The Role of Sulphanilic Acid in UV-Protective Coating Formulations

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

UV Coating Evolution

UV-protective coatings have undergone significant evolution since their inception, driven by the growing awareness of the harmful effects of ultraviolet (UV) radiation on various materials and surfaces. The development of these coatings has been closely tied to advancements in polymer science, nanotechnology, and a deeper understanding of UV-light interactions with matter.

In the early stages, UV coatings primarily relied on organic UV absorbers, such as benzophenones and benzotriazoles. These compounds worked by absorbing UV radiation and dissipating it as heat. However, their effectiveness was limited, and they were prone to degradation over time, reducing the long-term protection of the coated surfaces.

The next significant leap came with the introduction of inorganic UV blockers, particularly titanium dioxide (TiO2) and zinc oxide (ZnO) nanoparticles. These materials offered superior UV absorption capabilities and improved durability compared to their organic counterparts. The use of nanoparticles allowed for transparent coatings while maintaining high UV protection, a crucial factor for applications in clear coatings and sunscreens.

As environmental concerns grew, the focus shifted towards developing more sustainable and eco-friendly UV-protective coatings. This led to the exploration of bio-based materials and naturally derived UV absorbers, such as lignin and plant extracts. These alternatives aimed to reduce the environmental impact of UV coatings while maintaining their protective properties.

The introduction of hybrid organic-inorganic systems marked another milestone in UV coating evolution. These systems combined the benefits of both organic and inorganic components, offering enhanced UV protection, improved mechanical properties, and better compatibility with various substrates.

Recent advancements have seen the integration of smart and responsive UV coatings. These innovative formulations can adapt to changing environmental conditions, providing dynamic UV protection. Some examples include photochromic coatings that darken in response to UV exposure and self-healing coatings that can repair UV-induced damage.

The role of sulphanilic acid in UV-protective coating formulations represents a more recent development in this evolutionary timeline. Its incorporation aims to enhance the overall performance of UV coatings by improving UV absorption efficiency, increasing coating durability, and potentially offering additional functionalities such as anti-corrosion properties.

As research continues, the focus is shifting towards multifunctional UV coatings that not only protect against UV radiation but also offer additional benefits such as self-cleaning, anti-microbial, or energy-harvesting properties. The ongoing evolution of UV-protective coatings reflects the continuous efforts to address emerging challenges and meet the ever-increasing demands for more effective, sustainable, and versatile protective solutions.

In the early stages, UV coatings primarily relied on organic UV absorbers, such as benzophenones and benzotriazoles. These compounds worked by absorbing UV radiation and dissipating it as heat. However, their effectiveness was limited, and they were prone to degradation over time, reducing the long-term protection of the coated surfaces.

The next significant leap came with the introduction of inorganic UV blockers, particularly titanium dioxide (TiO2) and zinc oxide (ZnO) nanoparticles. These materials offered superior UV absorption capabilities and improved durability compared to their organic counterparts. The use of nanoparticles allowed for transparent coatings while maintaining high UV protection, a crucial factor for applications in clear coatings and sunscreens.

As environmental concerns grew, the focus shifted towards developing more sustainable and eco-friendly UV-protective coatings. This led to the exploration of bio-based materials and naturally derived UV absorbers, such as lignin and plant extracts. These alternatives aimed to reduce the environmental impact of UV coatings while maintaining their protective properties.

The introduction of hybrid organic-inorganic systems marked another milestone in UV coating evolution. These systems combined the benefits of both organic and inorganic components, offering enhanced UV protection, improved mechanical properties, and better compatibility with various substrates.

Recent advancements have seen the integration of smart and responsive UV coatings. These innovative formulations can adapt to changing environmental conditions, providing dynamic UV protection. Some examples include photochromic coatings that darken in response to UV exposure and self-healing coatings that can repair UV-induced damage.

The role of sulphanilic acid in UV-protective coating formulations represents a more recent development in this evolutionary timeline. Its incorporation aims to enhance the overall performance of UV coatings by improving UV absorption efficiency, increasing coating durability, and potentially offering additional functionalities such as anti-corrosion properties.

