Rail Gun Electromechanics and New Material Frontiers

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Rail Gun Tech Evolution

The evolution of rail gun technology has been marked by significant advancements in electromechanics and materials science over the past few decades. Initially conceived in the early 20th century, rail guns remained largely theoretical until the 1970s when practical research began in earnest. The fundamental principle of electromagnetic propulsion has remained constant, but the implementation has undergone substantial refinement.

In the 1980s, early prototypes demonstrated the feasibility of electromagnetic launch but were limited by low muzzle velocities and rapid rail erosion. The 1990s saw a focus on power supply systems, with the development of compact, high-energy capacitor banks and pulsed power sources. This period also witnessed the introduction of plasma armatures to replace solid projectiles, aiming to reduce rail wear and increase efficiency.

The turn of the millennium brought about a shift towards more practical rail gun designs. Researchers began exploring augmented rail gun configurations, incorporating multiple sets of rails or auxiliary electromagnetic coils to enhance performance. Simultaneously, advancements in materials science led to the development of more durable rail materials and projectile designs capable of withstanding the extreme conditions of launch.

The 2000s and early 2010s were characterized by a push towards higher muzzle velocities and increased projectile masses. This era saw the emergence of multi-stage rail guns and the integration of advanced cooling systems to manage the intense heat generated during firing. Parallel to these developments, significant progress was made in power management and energy storage technologies, crucial for field deployment.

Recent years have witnessed a focus on miniaturization and efficiency improvements. Researchers are now exploring novel rail geometries, advanced composite materials for rails and projectiles, and sophisticated control systems for precise energy delivery. The integration of artificial intelligence and machine learning algorithms for real-time adjustment of firing parameters represents the cutting edge of current rail gun technology.

Looking forward, the rail gun tech evolution is likely to continue along several key trajectories. These include the development of hyperconducting materials for rail construction, advanced nanotechnology-based projectiles with programmable flight characteristics, and the integration of rail guns with directed energy weapons for hybrid defense systems. Additionally, there is growing interest in adapting rail gun technology for non-military applications, such as space launch systems and high-speed impact testing facilities.

In the 1980s, early prototypes demonstrated the feasibility of electromagnetic launch but were limited by low muzzle velocities and rapid rail erosion. The 1990s saw a focus on power supply systems, with the development of compact, high-energy capacitor banks and pulsed power sources. This period also witnessed the introduction of plasma armatures to replace solid projectiles, aiming to reduce rail wear and increase efficiency.

The turn of the millennium brought about a shift towards more practical rail gun designs. Researchers began exploring augmented rail gun configurations, incorporating multiple sets of rails or auxiliary electromagnetic coils to enhance performance. Simultaneously, advancements in materials science led to the development of more durable rail materials and projectile designs capable of withstanding the extreme conditions of launch.

The 2000s and early 2010s were characterized by a push towards higher muzzle velocities and increased projectile masses. This era saw the emergence of multi-stage rail guns and the integration of advanced cooling systems to manage the intense heat generated during firing. Parallel to these developments, significant progress was made in power management and energy storage technologies, crucial for field deployment.

Recent years have witnessed a focus on miniaturization and efficiency improvements. Researchers are now exploring novel rail geometries, advanced composite materials for rails and projectiles, and sophisticated control systems for precise energy delivery. The integration of artificial intelligence and machine learning algorithms for real-time adjustment of firing parameters represents the cutting edge of current rail gun technology.

Looking forward, the rail gun tech evolution is likely to continue along several key trajectories. These include the development of hyperconducting materials for rail construction, advanced nanotechnology-based projectiles with programmable flight characteristics, and the integration of rail guns with directed energy weapons for hybrid defense systems. Additionally, there is growing interest in adapting rail gun technology for non-military applications, such as space launch systems and high-speed impact testing facilities.

Military Market Analysis

The military market for rail gun technology and advanced materials is experiencing significant growth and transformation. As global defense strategies evolve, there is an increasing demand for long-range, high-velocity weapons systems that can provide strategic advantages in various combat scenarios. Rail guns, with their potential to deliver projectiles at hypersonic speeds over extended distances, are attracting substantial investment from major military powers.

The United States Department of Defense has been at the forefront of rail gun research and development, allocating substantial resources to programs aimed at integrating these weapons into naval platforms. Other nations, including China and Russia, have also shown keen interest in developing rail gun capabilities, driving a competitive market landscape. This international focus has led to a surge in research and development activities, creating opportunities for both established defense contractors and innovative startups specializing in advanced materials and electromechanical systems.

