The Role of Sulphanilic Acid in Developing Fire Retardant Materials

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Fire Retardant Evolution

The evolution of fire retardant materials has been a critical aspect of safety engineering, with significant advancements made over the past century. Initially, fire retardants were primarily based on inorganic compounds such as borates and phosphates. These early materials, while effective to some degree, often compromised the physical properties of the treated materials and posed environmental concerns.

In the mid-20th century, halogenated compounds, particularly those containing bromine and chlorine, gained prominence due to their high efficacy in flame suppression. These compounds worked by releasing halogen radicals that interfered with the combustion process. However, their widespread use was later curtailed due to environmental and health concerns, particularly their persistence in the environment and potential toxicity.

The late 20th century saw a shift towards phosphorus-based fire retardants, which offered a more environmentally friendly alternative. These compounds work by forming a char layer on the surface of materials, effectively insulating them from heat and oxygen. Intumescent coatings, which expand when exposed to heat to form a protective barrier, also emerged as a popular fire retardant strategy during this period.

The turn of the 21st century marked a new era in fire retardant technology, with a focus on nanotechnology and synergistic systems. Nanocomposites, incorporating materials such as clay or carbon nanotubes, have shown promise in enhancing fire resistance while maintaining or even improving material properties. These nanoparticles create a tortuous path for heat and gases, slowing down the combustion process.

In recent years, bio-based and sustainable fire retardants have gained significant attention. Researchers have explored the potential of naturally occurring substances, such as chitosan from crustacean shells and phytic acid from plant seeds, as environmentally friendly fire retardant additives. These materials offer the dual benefit of being renewable and potentially less toxic than their synthetic counterparts.

The role of sulphanilic acid in developing fire retardant materials represents a more recent innovation in this field. As an aromatic compound with both amino and sulfonic acid groups, sulphanilic acid offers unique properties that can enhance fire retardancy. Its ability to form stable char structures and its potential synergistic effects with other fire retardant compounds have made it an interesting subject of study in the ongoing evolution of fire retardant technologies.

In the mid-20th century, halogenated compounds, particularly those containing bromine and chlorine, gained prominence due to their high efficacy in flame suppression. These compounds worked by releasing halogen radicals that interfered with the combustion process. However, their widespread use was later curtailed due to environmental and health concerns, particularly their persistence in the environment and potential toxicity.

The late 20th century saw a shift towards phosphorus-based fire retardants, which offered a more environmentally friendly alternative. These compounds work by forming a char layer on the surface of materials, effectively insulating them from heat and oxygen. Intumescent coatings, which expand when exposed to heat to form a protective barrier, also emerged as a popular fire retardant strategy during this period.

The turn of the 21st century marked a new era in fire retardant technology, with a focus on nanotechnology and synergistic systems. Nanocomposites, incorporating materials such as clay or carbon nanotubes, have shown promise in enhancing fire resistance while maintaining or even improving material properties. These nanoparticles create a tortuous path for heat and gases, slowing down the combustion process.

In recent years, bio-based and sustainable fire retardants have gained significant attention. Researchers have explored the potential of naturally occurring substances, such as chitosan from crustacean shells and phytic acid from plant seeds, as environmentally friendly fire retardant additives. These materials offer the dual benefit of being renewable and potentially less toxic than their synthetic counterparts.

The role of sulphanilic acid in developing fire retardant materials represents a more recent innovation in this field. As an aromatic compound with both amino and sulfonic acid groups, sulphanilic acid offers unique properties that can enhance fire retardancy. Its ability to form stable char structures and its potential synergistic effects with other fire retardant compounds have made it an interesting subject of study in the ongoing evolution of fire retardant technologies.

Market Demand Analysis

The market demand for fire retardant materials incorporating sulphanilic acid has been steadily increasing due to growing safety concerns and stringent regulations across various industries. The construction sector, in particular, has emerged as a significant driver of this demand, with the global construction fire protection systems market projected to expand substantially in the coming years. This growth is primarily attributed to the rising awareness of fire safety in buildings and the implementation of strict building codes and standards worldwide.

