Rail Gun Innovations Impact on Infantry Gear Design

AUG 6, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Rail Gun Tech Evolution

The evolution of rail gun technology has been marked by significant advancements over the past few decades. Initially conceived in the early 20th century, rail guns remained largely theoretical until the late 1970s when practical research and development began in earnest. The fundamental principle of electromagnetic propulsion has remained constant, but the implementation and efficiency have seen remarkable improvements.

In the 1980s and 1990s, rail gun research focused primarily on overcoming basic technological hurdles such as power supply limitations and rail erosion. These early prototypes were bulky, inefficient, and impractical for field use. However, they laid the groundwork for future innovations by demonstrating the feasibility of electromagnetic launch systems.

The turn of the millennium saw a shift towards miniaturization and increased power density. Advances in materials science, particularly in the development of high-strength conductors and insulators, allowed for more compact designs. Simultaneously, progress in capacitor technology and pulsed power systems enabled higher energy storage and faster discharge rates, critical for achieving the extreme accelerations required in rail gun operation.

By the 2010s, rail gun technology had progressed to the point where field testing of prototype weapons became possible. These tests demonstrated muzzle velocities exceeding Mach 7, with projectiles reaching ranges of over 100 nautical miles. This period also saw increased interest in the potential applications of rail guns beyond traditional naval platforms, including land-based systems and even man-portable devices.

Recent years have witnessed a focus on addressing the challenges of rail gun integration into existing military platforms. This includes developing more durable rail materials to withstand the extreme conditions of electromagnetic launch, as well as creating more efficient cooling systems to manage the intense heat generated during operation. Additionally, there has been significant progress in projectile design, with emphasis on aerodynamics and guidance systems for improved accuracy at extreme ranges.

The impact of rail gun innovations on infantry gear design has become increasingly apparent. As the technology scales down, the potential for man-portable electromagnetic weapons has emerged, necessitating new approaches to power supply and heat management in individual soldier equipment. This has spurred research into lightweight, high-capacity energy storage solutions and advanced cooling systems that could be integrated into infantry gear.

Looking forward, the rail gun technology evolution is likely to continue along several key paths. These include further miniaturization, increased energy efficiency, and the development of multi-shot capabilities. As these advancements progress, the implications for infantry gear design will become more pronounced, potentially revolutionizing the concept of personal firepower and necessitating a complete rethinking of individual soldier equipment and tactics.

In the 1980s and 1990s, rail gun research focused primarily on overcoming basic technological hurdles such as power supply limitations and rail erosion. These early prototypes were bulky, inefficient, and impractical for field use. However, they laid the groundwork for future innovations by demonstrating the feasibility of electromagnetic launch systems.

The turn of the millennium saw a shift towards miniaturization and increased power density. Advances in materials science, particularly in the development of high-strength conductors and insulators, allowed for more compact designs. Simultaneously, progress in capacitor technology and pulsed power systems enabled higher energy storage and faster discharge rates, critical for achieving the extreme accelerations required in rail gun operation.

By the 2010s, rail gun technology had progressed to the point where field testing of prototype weapons became possible. These tests demonstrated muzzle velocities exceeding Mach 7, with projectiles reaching ranges of over 100 nautical miles. This period also saw increased interest in the potential applications of rail guns beyond traditional naval platforms, including land-based systems and even man-portable devices.

Recent years have witnessed a focus on addressing the challenges of rail gun integration into existing military platforms. This includes developing more durable rail materials to withstand the extreme conditions of electromagnetic launch, as well as creating more efficient cooling systems to manage the intense heat generated during operation. Additionally, there has been significant progress in projectile design, with emphasis on aerodynamics and guidance systems for improved accuracy at extreme ranges.

The impact of rail gun innovations on infantry gear design has become increasingly apparent. As the technology scales down, the potential for man-portable electromagnetic weapons has emerged, necessitating new approaches to power supply and heat management in individual soldier equipment. This has spurred research into lightweight, high-capacity energy storage solutions and advanced cooling systems that could be integrated into infantry gear.