The market for rail gun technology extends beyond the weapons themselves, encompassing a wide range of supporting technologies and materials. Advanced power systems, energy storage solutions, and high-strength materials capable of withstanding extreme forces are all critical components of rail gun development. This has spurred growth in adjacent industries, including those focused on supercapacitors, high-performance conductors, and novel composite materials.

Defense analysts project that the global market for electromagnetic launch systems, including rail guns, could reach several billion dollars within the next decade. This growth is driven not only by direct military applications but also by potential dual-use technologies that could find applications in space launch systems and other civilian sectors. The crossover potential is attracting interest from aerospace companies and materials science firms, further expanding the market ecosystem.

However, the rail gun market faces challenges that could impact its growth trajectory. Technical hurdles, such as managing extreme heat generation and developing materials that can withstand repeated high-energy launches, remain significant obstacles. Additionally, the high cost of research and development, coupled with the need for extensive testing and validation, may limit market entry to well-funded entities or those with strong government backing.

Despite these challenges, the potential strategic advantages offered by rail gun technology continue to drive market interest. As geopolitical tensions persist and the need for advanced long-range strike capabilities grows, investments in rail gun research and related materials science are expected to remain robust. This sustained focus is likely to yield technological breakthroughs that could accelerate market growth and potentially reshape modern warfare strategies.

The United States Department of Defense has been at the forefront of rail gun research and development, allocating substantial resources to programs aimed at integrating these weapons into naval platforms. Other nations, including China and Russia, have also shown keen interest in developing rail gun capabilities, driving a competitive market landscape. This international focus has led to a surge in research and development activities, creating opportunities for both established defense contractors and innovative startups specializing in advanced materials and electromechanical systems.

The market for rail gun technology extends beyond the weapons themselves, encompassing a wide range of supporting technologies and materials. Advanced power systems, energy storage solutions, and high-strength materials capable of withstanding extreme forces are all critical components of rail gun development. This has spurred growth in adjacent industries, including those focused on supercapacitors, high-performance conductors, and novel composite materials.

Defense analysts project that the global market for electromagnetic launch systems, including rail guns, could reach several billion dollars within the next decade. This growth is driven not only by direct military applications but also by potential dual-use technologies that could find applications in space launch systems and other civilian sectors. The crossover potential is attracting interest from aerospace companies and materials science firms, further expanding the market ecosystem.

However, the rail gun market faces challenges that could impact its growth trajectory. Technical hurdles, such as managing extreme heat generation and developing materials that can withstand repeated high-energy launches, remain significant obstacles. Additionally, the high cost of research and development, coupled with the need for extensive testing and validation, may limit market entry to well-funded entities or those with strong government backing.

Despite these challenges, the potential strategic advantages offered by rail gun technology continue to drive market interest. As geopolitical tensions persist and the need for advanced long-range strike capabilities grows, investments in rail gun research and related materials science are expected to remain robust. This sustained focus is likely to yield technological breakthroughs that could accelerate market growth and potentially reshape modern warfare strategies.

Current Challenges

Rail gun technology faces several significant challenges that hinder its widespread adoption and practical implementation. One of the primary obstacles is the immense power requirements needed to generate the electromagnetic forces necessary for launching projectiles at hypersonic speeds. Current power systems struggle to provide the massive electrical currents required, limiting the rail gun's operational capabilities and deployment options.

Material degradation presents another critical challenge. The intense electromagnetic forces and extreme temperatures generated during firing cause rapid wear and erosion of the rail gun's components, particularly the conductive rails. This wear significantly reduces the weapon's lifespan and reliability, necessitating frequent maintenance and replacement of key parts. The development of more durable materials capable of withstanding these extreme conditions remains a crucial area of research.

The projectile design for rail guns also poses unique challenges. Unlike conventional firearms, rail gun projectiles must be engineered to withstand the enormous acceleration forces and electromagnetic fields they experience during launch. Balancing the projectile's structural integrity with its aerodynamic properties and payload capacity is a complex task that requires innovative materials and design approaches.

Thermal management is another significant hurdle in rail gun development. The rapid discharge of electrical energy generates intense heat, which can lead to component failure and reduced performance. Effective cooling systems and heat-resistant materials are essential for maintaining operational efficiency and preventing damage to the weapon system.

Accuracy and precision at extended ranges remain challenging due to the hypersonic velocities involved. Atmospheric effects, Earth's rotation, and other factors become more pronounced at these speeds, requiring advanced guidance systems and sophisticated fire control algorithms to ensure target acquisition and engagement.

