Sulphanilic Acid-Based Azo Compounds for Textile Dyeing Applications

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Azo Dye Development History and Objectives

Azo dyes have a rich history dating back to the mid-19th century when the first synthetic dye, mauveine, was discovered by William Henry Perkin in 1856. This serendipitous discovery marked the beginning of the synthetic dye industry and paved the way for the development of azo dyes. The first azo dye, aniline yellow, was synthesized by Carl Julius Peter Griess in 1858, initiating a new era in textile coloration.

Throughout the late 19th and early 20th centuries, azo dyes rapidly gained prominence due to their vibrant colors, ease of synthesis, and superior fastness properties compared to natural dyes. The discovery of diazotization and coupling reactions by Peter Griess in 1858 provided a versatile method for synthesizing a wide range of azo compounds, leading to an explosion in the number of available dyes.

The development of sulphanilic acid-based azo compounds represented a significant milestone in the evolution of textile dyes. Sulphanilic acid, derived from sulfonation of aniline, offered improved water solubility and affinity for textile fibers, particularly cellulosic materials. This advancement addressed the limitations of earlier azo dyes, which often suffered from poor solubility and inadequate fixation to fabrics.

As the textile industry expanded in the 20th century, the demand for more diverse and high-performance dyes grew. This led to intensive research efforts focused on developing new azo dye structures with enhanced properties. The introduction of various substituents and functional groups to the basic azo framework allowed for fine-tuning of color shades, improved light fastness, and better wash resistance.

The objectives of modern research on sulphanilic acid-based azo compounds for textile dyeing applications are multifaceted. Primarily, there is a strong focus on developing environmentally friendly dyes that meet increasingly stringent regulations on chemical safety and environmental impact. This includes the design of azo dyes with reduced toxicity, improved biodegradability, and minimized ecological footprint.

Another key objective is to enhance the performance characteristics of azo dyes, such as color brilliance, fastness to light and washing, and compatibility with various textile substrates. Researchers are exploring novel molecular structures and application techniques to achieve these goals. Additionally, there is a growing interest in developing azo dyes with multifunctional properties, such as antimicrobial or flame-retardant characteristics, to add value to textile products.

The ongoing research also aims to optimize the synthesis and application processes of sulphanilic acid-based azo dyes. This includes improving reaction yields, reducing energy consumption, and developing more efficient dyeing methods. The ultimate goal is to create sustainable, cost-effective, and high-performance dye systems that can meet the evolving needs of the textile industry while addressing environmental concerns.

Throughout the late 19th and early 20th centuries, azo dyes rapidly gained prominence due to their vibrant colors, ease of synthesis, and superior fastness properties compared to natural dyes. The discovery of diazotization and coupling reactions by Peter Griess in 1858 provided a versatile method for synthesizing a wide range of azo compounds, leading to an explosion in the number of available dyes.

The development of sulphanilic acid-based azo compounds represented a significant milestone in the evolution of textile dyes. Sulphanilic acid, derived from sulfonation of aniline, offered improved water solubility and affinity for textile fibers, particularly cellulosic materials. This advancement addressed the limitations of earlier azo dyes, which often suffered from poor solubility and inadequate fixation to fabrics.

As the textile industry expanded in the 20th century, the demand for more diverse and high-performance dyes grew. This led to intensive research efforts focused on developing new azo dye structures with enhanced properties. The introduction of various substituents and functional groups to the basic azo framework allowed for fine-tuning of color shades, improved light fastness, and better wash resistance.

The objectives of modern research on sulphanilic acid-based azo compounds for textile dyeing applications are multifaceted. Primarily, there is a strong focus on developing environmentally friendly dyes that meet increasingly stringent regulations on chemical safety and environmental impact. This includes the design of azo dyes with reduced toxicity, improved biodegradability, and minimized ecological footprint.

Another key objective is to enhance the performance characteristics of azo dyes, such as color brilliance, fastness to light and washing, and compatibility with various textile substrates. Researchers are exploring novel molecular structures and application techniques to achieve these goals. Additionally, there is a growing interest in developing azo dyes with multifunctional properties, such as antimicrobial or flame-retardant characteristics, to add value to textile products.

The ongoing research also aims to optimize the synthesis and application processes of sulphanilic acid-based azo dyes. This includes improving reaction yields, reducing energy consumption, and developing more efficient dyeing methods. The ultimate goal is to create sustainable, cost-effective, and high-performance dye systems that can meet the evolving needs of the textile industry while addressing environmental concerns.