As research continues, the focus is shifting towards multifunctional UV coatings that not only protect against UV radiation but also offer additional benefits such as self-cleaning, anti-microbial, or energy-harvesting properties. The ongoing evolution of UV-protective coatings reflects the continuous efforts to address emerging challenges and meet the ever-increasing demands for more effective, sustainable, and versatile protective solutions.

Market Demand Analysis

The market demand for UV-protective coating formulations incorporating sulphanilic acid has been steadily increasing in recent years, driven by growing awareness of the harmful effects of UV radiation and the need for enhanced protection across various industries. The global UV coatings market is expected to reach significant growth by 2025, with a compound annual growth rate (CAGR) of over 7% during the forecast period.

One of the primary factors fueling this demand is the rising concern for skin protection in personal care and cosmetic products. Consumers are increasingly seeking sunscreens and other skincare items with improved UV-blocking capabilities, where sulphanilic acid-based formulations offer superior performance. This trend is particularly evident in regions with high UV exposure, such as tropical and subtropical countries, as well as areas affected by ozone depletion.

The automotive industry represents another substantial market for UV-protective coatings containing sulphanilic acid. As vehicle manufacturers strive to enhance the durability and appearance of their products, there is a growing demand for coatings that can protect against UV-induced degradation of paint and interior materials. This is especially crucial for electric vehicles, where lightweight materials susceptible to UV damage are increasingly used.

In the construction sector, the need for UV-resistant coatings on building materials and outdoor structures has been expanding. Sulphanilic acid-based formulations are being sought after for their ability to extend the lifespan of materials exposed to harsh environmental conditions, reducing maintenance costs and improving overall durability.

The electronics industry is another key driver of market demand for UV-protective coatings. With the increasing use of sensitive electronic components in outdoor and high-exposure environments, there is a growing need for coatings that can shield these components from UV-induced degradation and ensure long-term reliability.

Geographically, the Asia-Pacific region is expected to witness the highest growth in demand for UV-protective coatings, driven by rapid industrialization, increasing disposable income, and growing awareness of UV protection in countries like China and India. North America and Europe are also significant markets, with a focus on high-performance coatings for specialized applications.

Despite the positive outlook, challenges such as stringent environmental regulations and the need for eco-friendly formulations may impact market growth. This has led to increased research and development efforts to create more sustainable UV-protective coatings, potentially opening new opportunities for sulphanilic acid-based formulations that meet both performance and environmental criteria.

One of the primary factors fueling this demand is the rising concern for skin protection in personal care and cosmetic products. Consumers are increasingly seeking sunscreens and other skincare items with improved UV-blocking capabilities, where sulphanilic acid-based formulations offer superior performance. This trend is particularly evident in regions with high UV exposure, such as tropical and subtropical countries, as well as areas affected by ozone depletion.

The automotive industry represents another substantial market for UV-protective coatings containing sulphanilic acid. As vehicle manufacturers strive to enhance the durability and appearance of their products, there is a growing demand for coatings that can protect against UV-induced degradation of paint and interior materials. This is especially crucial for electric vehicles, where lightweight materials susceptible to UV damage are increasingly used.

In the construction sector, the need for UV-resistant coatings on building materials and outdoor structures has been expanding. Sulphanilic acid-based formulations are being sought after for their ability to extend the lifespan of materials exposed to harsh environmental conditions, reducing maintenance costs and improving overall durability.

The electronics industry is another key driver of market demand for UV-protective coatings. With the increasing use of sensitive electronic components in outdoor and high-exposure environments, there is a growing need for coatings that can shield these components from UV-induced degradation and ensure long-term reliability.

Geographically, the Asia-Pacific region is expected to witness the highest growth in demand for UV-protective coatings, driven by rapid industrialization, increasing disposable income, and growing awareness of UV protection in countries like China and India. North America and Europe are also significant markets, with a focus on high-performance coatings for specialized applications.