The integration of rail gun technology into existing military platforms presents logistical and operational challenges. The size, weight, and power requirements of current rail gun systems limit their deployment options, particularly on naval vessels and mobile ground platforms. Miniaturization and increased energy efficiency are crucial for broader adoption across various military applications.

Lastly, the electromagnetic signature produced by rail guns during operation poses potential vulnerabilities. The intense electromagnetic fields generated can interfere with nearby electronic systems and may be detectable by enemy sensors, potentially compromising operational security. Developing methods to mitigate these electromagnetic emissions while maintaining performance is an ongoing area of research in rail gun technology.

Material degradation presents another critical challenge. The intense electromagnetic forces and extreme temperatures generated during firing cause rapid wear and erosion of the rail gun's components, particularly the conductive rails. This wear significantly reduces the weapon's lifespan and reliability, necessitating frequent maintenance and replacement of key parts. The development of more durable materials capable of withstanding these extreme conditions remains a crucial area of research.

The projectile design for rail guns also poses unique challenges. Unlike conventional firearms, rail gun projectiles must be engineered to withstand the enormous acceleration forces and electromagnetic fields they experience during launch. Balancing the projectile's structural integrity with its aerodynamic properties and payload capacity is a complex task that requires innovative materials and design approaches.

Thermal management is another significant hurdle in rail gun development. The rapid discharge of electrical energy generates intense heat, which can lead to component failure and reduced performance. Effective cooling systems and heat-resistant materials are essential for maintaining operational efficiency and preventing damage to the weapon system.

Accuracy and precision at extended ranges remain challenging due to the hypersonic velocities involved. Atmospheric effects, Earth's rotation, and other factors become more pronounced at these speeds, requiring advanced guidance systems and sophisticated fire control algorithms to ensure target acquisition and engagement.

The integration of rail gun technology into existing military platforms presents logistical and operational challenges. The size, weight, and power requirements of current rail gun systems limit their deployment options, particularly on naval vessels and mobile ground platforms. Miniaturization and increased energy efficiency are crucial for broader adoption across various military applications.

Lastly, the electromagnetic signature produced by rail guns during operation poses potential vulnerabilities. The intense electromagnetic fields generated can interfere with nearby electronic systems and may be detectable by enemy sensors, potentially compromising operational security. Developing methods to mitigate these electromagnetic emissions while maintaining performance is an ongoing area of research in rail gun technology.

Existing Rail Gun Designs

01 Electromagnetic propulsion systems

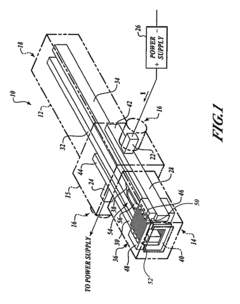

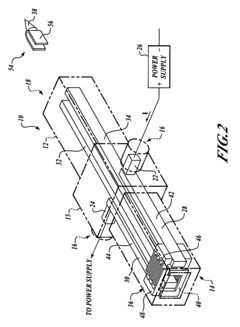

Rail guns utilize electromagnetic forces to propel projectiles at high velocities. These systems typically consist of parallel conductive rails and a sliding armature. When a large electric current is passed through the rails and armature, it creates a powerful magnetic field that accelerates the projectile. This technology offers advantages in terms of projectile speed and range compared to traditional propulsion methods.- Electromagnetic propulsion systems: Rail guns utilize electromagnetic forces to accelerate projectiles to high velocities. The system typically consists of two parallel conductive rails connected to a power source, creating a magnetic field that propels the projectile. This technology offers advantages in terms of projectile speed and range compared to traditional propulsion methods.

- Power supply and energy storage: Efficient power supply and energy storage systems are crucial for rail gun operation. These systems often involve high-capacity capacitors or pulse-forming networks to deliver the intense electrical current required for projectile acceleration. Advanced power management techniques are employed to optimize energy transfer and minimize losses.

- Rail and projectile design: The design of rails and projectiles plays a significant role in rail gun performance. Specialized materials and geometries are used to withstand the high temperatures and pressures generated during firing. Projectile designs focus on aerodynamics and structural integrity to maintain stability and effectiveness at hypersonic speeds.

- Cooling and thermal management: Effective cooling and thermal management systems are essential for maintaining rail gun performance and longevity. These systems address the intense heat generated during firing, which can cause rail erosion and affect overall system efficiency. Various cooling methods, including liquid cooling and advanced heat-dissipating materials, are employed.