Looking forward, the rail gun technology evolution is likely to continue along several key paths. These include further miniaturization, increased energy efficiency, and the development of multi-shot capabilities. As these advancements progress, the implications for infantry gear design will become more pronounced, potentially revolutionizing the concept of personal firepower and necessitating a complete rethinking of individual soldier equipment and tactics.

Infantry Gear Demand

The demand for infantry gear has been significantly influenced by the development of rail gun technology. As rail guns become more prevalent on the battlefield, infantry units face new challenges that require innovative gear solutions. The primary driver of this demand is the need for enhanced protection against high-velocity projectiles fired by rail guns, which can reach speeds far exceeding those of conventional firearms.

One of the key areas of focus is the development of advanced body armor capable of withstanding impacts from rail gun projectiles. Traditional ceramic and polymer-based armor systems are being pushed to their limits, necessitating research into new materials and composite structures. There is a growing interest in lightweight, high-strength materials such as graphene and carbon nanotubes, which could potentially offer superior protection without significantly increasing the overall weight burden on infantry soldiers.

Another critical aspect of infantry gear demand is the need for improved mobility and agility. As rail guns increase the lethality of long-range engagements, infantry units must be able to move quickly and efficiently across the battlefield to avoid detection and engage targets effectively. This has led to a surge in demand for lightweight, modular gear systems that allow soldiers to customize their loadouts based on mission requirements without compromising protection or mobility.

The integration of advanced sensor systems into infantry gear is also becoming increasingly important. With rail guns capable of engaging targets at extreme ranges, infantry units require enhanced situational awareness to detect and respond to threats effectively. This has driven demand for helmet-mounted displays, augmented reality systems, and networked communication devices that can provide real-time battlefield information and coordinate with other units and support elements.

Furthermore, the potential electromagnetic effects of rail gun technology have created a need for gear with improved electromagnetic shielding. This includes protection for electronic equipment carried by infantry, as well as measures to reduce the electromagnetic signature of individual soldiers to avoid detection by advanced sensor systems that may be linked to rail gun platforms.

The demand for infantry gear is also being shaped by the need for counter-rail gun capabilities. This includes the development of portable electronic warfare systems that can disrupt rail gun targeting and fire control systems, as well as specialized ammunition and weapons designed to neutralize or disable rail gun emplacements.

Overall, the impact of rail gun innovations on infantry gear demand is driving a new era of technological advancement in personal protective equipment, communication systems, and tactical gear. The challenge for manufacturers and military planners is to balance the need for increased protection and capability with the practical limitations of weight, cost, and usability in the field.

One of the key areas of focus is the development of advanced body armor capable of withstanding impacts from rail gun projectiles. Traditional ceramic and polymer-based armor systems are being pushed to their limits, necessitating research into new materials and composite structures. There is a growing interest in lightweight, high-strength materials such as graphene and carbon nanotubes, which could potentially offer superior protection without significantly increasing the overall weight burden on infantry soldiers.

Another critical aspect of infantry gear demand is the need for improved mobility and agility. As rail guns increase the lethality of long-range engagements, infantry units must be able to move quickly and efficiently across the battlefield to avoid detection and engage targets effectively. This has led to a surge in demand for lightweight, modular gear systems that allow soldiers to customize their loadouts based on mission requirements without compromising protection or mobility.

The integration of advanced sensor systems into infantry gear is also becoming increasingly important. With rail guns capable of engaging targets at extreme ranges, infantry units require enhanced situational awareness to detect and respond to threats effectively. This has driven demand for helmet-mounted displays, augmented reality systems, and networked communication devices that can provide real-time battlefield information and coordinate with other units and support elements.