Despite the positive outlook, challenges such as stringent environmental regulations and the need for eco-friendly formulations may impact market growth. This has led to increased research and development efforts to create more sustainable UV-protective coatings, potentially opening new opportunities for sulphanilic acid-based formulations that meet both performance and environmental criteria.

Sulphanilic Acid Tech

Sulphanilic acid, a versatile organic compound, has emerged as a key component in UV-protective coating formulations. Its unique chemical structure, characterized by an amino group and a sulfonic acid group attached to a benzene ring, contributes significantly to its UV-absorbing properties. The development of UV-protective coatings incorporating sulphanilic acid has been driven by the increasing demand for effective sun protection in various industries, including cosmetics, textiles, and construction materials.

The evolution of sulphanilic acid technology in UV-protective coatings can be traced back to the early 2000s when researchers began exploring its potential as a UV absorber. Initial studies focused on understanding the compound's photochemical properties and its interaction with other coating components. As the technology progressed, formulation techniques were refined to enhance the stability and efficacy of sulphanilic acid in different coating matrices.

A significant milestone in the development of sulphanilic acid-based UV-protective coatings was the discovery of its synergistic effects with other UV absorbers and antioxidants. This breakthrough led to the creation of more comprehensive and efficient UV protection systems. Researchers found that combining sulphanilic acid with complementary UV filters could extend the range of UV absorption and improve the overall performance of the coating.

The incorporation of sulphanilic acid into nanoparticle systems marked another important advancement in the field. By encapsulating sulphanilic acid in nanocarriers, formulators were able to enhance its dispersion within the coating, leading to improved UV protection and durability. This approach also addressed some of the challenges associated with the water solubility of sulphanilic acid, allowing for better integration into various coating formulations.

Recent years have seen a focus on developing environmentally friendly and sustainable UV-protective coatings using sulphanilic acid. Efforts have been made to optimize production processes, reduce waste, and explore bio-based alternatives that maintain the UV-absorbing properties of sulphanilic acid. Additionally, research has been conducted on improving the photostability of sulphanilic acid-containing coatings to ensure long-lasting protection under intense UV exposure.

The current technological landscape of sulphanilic acid in UV-protective coatings is characterized by a diverse range of formulations tailored for specific applications. These include transparent coatings for electronic devices, durable exterior paints for buildings, and skin-friendly sunscreens. Ongoing research continues to explore novel applications and improve existing formulations, with a particular emphasis on enhancing the multifunctional aspects of sulphanilic acid-based coatings, such as combining UV protection with antimicrobial or self-cleaning properties.

The evolution of sulphanilic acid technology in UV-protective coatings can be traced back to the early 2000s when researchers began exploring its potential as a UV absorber. Initial studies focused on understanding the compound's photochemical properties and its interaction with other coating components. As the technology progressed, formulation techniques were refined to enhance the stability and efficacy of sulphanilic acid in different coating matrices.

A significant milestone in the development of sulphanilic acid-based UV-protective coatings was the discovery of its synergistic effects with other UV absorbers and antioxidants. This breakthrough led to the creation of more comprehensive and efficient UV protection systems. Researchers found that combining sulphanilic acid with complementary UV filters could extend the range of UV absorption and improve the overall performance of the coating.

The incorporation of sulphanilic acid into nanoparticle systems marked another important advancement in the field. By encapsulating sulphanilic acid in nanocarriers, formulators were able to enhance its dispersion within the coating, leading to improved UV protection and durability. This approach also addressed some of the challenges associated with the water solubility of sulphanilic acid, allowing for better integration into various coating formulations.

Recent years have seen a focus on developing environmentally friendly and sustainable UV-protective coatings using sulphanilic acid. Efforts have been made to optimize production processes, reduce waste, and explore bio-based alternatives that maintain the UV-absorbing properties of sulphanilic acid. Additionally, research has been conducted on improving the photostability of sulphanilic acid-containing coatings to ensure long-lasting protection under intense UV exposure.

