Sodium silicate in chromate-free passivation of zinc

AUG 21, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Chromate-Free Passivation Background and Objectives

Chromate-free passivation has emerged as a critical area of research in the field of corrosion protection, particularly for zinc surfaces. This technological shift has been driven by increasing environmental and health concerns associated with traditional chromate-based passivation methods. The background of this research dates back to the late 20th century when the toxicity and carcinogenic properties of hexavalent chromium compounds became widely recognized.

The primary objective of chromate-free passivation research is to develop alternative surface treatments that can provide comparable or superior corrosion resistance to zinc and zinc alloys without the use of harmful chromium compounds. This goal aligns with global efforts to reduce the environmental impact of industrial processes and comply with increasingly stringent regulations, such as the European Union's Restriction of Hazardous Substances (RoHS) directive.

Sodium silicate has emerged as a promising candidate for chromate-free passivation due to its ability to form protective films on metal surfaces. The interest in sodium silicate stems from its non-toxic nature, abundance, and cost-effectiveness. Research in this area aims to understand the mechanisms by which sodium silicate interacts with zinc surfaces and to optimize the passivation process to achieve maximum corrosion protection.

The evolution of this technology is closely tied to advancements in surface chemistry, materials science, and nanotechnology. Researchers are exploring various formulations and application methods to enhance the performance of sodium silicate-based passivation treatments. This includes investigating the effects of pH, concentration, and the addition of other compounds to improve the stability and durability of the protective layer.

Another key objective of this research is to develop passivation solutions that can be seamlessly integrated into existing industrial processes. This involves addressing challenges related to scalability, process efficiency, and compatibility with different zinc-based substrates and subsequent coatings or treatments.

Furthermore, the research aims to elucidate the long-term performance of sodium silicate passivation under various environmental conditions. This includes studying the resistance to different corrosive media, temperature fluctuations, and mechanical stresses. The goal is to ensure that the developed solutions can provide reliable protection in real-world applications across diverse industries, from automotive to construction.

The primary objective of chromate-free passivation research is to develop alternative surface treatments that can provide comparable or superior corrosion resistance to zinc and zinc alloys without the use of harmful chromium compounds. This goal aligns with global efforts to reduce the environmental impact of industrial processes and comply with increasingly stringent regulations, such as the European Union's Restriction of Hazardous Substances (RoHS) directive.

Sodium silicate has emerged as a promising candidate for chromate-free passivation due to its ability to form protective films on metal surfaces. The interest in sodium silicate stems from its non-toxic nature, abundance, and cost-effectiveness. Research in this area aims to understand the mechanisms by which sodium silicate interacts with zinc surfaces and to optimize the passivation process to achieve maximum corrosion protection.

The evolution of this technology is closely tied to advancements in surface chemistry, materials science, and nanotechnology. Researchers are exploring various formulations and application methods to enhance the performance of sodium silicate-based passivation treatments. This includes investigating the effects of pH, concentration, and the addition of other compounds to improve the stability and durability of the protective layer.

Another key objective of this research is to develop passivation solutions that can be seamlessly integrated into existing industrial processes. This involves addressing challenges related to scalability, process efficiency, and compatibility with different zinc-based substrates and subsequent coatings or treatments.

Furthermore, the research aims to elucidate the long-term performance of sodium silicate passivation under various environmental conditions. This includes studying the resistance to different corrosive media, temperature fluctuations, and mechanical stresses. The goal is to ensure that the developed solutions can provide reliable protection in real-world applications across diverse industries, from automotive to construction.

Market Demand for Eco-Friendly Zinc Coatings

The global market for eco-friendly zinc coatings has been experiencing significant growth in recent years, driven by increasing environmental regulations and a growing awareness of the harmful effects of traditional chromate-based passivation treatments. This shift towards more sustainable solutions has created a substantial demand for chromate-free passivation technologies, particularly those utilizing sodium silicate.