Furthermore, the potential electromagnetic effects of rail gun technology have created a need for gear with improved electromagnetic shielding. This includes protection for electronic equipment carried by infantry, as well as measures to reduce the electromagnetic signature of individual soldiers to avoid detection by advanced sensor systems that may be linked to rail gun platforms.

The demand for infantry gear is also being shaped by the need for counter-rail gun capabilities. This includes the development of portable electronic warfare systems that can disrupt rail gun targeting and fire control systems, as well as specialized ammunition and weapons designed to neutralize or disable rail gun emplacements.

Overall, the impact of rail gun innovations on infantry gear demand is driving a new era of technological advancement in personal protective equipment, communication systems, and tactical gear. The challenge for manufacturers and military planners is to balance the need for increased protection and capability with the practical limitations of weight, cost, and usability in the field.

Rail Gun Challenges

Rail guns face several significant challenges that hinder their widespread adoption and integration into infantry gear design. One of the primary obstacles is the enormous power requirement needed to operate these electromagnetic weapons effectively. The energy demands far exceed the capabilities of current portable power sources, making it difficult to create a compact and mobile rail gun suitable for infantry use.

The intense electromagnetic fields generated during rail gun operation pose another major challenge. These fields can interfere with nearby electronic equipment, potentially disrupting communication systems and other crucial gear relied upon by infantry units. Shielding against such interference adds complexity and weight to the overall design, further complicating the integration process.

Durability and longevity of rail gun components present additional hurdles. The extreme forces and temperatures involved in launching projectiles at hypersonic speeds cause rapid wear and tear on the gun's rails and other critical parts. This results in a limited operational lifespan and necessitates frequent maintenance or replacement, which is impractical for field deployment.

The accuracy and precision of rail guns also require significant improvement to meet infantry needs. While these weapons can achieve incredible muzzle velocities, maintaining consistent accuracy over various ranges and environmental conditions remains a challenge. Factors such as projectile design, electromagnetic field stability, and barrel wear all contribute to accuracy issues that must be addressed.

Heat management is another critical concern in rail gun development. The rapid discharge of electromagnetic energy generates substantial heat, which can lead to performance degradation and potential safety hazards. Effective cooling systems must be developed to dissipate this heat quickly and efficiently, without adding excessive bulk or weight to the weapon system.

The integration of rail gun technology with existing infantry gear poses its own set of challenges. Current gear designs are not optimized to accommodate the unique requirements of rail guns, such as power distribution, electromagnetic shielding, and recoil management. Significant redesigns may be necessary to create a cohesive and functional infantry loadout that incorporates rail gun capabilities.

Lastly, the cost associated with developing and manufacturing rail guns remains prohibitively high for widespread infantry adoption. The advanced materials, precision engineering, and specialized components required for these weapons drive up production expenses, making it difficult to justify their deployment on a large scale compared to conventional firearms.

The intense electromagnetic fields generated during rail gun operation pose another major challenge. These fields can interfere with nearby electronic equipment, potentially disrupting communication systems and other crucial gear relied upon by infantry units. Shielding against such interference adds complexity and weight to the overall design, further complicating the integration process.

Durability and longevity of rail gun components present additional hurdles. The extreme forces and temperatures involved in launching projectiles at hypersonic speeds cause rapid wear and tear on the gun's rails and other critical parts. This results in a limited operational lifespan and necessitates frequent maintenance or replacement, which is impractical for field deployment.

The accuracy and precision of rail guns also require significant improvement to meet infantry needs. While these weapons can achieve incredible muzzle velocities, maintaining consistent accuracy over various ranges and environmental conditions remains a challenge. Factors such as projectile design, electromagnetic field stability, and barrel wear all contribute to accuracy issues that must be addressed.

Heat management is another critical concern in rail gun development. The rapid discharge of electromagnetic energy generates substantial heat, which can lead to performance degradation and potential safety hazards. Effective cooling systems must be developed to dissipate this heat quickly and efficiently, without adding excessive bulk or weight to the weapon system.

