Sodium silicate stabilization in LED encapsulation materials

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LED Encapsulation Background and Objectives

Light-emitting diodes (LEDs) have revolutionized the lighting industry, offering superior energy efficiency, longevity, and versatility compared to traditional lighting technologies. At the heart of LED performance and reliability lies the encapsulation material, which plays a crucial role in protecting the LED chip and enhancing light extraction. The development of advanced encapsulation materials has been a key focus in LED research and development over the past decades.

Sodium silicate, also known as water glass, has emerged as a promising component in LED encapsulation materials due to its unique properties. This inorganic compound offers excellent thermal stability, optical transparency, and moisture resistance, making it an attractive option for enhancing the performance and durability of LED devices. However, the integration of sodium silicate into LED encapsulation materials presents several challenges that need to be addressed to fully harness its potential.

The primary objective of researching sodium silicate stabilization in LED encapsulation materials is to overcome these challenges and develop a robust, high-performance encapsulation solution. This research aims to enhance the compatibility of sodium silicate with other components of the encapsulation material, improve its long-term stability, and optimize its optical and thermal properties for LED applications.

One of the key goals is to mitigate the tendency of sodium silicate to form crystalline structures over time, which can lead to reduced transparency and compromised LED performance. Additionally, researchers are focusing on developing methods to control the pH and chemical reactivity of sodium silicate within the encapsulation matrix, ensuring long-term stability and preventing undesired interactions with the LED chip or other components.

Another important aspect of this research is to explore the potential of sodium silicate in enhancing the light extraction efficiency of LEDs. By optimizing the refractive index and surface properties of the encapsulation material, researchers aim to minimize total internal reflection and maximize the amount of light emitted from the device.

Furthermore, the investigation into sodium silicate stabilization seeks to improve the thermal management capabilities of LED encapsulation materials. As LEDs generate significant heat during operation, developing encapsulation materials with enhanced thermal conductivity and stability is crucial for maintaining device performance and longevity.

The research on sodium silicate stabilization in LED encapsulation materials aligns with the broader industry trends towards more efficient, reliable, and environmentally friendly lighting solutions. By addressing the challenges associated with sodium silicate integration, this research has the potential to contribute significantly to the advancement of LED technology, paving the way for next-generation lighting devices with improved performance, durability, and cost-effectiveness.

Sodium silicate, also known as water glass, has emerged as a promising component in LED encapsulation materials due to its unique properties. This inorganic compound offers excellent thermal stability, optical transparency, and moisture resistance, making it an attractive option for enhancing the performance and durability of LED devices. However, the integration of sodium silicate into LED encapsulation materials presents several challenges that need to be addressed to fully harness its potential.

The primary objective of researching sodium silicate stabilization in LED encapsulation materials is to overcome these challenges and develop a robust, high-performance encapsulation solution. This research aims to enhance the compatibility of sodium silicate with other components of the encapsulation material, improve its long-term stability, and optimize its optical and thermal properties for LED applications.

One of the key goals is to mitigate the tendency of sodium silicate to form crystalline structures over time, which can lead to reduced transparency and compromised LED performance. Additionally, researchers are focusing on developing methods to control the pH and chemical reactivity of sodium silicate within the encapsulation matrix, ensuring long-term stability and preventing undesired interactions with the LED chip or other components.

Another important aspect of this research is to explore the potential of sodium silicate in enhancing the light extraction efficiency of LEDs. By optimizing the refractive index and surface properties of the encapsulation material, researchers aim to minimize total internal reflection and maximize the amount of light emitted from the device.

Furthermore, the investigation into sodium silicate stabilization seeks to improve the thermal management capabilities of LED encapsulation materials. As LEDs generate significant heat during operation, developing encapsulation materials with enhanced thermal conductivity and stability is crucial for maintaining device performance and longevity.

The research on sodium silicate stabilization in LED encapsulation materials aligns with the broader industry trends towards more efficient, reliable, and environmentally friendly lighting solutions. By addressing the challenges associated with sodium silicate integration, this research has the potential to contribute significantly to the advancement of LED technology, paving the way for next-generation lighting devices with improved performance, durability, and cost-effectiveness.

Market Analysis for Stable LED Encapsulants

The LED encapsulation materials market has been experiencing significant growth due to the increasing demand for LED lighting solutions across various industries. The global LED market is projected to reach $72.7 billion by 2025, with a compound annual growth rate (CAGR) of 12.5% from 2020 to 2025. This growth is primarily driven by the adoption of energy-efficient lighting solutions, government initiatives promoting LED usage, and the declining prices of LED products.