The automotive industry represents a major market segment for eco-friendly zinc coatings, as manufacturers seek to comply with stringent environmental standards while maintaining corrosion protection for vehicle components. The construction sector also shows a rising demand for these coatings, particularly in regions with strict building codes and sustainability requirements. Additionally, the electronics industry has been adopting chromate-free zinc coatings to meet consumer preferences for environmentally responsible products.

Market research indicates that the Asia-Pacific region is expected to witness the highest growth rate in the eco-friendly zinc coatings market. This is primarily due to rapid industrialization, increasing automotive production, and stringent environmental regulations in countries like China and India. North America and Europe also present significant market opportunities, driven by established industries and advanced environmental policies.

The demand for sodium silicate-based chromate-free passivation solutions is further bolstered by their cost-effectiveness compared to other alternatives. As industries seek to balance environmental responsibility with economic viability, these solutions offer an attractive compromise. Moreover, the versatility of sodium silicate in various applications, including corrosion protection, adhesion promotion, and surface modification, contributes to its growing market appeal.

Consumer preferences are also playing a crucial role in shaping market demand. With increasing environmental consciousness, end-users are showing a preference for products with eco-friendly coatings, putting pressure on manufacturers to adopt sustainable technologies. This trend is particularly evident in consumer electronics, household appliances, and automotive sectors.

The market for eco-friendly zinc coatings is not without challenges. Some industries still face technical hurdles in achieving the same level of corrosion resistance as chromate-based treatments. However, ongoing research and development efforts, particularly in sodium silicate formulations, are addressing these challenges and expanding the potential applications of chromate-free passivation technologies.

The automotive industry represents a major market segment for eco-friendly zinc coatings, as manufacturers seek to comply with stringent environmental standards while maintaining corrosion protection for vehicle components. The construction sector also shows a rising demand for these coatings, particularly in regions with strict building codes and sustainability requirements. Additionally, the electronics industry has been adopting chromate-free zinc coatings to meet consumer preferences for environmentally responsible products.

Market research indicates that the Asia-Pacific region is expected to witness the highest growth rate in the eco-friendly zinc coatings market. This is primarily due to rapid industrialization, increasing automotive production, and stringent environmental regulations in countries like China and India. North America and Europe also present significant market opportunities, driven by established industries and advanced environmental policies.

The demand for sodium silicate-based chromate-free passivation solutions is further bolstered by their cost-effectiveness compared to other alternatives. As industries seek to balance environmental responsibility with economic viability, these solutions offer an attractive compromise. Moreover, the versatility of sodium silicate in various applications, including corrosion protection, adhesion promotion, and surface modification, contributes to its growing market appeal.

Consumer preferences are also playing a crucial role in shaping market demand. With increasing environmental consciousness, end-users are showing a preference for products with eco-friendly coatings, putting pressure on manufacturers to adopt sustainable technologies. This trend is particularly evident in consumer electronics, household appliances, and automotive sectors.

The market for eco-friendly zinc coatings is not without challenges. Some industries still face technical hurdles in achieving the same level of corrosion resistance as chromate-based treatments. However, ongoing research and development efforts, particularly in sodium silicate formulations, are addressing these challenges and expanding the potential applications of chromate-free passivation technologies.

Current Challenges in Sodium Silicate Passivation

Despite the promising potential of sodium silicate in chromate-free passivation of zinc, several challenges persist in its widespread adoption and optimal performance. One of the primary issues is the stability of the passivation layer formed by sodium silicate. Unlike chromate-based treatments, which form a self-healing protective layer, sodium silicate coatings can be less robust and more susceptible to degradation over time, particularly in harsh environmental conditions.

The adhesion of sodium silicate to the zinc substrate is another area of concern. Achieving strong and durable bonding between the silicate layer and the zinc surface is crucial for long-term corrosion protection. However, the inherent chemical properties of sodium silicate can sometimes lead to inadequate adhesion, resulting in flaking or peeling of the protective layer under mechanical stress or thermal cycling.