The integration of rail gun technology with existing infantry gear poses its own set of challenges. Current gear designs are not optimized to accommodate the unique requirements of rail guns, such as power distribution, electromagnetic shielding, and recoil management. Significant redesigns may be necessary to create a cohesive and functional infantry loadout that incorporates rail gun capabilities.

Lastly, the cost associated with developing and manufacturing rail guns remains prohibitively high for widespread infantry adoption. The advanced materials, precision engineering, and specialized components required for these weapons drive up production expenses, making it difficult to justify their deployment on a large scale compared to conventional firearms.

Current Infantry Gear

01 Electromagnetic rail gun design for infantry

Electromagnetic rail guns adapted for infantry use, featuring compact designs and portable power sources. These systems utilize electromagnetic forces to accelerate projectiles, offering increased muzzle velocity and range compared to traditional firearms. The designs focus on reducing weight and size while maintaining effectiveness for infantry applications.- Rail gun design for infantry use: Adapting rail gun technology for portable infantry weapons, focusing on miniaturization and power efficiency. This includes designs for handheld electromagnetic projectile launchers that are lightweight and suitable for individual soldier use.

- Power supply and energy storage systems: Development of compact, high-capacity power sources and energy storage systems to support rail gun operation in infantry gear. This involves advanced battery technologies, capacitors, or other portable energy solutions that can deliver the high power required for electromagnetic launching.

- Projectile design for infantry rail guns: Specialized projectile designs optimized for use in infantry-scale rail guns. These projectiles are engineered for improved aerodynamics, increased penetration, and enhanced effectiveness while being compatible with electromagnetic launching systems.

- Cooling and heat management systems: Innovative cooling solutions to manage the intense heat generated by rail gun operation in infantry gear. This includes advanced materials, heat sinks, and active cooling systems designed to maintain operational temperatures and prevent overheating during sustained use.

- Integration with infantry combat systems: Methods for integrating rail gun technology with existing infantry gear and combat systems. This involves designing modular components, developing interfaces with other equipment, and ensuring compatibility with standard infantry loadouts and tactics.

02 Protective gear for rail gun operators

Specialized protective equipment designed for infantry using rail guns. This gear includes enhanced body armor to protect against electromagnetic fields and potential weapon malfunctions. It may also incorporate cooling systems to manage heat generated by the rail gun operation and improve operator comfort in various combat scenarios.Expand Specific Solutions03 Power supply and energy management systems

Advanced power supply and energy management systems tailored for infantry rail guns. These systems focus on providing sufficient power for multiple shots while minimizing weight and bulk. They may include high-capacity batteries, energy harvesting technologies, or compact generators to ensure sustained operation in the field.Expand Specific Solutions04 Ammunition and projectile designs

Specialized ammunition and projectile designs optimized for infantry rail guns. These may include lightweight, aerodynamic projectiles capable of maintaining stability at high velocities. The designs focus on maximizing range, accuracy, and impact energy while considering the unique launch characteristics of electromagnetic rail guns.Expand Specific Solutions05 Targeting and fire control systems

Advanced targeting and fire control systems adapted for infantry rail guns. These systems may incorporate smart optics, ballistic computers, and environmental sensors to improve accuracy and effectiveness. They are designed to account for the unique ballistic properties of rail gun projectiles and assist operators in engaging targets at extended ranges.Expand Specific Solutions

Key Rail Gun Players

The research on rail gun innovations and their impact on infantry gear design is in an early developmental stage, with a growing market potential as military modernization efforts intensify globally. The technology is still maturing, with key players like Raytheon Co., The Boeing Co., and Naval Research Laboratory leading research efforts. Universities such as Nanjing University of Science & Technology and Beijing Institute of Technology are contributing to advancements in this field. The market size is expanding, driven by increasing defense budgets and the need for advanced weaponry. However, the technology's full integration into infantry gear remains a complex challenge, requiring further refinement and testing to ensure practical battlefield application.