Within this expanding market, there is a growing need for stable LED encapsulants, particularly those utilizing sodium silicate stabilization. This demand is fueled by the increasing requirements for high-performance, long-lasting LED products in applications such as automotive lighting, outdoor displays, and industrial lighting. The automotive LED market alone is expected to grow at a CAGR of 14.5% from 2020 to 2025, reaching $3.5 billion by the end of the forecast period.

The demand for stable LED encapsulants is also driven by the need for improved reliability and longevity in LED products. As LEDs are increasingly used in harsh environments and critical applications, the importance of encapsulants that can withstand temperature fluctuations, humidity, and UV exposure has become paramount. This has led to a surge in research and development activities focused on enhancing the stability of LED encapsulation materials.

Geographically, the Asia-Pacific region dominates the LED encapsulation materials market, accounting for over 60% of the global market share. This is primarily due to the presence of major LED manufacturers in countries like China, South Korea, and Japan. However, North America and Europe are also witnessing significant growth in demand for stable LED encapsulants, driven by stringent energy efficiency regulations and the adoption of smart lighting solutions.

The market for sodium silicate-stabilized LED encapsulants is expected to grow at a faster rate compared to traditional encapsulants. This is due to their superior properties, including improved thermal stability, enhanced moisture resistance, and better optical performance. The automotive and outdoor lighting sectors are anticipated to be the primary drivers for this growth, as these applications require encapsulants that can withstand extreme conditions while maintaining optimal light output.

As the LED industry continues to evolve, there is an increasing focus on developing eco-friendly and sustainable encapsulation materials. This trend is likely to create new opportunities for sodium silicate-based encapsulants, as they offer a more environmentally friendly alternative to some traditional materials. The growing emphasis on circular economy principles and recyclability in the electronics industry is expected to further boost the demand for such sustainable encapsulation solutions in the coming years.

Within this expanding market, there is a growing need for stable LED encapsulants, particularly those utilizing sodium silicate stabilization. This demand is fueled by the increasing requirements for high-performance, long-lasting LED products in applications such as automotive lighting, outdoor displays, and industrial lighting. The automotive LED market alone is expected to grow at a CAGR of 14.5% from 2020 to 2025, reaching $3.5 billion by the end of the forecast period.

The demand for stable LED encapsulants is also driven by the need for improved reliability and longevity in LED products. As LEDs are increasingly used in harsh environments and critical applications, the importance of encapsulants that can withstand temperature fluctuations, humidity, and UV exposure has become paramount. This has led to a surge in research and development activities focused on enhancing the stability of LED encapsulation materials.

Geographically, the Asia-Pacific region dominates the LED encapsulation materials market, accounting for over 60% of the global market share. This is primarily due to the presence of major LED manufacturers in countries like China, South Korea, and Japan. However, North America and Europe are also witnessing significant growth in demand for stable LED encapsulants, driven by stringent energy efficiency regulations and the adoption of smart lighting solutions.

The market for sodium silicate-stabilized LED encapsulants is expected to grow at a faster rate compared to traditional encapsulants. This is due to their superior properties, including improved thermal stability, enhanced moisture resistance, and better optical performance. The automotive and outdoor lighting sectors are anticipated to be the primary drivers for this growth, as these applications require encapsulants that can withstand extreme conditions while maintaining optimal light output.

As the LED industry continues to evolve, there is an increasing focus on developing eco-friendly and sustainable encapsulation materials. This trend is likely to create new opportunities for sodium silicate-based encapsulants, as they offer a more environmentally friendly alternative to some traditional materials. The growing emphasis on circular economy principles and recyclability in the electronics industry is expected to further boost the demand for such sustainable encapsulation solutions in the coming years.

Sodium Silicate Challenges in LED Packaging

Sodium silicate, also known as water glass, has emerged as a critical component in LED encapsulation materials due to its unique properties. However, its application in LED packaging presents several significant challenges that researchers and manufacturers must address to optimize performance and reliability.

One of the primary challenges is the inherent instability of sodium silicate in LED encapsulation materials. The high alkalinity of sodium silicate can lead to chemical reactions with other components in the encapsulant, potentially causing degradation of the LED package over time. This instability can result in reduced light output, color shift, and shortened lifespan of the LED device.

Another major challenge is the moisture sensitivity of sodium silicate. When exposed to humidity, sodium silicate can absorb water, leading to swelling and potential delamination of the encapsulant from the LED chip or substrate. This moisture-induced degradation can compromise the optical and mechanical properties of the LED package, ultimately affecting its performance and reliability.