- Control and targeting systems: Advanced control and targeting systems are integrated into rail gun technology to enhance accuracy and operational effectiveness. These systems may include sophisticated sensors, real-time data processing, and adaptive firing algorithms to account for various factors affecting projectile trajectory and impact.

02 Power supply and energy storage

Efficient power supply and energy storage systems are crucial for rail gun operation. These systems often involve high-capacity capacitors or pulse-forming networks to deliver the intense electrical current required for projectile acceleration. Advanced power management techniques and energy recovery systems may be employed to improve overall efficiency and reduce the time between shots.Expand Specific Solutions03 Rail and armature design

The design of rails and armatures is critical for rail gun performance and durability. Innovations in this area focus on materials selection, geometry optimization, and thermal management to withstand the extreme conditions during firing. Advanced rail configurations and armature designs aim to reduce wear, improve conductivity, and enhance overall system efficiency.Expand Specific Solutions04 Projectile design and guidance

Specialized projectile designs are developed to withstand the high accelerations and electromagnetic forces in rail guns. These projectiles may incorporate features for improved aerodynamics, stability, and accuracy. Some designs also integrate guidance systems or smart materials to enhance performance and control during flight.Expand Specific Solutions05 Control systems and firing mechanisms

Advanced control systems and firing mechanisms are essential for precise operation of rail guns. These systems manage the timing and sequencing of power delivery, projectile loading, and firing. They may incorporate sensors, feedback loops, and predictive algorithms to optimize performance and adapt to varying conditions. Innovations in this area aim to improve reliability, repeatability, and overall system integration.Expand Specific Solutions

Key Rail Gun Developers

The research on rail gun electromechanics and new material frontiers is in an early development stage, with significant potential for growth. The market size is relatively small but expanding as military and research institutions invest in this cutting-edge technology. While still emerging, the field is attracting attention from major players across academia, industry, and government. Key companies like Boeing, Raytheon, and General Atomics are actively involved, alongside research institutions such as the Naval Research Laboratory and universities like Tsinghua and Johns Hopkins. The technology's maturity varies, with some aspects more advanced than others, but overall it remains in the experimental phase with ongoing challenges in materials, power systems, and durability to overcome before widespread practical application.

The Boeing Co.

Technical Solution: Boeing's research in rail gun technology focuses on integrating these systems into various aerospace and defense platforms. Their approach emphasizes lightweight, compact designs suitable for airborne and naval applications. Boeing has invested in developing advanced composite materials for rail gun components, aiming to reduce weight while maintaining structural integrity under extreme conditions [8]. Their research includes innovative cooling systems using advanced materials and novel geometries to manage thermal loads. Boeing has also explored the use of additive manufacturing techniques to create complex rail geometries that optimize electromagnetic performance and durability. Additionally, their work on power systems focuses on developing high-density energy storage solutions and efficient power distribution networks tailored for rail gun applications [9].

Strengths: Extensive experience in aerospace systems integration and platform-specific adaptations. Strong capabilities in advanced manufacturing and materials. Weaknesses: Potential limitations in ground-based applications and heavy-duty rail gun systems.

Tsinghua University

Technical Solution: Tsinghua University has made significant contributions to rail gun research, particularly in electromechanics and new materials. Their research team has focused on developing high-performance conductors and novel rail designs to enhance efficiency and durability. Tsinghua's work includes the use of advanced composite materials and nanostructured coatings to reduce rail wear and improve conductivity [10]. They have also made progress in pulse power technology, developing compact and efficient capacitor banks and pulse-forming networks. Tsinghua's research extends to advanced simulation and modeling techniques, allowing for detailed analysis of electromagnetic fields, thermal effects, and structural dynamics in rail gun systems. Their work on plasma dynamics and arc behavior has led to improved understanding of rail gun physics and potential performance enhancements [11].

Strengths: Strong theoretical foundation and advanced modeling capabilities. Innovative approaches to materials science and electromechanics. Weaknesses: Potential challenges in translating research into large-scale, practical applications.

Core Electromech Patents

Electromagnetic launcher with augmenting breech

PatentActiveUS7730821B2

Innovation

- The design includes a slidable electromagnetic launcher housing with augmentation conductors and main conductors connected via a current cross-over connection, allowing for recoil accommodation while maintaining electrical contact, and reducing overall inductance by limiting augmentation to early stages of the launch cycle, facilitating faster current rise and balanced weight distribution.