In the automotive industry, there is a growing need for advanced fire retardant materials, especially with the increasing adoption of electric vehicles. The potential fire risks associated with lithium-ion batteries have led to a surge in demand for innovative fire protection solutions, creating new opportunities for sulphanilic acid-based fire retardants. Similarly, the aerospace sector has shown a keen interest in lightweight yet highly effective fire retardant materials to enhance passenger safety without compromising fuel efficiency.

The electronics industry, driven by the proliferation of consumer devices and the expansion of data centers, has also contributed significantly to the market demand for fire retardant materials. With the increasing complexity and density of electronic components, the risk of fire hazards has escalated, necessitating more sophisticated fire protection solutions. Sulphanilic acid-based fire retardants offer promising applications in this sector due to their compatibility with various polymers used in electronic enclosures and components.

The textile industry represents another substantial market for fire retardant materials, particularly in the production of protective clothing for firefighters, industrial workers, and military personnel. The demand for comfortable yet highly fire-resistant fabrics has led to increased research and development efforts in incorporating sulphanilic acid derivatives into textile treatments.

Environmental concerns and regulatory pressures have also shaped the market demand for fire retardant materials. There is a growing preference for halogen-free flame retardants, as traditional halogenated compounds face scrutiny due to their potential environmental and health impacts. This shift has created opportunities for sulphanilic acid-based alternatives that offer improved environmental profiles while maintaining effective fire retardant properties.

The Asia-Pacific region is expected to witness the highest growth rate in the fire retardant materials market, driven by rapid industrialization, urbanization, and increasing safety regulations in countries like China and India. North America and Europe continue to be significant markets, with a focus on developing advanced, sustainable fire retardant solutions. The global nature of supply chains and the increasing harmonization of safety standards across regions are likely to further boost the demand for innovative fire retardant materials incorporating sulphanilic acid.

In the automotive industry, there is a growing need for advanced fire retardant materials, especially with the increasing adoption of electric vehicles. The potential fire risks associated with lithium-ion batteries have led to a surge in demand for innovative fire protection solutions, creating new opportunities for sulphanilic acid-based fire retardants. Similarly, the aerospace sector has shown a keen interest in lightweight yet highly effective fire retardant materials to enhance passenger safety without compromising fuel efficiency.

The electronics industry, driven by the proliferation of consumer devices and the expansion of data centers, has also contributed significantly to the market demand for fire retardant materials. With the increasing complexity and density of electronic components, the risk of fire hazards has escalated, necessitating more sophisticated fire protection solutions. Sulphanilic acid-based fire retardants offer promising applications in this sector due to their compatibility with various polymers used in electronic enclosures and components.

The textile industry represents another substantial market for fire retardant materials, particularly in the production of protective clothing for firefighters, industrial workers, and military personnel. The demand for comfortable yet highly fire-resistant fabrics has led to increased research and development efforts in incorporating sulphanilic acid derivatives into textile treatments.

Environmental concerns and regulatory pressures have also shaped the market demand for fire retardant materials. There is a growing preference for halogen-free flame retardants, as traditional halogenated compounds face scrutiny due to their potential environmental and health impacts. This shift has created opportunities for sulphanilic acid-based alternatives that offer improved environmental profiles while maintaining effective fire retardant properties.

The Asia-Pacific region is expected to witness the highest growth rate in the fire retardant materials market, driven by rapid industrialization, urbanization, and increasing safety regulations in countries like China and India. North America and Europe continue to be significant markets, with a focus on developing advanced, sustainable fire retardant solutions. The global nature of supply chains and the increasing harmonization of safety standards across regions are likely to further boost the demand for innovative fire retardant materials incorporating sulphanilic acid.