The thermal stability of sodium silicate in LED encapsulation materials is also a concern. LEDs generate significant heat during operation, and the encapsulant must withstand these elevated temperatures without degrading. Sodium silicate's thermal behavior in the presence of other encapsulant components can lead to changes in its structure and properties, potentially impacting the LED's long-term performance.

Furthermore, achieving uniform dispersion of sodium silicate within the encapsulation material poses a challenge. Inadequate dispersion can result in localized areas of high concentration, leading to non-uniform optical properties and potential hotspots within the LED package. This non-uniformity can affect light output, color consistency, and overall device efficiency.

The interaction between sodium silicate and phosphors used in white LEDs presents another challenge. Sodium silicate can potentially react with or alter the properties of phosphor materials, affecting color rendering and light conversion efficiency. Balancing the stabilizing effects of sodium silicate with its potential impact on phosphor performance requires careful consideration and formulation.

Lastly, the long-term reliability and aging characteristics of sodium silicate-containing LED encapsulants remain a challenge. Understanding how these materials behave over extended periods under various environmental conditions is crucial for predicting and ensuring the longevity of LED devices. Accelerated aging tests and comprehensive reliability studies are necessary to address this challenge and develop more robust encapsulation solutions.

One of the primary challenges is the inherent instability of sodium silicate in LED encapsulation materials. The high alkalinity of sodium silicate can lead to chemical reactions with other components in the encapsulant, potentially causing degradation of the LED package over time. This instability can result in reduced light output, color shift, and shortened lifespan of the LED device.

Another major challenge is the moisture sensitivity of sodium silicate. When exposed to humidity, sodium silicate can absorb water, leading to swelling and potential delamination of the encapsulant from the LED chip or substrate. This moisture-induced degradation can compromise the optical and mechanical properties of the LED package, ultimately affecting its performance and reliability.

The thermal stability of sodium silicate in LED encapsulation materials is also a concern. LEDs generate significant heat during operation, and the encapsulant must withstand these elevated temperatures without degrading. Sodium silicate's thermal behavior in the presence of other encapsulant components can lead to changes in its structure and properties, potentially impacting the LED's long-term performance.

Furthermore, achieving uniform dispersion of sodium silicate within the encapsulation material poses a challenge. Inadequate dispersion can result in localized areas of high concentration, leading to non-uniform optical properties and potential hotspots within the LED package. This non-uniformity can affect light output, color consistency, and overall device efficiency.

The interaction between sodium silicate and phosphors used in white LEDs presents another challenge. Sodium silicate can potentially react with or alter the properties of phosphor materials, affecting color rendering and light conversion efficiency. Balancing the stabilizing effects of sodium silicate with its potential impact on phosphor performance requires careful consideration and formulation.

Lastly, the long-term reliability and aging characteristics of sodium silicate-containing LED encapsulants remain a challenge. Understanding how these materials behave over extended periods under various environmental conditions is crucial for predicting and ensuring the longevity of LED devices. Accelerated aging tests and comprehensive reliability studies are necessary to address this challenge and develop more robust encapsulation solutions.

Current Sodium Silicate Stabilization Methods

01 Stabilization of sodium silicate solutions

Various methods are employed to stabilize sodium silicate solutions, preventing gelation and precipitation. These methods include adjusting pH, adding stabilizing agents, and controlling temperature and concentration. Stabilized solutions have improved shelf life and performance in applications such as detergents, water treatment, and paper production.- Stabilization of sodium silicate solutions: Various methods are employed to stabilize sodium silicate solutions, preventing gelation and precipitation. These methods include adjusting pH, adding stabilizing agents, and controlling temperature and concentration. Stabilized solutions have improved shelf life and performance in applications such as detergents, water treatment, and paper production.

- Use of additives for sodium silicate stabilization: Specific additives are incorporated into sodium silicate solutions to enhance stability. These may include organic compounds, inorganic salts, or polymers that interact with silicate species to prevent aggregation and gelation. The choice of additive depends on the intended application and desired properties of the stabilized solution.

- Sodium silicate stabilization in cement and concrete applications: Sodium silicate is used as a stabilizing agent in cement and concrete mixtures. It can improve the strength, durability, and water resistance of concrete. Stabilization techniques are developed to ensure proper dispersion and reactivity of sodium silicate within the cementitious matrix, leading to enhanced performance of the final product.

