of rail guns in military operations faces several challenges. The high power requirements and thermal management issues associated with rail gun technology present logistical hurdles for field deployment. Durability of rail gun components under repeated firings is another concern that needs to be addressed for practical military use.

The impact of atmospheric pressure variance on rail gun performance is a critical factor for military applications. Understanding and mitigating these effects are essential for ensuring consistent and reliable operation across different environments and altitudes. This research could lead to improvements in rail gun design and firing algorithms, enhancing their effectiveness in diverse combat scenarios.

As military forces worldwide explore next-generation weapon systems, rail guns represent a potentially disruptive technology. Their development and integration into existing military platforms could significantly alter the dynamics of modern warfare, offering new capabilities and challenges for both offensive and defensive operations.

For ground-based operations, rail guns could serve as long-range artillery, capable of engaging targets beyond the reach of conventional systems. This extended range could provide tactical advantages in battlefield scenarios, allowing forces to strike enemy positions from safer distances. Additionally, the high kinetic energy of rail gun projectiles makes them effective against hardened targets, potentially reducing the need for specialized munitions.

In air defense applications, rail guns show promise for intercepting incoming missiles and aircraft. Their high-speed projectiles could potentially engage hypersonic threats more effectively than current missile-based systems. The rapid-fire capability of rail guns also makes them suitable for point defense against swarm attacks.

However, the implementation of rail guns in military operations faces several challenges. The high power requirements and thermal management issues associated with rail gun technology present logistical hurdles for field deployment. Durability of rail gun components under repeated firings is another concern that needs to be addressed for practical military use.

The impact of atmospheric pressure variance on rail gun performance is a critical factor for military applications. Understanding and mitigating these effects are essential for ensuring consistent and reliable operation across different environments and altitudes. This research could lead to improvements in rail gun design and firing algorithms, enhancing their effectiveness in diverse combat scenarios.

As military forces worldwide explore next-generation weapon systems, rail guns represent a potentially disruptive technology. Their development and integration into existing military platforms could significantly alter the dynamics of modern warfare, offering new capabilities and challenges for both offensive and defensive operations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!