Harbin Institute of Technology

Technical Solution: Harbin Institute of Technology has been focusing on the integration of railgun technology with advanced infantry protection systems. Their research involves developing electromagnetic shielding materials that can protect infantry personnel from the intense electromagnetic fields generated by railguns[13]. The institute has also been working on adaptive armor systems that can respond to the high-velocity impacts of railgun projectiles, potentially revolutionizing infantry protective gear[15]. Additionally, they are exploring the use of nanotechnology in railgun components to reduce weight and improve performance, making the technology more suitable for infantry applications[17].

Strengths: Innovative approach to infantry protection, expertise in electromagnetic shielding, and application of nanotechnology. Weaknesses: Potential challenges in balancing protection with mobility and cost-effectiveness for widespread infantry use.

Beijing Institute of Technology

Technical Solution: The Beijing Institute of Technology has been conducting research on railgun technology with a focus on its potential impact on infantry gear design. Their approach involves developing lightweight, high-strength materials for railgun components that can withstand the extreme forces involved in railgun operation[8]. The institute has also been working on advanced power management systems that could allow for more efficient use of energy in railgun-equipped infantry gear[10]. Additionally, their research includes the development of smart projectiles with guidance systems that could significantly enhance the accuracy and effectiveness of infantry-operated railguns[12].

Strengths: Expertise in materials science, advanced power management systems, and smart projectile technology. Weaknesses: Potential challenges in field testing and international collaboration due to geopolitical factors.

Rail Gun Breakthroughs

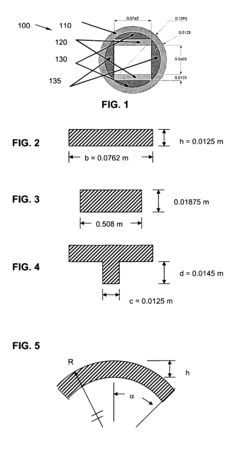

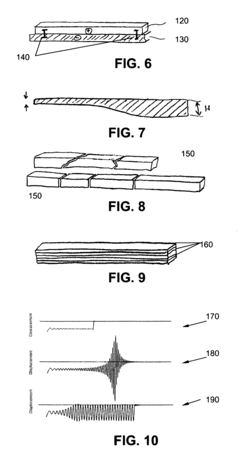

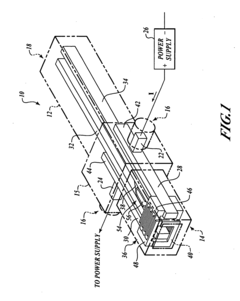

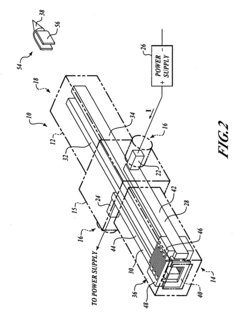

Rails for electromagnetic hypervelocity launcher

PatentInactiveUS7409900B1

Innovation

- The introduction of geometric and material configurations that increase critical velocity along the axial direction of the launcher, including varying materials and shapes, and the use of an insulating structural buffer between the rail and containment tube to prevent electrical conduction and support the projectile.

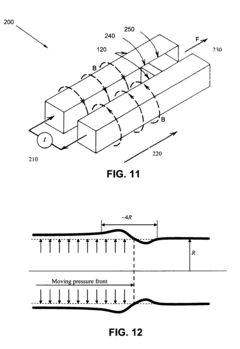

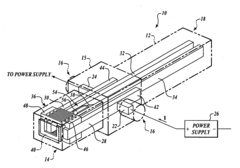

Electromagnetic launcher with augmenting breech

PatentActiveUS20080053299A1

Innovation

- The design includes a slidable electromagnetic launcher housing with augmentation conductors and main conductors connected via a current cross-over connection, allowing for recoil accommodation while maintaining electrical contact, and reducing overall inductance by limiting augmentation to early stages of the launch cycle, which facilitates faster current rise and balanced weight distribution.