Textile Industry Demand for Sulphanilic Acid-Based Azo Dyes

The textile industry's demand for sulphanilic acid-based azo dyes has been steadily increasing due to their versatility, cost-effectiveness, and superior colorfastness properties. These dyes are particularly valued for their ability to produce vibrant and long-lasting colors across a wide spectrum, making them indispensable in various textile applications.

In recent years, the global textile dye market has experienced significant growth, with azo dyes accounting for a substantial portion of this expansion. The demand is primarily driven by the fashion industry's constant need for new and innovative color options, as well as the growing textile production in developing countries. Sulphanilic acid-based azo dyes have gained prominence due to their excellent dyeing performance on both natural and synthetic fibers, including cotton, wool, silk, and polyester.

The automotive textile sector has emerged as a key driver for the demand of these dyes, particularly in the production of car interiors and seat covers. The ability of sulphanilic acid-based azo dyes to withstand harsh conditions, such as prolonged exposure to sunlight and frequent cleaning, makes them ideal for this application. Additionally, the growing emphasis on sustainable and eco-friendly textile production has led to increased research and development efforts focused on improving the environmental profile of these dyes.

The sportswear and athleisure markets have also contributed significantly to the rising demand for sulphanilic acid-based azo dyes. These segments require dyes that can maintain their color intensity and brightness even after repeated washing and exposure to sweat and sunlight. The superior performance of these dyes in such demanding conditions has made them a preferred choice for manufacturers of high-performance sportswear and activewear.

In the home textiles sector, there is a growing trend towards customization and personalization, which has further boosted the demand for a diverse range of colors and shades. Sulphanilic acid-based azo dyes offer manufacturers the flexibility to create unique color combinations and effects, catering to the evolving consumer preferences in home decor and furnishings.

The technical textiles industry, encompassing products such as protective clothing, medical textiles, and industrial fabrics, has also shown increased interest in these dyes. The ability of sulphanilic acid-based azo dyes to maintain their properties under extreme conditions and their compatibility with various functional finishes make them suitable for these specialized applications.

As the textile industry continues to evolve, the demand for sulphanilic acid-based azo dyes is expected to grow further. Manufacturers are investing in research to develop new derivatives and formulations that can offer enhanced performance, improved sustainability, and compliance with stringent environmental regulations. This ongoing innovation is likely to expand the application scope of these dyes and reinforce their position as a crucial component in the textile dyeing industry.

In recent years, the global textile dye market has experienced significant growth, with azo dyes accounting for a substantial portion of this expansion. The demand is primarily driven by the fashion industry's constant need for new and innovative color options, as well as the growing textile production in developing countries. Sulphanilic acid-based azo dyes have gained prominence due to their excellent dyeing performance on both natural and synthetic fibers, including cotton, wool, silk, and polyester.

The automotive textile sector has emerged as a key driver for the demand of these dyes, particularly in the production of car interiors and seat covers. The ability of sulphanilic acid-based azo dyes to withstand harsh conditions, such as prolonged exposure to sunlight and frequent cleaning, makes them ideal for this application. Additionally, the growing emphasis on sustainable and eco-friendly textile production has led to increased research and development efforts focused on improving the environmental profile of these dyes.

The sportswear and athleisure markets have also contributed significantly to the rising demand for sulphanilic acid-based azo dyes. These segments require dyes that can maintain their color intensity and brightness even after repeated washing and exposure to sweat and sunlight. The superior performance of these dyes in such demanding conditions has made them a preferred choice for manufacturers of high-performance sportswear and activewear.

In the home textiles sector, there is a growing trend towards customization and personalization, which has further boosted the demand for a diverse range of colors and shades. Sulphanilic acid-based azo dyes offer manufacturers the flexibility to create unique color combinations and effects, catering to the evolving consumer preferences in home decor and furnishings.

The technical textiles industry, encompassing products such as protective clothing, medical textiles, and industrial fabrics, has also shown increased interest in these dyes. The ability of sulphanilic acid-based azo dyes to maintain their properties under extreme conditions and their compatibility with various functional finishes make them suitable for these specialized applications.

As the textile industry continues to evolve, the demand for sulphanilic acid-based azo dyes is expected to grow further. Manufacturers are investing in research to develop new derivatives and formulations that can offer enhanced performance, improved sustainability, and compliance with stringent environmental regulations. This ongoing innovation is likely to expand the application scope of these dyes and reinforce their position as a crucial component in the textile dyeing industry.