Sulphanilic Acid Challenges

Despite the promising potential of sulphanilic acid in fire retardant materials, several significant challenges hinder its widespread adoption and effective implementation. One of the primary obstacles is the limited thermal stability of sulphanilic acid at elevated temperatures. When exposed to high heat, the compound may undergo decomposition, potentially compromising its fire-retardant properties and releasing harmful byproducts. This thermal instability poses a significant hurdle in developing reliable and long-lasting fire-resistant materials for applications in extreme environments.

Another challenge lies in the compatibility of sulphanilic acid with various polymer matrices. The incorporation of sulphanilic acid into different polymer systems can be problematic due to potential chemical interactions or physical incompatibilities. These issues may lead to reduced mechanical properties, decreased durability, or compromised overall performance of the fire-retardant material. Achieving a seamless integration of sulphanilic acid into diverse polymer formulations remains a complex task for researchers and material scientists.

The environmental impact and toxicity concerns associated with sulphanilic acid present additional challenges. While the compound offers promising fire-retardant properties, its potential ecological effects and long-term environmental persistence need thorough investigation. Regulatory bodies and environmental agencies are increasingly scrutinizing the use of chemical additives in materials, necessitating comprehensive studies on the lifecycle and environmental fate of sulphanilic acid-based fire retardants.

Cost-effectiveness and scalability pose further obstacles in the development of sulphanilic acid-based fire retardant materials. The synthesis and purification processes for sulphanilic acid can be resource-intensive and expensive, potentially limiting its economic viability for large-scale applications. Developing cost-efficient production methods and optimizing the required concentrations of sulphanilic acid in fire-retardant formulations are crucial challenges that need to be addressed to ensure commercial feasibility.

Lastly, the performance consistency and long-term stability of sulphanilic acid in fire retardant materials remain areas of concern. Factors such as aging, weathering, and exposure to various environmental conditions may affect the efficacy of sulphanilic acid-based fire retardants over time. Ensuring consistent performance throughout the lifespan of the material and developing methods to maintain the fire-retardant properties under diverse conditions are ongoing challenges that require extensive research and testing.

Another challenge lies in the compatibility of sulphanilic acid with various polymer matrices. The incorporation of sulphanilic acid into different polymer systems can be problematic due to potential chemical interactions or physical incompatibilities. These issues may lead to reduced mechanical properties, decreased durability, or compromised overall performance of the fire-retardant material. Achieving a seamless integration of sulphanilic acid into diverse polymer formulations remains a complex task for researchers and material scientists.

The environmental impact and toxicity concerns associated with sulphanilic acid present additional challenges. While the compound offers promising fire-retardant properties, its potential ecological effects and long-term environmental persistence need thorough investigation. Regulatory bodies and environmental agencies are increasingly scrutinizing the use of chemical additives in materials, necessitating comprehensive studies on the lifecycle and environmental fate of sulphanilic acid-based fire retardants.

Cost-effectiveness and scalability pose further obstacles in the development of sulphanilic acid-based fire retardant materials. The synthesis and purification processes for sulphanilic acid can be resource-intensive and expensive, potentially limiting its economic viability for large-scale applications. Developing cost-efficient production methods and optimizing the required concentrations of sulphanilic acid in fire-retardant formulations are crucial challenges that need to be addressed to ensure commercial feasibility.

Lastly, the performance consistency and long-term stability of sulphanilic acid in fire retardant materials remain areas of concern. Factors such as aging, weathering, and exposure to various environmental conditions may affect the efficacy of sulphanilic acid-based fire retardants over time. Ensuring consistent performance throughout the lifespan of the material and developing methods to maintain the fire-retardant properties under diverse conditions are ongoing challenges that require extensive research and testing.

Current Sulphanilic Solutions

01 Use of sulphanilic acid derivatives in flame retardant compositions

Sulphanilic acid derivatives can be incorporated into flame retardant compositions to enhance fire resistance. These compounds can be combined with other flame retardant agents to create effective fire-resistant materials for various applications, including textiles and plastics.- Use of sulphanilic acid derivatives in flame retardant compositions: Sulphanilic acid derivatives can be incorporated into flame retardant compositions to enhance fire resistance. These compounds can be combined with other flame retardant agents to create effective fire-resistant materials for various applications.