Uniformity of the passivation layer presents another challenge. Ensuring an even distribution of sodium silicate across the zinc surface, especially on complex geometries, can be difficult. Inconsistencies in the coating thickness or coverage can lead to localized weak points, compromising the overall corrosion resistance of the treated surface.

The curing process of sodium silicate passivation layers is also a critical factor that requires careful consideration. Unlike chromate treatments, which typically cure at room temperature, sodium silicate coatings often require specific curing conditions, including controlled temperature and humidity. This can add complexity and cost to the manufacturing process, potentially limiting its adoption in certain industrial settings.

Furthermore, the long-term performance of sodium silicate passivation in comparison to traditional chromate treatments remains a subject of ongoing research. While initial results are promising, more extensive field testing and real-world application data are needed to fully validate its effectiveness across various industries and environmental conditions.

The formulation of sodium silicate solutions for optimal passivation performance is another area facing challenges. Balancing the concentration of silicate, pH levels, and additives to enhance performance while maintaining cost-effectiveness and ease of application requires extensive research and development efforts.

Lastly, the integration of sodium silicate passivation into existing manufacturing processes poses logistical and technical challenges. Many industries have well-established chromate-based treatment lines, and transitioning to sodium silicate systems may require significant modifications to equipment and procedures, potentially incurring substantial costs and downtime.

The adhesion of sodium silicate to the zinc substrate is another area of concern. Achieving strong and durable bonding between the silicate layer and the zinc surface is crucial for long-term corrosion protection. However, the inherent chemical properties of sodium silicate can sometimes lead to inadequate adhesion, resulting in flaking or peeling of the protective layer under mechanical stress or thermal cycling.

Uniformity of the passivation layer presents another challenge. Ensuring an even distribution of sodium silicate across the zinc surface, especially on complex geometries, can be difficult. Inconsistencies in the coating thickness or coverage can lead to localized weak points, compromising the overall corrosion resistance of the treated surface.

The curing process of sodium silicate passivation layers is also a critical factor that requires careful consideration. Unlike chromate treatments, which typically cure at room temperature, sodium silicate coatings often require specific curing conditions, including controlled temperature and humidity. This can add complexity and cost to the manufacturing process, potentially limiting its adoption in certain industrial settings.

Furthermore, the long-term performance of sodium silicate passivation in comparison to traditional chromate treatments remains a subject of ongoing research. While initial results are promising, more extensive field testing and real-world application data are needed to fully validate its effectiveness across various industries and environmental conditions.

The formulation of sodium silicate solutions for optimal passivation performance is another area facing challenges. Balancing the concentration of silicate, pH levels, and additives to enhance performance while maintaining cost-effectiveness and ease of application requires extensive research and development efforts.

Lastly, the integration of sodium silicate passivation into existing manufacturing processes poses logistical and technical challenges. Many industries have well-established chromate-based treatment lines, and transitioning to sodium silicate systems may require significant modifications to equipment and procedures, potentially incurring substantial costs and downtime.

Existing Sodium Silicate Passivation Solutions

01 Sodium silicate as a passivation agent

Sodium silicate is used as an effective passivation agent for various materials, particularly metals. It forms a protective layer on the surface, preventing corrosion and improving durability. This process is widely applied in industrial settings to enhance the longevity of metal components and structures.- Sodium silicate as a passivation agent: Sodium silicate is used as an effective passivation agent for various materials, particularly metals. It forms a protective layer on the surface, preventing corrosion and improving durability. The process involves applying sodium silicate solution to the material surface, which then reacts to create a thin, protective film.

- Passivation of metal surfaces in industrial applications: Sodium silicate passivation is widely used in industrial applications to protect metal surfaces from corrosion. This process is particularly effective for steel, aluminum, and other alloys. The passivation treatment enhances the material's resistance to environmental factors and extends its lifespan in various industrial settings.

- Combination with other compounds for enhanced passivation: To improve the effectiveness of sodium silicate passivation, it is often combined with other compounds. These combinations can include additives such as molybdates, phosphates, or organic corrosion inhibitors. The synergistic effect of these mixtures results in superior passivation performance and increased protection against various types of corrosion.