Current Challenges in Sulphanilic Acid-Based Azo Dye Synthesis

The synthesis of sulphanilic acid-based azo dyes for textile applications faces several significant challenges that hinder their widespread adoption and optimal performance. One of the primary issues is the environmental impact associated with the production process. Traditional synthesis methods often involve the use of hazardous chemicals and generate substantial amounts of waste, raising concerns about sustainability and regulatory compliance.

Another major challenge lies in achieving consistent color quality and fastness properties. The molecular structure of azo dyes can be sensitive to various factors during synthesis, leading to batch-to-batch variations in shade and intensity. This inconsistency poses difficulties for textile manufacturers who require precise color matching and reproducibility in their products.

The scalability of production processes presents a further obstacle. While laboratory-scale synthesis may yield satisfactory results, translating these methods to industrial-scale production often encounters efficiency and cost-effectiveness issues. The need for specialized equipment and controlled reaction conditions can significantly increase manufacturing costs.

Toxicity concerns also persist in the development of sulphanilic acid-based azo dyes. Some azo compounds have been associated with potential carcinogenic effects, prompting stringent regulations in many countries. Researchers face the challenge of developing safer alternatives that maintain the desired dyeing properties while minimizing health risks.

Water solubility and fixation to textile fibers remain critical areas for improvement. Many azo dyes exhibit limited solubility in water, which can lead to uneven dyeing and reduced color fastness. Enhancing the dye-fiber interaction without compromising other performance attributes is a complex task that requires innovative molecular design approaches.

The development of azo dyes with improved light fastness is another ongoing challenge. Exposure to sunlight and artificial light sources can cause color fading, limiting the longevity of dyed textiles. Researchers are exploring various stabilization techniques and molecular modifications to enhance the photostability of these compounds.

Lastly, the synthesis of sulphanilic acid-based azo dyes with expanded color gamut and improved brilliance remains a significant challenge. While these dyes offer a wide range of colors, there is a constant demand for novel shades and enhanced visual properties to meet evolving market trends and consumer preferences.

Another major challenge lies in achieving consistent color quality and fastness properties. The molecular structure of azo dyes can be sensitive to various factors during synthesis, leading to batch-to-batch variations in shade and intensity. This inconsistency poses difficulties for textile manufacturers who require precise color matching and reproducibility in their products.

The scalability of production processes presents a further obstacle. While laboratory-scale synthesis may yield satisfactory results, translating these methods to industrial-scale production often encounters efficiency and cost-effectiveness issues. The need for specialized equipment and controlled reaction conditions can significantly increase manufacturing costs.

Toxicity concerns also persist in the development of sulphanilic acid-based azo dyes. Some azo compounds have been associated with potential carcinogenic effects, prompting stringent regulations in many countries. Researchers face the challenge of developing safer alternatives that maintain the desired dyeing properties while minimizing health risks.

Water solubility and fixation to textile fibers remain critical areas for improvement. Many azo dyes exhibit limited solubility in water, which can lead to uneven dyeing and reduced color fastness. Enhancing the dye-fiber interaction without compromising other performance attributes is a complex task that requires innovative molecular design approaches.

The development of azo dyes with improved light fastness is another ongoing challenge. Exposure to sunlight and artificial light sources can cause color fading, limiting the longevity of dyed textiles. Researchers are exploring various stabilization techniques and molecular modifications to enhance the photostability of these compounds.

Lastly, the synthesis of sulphanilic acid-based azo dyes with expanded color gamut and improved brilliance remains a significant challenge. While these dyes offer a wide range of colors, there is a constant demand for novel shades and enhanced visual properties to meet evolving market trends and consumer preferences.

Existing Sulphanilic Acid-Based Azo Dye Formulations

01 Synthesis of sulphanilic acid-based azo compounds

Various methods for synthesizing sulphanilic acid-based azo compounds are described. These processes typically involve diazotization of sulphanilic acid followed by coupling with suitable aromatic compounds. The resulting azo compounds have applications in dyes, pigments, and other industrial uses.- Synthesis of sulphanilic acid-based azo compounds: Various methods for synthesizing sulphanilic acid-based azo compounds are described. These processes typically involve diazotization of sulphanilic acid followed by coupling with suitable aromatic compounds. The resulting azo compounds have applications in dyes, pigments, and other industrial uses.