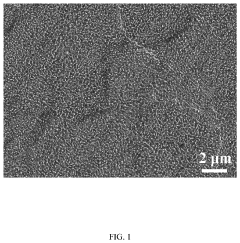

High-toughness heat-resistant aluminum alloy armature material and preparation method thereof

PatentActiveUS20240191324A1

Innovation

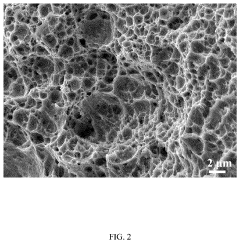

- A high-toughness heat-resistant aluminum alloy armature material is developed by heating an aluminum ingot, adding specific elements like Ce, Y, Zr, Mg, and Si, and processing the alloy into spherical powder for selective laser melting, forming nano-scale intermetallic compounds with a net-like skeleton structure within an aluminum matrix.

Energy Storage Solutions

Energy storage solutions play a crucial role in the development and optimization of rail gun technology. The high-energy, pulsed power requirements of rail guns necessitate advanced storage systems capable of delivering massive amounts of electrical energy in extremely short time frames. Current research focuses on several promising avenues for energy storage in rail gun applications.

Capacitor-based systems remain at the forefront of rail gun energy storage solutions. Recent advancements in capacitor technology have led to the development of high-energy density, low-inductance capacitors specifically designed for pulsed power applications. These capacitors utilize advanced dielectric materials and novel geometries to achieve rapid discharge rates and high power densities. Ongoing research aims to further improve capacitor performance by exploring new materials such as nanostructured ceramics and advanced polymer composites.

Inductive energy storage systems present another viable option for rail gun power supplies. Superconducting magnetic energy storage (SMES) systems, in particular, show great promise due to their ability to store large amounts of energy with minimal losses. Recent breakthroughs in high-temperature superconductors have made SMES systems more practical for mobile applications, potentially enabling the integration of rail gun technology into naval vessels and other mobile platforms.

Hybrid energy storage solutions, combining multiple storage technologies, are gaining traction in rail gun research. These systems often integrate capacitors for rapid energy release with other storage methods like batteries or flywheels for overall energy capacity. This approach allows for optimized performance across different operational phases, from initial charging to rapid discharge during firing.

Advancements in power electronics and switching technologies are equally critical to the development of effective energy storage solutions for rail guns. High-power solid-state switches, such as those based on silicon carbide (SiC) or gallium nitride (GaN), enable more efficient and precise control of energy flow from storage systems to the rail gun. These switches can handle the extreme currents and voltages associated with rail gun operation while minimizing losses and improving overall system efficiency.

As research in rail gun technology progresses, the focus on energy storage solutions continues to evolve. Future developments may include the integration of novel materials like graphene-based supercapacitors or advanced metal-air batteries. Additionally, the exploration of compact fusion reactors as potential power sources for rail guns represents a long-term research direction that could revolutionize the field of electromagnetic launch systems.

Capacitor-based systems remain at the forefront of rail gun energy storage solutions. Recent advancements in capacitor technology have led to the development of high-energy density, low-inductance capacitors specifically designed for pulsed power applications. These capacitors utilize advanced dielectric materials and novel geometries to achieve rapid discharge rates and high power densities. Ongoing research aims to further improve capacitor performance by exploring new materials such as nanostructured ceramics and advanced polymer composites.

Inductive energy storage systems present another viable option for rail gun power supplies. Superconducting magnetic energy storage (SMES) systems, in particular, show great promise due to their ability to store large amounts of energy with minimal losses. Recent breakthroughs in high-temperature superconductors have made SMES systems more practical for mobile applications, potentially enabling the integration of rail gun technology into naval vessels and other mobile platforms.

Hybrid energy storage solutions, combining multiple storage technologies, are gaining traction in rail gun research. These systems often integrate capacitors for rapid energy release with other storage methods like batteries or flywheels for overall energy capacity. This approach allows for optimized performance across different operational phases, from initial charging to rapid discharge during firing.

Advancements in power electronics and switching technologies are equally critical to the development of effective energy storage solutions for rail guns. High-power solid-state switches, such as those based on silicon carbide (SiC) or gallium nitride (GaN), enable more efficient and precise control of energy flow from storage systems to the rail gun. These switches can handle the extreme currents and voltages associated with rail gun operation while minimizing losses and improving overall system efficiency.

As research in rail gun technology progresses, the focus on energy storage solutions continues to evolve. Future developments may include the integration of novel materials like graphene-based supercapacitors or advanced metal-air batteries. Additionally, the exploration of compact fusion reactors as potential power sources for rail guns represents a long-term research direction that could revolutionize the field of electromagnetic launch systems.