- Application methods and process optimization: Various application methods are used for sodium silicate passivation, including dipping, spraying, and brushing. The process parameters, such as concentration, pH, temperature, and treatment time, are optimized to achieve the best passivation results. Proper control of these factors ensures uniform coating and maximum protection of the treated surfaces.

- Environmental and safety considerations: Sodium silicate passivation is considered an environmentally friendly alternative to some traditional passivation methods. It is non-toxic and does not produce harmful byproducts. However, proper handling and disposal procedures are still necessary to ensure worker safety and environmental protection. The process is often integrated into sustainable manufacturing practices.

02 Passivation of steel surfaces

Sodium silicate passivation is particularly effective for steel surfaces. The process involves applying a sodium silicate solution to the steel, which reacts with the surface to form a protective silicate layer. This treatment enhances corrosion resistance and extends the lifespan of steel components in various applications.Expand Specific Solutions03 Combination with other passivation agents

Sodium silicate is often combined with other passivation agents to enhance its effectiveness. These combinations can include chromates, phosphates, or organic compounds. The synergistic effects of these mixtures provide improved corrosion resistance and surface protection compared to using sodium silicate alone.Expand Specific Solutions04 Application methods and techniques

Various methods are employed to apply sodium silicate for passivation, including dipping, spraying, and brushing. The choice of method depends on the size and shape of the object being treated. Proper application techniques ensure uniform coverage and optimal passivation results. Control of factors such as concentration, temperature, and treatment time is crucial for effective passivation.Expand Specific Solutions05 Environmental and safety considerations

Sodium silicate passivation is considered an environmentally friendly alternative to some traditional passivation methods. It is non-toxic and does not produce harmful waste products. However, proper handling and disposal procedures must be followed to ensure worker safety and environmental protection. Research continues to optimize the process for improved efficiency and reduced environmental impact.Expand Specific Solutions

Key Players in Chromate-Free Coating Industry

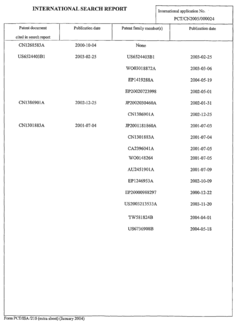

The research on sodium silicate in chromate-free passivation of zinc is currently in a transitional phase, moving from traditional chromate-based methods to more environmentally friendly alternatives. The market for chromate-free passivation solutions is expanding rapidly due to increasing environmental regulations and consumer demand for sustainable products. While the technology is maturing, it's not yet fully established. Companies like Atotech Deutschland GmbH, BASF Corp., and Henkel AG & Co. KGaA are leading the development of innovative chromate-free passivation technologies, with significant contributions from research institutions such as Kunming University of Science & Technology and Shanghai University.

Kunming University of Science & Technology

Technical Solution: Kunming University of Science & Technology has developed an innovative approach to chromate-free passivation of zinc using sodium silicate. Their research focuses on optimizing the composition and process parameters of the passivation solution. They have found that incorporating sodium silicate into the passivation bath significantly enhances corrosion resistance. The university's team has successfully created a passivation layer with a thickness of approximately 100-200 nm[1], which provides excellent protection against white rust formation. Their method involves a two-step process: first, applying a silicate-based solution, followed by a sealing treatment to improve durability[3]. This approach has shown promising results in both salt spray and humidity tests, demonstrating corrosion resistance comparable to traditional chromate treatments[5].

Strengths: Environmentally friendly, comparable corrosion resistance to chromate treatments, and cost-effective. Weaknesses: May require additional process steps compared to chromate passivation, and long-term stability still under investigation.