- Stabilization of sodium silicate for water treatment: Sodium silicate is utilized in water treatment processes, requiring stabilization to maintain its effectiveness. Techniques are developed to prevent premature gelation or precipitation of silica in water treatment systems. This ensures consistent performance in applications such as corrosion inhibition, scale prevention, and heavy metal removal.

- Sodium silicate stabilization in coating formulations: Stabilized sodium silicate solutions are used in various coating applications. Techniques are developed to ensure compatibility with other coating components and to prevent unwanted reactions during storage or application. Stabilized sodium silicate coatings offer improved adhesion, durability, and barrier properties.

02 Use of additives for sodium silicate stabilization

Specific additives are incorporated into sodium silicate solutions to enhance stability. These may include organic compounds, inorganic salts, or polymers that interact with silicate species to prevent aggregation and gelation. The choice of additive depends on the intended application and desired properties of the stabilized solution.Expand Specific Solutions03 Sodium silicate stabilization in cement and concrete applications

Sodium silicate is used as a stabilizing agent in cement and concrete mixtures to improve strength, durability, and resistance to chemical attack. Stabilization techniques involve optimizing the silicate concentration, adjusting the modulus, and incorporating complementary additives to enhance performance in construction materials.Expand Specific Solutions04 Stabilization of sodium silicate for water treatment

Sodium silicate solutions are stabilized for use in water treatment applications, such as corrosion inhibition and scale prevention. Stabilization methods focus on maintaining the active silicate species in solution over extended periods and under varying water conditions. This ensures consistent performance in water distribution systems and industrial processes.Expand Specific Solutions05 Sodium silicate stabilization in detergent formulations

Stabilized sodium silicate is incorporated into detergent formulations to enhance cleaning performance and protect washing machines from corrosion. Stabilization techniques for this application focus on preventing silicate precipitation in the presence of other detergent components and maintaining effectiveness across a range of wash temperatures and water hardness levels.Expand Specific Solutions

Key Players in LED Encapsulation Industry

The research on sodium silicate stabilization in LED encapsulation materials is in a developing stage, with the market showing significant growth potential. The LED industry's expansion drives demand for advanced encapsulation materials, creating a competitive landscape. Key players like Wacker Chemie AG, Shin-Etsu Chemical Co., Ltd., and Momentive Performance Materials Japan LLC are leveraging their expertise in silicone technologies to develop innovative solutions. The market is characterized by ongoing R&D efforts to enhance material stability and performance, with companies like LG Chem Ltd. and Koninklijke Philips NV also contributing to advancements. As the technology matures, collaboration between academic institutions and industry leaders is likely to accelerate progress in this field.

Wacker Chemie AG

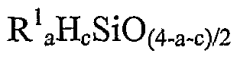

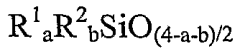

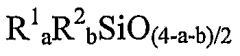

Technical Solution: Wacker Chemie AG has developed advanced silicone-based LED encapsulation materials with improved sodium silicate stabilization. Their approach involves incorporating specially designed silane coupling agents that form strong chemical bonds with both the silicone matrix and the sodium silicate particles[1]. This enhances the overall stability of the encapsulant and reduces the risk of sodium ion migration. Additionally, Wacker has implemented a proprietary surface treatment process for the sodium silicate particles, which creates a protective barrier against moisture ingress and further improves long-term stability[3]. The company has also optimized the particle size distribution of sodium silicate to achieve better dispersion within the silicone matrix, resulting in improved optical properties and reduced light scattering[5].

Strengths: Excellent chemical compatibility with silicone, enhanced moisture resistance, and improved optical performance. Weaknesses: Potentially higher production costs due to specialized treatments and materials.

Shin-Etsu Chemical Co., Ltd.

Technical Solution: Shin-Etsu Chemical Co., Ltd. has developed a novel approach to sodium silicate stabilization in LED encapsulation materials using their proprietary silicone technology. Their method involves the creation of a hybrid organic-inorganic network structure that effectively encapsulates sodium silicate particles[2]. This is achieved through the use of specially designed silane coupling agents that form covalent bonds between the silicone matrix and the sodium silicate surface. Additionally, Shin-Etsu has implemented a unique curing process that promotes the formation of a dense, cross-linked structure around the sodium silicate particles, further enhancing their stability[4]. The company has also developed a series of additives that act as ion scavengers, effectively trapping any free sodium ions and preventing their migration within the encapsulant[6].

Strengths: High stability under harsh environmental conditions, excellent optical transparency, and reduced ion migration. Weaknesses: May require specialized processing equipment and conditions for optimal performance.