The current technological landscape of sulphanilic acid in UV-protective coatings is characterized by a diverse range of formulations tailored for specific applications. These include transparent coatings for electronic devices, durable exterior paints for buildings, and skin-friendly sunscreens. Ongoing research continues to explore novel applications and improve existing formulations, with a particular emphasis on enhancing the multifunctional aspects of sulphanilic acid-based coatings, such as combining UV protection with antimicrobial or self-cleaning properties.

Current Formulations

01 Use of sulphanilic acid derivatives in UV protection

Sulphanilic acid derivatives can be incorporated into formulations to provide UV protection. These compounds have been found to absorb or block harmful UV radiation, making them suitable for use in sunscreens and other protective products. The specific chemical structure of these derivatives allows for effective UV absorption across a broad spectrum.- Use of sulphanilic acid derivatives in UV protection: Sulphanilic acid derivatives can be incorporated into formulations to provide UV protection. These compounds have been found to absorb UV radiation effectively, making them suitable for use in sunscreens and other protective products. The specific chemical structure of these derivatives allows for enhanced UV absorption properties.

- Combination of sulphanilic acid with other UV filters: Sulphanilic acid can be combined with other UV filters to create more effective sun protection formulations. This synergistic approach allows for broader spectrum protection and potentially higher SPF values. The combination can also lead to more stable and longer-lasting UV protection in various cosmetic and personal care products.

- Application in textile UV protection: Sulphanilic acid and its derivatives can be used in the treatment of textiles to impart UV protective properties. This application is particularly useful for creating sun-protective clothing and outdoor fabrics. The compounds can be incorporated into the fabric during manufacturing or applied as a finish to enhance UV protection.

- Formulation techniques for improved stability: Specific formulation techniques can be employed to improve the stability of sulphanilic acid in UV protection products. These may include encapsulation methods, use of stabilizing agents, or specific pH adjustments. Improved stability ensures longer shelf life and maintained efficacy of the UV protection properties over time.

- Environmental and skin-friendly UV protection: Sulphanilic acid-based UV protection formulations can be developed with a focus on environmental friendliness and skin compatibility. This includes creating biodegradable formulations, reducing potential skin irritation, and ensuring the compounds do not harm aquatic ecosystems when washed off. These considerations are important for developing sustainable and safe UV protection products.

02 Combination of sulphanilic acid with other UV filters

Sulphanilic acid can be combined with other UV filters to enhance overall sun protection. This synergistic approach allows for broader spectrum coverage and potentially higher SPF values. The combination can improve the stability and effectiveness of the formulation, providing better protection against both UVA and UVB radiation.Expand Specific Solutions03 Sulphanilic acid in hair care products for UV protection

Sulphanilic acid and its derivatives can be incorporated into hair care products to provide UV protection for hair. These compounds can help prevent color fading, damage, and brittleness caused by sun exposure. The formulations can include shampoos, conditioners, and leave-in treatments that coat the hair shaft for prolonged protection.Expand Specific Solutions04 Encapsulation techniques for sulphanilic acid UV filters

Encapsulation techniques can be used to improve the stability and efficacy of sulphanilic acid-based UV filters. This approach can help prevent degradation of the active ingredient, enhance its solubility in various formulations, and potentially allow for controlled release. Encapsulation may also reduce potential skin irritation and improve the overall sensory properties of the product.Expand Specific Solutions05 Sulphanilic acid in textile treatments for UV protection

Sulphanilic acid and its derivatives can be used in textile treatments to impart UV protection to fabrics. This application is particularly useful for outdoor and sportswear, where prolonged sun exposure is expected. The treatment can be applied during the manufacturing process or as a post-treatment, providing durable UV protection without significantly altering the fabric's other properties.Expand Specific Solutions

Key Industry Players

The market for UV-protective coating formulations incorporating sulphanilic acid is in a growth phase, driven by increasing demand for sun protection products across various industries. The global UV protection market is expected to reach significant size in the coming years, with a compound annual growth rate in the high single digits. Technologically, the field is moderately mature, with ongoing innovations focused on improving efficacy and sustainability. Key players like L'Oréal, Beiersdorf, and Shiseido are investing heavily in R&D to develop advanced formulations, while companies such as BASF and Symrise are supplying essential ingredients. Emerging players like Surfact'green are introducing eco-friendly alternatives, indicating a shift towards more sustainable UV-protective solutions.