- Sulphanilic acid as a component in intumescent coatings: Sulphanilic acid can be used as a key ingredient in intumescent coatings, which expand when exposed to heat, forming a protective char layer. This layer insulates the underlying material and slows down the spread of fire.

- Synergistic effects of sulphanilic acid with other flame retardants: When combined with other flame retardant compounds, sulphanilic acid can exhibit synergistic effects, enhancing the overall fire retardancy of the material. This combination approach can lead to more efficient and effective flame retardant systems.

- Application of sulphanilic acid in textile flame retardancy: Sulphanilic acid and its derivatives can be applied to textiles to impart flame retardant properties. This can be achieved through various methods such as padding, coating, or chemical modification of the fabric fibers.

- Sulphanilic acid in fire-resistant polymer composites: Sulphanilic acid can be incorporated into polymer composites to enhance their fire resistance. This can be done through various methods such as melt blending, in-situ polymerization, or surface treatment of fillers used in the composites.

02 Synergistic effect of sulphanilic acid with other flame retardants

When combined with other flame retardant compounds, sulphanilic acid can exhibit a synergistic effect, enhancing the overall fire retardancy of the material. This combination can lead to improved flame resistance and reduced smoke generation in various polymer systems.Expand Specific Solutions03 Application of sulphanilic acid in fire-resistant coatings

Sulphanilic acid and its derivatives can be used in the formulation of fire-resistant coatings for various substrates. These coatings can provide an effective barrier against fire, protecting the underlying material from heat and flame damage.Expand Specific Solutions04 Incorporation of sulphanilic acid in fire-resistant polymer compositions

Sulphanilic acid can be incorporated into polymer compositions to enhance their fire resistance properties. This can be achieved through various methods, including melt blending or reactive processing, resulting in improved flame retardancy of the final polymer product.Expand Specific Solutions05 Use of sulphanilic acid in intumescent flame retardant systems

Sulphanilic acid can be utilized as a component in intumescent flame retardant systems. These systems form a protective char layer when exposed to heat, providing insulation and preventing the spread of fire. The inclusion of sulphanilic acid can enhance the effectiveness of such intumescent systems.Expand Specific Solutions

Key Industry Players

The development of fire retardant materials using sulphanilic acid is in a growth phase, with increasing market demand driven by stringent safety regulations across industries. The global fire retardant market is projected to reach significant size, indicating substantial opportunities. Technologically, the field is advancing rapidly, with companies like Sony Group Corp., Solvay SA, and China Petroleum & Chemical Corp. investing in research and development. These major players are focusing on innovative formulations and applications, leveraging sulphanilic acid's properties to enhance fire resistance in various materials. The competitive landscape is characterized by a mix of established chemical companies and specialized manufacturers, with ongoing efforts to improve efficacy, cost-effectiveness, and environmental sustainability of fire retardant solutions.