Innovative Approaches to Silicate Stabilization

Method of making light emitting device with silicon-containing encapsulant

PatentWO2006055196A1

Innovation

- A method using a silicon-containing resin with aliphatic unsaturation and a metal-containing catalyst, cured by actinic radiation of 700 nm or less, providing a stable and rapid curing encapsulant for LEDs, avoiding high temperatures and simplifying the formulation process.

Method of making light emitting device having a molded encapsulant

PatentWO2007050483A2

Innovation

- A method using a photopolymerizable silicon-containing resin with a first metal-containing catalyst activated by actinic radiation and a second catalyst activated by heat, allowing for low-temperature molding with low to moderate viscosity resins, which avoids wire sweep and thermal stresses by initiating hydrosilylation through actinic radiation or heat.

Environmental Impact of LED Encapsulation Materials

The environmental impact of LED encapsulation materials, particularly those containing sodium silicate, is a crucial consideration in the development and production of LED technologies. Sodium silicate, while offering potential benefits for LED encapsulation, also presents environmental challenges that must be carefully evaluated.

One of the primary environmental concerns associated with sodium silicate in LED encapsulation is its production process. The manufacturing of sodium silicate typically involves high-temperature fusion of sodium carbonate and silica sand, which consumes significant energy and contributes to greenhouse gas emissions. This energy-intensive process can have a substantial carbon footprint, potentially offsetting some of the energy-saving benefits of LED technology.

Water consumption and pollution are additional environmental factors to consider. The production and use of sodium silicate can lead to increased water usage and potential contamination of water sources if not properly managed. Effluents from manufacturing processes may contain high levels of alkalinity, which can disrupt aquatic ecosystems if released untreated into natural water bodies.

The disposal of LED products containing sodium silicate-based encapsulation materials also raises environmental concerns. As LEDs reach the end of their lifecycle, proper recycling and disposal methods are essential to prevent the release of potentially harmful substances into the environment. The presence of sodium silicate may complicate recycling processes, requiring specialized treatment to separate and recover valuable materials.

On the positive side, the use of sodium silicate in LED encapsulation may contribute to improved durability and longevity of LED products. This increased lifespan can lead to reduced electronic waste generation over time, as fewer LED units need to be replaced. Additionally, the enhanced stability provided by sodium silicate may result in more efficient LEDs, potentially reducing overall energy consumption and associated environmental impacts.

The environmental impact of sodium silicate in LED encapsulation must also be considered in the context of alternative materials. Comparative life cycle assessments are necessary to determine whether sodium silicate-based encapsulation offers environmental advantages over other options. Factors such as raw material sourcing, production efficiency, and end-of-life management should be evaluated holistically to make informed decisions about material selection.

As the LED industry continues to evolve, there is a growing emphasis on developing more environmentally friendly encapsulation materials. Research into bio-based alternatives and materials with lower environmental footprints is ongoing. These efforts aim to address the environmental challenges associated with traditional encapsulation materials while maintaining or improving the performance and reliability of LED products.

One of the primary environmental concerns associated with sodium silicate in LED encapsulation is its production process. The manufacturing of sodium silicate typically involves high-temperature fusion of sodium carbonate and silica sand, which consumes significant energy and contributes to greenhouse gas emissions. This energy-intensive process can have a substantial carbon footprint, potentially offsetting some of the energy-saving benefits of LED technology.

Water consumption and pollution are additional environmental factors to consider. The production and use of sodium silicate can lead to increased water usage and potential contamination of water sources if not properly managed. Effluents from manufacturing processes may contain high levels of alkalinity, which can disrupt aquatic ecosystems if released untreated into natural water bodies.

The disposal of LED products containing sodium silicate-based encapsulation materials also raises environmental concerns. As LEDs reach the end of their lifecycle, proper recycling and disposal methods are essential to prevent the release of potentially harmful substances into the environment. The presence of sodium silicate may complicate recycling processes, requiring specialized treatment to separate and recover valuable materials.

On the positive side, the use of sodium silicate in LED encapsulation may contribute to improved durability and longevity of LED products. This increased lifespan can lead to reduced electronic waste generation over time, as fewer LED units need to be replaced. Additionally, the enhanced stability provided by sodium silicate may result in more efficient LEDs, potentially reducing overall energy consumption and associated environmental impacts.