Electromagnetic Shielding

Electromagnetic shielding is a critical consideration in the development of infantry gear designed to withstand the effects of rail gun innovations. As rail guns utilize powerful electromagnetic fields to accelerate projectiles, the resulting electromagnetic pulse (EMP) can potentially disrupt or damage electronic equipment carried by infantry personnel. To address this challenge, advanced shielding techniques are being incorporated into modern infantry gear designs.

One of the primary methods employed for electromagnetic shielding is the use of conductive materials. These materials, such as metal foils or conductive fabrics, are integrated into the outer layers of infantry gear to create a Faraday cage effect. This approach helps to redirect electromagnetic energy around sensitive electronic components, effectively protecting them from interference or damage. Recent advancements in material science have led to the development of lightweight, flexible conductive materials that can be seamlessly incorporated into gear without compromising mobility or comfort.

Another innovative approach to electromagnetic shielding involves the application of specialized coatings. These coatings, often composed of metallic particles suspended in a polymer matrix, can be applied to the surfaces of equipment or integrated into fabric layers. When exposed to electromagnetic fields, these coatings act as a barrier, absorbing or reflecting the energy to prevent it from penetrating the protected components. The advantage of this method is its versatility, as coatings can be applied to various surfaces and shapes without significantly altering the gear's overall design.

Advancements in metamaterials have also opened up new possibilities for electromagnetic shielding in infantry gear. These engineered materials possess unique electromagnetic properties that can be tailored to specific frequencies or field strengths. By incorporating metamaterial structures into gear designs, it is possible to create highly effective shields that are both lightweight and low-profile. This approach allows for targeted protection against the specific electromagnetic threats posed by rail gun technology while minimizing the impact on the overall weight and bulk of infantry equipment.

The integration of active shielding systems represents a cutting-edge development in electromagnetic protection for infantry gear. These systems utilize sensors to detect incoming electromagnetic pulses and rapidly generate opposing fields to neutralize their effects. While still in the early stages of development, active shielding holds promise for providing adaptive protection against varying levels of electromagnetic threats encountered in the field.

As rail gun technology continues to evolve, the field of electromagnetic shielding for infantry gear is likely to see further innovations. Research efforts are focused on developing more efficient, lightweight, and adaptable shielding solutions that can keep pace with advancements in electromagnetic weapon systems. The goal is to ensure that infantry personnel remain protected and operationally effective in environments where rail gun technology may be deployed, without sacrificing mobility or combat readiness.

One of the primary methods employed for electromagnetic shielding is the use of conductive materials. These materials, such as metal foils or conductive fabrics, are integrated into the outer layers of infantry gear to create a Faraday cage effect. This approach helps to redirect electromagnetic energy around sensitive electronic components, effectively protecting them from interference or damage. Recent advancements in material science have led to the development of lightweight, flexible conductive materials that can be seamlessly incorporated into gear without compromising mobility or comfort.

Another innovative approach to electromagnetic shielding involves the application of specialized coatings. These coatings, often composed of metallic particles suspended in a polymer matrix, can be applied to the surfaces of equipment or integrated into fabric layers. When exposed to electromagnetic fields, these coatings act as a barrier, absorbing or reflecting the energy to prevent it from penetrating the protected components. The advantage of this method is its versatility, as coatings can be applied to various surfaces and shapes without significantly altering the gear's overall design.

Advancements in metamaterials have also opened up new possibilities for electromagnetic shielding in infantry gear. These engineered materials possess unique electromagnetic properties that can be tailored to specific frequencies or field strengths. By incorporating metamaterial structures into gear designs, it is possible to create highly effective shields that are both lightweight and low-profile. This approach allows for targeted protection against the specific electromagnetic threats posed by rail gun technology while minimizing the impact on the overall weight and bulk of infantry equipment.