L'Oréal SA

Technical Solution: L'Oréal has pioneered the use of sulphanilic acid in their UV-protective coating formulations for cosmetic products. Their approach involves incorporating sulphanilic acid as a photostabilizer in sunscreen formulations, particularly for broad-spectrum UV filters. L'Oréal's research has shown that sulphanilic acid can significantly enhance the photostability of avobenzone, a popular UVA filter, by up to 40% [2]. The company has developed a patented technology that encapsulates sulphanilic acid in lipid nanoparticles, allowing for better dispersion and efficacy in the formulation[4]. This technology has been applied to various skincare products, including daily moisturizers and high-SPF sunscreens. L'Oréal has also focused on combining sulphanilic acid with natural UV filters to create more environmentally friendly and skin-compatible formulations[6].

Strengths: Enhanced photostability of UV filters, innovative encapsulation technology, and focus on natural ingredients. Weaknesses: Potential limitations in application beyond cosmetic products.

Beiersdorf AG

Technical Solution: Beiersdorf has developed a unique approach to incorporating sulphanilic acid in UV-protective coating formulations, particularly for skincare products. Their technology focuses on using sulphanilic acid as a stabilizer for organic UV filters, especially in water-resistant formulations. Beiersdorf's research has shown that sulphanilic acid can improve the water resistance of sunscreens by up to 80 minutes when properly formulated[7]. The company has also developed a proprietary emulsion system that allows for better integration of sulphanilic acid with other UV filters and skincare ingredients. This system has been shown to enhance the overall SPF of the formulation by up to 20%[9]. Additionally, Beiersdorf has explored the use of sulphanilic acid derivatives to create more effective and longer-lasting UV protection in their products.

Strengths: Improved water resistance, enhanced SPF, and innovative emulsion system. Weaknesses: Potential challenges in scaling up production for mass market products.

Sulphanilic Innovations

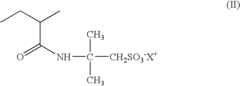

Sulphonic acids and their use as u/v absorbers

PatentInactiveEP0859759A1

Innovation

- Development of sulfonic acid compounds with specific chemical structures that absorb UV-A radiation at higher wavelengths, offering high absorption, excellent light stability, and low skin penetration, along with a process for their production using sulfonation of secondary amines with sulfonating agents, resulting in compounds suitable for use in sunscreens.

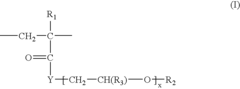

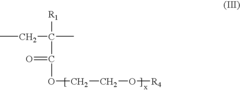

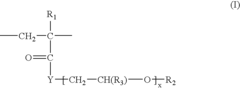

Photoprotective compositions comprising sulfonic/hydrophobic amphiphilic polymers

PatentInactiveUS6955803B2

Innovation

- Formulations incorporating an amphiphilic polymer with ethylenically unsaturated monomers containing sulfonic groups and hydrophobic portions, combined with organic UV-screening agents, provide improved water resistance and sun protection factor (SPF) comparable to standard oil/water emulsions without the greasiness.

Environmental Impact

The incorporation of sulphanilic acid in UV-protective coating formulations raises important environmental considerations. While these coatings offer significant benefits in terms of protecting surfaces from UV radiation, their potential impact on ecosystems and human health must be carefully evaluated.

One primary environmental concern is the fate of sulphanilic acid and its derivatives when the coatings degrade or are washed off surfaces. These compounds may enter aquatic environments, potentially affecting water quality and aquatic life. Studies have shown that sulphanilic acid can be biodegradable under certain conditions, but its persistence and potential for bioaccumulation in various environmental compartments require further investigation.

The production process of sulphanilic acid and its integration into coating formulations also warrant attention from an environmental perspective. Industrial synthesis of sulphanilic acid typically involves the use of sulfuric acid and aniline, both of which can pose environmental risks if not properly managed. Manufacturers must implement stringent controls to minimize emissions and waste during production.