The environmental impact of sodium silicate in LED encapsulation must also be considered in the context of alternative materials. Comparative life cycle assessments are necessary to determine whether sodium silicate-based encapsulation offers environmental advantages over other options. Factors such as raw material sourcing, production efficiency, and end-of-life management should be evaluated holistically to make informed decisions about material selection.

As the LED industry continues to evolve, there is a growing emphasis on developing more environmentally friendly encapsulation materials. Research into bio-based alternatives and materials with lower environmental footprints is ongoing. These efforts aim to address the environmental challenges associated with traditional encapsulation materials while maintaining or improving the performance and reliability of LED products.

Regulatory Framework for LED Packaging Materials

The regulatory framework for LED packaging materials plays a crucial role in ensuring the safety, quality, and environmental sustainability of LED products. In the context of sodium silicate stabilization in LED encapsulation materials, several key regulations and standards come into play.

The International Electrotechnical Commission (IEC) has established standards specifically for LED products, including IEC 62031 for LED modules and IEC 62471 for photobiological safety. These standards set guidelines for the materials used in LED packaging, including encapsulants, and their performance requirements.

In the United States, the Environmental Protection Agency (EPA) regulates the use of certain chemicals in electronic products through the Toxic Substances Control Act (TSCA). This regulation may impact the use of sodium silicate and other materials in LED encapsulation, particularly if they contain potentially hazardous substances.

The European Union's Restriction of Hazardous Substances (RoHS) Directive is another significant regulation affecting LED packaging materials. It restricts the use of certain hazardous substances in electrical and electronic equipment, including lead, mercury, and cadmium. Manufacturers must ensure that their LED encapsulation materials comply with these restrictions.

The REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation in the EU also applies to LED packaging materials. It requires manufacturers to register chemicals used in their products and provide safety information, which may include data on sodium silicate stabilization in encapsulants.

In addition to these regulations, various industry standards and certifications influence the development and use of LED packaging materials. For instance, the Illuminating Engineering Society (IES) provides guidelines for LED performance and reliability, which indirectly affect the choice of encapsulation materials.

Energy efficiency standards, such as those set by the U.S. Department of Energy's Energy Star program, also impact LED packaging materials. While these standards primarily focus on energy consumption, they indirectly influence material choices as manufacturers strive to meet efficiency requirements.

As the LED industry continues to evolve, regulatory bodies are likely to update existing frameworks and introduce new regulations. This may include more specific guidelines for encapsulation materials and their stabilization techniques, potentially addressing sodium silicate usage directly.

Manufacturers and researchers working on sodium silicate stabilization in LED encapsulation materials must stay informed about these regulations and standards. Compliance with these frameworks is essential not only for legal reasons but also to ensure product quality, safety, and market acceptance.

The International Electrotechnical Commission (IEC) has established standards specifically for LED products, including IEC 62031 for LED modules and IEC 62471 for photobiological safety. These standards set guidelines for the materials used in LED packaging, including encapsulants, and their performance requirements.

In the United States, the Environmental Protection Agency (EPA) regulates the use of certain chemicals in electronic products through the Toxic Substances Control Act (TSCA). This regulation may impact the use of sodium silicate and other materials in LED encapsulation, particularly if they contain potentially hazardous substances.

The European Union's Restriction of Hazardous Substances (RoHS) Directive is another significant regulation affecting LED packaging materials. It restricts the use of certain hazardous substances in electrical and electronic equipment, including lead, mercury, and cadmium. Manufacturers must ensure that their LED encapsulation materials comply with these restrictions.

The REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation in the EU also applies to LED packaging materials. It requires manufacturers to register chemicals used in their products and provide safety information, which may include data on sodium silicate stabilization in encapsulants.

In addition to these regulations, various industry standards and certifications influence the development and use of LED packaging materials. For instance, the Illuminating Engineering Society (IES) provides guidelines for LED performance and reliability, which indirectly affect the choice of encapsulation materials.

Energy efficiency standards, such as those set by the U.S. Department of Energy's Energy Star program, also impact LED packaging materials. While these standards primarily focus on energy consumption, they indirectly influence material choices as manufacturers strive to meet efficiency requirements.

As the LED industry continues to evolve, regulatory bodies are likely to update existing frameworks and introduce new regulations. This may include more specific guidelines for encapsulation materials and their stabilization techniques, potentially addressing sodium silicate usage directly.

Manufacturers and researchers working on sodium silicate stabilization in LED encapsulation materials must stay informed about these regulations and standards. Compliance with these frameworks is essential not only for legal reasons but also to ensure product quality, safety, and market acceptance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!