- Applications in textile dyeing: Sulphanilic acid-based azo compounds are widely used in textile dyeing processes. These compounds provide vibrant and stable colors for various fabrics, including cotton, wool, and synthetic fibers. The dyes offer good fastness properties and can be applied using different dyeing techniques.

- Use in paper and leather coloration: Azo compounds derived from sulphanilic acid find applications in coloring paper and leather products. These dyes offer a range of colors and can be formulated to provide good lightfastness and resistance to various environmental factors. The compounds are suitable for both surface dyeing and bulk coloration processes.

- Modifications for improved properties: Research has been conducted on modifying sulphanilic acid-based azo compounds to enhance their properties. These modifications include the introduction of additional functional groups, metal complexation, and structural alterations to improve solubility, fastness, and color intensity. Such improvements expand the range of applications for these compounds.

- Environmental and safety considerations: Recent developments in sulphanilic acid-based azo compounds focus on addressing environmental and safety concerns. This includes the development of eco-friendly synthesis methods, reduction of harmful byproducts, and the creation of non-toxic alternatives. Efforts are also made to ensure compliance with regulations regarding the use of azo dyes in various industries.

02 Applications in textile dyeing

Sulphanilic acid-based azo compounds are widely used in textile dyeing processes. These compounds provide vibrant and stable colors for various fabrics, including cotton, wool, and synthetic fibers. The dyes offer good fastness properties and can be applied using different dyeing techniques.Expand Specific Solutions03 Use in paper and leather coloration

Azo compounds derived from sulphanilic acid find applications in coloring paper and leather products. These dyes offer good penetration and uniform coloration, enhancing the aesthetic appeal of the final products. They are also known for their resistance to fading and environmental factors.Expand Specific Solutions04 Modifications for improved properties

Research has focused on modifying sulphanilic acid-based azo compounds to enhance their properties. These modifications include the introduction of additional functional groups, altering the coupling components, or incorporating metal complexes. Such changes can improve color intensity, fastness, and applicability in various industries.Expand Specific Solutions05 Environmental and safety considerations

Recent developments in sulphanilic acid-based azo compounds have addressed environmental and safety concerns. This includes the creation of eco-friendly synthesis methods, reduction of harmful byproducts, and the development of non-toxic alternatives. These advancements aim to make the production and use of these compounds more sustainable and safe for both workers and consumers.Expand Specific Solutions

Key Players in Textile Dye Manufacturing

The research on sulphanilic acid-based azo compounds for textile dyeing applications is in a mature stage, with a well-established market and significant industry players. The global textile dyes market, valued at approximately $8 billion in 2020, is expected to grow steadily. Major companies like BASF, Huntsman, and Archroma dominate the field, leveraging their extensive R&D capabilities and global presence. These industry leaders, along with specialized firms such as Colourtex Industries and DyStar, continue to innovate in eco-friendly and high-performance dyes. The technology's maturity is evident in the diverse range of products and applications offered by companies across different regions, including Zhejiang Wanfeng Chemical and Zhejiang Longsheng Group in China.

BASF Corp.

Technical Solution: BASF has developed innovative sulphanilic acid-based azo compounds for textile dyeing applications. Their research focuses on improving color fastness and sustainability. They have introduced a range of eco-friendly dyes under the Helizarin® brand, which offer excellent wash and light fastness properties[1]. BASF's approach involves optimizing the molecular structure of azo compounds to enhance their affinity for various textile fibers, resulting in more efficient dyeing processes and reduced water consumption[2]. The company has also invested in developing azo dyes with improved solubility and stability, allowing for better penetration into fibers and more uniform color distribution[3].

Strengths: Wide range of eco-friendly dyes, excellent color fastness, reduced water consumption. Weaknesses: Potentially higher production costs, may require specialized application processes.

Huntsman Advanced Materials (Switzerland) GmbH

Technical Solution: Huntsman has made significant advancements in sulphanilic acid-based azo compounds for textile dyeing. Their research focuses on developing high-performance dyes that offer superior color brilliance and durability. The company has introduced the NOVACRON® series, which includes azo dyes specifically designed for cellulosic fibers[4]. These dyes provide excellent wet fastness properties and are suitable for various application methods, including exhaust dyeing and continuous dyeing processes[5]. Huntsman has also developed innovative dyeing technologies that reduce water and energy consumption, aligning with sustainable textile production practices[6].