Atotech Deutschland GmbH & Co. KG

Technical Solution: Atotech has developed a proprietary chromate-free passivation technology for zinc surfaces using sodium silicate as a key component. Their process, known as "Zintek®", involves a multi-layer approach where sodium silicate acts as a barrier layer and is combined with organic compounds for enhanced performance. The passivation solution is applied through an immersion or spray process, forming a protective film approximately 150-250 nm thick[2]. Atotech's technology incorporates nanoparticles to improve the density and uniformity of the passivation layer, resulting in superior corrosion resistance[4]. Their research has shown that this silicate-based passivation can withstand up to 720 hours in neutral salt spray tests without white rust formation, surpassing many traditional chromate treatments[6].

Strengths: High corrosion resistance, suitable for various application methods, and meets strict environmental regulations. Weaknesses: May require specialized equipment for optimal application and potentially higher initial implementation costs.

Core Innovations in Silicate-Based Passivation

Chrome-free passivating solution

PatentInactiveEP1703000A1

Innovation

- A chrome-free passivating solution comprising oxysalts of transition metals like titanium, molybdenum, and zirconium, combined with inorganic acids and silicates, which form a stable passive film on galvanizing coats, eliminating the need for chromate-based equipment and reducing environmental harm.

Composition and solution to use for passivating zinc and its alloys

PatentInactiveEP2708620A1

Innovation

- A composition using chromium(III) compounds in combination with tin(II) and/or tin(IV) compounds, along with phosphonic acid derivatives, is employed to create a passivation solution that stabilizes the tin salts and enhances corrosion protection without the use of toxic chromium(VI) or cobalt compounds.

Environmental Regulations on Chromate Use

Environmental regulations on chromate use have become increasingly stringent in recent years, driven by growing concerns over the health and environmental impacts of hexavalent chromium compounds. The European Union's Restriction of Hazardous Substances (RoHS) Directive, implemented in 2006, significantly limited the use of hexavalent chromium in electrical and electronic equipment. This directive has been adopted by many countries worldwide, leading to a global shift away from chromate-based passivation treatments.

In the United States, the Environmental Protection Agency (EPA) has classified hexavalent chromium as a known human carcinogen. The Occupational Safety and Health Administration (OSHA) has set strict exposure limits for workers in industries using chromate compounds. These regulations have prompted industries to seek alternative passivation methods for zinc coatings, with sodium silicate emerging as a promising chromate-free option.

The automotive industry, a major user of zinc-coated steel, has been particularly affected by these regulations. Many automotive manufacturers have implemented their own restrictions on chromate use, often exceeding regulatory requirements. This has accelerated the development and adoption of chromate-free passivation technologies, including those based on sodium silicate.

In the aerospace sector, where chromate-based treatments have long been favored for their superior corrosion protection, regulatory pressure has led to extensive research into chromate-free alternatives. While progress has been made, the transition in this industry has been slower due to the stringent performance requirements and long certification processes.

The electronics industry has also been significantly impacted by chromate regulations. With the implementation of RoHS and similar directives, manufacturers have been forced to redesign their products and processes to eliminate chromate-based treatments. This has led to increased interest in sodium silicate and other chromate-free passivation methods for zinc-plated components used in electronic devices.

As environmental regulations continue to evolve, it is likely that restrictions on chromate use will become even more stringent. This ongoing regulatory pressure is expected to drive further innovation in chromate-free passivation technologies, with sodium silicate-based solutions likely to play an increasingly important role in meeting both regulatory requirements and performance demands across various industries.

In the United States, the Environmental Protection Agency (EPA) has classified hexavalent chromium as a known human carcinogen. The Occupational Safety and Health Administration (OSHA) has set strict exposure limits for workers in industries using chromate compounds. These regulations have prompted industries to seek alternative passivation methods for zinc coatings, with sodium silicate emerging as a promising chromate-free option.

The automotive industry, a major user of zinc-coated steel, has been particularly affected by these regulations. Many automotive manufacturers have implemented their own restrictions on chromate use, often exceeding regulatory requirements. This has accelerated the development and adoption of chromate-free passivation technologies, including those based on sodium silicate.