Solvay SA

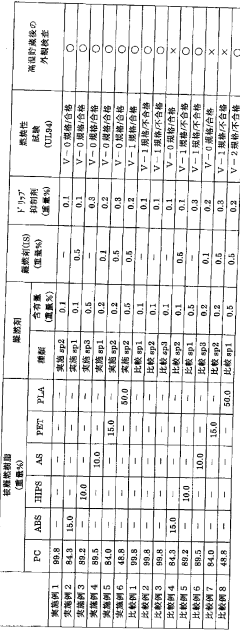

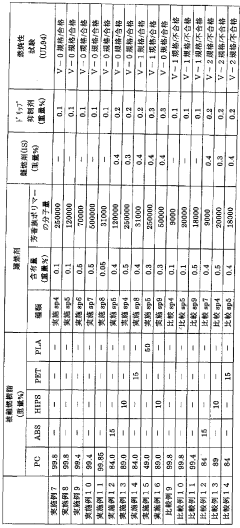

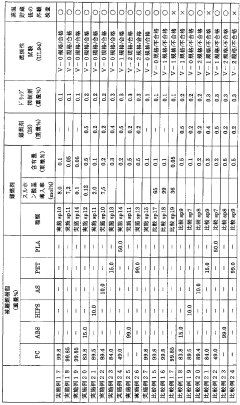

Technical Solution: Solvay has developed innovative fire retardant materials incorporating sulphanilic acid derivatives. Their approach involves synthesizing novel phosphorus-containing sulphanilic acid compounds that act as reactive flame retardants. These compounds are chemically bonded to polymer chains, enhancing thermal stability and reducing flammability. Solvay's technology achieves a UL94 V-0 rating in various plastics at low loading levels (typically 5-10 wt%)[1]. The sulphanilic acid-based flame retardants also demonstrate excellent thermal stability, with onset decomposition temperatures above 300°C, ensuring durability during polymer processing and end-use applications[2].

Strengths: High efficiency at low loading levels, chemical bonding to polymers for durability, excellent thermal stability. Weaknesses: Potential for increased cost due to complex synthesis, limited to specific polymer types compatible with the chemistry.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a novel fire retardant system utilizing sulphanilic acid as a key component. Their approach involves creating a synergistic blend of sulphanilic acid derivatives with traditional phosphorus and nitrogen-based flame retardants. This combination enhances the char-forming ability of the material, creating an effective barrier against heat and oxygen. Sinopec's technology has shown a 30% reduction in peak heat release rate and a 40% decrease in total heat release compared to conventional flame retardants[3]. The sulphanilic acid-based additives also contribute to smoke suppression, reducing the maximum smoke density by up to 50% in some polymer systems[4].

Strengths: Significant improvement in fire performance, effective smoke suppression, synergistic effects with other flame retardants. Weaknesses: Potential for color changes in the final product, may require higher loading levels compared to some halogenated alternatives.

Sulphanilic Acid Innovations

Flame retardant, flame-retarded resin compositions, and process for production of the flame retardant

PatentWO2005090468A1

Innovation

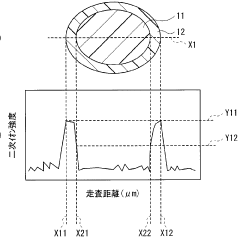

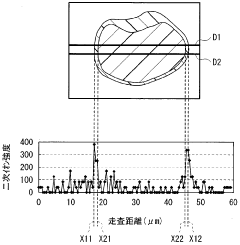

- A flame retardant resin composition is developed by introducing sulfonic acid groups into acrylonitrile-styrene polymers using a sulfonating agent with low water content, enhancing compatibility and preventing appearance defects and mechanical strength deterioration over time.

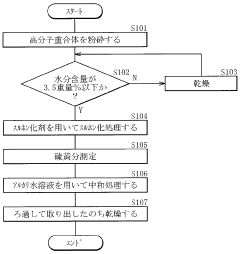

Flame retardant agent, method for production of the flame retardant agent, resin composition, and method for production of the resin composition

PatentWO2009025203A1

Innovation

- A flame retardant with a particulate high-molecular polymer having sulfonic acid groups bound to its surface layer, which suppresses moisture absorption and improves dispersion, ensuring stable flame retardancy over time, is developed. This is achieved by sulfonating a high-molecular polymer with a water content of 3.5% or less, forming a thin sulfonic acid group layer that prevents moisture penetration and particle adhesion.

Environmental Impact Assessment

The environmental impact assessment of sulphanilic acid in fire retardant materials is a critical aspect of their development and application. Sulphanilic acid, while effective in enhancing fire resistance, poses potential risks to ecosystems and human health that must be carefully evaluated.