Environmental Impact

The environmental impact of rail gun technology and associated new materials research is a critical consideration in the development and deployment of these advanced weapon systems. The high-energy nature of rail guns and the materials used in their construction pose unique challenges and potential risks to the environment.

One of the primary environmental concerns associated with rail guns is the electromagnetic pulse (EMP) generated during firing. This intense burst of electromagnetic energy can potentially disrupt electronic systems in the surrounding area, affecting both military and civilian infrastructure. Long-term exposure to electromagnetic fields may also have implications for local ecosystems, although further research is needed to fully understand these effects.

The materials used in rail gun construction and projectiles also warrant environmental scrutiny. Advanced composites and alloys, often incorporating rare earth elements, are essential for withstanding the extreme conditions of rail gun operation. The mining and processing of these materials can have significant environmental impacts, including habitat destruction, water pollution, and greenhouse gas emissions. Sustainable sourcing and responsible manufacturing practices are crucial to mitigate these effects.

Another environmental consideration is the potential for contamination from rail gun projectiles. Unlike traditional ammunition, rail gun projectiles do not contain explosive materials, which reduces the risk of chemical contamination. However, the high-velocity impact of these projectiles can generate fine particulate matter and potentially release harmful substances upon target impact, depending on the composition of both the projectile and the target.

The energy requirements for operating rail gun systems are substantial, which indirectly contributes to environmental concerns. The power generation needed to support these weapons may increase reliance on fossil fuels, leading to increased carbon emissions unless clean energy sources are prioritized. Additionally, the thermal management systems required to dissipate heat from rail gun operations may have localized impacts on water resources and ambient temperatures.

Noise pollution is another environmental factor to consider. The acoustic signature of rail gun firing can be significant, potentially affecting wildlife and human populations in the vicinity of testing and deployment sites. Mitigation strategies, such as sound barriers and strategic placement of rail gun installations, may be necessary to minimize these impacts.

As research in rail gun technology and new materials progresses, it is essential to incorporate environmental impact assessments into the development process. This includes lifecycle analysis of materials, evaluation of operational impacts, and exploration of recycling and disposal methods for rail gun components. By proactively addressing environmental concerns, researchers and developers can work towards more sustainable and environmentally responsible rail gun systems, balancing technological advancement with ecological stewardship.

One of the primary environmental concerns associated with rail guns is the electromagnetic pulse (EMP) generated during firing. This intense burst of electromagnetic energy can potentially disrupt electronic systems in the surrounding area, affecting both military and civilian infrastructure. Long-term exposure to electromagnetic fields may also have implications for local ecosystems, although further research is needed to fully understand these effects.

The materials used in rail gun construction and projectiles also warrant environmental scrutiny. Advanced composites and alloys, often incorporating rare earth elements, are essential for withstanding the extreme conditions of rail gun operation. The mining and processing of these materials can have significant environmental impacts, including habitat destruction, water pollution, and greenhouse gas emissions. Sustainable sourcing and responsible manufacturing practices are crucial to mitigate these effects.

Another environmental consideration is the potential for contamination from rail gun projectiles. Unlike traditional ammunition, rail gun projectiles do not contain explosive materials, which reduces the risk of chemical contamination. However, the high-velocity impact of these projectiles can generate fine particulate matter and potentially release harmful substances upon target impact, depending on the composition of both the projectile and the target.

The energy requirements for operating rail gun systems are substantial, which indirectly contributes to environmental concerns. The power generation needed to support these weapons may increase reliance on fossil fuels, leading to increased carbon emissions unless clean energy sources are prioritized. Additionally, the thermal management systems required to dissipate heat from rail gun operations may have localized impacts on water resources and ambient temperatures.

Noise pollution is another environmental factor to consider. The acoustic signature of rail gun firing can be significant, potentially affecting wildlife and human populations in the vicinity of testing and deployment sites. Mitigation strategies, such as sound barriers and strategic placement of rail gun installations, may be necessary to minimize these impacts.

As research in rail gun technology and new materials progresses, it is essential to incorporate environmental impact assessments into the development process. This includes lifecycle analysis of materials, evaluation of operational impacts, and exploration of recycling and disposal methods for rail gun components. By proactively addressing environmental concerns, researchers and developers can work towards more sustainable and environmentally responsible rail gun systems, balancing technological advancement with ecological stewardship.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!