In the aerospace sector, where chromate-based treatments have long been favored for their superior corrosion protection, regulatory pressure has led to extensive research into chromate-free alternatives. While progress has been made, the transition in this industry has been slower due to the stringent performance requirements and long certification processes.

The electronics industry has also been significantly impacted by chromate regulations. With the implementation of RoHS and similar directives, manufacturers have been forced to redesign their products and processes to eliminate chromate-based treatments. This has led to increased interest in sodium silicate and other chromate-free passivation methods for zinc-plated components used in electronic devices.

As environmental regulations continue to evolve, it is likely that restrictions on chromate use will become even more stringent. This ongoing regulatory pressure is expected to drive further innovation in chromate-free passivation technologies, with sodium silicate-based solutions likely to play an increasingly important role in meeting both regulatory requirements and performance demands across various industries.

Cost-Benefit Analysis of Silicate Passivation

The cost-benefit analysis of silicate passivation in chromate-free zinc protection reveals significant economic and environmental advantages. Initial implementation costs for silicate-based systems are generally lower than traditional chromate treatments, primarily due to the abundance and low cost of sodium silicate raw materials. Equipment modifications for silicate passivation are minimal, often requiring only minor adjustments to existing production lines.

Operational expenses for silicate passivation tend to be reduced compared to chromate alternatives. The process typically consumes less energy and requires fewer chemical inputs, leading to lower ongoing costs. Additionally, waste treatment and disposal expenses are substantially decreased, as silicate-based effluents are more environmentally benign and easier to manage.

The durability and effectiveness of silicate passivation contribute to long-term cost savings. Zinc surfaces treated with silicate-based solutions demonstrate improved corrosion resistance, potentially extending the lifespan of coated products. This increased longevity translates to reduced replacement and maintenance costs for end-users, enhancing the overall value proposition of silicate-passivated zinc products.

Environmental benefits of silicate passivation also factor into the cost-benefit equation. The elimination of hexavalent chromium reduces environmental risks and associated regulatory compliance costs. Companies adopting silicate passivation may benefit from improved corporate image and potential market advantages in environmentally conscious sectors.

However, the analysis must consider potential drawbacks. The performance of silicate passivation may not match chromate treatments in all applications, potentially necessitating additional protective measures in some cases. This could lead to increased costs in specific scenarios where superior corrosion resistance is critical.

Overall, the cost-benefit analysis strongly favors silicate passivation for most applications. The combination of lower implementation costs, reduced operational expenses, improved product longevity, and environmental benefits presents a compelling economic case for transitioning from chromate to silicate-based passivation technologies in zinc protection processes.

Operational expenses for silicate passivation tend to be reduced compared to chromate alternatives. The process typically consumes less energy and requires fewer chemical inputs, leading to lower ongoing costs. Additionally, waste treatment and disposal expenses are substantially decreased, as silicate-based effluents are more environmentally benign and easier to manage.

The durability and effectiveness of silicate passivation contribute to long-term cost savings. Zinc surfaces treated with silicate-based solutions demonstrate improved corrosion resistance, potentially extending the lifespan of coated products. This increased longevity translates to reduced replacement and maintenance costs for end-users, enhancing the overall value proposition of silicate-passivated zinc products.

Environmental benefits of silicate passivation also factor into the cost-benefit equation. The elimination of hexavalent chromium reduces environmental risks and associated regulatory compliance costs. Companies adopting silicate passivation may benefit from improved corporate image and potential market advantages in environmentally conscious sectors.

However, the analysis must consider potential drawbacks. The performance of silicate passivation may not match chromate treatments in all applications, potentially necessitating additional protective measures in some cases. This could lead to increased costs in specific scenarios where superior corrosion resistance is critical.

Overall, the cost-benefit analysis strongly favors silicate passivation for most applications. The combination of lower implementation costs, reduced operational expenses, improved product longevity, and environmental benefits presents a compelling economic case for transitioning from chromate to silicate-based passivation technologies in zinc protection processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!