Strengths: High-performance dyes with superior color brilliance, versatile application methods, focus on sustainability. Weaknesses: May be more expensive than traditional dyes, potentially limited to specific fiber types.

Innovative Approaches in Azo Dye Molecular Design

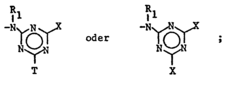

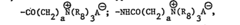

Cationic thiazolazo and benzothiazolazo dyestuffs

PatentInactiveEP0757083A3

Innovation

- Development of cationic azo dyes without sulfonic acid groups, specifically designed for high substantivity on paper and wood pulp, using a formula that includes various alkyl, aryl, and amine residues, allowing for the creation of blue or violet shades with excellent fastness properties and colorless wastewater.

Basic and/or cationic azo compounds free from sulfonic-acid groups

PatentInactiveEP0051559A1

Innovation

- Development of azo compounds without sulfonic acid groups, specifically dis-, tris-, or tetrakisazo compounds with basic and/or cationic groups, which are converted into water-soluble salts or quaternary ammonium salts, allowing for effective dyeing of cellulosic materials, paper, and low-affinity leathers using acid addition salts or quaternary ammonium forms.

Environmental Regulations for Textile Dye Production

Environmental regulations for textile dye production have become increasingly stringent in recent years, reflecting growing concerns about the industry's environmental impact. These regulations aim to mitigate the adverse effects of dye manufacturing and application processes on ecosystems and human health.

The European Union has been at the forefront of implementing comprehensive environmental regulations for the textile industry. The REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation, introduced in 2007, requires manufacturers and importers to assess and manage the risks associated with chemicals they produce or use. This regulation has had a significant impact on the textile dye industry, necessitating the development of more environmentally friendly dye formulations.

In the United States, the Environmental Protection Agency (EPA) enforces regulations under the Clean Water Act and the Toxic Substances Control Act. These regulations set limits on the discharge of pollutants from textile dyeing facilities and require the use of best available technologies to reduce environmental impact.

Many developing countries, which are major textile producers, have also begun to implement stricter environmental regulations. For instance, China's Water Pollution Prevention and Control Action Plan, introduced in 2015, has led to the closure of numerous non-compliant dyeing facilities and pushed the industry towards cleaner production methods.

The global trend towards sustainable fashion has further accelerated the adoption of eco-friendly dyeing processes. Regulations now often require the use of low-impact dyes, water-efficient dyeing technologies, and improved wastewater treatment systems. This has spurred innovation in the development of sulphanilic acid-based azo compounds that meet both performance and environmental criteria.

Compliance with these regulations has become a key factor in the competitiveness of textile dye manufacturers. Companies investing in research and development of environmentally friendly dyes, including those based on sulphanilic acid, are better positioned to meet the evolving regulatory landscape and consumer demands for sustainable products.

As regulations continue to evolve, the textile dyeing industry faces ongoing challenges in balancing environmental compliance with cost-effectiveness and product performance. This dynamic regulatory environment is driving continuous innovation in dye chemistry and application technologies, with a focus on reducing water consumption, minimizing chemical waste, and developing biodegradable dye formulations.

The European Union has been at the forefront of implementing comprehensive environmental regulations for the textile industry. The REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation, introduced in 2007, requires manufacturers and importers to assess and manage the risks associated with chemicals they produce or use. This regulation has had a significant impact on the textile dye industry, necessitating the development of more environmentally friendly dye formulations.

In the United States, the Environmental Protection Agency (EPA) enforces regulations under the Clean Water Act and the Toxic Substances Control Act. These regulations set limits on the discharge of pollutants from textile dyeing facilities and require the use of best available technologies to reduce environmental impact.

Many developing countries, which are major textile producers, have also begun to implement stricter environmental regulations. For instance, China's Water Pollution Prevention and Control Action Plan, introduced in 2015, has led to the closure of numerous non-compliant dyeing facilities and pushed the industry towards cleaner production methods.

The global trend towards sustainable fashion has further accelerated the adoption of eco-friendly dyeing processes. Regulations now often require the use of low-impact dyes, water-efficient dyeing technologies, and improved wastewater treatment systems. This has spurred innovation in the development of sulphanilic acid-based azo compounds that meet both performance and environmental criteria.