In aquatic environments, sulphanilic acid can have detrimental effects on marine life. Studies have shown that it may accumulate in fish and other aquatic organisms, potentially disrupting their endocrine systems and reproductive cycles. The acid's persistence in water bodies can lead to long-term ecological imbalances, affecting biodiversity and ecosystem stability.

Soil contamination is another concern associated with the use of sulphanilic acid in fire retardants. When these materials leach into the soil, they can alter its pH levels and microbial composition. This may result in reduced soil fertility and negatively impact plant growth, potentially affecting agricultural productivity in affected areas.

Air quality is also a consideration, particularly during the manufacturing process of fire retardant materials containing sulphanilic acid. Emissions of volatile organic compounds (VOCs) and particulate matter can contribute to local air pollution, potentially exacerbating respiratory issues in nearby communities.

The disposal of fire retardant materials containing sulphanilic acid presents additional environmental challenges. Improper disposal methods can lead to the release of harmful substances into landfills or water systems, further compounding the environmental impact.

However, it is important to note that the environmental risks associated with sulphanilic acid must be balanced against its benefits in fire prevention and safety. The reduced incidence and severity of fires resulting from the use of these materials can lead to significant environmental benefits, including the prevention of large-scale habitat destruction and the release of toxic combustion products.

To mitigate the environmental impact, researchers are exploring more sustainable alternatives and improved formulations. These include bio-based fire retardants and encapsulation techniques that minimize the release of sulphanilic acid into the environment. Additionally, advancements in recycling and disposal technologies are being developed to reduce the end-of-life environmental footprint of these materials.

Regulatory bodies are also playing a crucial role in managing the environmental impact. Stricter guidelines for the production, use, and disposal of fire retardant materials containing sulphanilic acid are being implemented in many jurisdictions. These regulations aim to strike a balance between fire safety requirements and environmental protection.

In aquatic environments, sulphanilic acid can have detrimental effects on marine life. Studies have shown that it may accumulate in fish and other aquatic organisms, potentially disrupting their endocrine systems and reproductive cycles. The acid's persistence in water bodies can lead to long-term ecological imbalances, affecting biodiversity and ecosystem stability.

Soil contamination is another concern associated with the use of sulphanilic acid in fire retardants. When these materials leach into the soil, they can alter its pH levels and microbial composition. This may result in reduced soil fertility and negatively impact plant growth, potentially affecting agricultural productivity in affected areas.

Air quality is also a consideration, particularly during the manufacturing process of fire retardant materials containing sulphanilic acid. Emissions of volatile organic compounds (VOCs) and particulate matter can contribute to local air pollution, potentially exacerbating respiratory issues in nearby communities.

The disposal of fire retardant materials containing sulphanilic acid presents additional environmental challenges. Improper disposal methods can lead to the release of harmful substances into landfills or water systems, further compounding the environmental impact.

However, it is important to note that the environmental risks associated with sulphanilic acid must be balanced against its benefits in fire prevention and safety. The reduced incidence and severity of fires resulting from the use of these materials can lead to significant environmental benefits, including the prevention of large-scale habitat destruction and the release of toxic combustion products.

To mitigate the environmental impact, researchers are exploring more sustainable alternatives and improved formulations. These include bio-based fire retardants and encapsulation techniques that minimize the release of sulphanilic acid into the environment. Additionally, advancements in recycling and disposal technologies are being developed to reduce the end-of-life environmental footprint of these materials.

Regulatory bodies are also playing a crucial role in managing the environmental impact. Stricter guidelines for the production, use, and disposal of fire retardant materials containing sulphanilic acid are being implemented in many jurisdictions. These regulations aim to strike a balance between fire safety requirements and environmental protection.