The integration of active shielding systems represents a cutting-edge development in electromagnetic protection for infantry gear. These systems utilize sensors to detect incoming electromagnetic pulses and rapidly generate opposing fields to neutralize their effects. While still in the early stages of development, active shielding holds promise for providing adaptive protection against varying levels of electromagnetic threats encountered in the field.

As rail gun technology continues to evolve, the field of electromagnetic shielding for infantry gear is likely to see further innovations. Research efforts are focused on developing more efficient, lightweight, and adaptable shielding solutions that can keep pace with advancements in electromagnetic weapon systems. The goal is to ensure that infantry personnel remain protected and operationally effective in environments where rail gun technology may be deployed, without sacrificing mobility or combat readiness.

Ethical Considerations

The development and potential deployment of rail gun technology in infantry gear design raises significant ethical considerations that must be carefully addressed. One primary concern is the potential for increased lethality and destructive power, which could lead to more severe casualties and collateral damage in conflict zones. This escalation in weaponry might violate principles of proportionality and distinction in warfare, as outlined in international humanitarian law.

Another ethical issue is the potential for misuse or proliferation of this advanced technology. If rail gun-based infantry weapons fall into the hands of non-state actors or rogue nations, it could destabilize global security and exacerbate existing conflicts. The international community must consider how to prevent such proliferation and establish robust control mechanisms.

The integration of rail gun technology into infantry gear also raises questions about the changing nature of warfare and its impact on combatants. The psychological effects on soldiers wielding such powerful weapons, as well as the potential for increased post-traumatic stress disorder (PTSD) rates, must be thoroughly examined. Additionally, the use of rail gun technology may blur the lines between human and machine-driven combat decisions, raising concerns about accountability and the ethical implications of automated targeting systems.

Furthermore, the development of rail gun-based infantry gear could trigger an arms race, leading to increased military spending and diverting resources from other critical areas such as healthcare, education, and environmental protection. This raises ethical questions about the prioritization of military technology over social welfare and sustainable development.

The environmental impact of rail gun technology in infantry gear is another ethical consideration. The production, testing, and use of these advanced weapons may have unforeseen consequences on ecosystems and contribute to environmental degradation. Researchers and policymakers must carefully assess and mitigate these potential environmental risks.

Lastly, the introduction of rail gun technology in infantry gear design may exacerbate existing power imbalances between nations, potentially leading to increased global tensions and conflicts. Ethical frameworks must be developed to ensure that the deployment of such advanced weaponry does not undermine international peace and security efforts.

Another ethical issue is the potential for misuse or proliferation of this advanced technology. If rail gun-based infantry weapons fall into the hands of non-state actors or rogue nations, it could destabilize global security and exacerbate existing conflicts. The international community must consider how to prevent such proliferation and establish robust control mechanisms.

The integration of rail gun technology into infantry gear also raises questions about the changing nature of warfare and its impact on combatants. The psychological effects on soldiers wielding such powerful weapons, as well as the potential for increased post-traumatic stress disorder (PTSD) rates, must be thoroughly examined. Additionally, the use of rail gun technology may blur the lines between human and machine-driven combat decisions, raising concerns about accountability and the ethical implications of automated targeting systems.

Furthermore, the development of rail gun-based infantry gear could trigger an arms race, leading to increased military spending and diverting resources from other critical areas such as healthcare, education, and environmental protection. This raises ethical questions about the prioritization of military technology over social welfare and sustainable development.

The environmental impact of rail gun technology in infantry gear is another ethical consideration. The production, testing, and use of these advanced weapons may have unforeseen consequences on ecosystems and contribute to environmental degradation. Researchers and policymakers must carefully assess and mitigate these potential environmental risks.

Lastly, the introduction of rail gun technology in infantry gear design may exacerbate existing power imbalances between nations, potentially leading to increased global tensions and conflicts. Ethical frameworks must be developed to ensure that the deployment of such advanced weaponry does not undermine international peace and security efforts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!