Compliance with these regulations has become a key factor in the competitiveness of textile dye manufacturers. Companies investing in research and development of environmentally friendly dyes, including those based on sulphanilic acid, are better positioned to meet the evolving regulatory landscape and consumer demands for sustainable products.

As regulations continue to evolve, the textile dyeing industry faces ongoing challenges in balancing environmental compliance with cost-effectiveness and product performance. This dynamic regulatory environment is driving continuous innovation in dye chemistry and application technologies, with a focus on reducing water consumption, minimizing chemical waste, and developing biodegradable dye formulations.

Color Fastness and Durability Considerations

Color fastness and durability are critical factors in the development and application of sulphanilic acid-based azo compounds for textile dyeing. These properties determine the longevity and quality of the dyed textiles, directly impacting consumer satisfaction and product value. The color fastness of azo dyes is influenced by various factors, including the chemical structure of the dye, the dyeing process, and the nature of the textile substrate.

One of the primary considerations in color fastness is the resistance to fading caused by exposure to light, washing, and environmental factors. Sulphanilic acid-based azo compounds generally exhibit good light fastness due to their stable molecular structure. However, the specific performance can vary depending on the substituents and the overall molecular design. Researchers are continuously working on optimizing the chemical structure to enhance light fastness without compromising other desirable properties.

Wash fastness is another crucial aspect, particularly for textiles that undergo frequent laundering. The ability of the dye to resist removal during washing processes is essential for maintaining the appearance and quality of the textile over time. Sulphanilic acid-based azo dyes typically show good wash fastness, but improvements are still being sought through the development of new fixation methods and the incorporation of reactive groups that form covalent bonds with the fiber.

Durability considerations extend beyond color fastness to include the overall stability of the dyed textile under various conditions. This encompasses resistance to abrasion, perspiration, and other environmental stresses. The interaction between the dye molecules and the textile fibers plays a significant role in determining the durability of the coloration. Research efforts are focused on enhancing these interactions through the development of new dyeing techniques and the modification of dye structures to improve affinity for specific fiber types.

Environmental factors also play a crucial role in the durability of dyed textiles. Exposure to sunlight, air pollution, and varying humidity levels can all impact the longevity of the coloration. Sulphanilic acid-based azo compounds are being studied for their resistance to these environmental factors, with particular attention given to the development of dyes that maintain their color integrity in challenging outdoor conditions.

The textile industry's increasing focus on sustainability has led to research into more environmentally friendly dyeing processes that maintain or improve color fastness and durability. This includes the exploration of low-temperature dyeing methods, reduced water usage, and the development of dyes with improved exhaustion rates to minimize effluent issues while ensuring long-lasting coloration.

One of the primary considerations in color fastness is the resistance to fading caused by exposure to light, washing, and environmental factors. Sulphanilic acid-based azo compounds generally exhibit good light fastness due to their stable molecular structure. However, the specific performance can vary depending on the substituents and the overall molecular design. Researchers are continuously working on optimizing the chemical structure to enhance light fastness without compromising other desirable properties.

Wash fastness is another crucial aspect, particularly for textiles that undergo frequent laundering. The ability of the dye to resist removal during washing processes is essential for maintaining the appearance and quality of the textile over time. Sulphanilic acid-based azo dyes typically show good wash fastness, but improvements are still being sought through the development of new fixation methods and the incorporation of reactive groups that form covalent bonds with the fiber.

Durability considerations extend beyond color fastness to include the overall stability of the dyed textile under various conditions. This encompasses resistance to abrasion, perspiration, and other environmental stresses. The interaction between the dye molecules and the textile fibers plays a significant role in determining the durability of the coloration. Research efforts are focused on enhancing these interactions through the development of new dyeing techniques and the modification of dye structures to improve affinity for specific fiber types.

Environmental factors also play a crucial role in the durability of dyed textiles. Exposure to sunlight, air pollution, and varying humidity levels can all impact the longevity of the coloration. Sulphanilic acid-based azo compounds are being studied for their resistance to these environmental factors, with particular attention given to the development of dyes that maintain their color integrity in challenging outdoor conditions.

The textile industry's increasing focus on sustainability has led to research into more environmentally friendly dyeing processes that maintain or improve color fastness and durability. This includes the exploration of low-temperature dyeing methods, reduced water usage, and the development of dyes with improved exhaustion rates to minimize effluent issues while ensuring long-lasting coloration.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!