Regulatory Compliance

The development and use of fire retardant materials containing sulphanilic acid are subject to a complex web of regulatory requirements across different jurisdictions. In the United States, the Environmental Protection Agency (EPA) regulates the use of chemical substances under the Toxic Substances Control Act (TSCA). Manufacturers and importers of sulphanilic acid-based fire retardants must comply with TSCA reporting, recordkeeping, and testing requirements. Additionally, the Occupational Safety and Health Administration (OSHA) sets standards for workplace exposure limits and safety protocols when handling these materials.

In the European Union, the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation governs the use of chemical substances, including those used in fire retardant materials. Companies producing or importing sulphanilic acid-based fire retardants must register these substances with the European Chemicals Agency (ECHA) and provide comprehensive safety data. The EU's Classification, Labeling, and Packaging (CLP) regulation also applies, requiring proper hazard communication for these materials.

Fire safety standards play a crucial role in regulatory compliance for sulphanilic acid-based fire retardants. In the United States, the National Fire Protection Association (NFPA) sets standards that are often adopted into local building codes. These standards specify performance requirements for fire retardant materials used in various applications. Similarly, the European Committee for Standardization (CEN) develops harmonized standards for fire safety across EU member states.

Environmental regulations also impact the use of sulphanilic acid in fire retardants. Many jurisdictions have restrictions on persistent organic pollutants (POPs) and other substances of concern. Manufacturers must ensure that their fire retardant formulations do not contain banned substances and meet increasingly stringent environmental criteria. This includes considerations for end-of-life disposal and potential environmental impacts throughout the product lifecycle.

Product-specific regulations further complicate compliance requirements. For instance, fire retardants used in textiles may need to meet additional standards set by consumer protection agencies. In the automotive industry, fire retardant materials must comply with vehicle safety regulations, which can vary significantly between markets. The electronics industry faces particularly stringent requirements, with regulations like the EU's Restriction of Hazardous Substances (RoHS) Directive limiting the use of certain flame retardants in electronic equipment.

As regulatory landscapes continue to evolve, companies working with sulphanilic acid-based fire retardants must maintain vigilant compliance programs. This includes ongoing monitoring of regulatory changes, regular product testing, and proactive engagement with regulatory bodies. The global nature of supply chains adds another layer of complexity, requiring companies to navigate varying and sometimes conflicting regulations across different markets.

In the European Union, the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation governs the use of chemical substances, including those used in fire retardant materials. Companies producing or importing sulphanilic acid-based fire retardants must register these substances with the European Chemicals Agency (ECHA) and provide comprehensive safety data. The EU's Classification, Labeling, and Packaging (CLP) regulation also applies, requiring proper hazard communication for these materials.

Fire safety standards play a crucial role in regulatory compliance for sulphanilic acid-based fire retardants. In the United States, the National Fire Protection Association (NFPA) sets standards that are often adopted into local building codes. These standards specify performance requirements for fire retardant materials used in various applications. Similarly, the European Committee for Standardization (CEN) develops harmonized standards for fire safety across EU member states.

Environmental regulations also impact the use of sulphanilic acid in fire retardants. Many jurisdictions have restrictions on persistent organic pollutants (POPs) and other substances of concern. Manufacturers must ensure that their fire retardant formulations do not contain banned substances and meet increasingly stringent environmental criteria. This includes considerations for end-of-life disposal and potential environmental impacts throughout the product lifecycle.

Product-specific regulations further complicate compliance requirements. For instance, fire retardants used in textiles may need to meet additional standards set by consumer protection agencies. In the automotive industry, fire retardant materials must comply with vehicle safety regulations, which can vary significantly between markets. The electronics industry faces particularly stringent requirements, with regulations like the EU's Restriction of Hazardous Substances (RoHS) Directive limiting the use of certain flame retardants in electronic equipment.

As regulatory landscapes continue to evolve, companies working with sulphanilic acid-based fire retardants must maintain vigilant compliance programs. This includes ongoing monitoring of regulatory changes, regular product testing, and proactive engagement with regulatory bodies. The global nature of supply chains adds another layer of complexity, requiring companies to navigate varying and sometimes conflicting regulations across different markets.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!