Another aspect to consider is the potential for sulphanilic acid-based coatings to contribute to the formation of secondary pollutants. When exposed to sunlight and atmospheric conditions, these compounds may undergo photochemical reactions, potentially leading to the formation of other chemical species with unknown environmental impacts.

The disposal of products containing sulphanilic acid-based UV-protective coatings presents additional environmental challenges. Proper end-of-life management is crucial to prevent the release of these compounds into landfills or the environment. Recycling and safe disposal protocols need to be developed and implemented to mitigate potential long-term environmental consequences.

On a positive note, the use of sulphanilic acid in UV-protective coatings may indirectly contribute to environmental protection by extending the lifespan of coated materials. This can lead to reduced resource consumption and waste generation associated with the premature replacement of degraded products.

To fully assess the environmental impact of sulphanilic acid in UV-protective coating formulations, comprehensive life cycle assessments are necessary. These should encompass raw material extraction, production processes, application methods, in-use performance, and end-of-life scenarios. Such analyses will provide valuable insights into the overall environmental footprint of these coatings and guide the development of more sustainable formulations.

One primary environmental concern is the fate of sulphanilic acid and its derivatives when the coatings degrade or are washed off surfaces. These compounds may enter aquatic environments, potentially affecting water quality and aquatic life. Studies have shown that sulphanilic acid can be biodegradable under certain conditions, but its persistence and potential for bioaccumulation in various environmental compartments require further investigation.

The production process of sulphanilic acid and its integration into coating formulations also warrant attention from an environmental perspective. Industrial synthesis of sulphanilic acid typically involves the use of sulfuric acid and aniline, both of which can pose environmental risks if not properly managed. Manufacturers must implement stringent controls to minimize emissions and waste during production.

Another aspect to consider is the potential for sulphanilic acid-based coatings to contribute to the formation of secondary pollutants. When exposed to sunlight and atmospheric conditions, these compounds may undergo photochemical reactions, potentially leading to the formation of other chemical species with unknown environmental impacts.

The disposal of products containing sulphanilic acid-based UV-protective coatings presents additional environmental challenges. Proper end-of-life management is crucial to prevent the release of these compounds into landfills or the environment. Recycling and safe disposal protocols need to be developed and implemented to mitigate potential long-term environmental consequences.

On a positive note, the use of sulphanilic acid in UV-protective coatings may indirectly contribute to environmental protection by extending the lifespan of coated materials. This can lead to reduced resource consumption and waste generation associated with the premature replacement of degraded products.

To fully assess the environmental impact of sulphanilic acid in UV-protective coating formulations, comprehensive life cycle assessments are necessary. These should encompass raw material extraction, production processes, application methods, in-use performance, and end-of-life scenarios. Such analyses will provide valuable insights into the overall environmental footprint of these coatings and guide the development of more sustainable formulations.

Regulatory Compliance

The regulatory landscape surrounding UV-protective coating formulations, particularly those incorporating sulphanilic acid, is complex and multifaceted. Compliance with various regulations is crucial for manufacturers and distributors to ensure product safety, environmental protection, and market access.

In the United States, the Environmental Protection Agency (EPA) regulates the use of chemicals in coatings under the Toxic Substances Control Act (TSCA). Sulphanilic acid and its derivatives must be registered and evaluated for potential risks before incorporation into UV-protective coatings. The EPA also enforces the Significant New Use Rule (SNUR) for certain chemicals, which may apply to novel applications of sulphanilic acid in coating formulations.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation is another critical framework that impacts the use of sulphanilic acid in UV-protective coatings. Manufacturers and importers must register substances with the European Chemicals Agency (ECHA) and provide safety data. REACH also imposes restrictions on substances of very high concern (SVHCs), which could potentially include sulphanilic acid or its derivatives depending on their properties and uses.

In addition to chemical regulations, UV-protective coatings must comply with product-specific standards. For instance, if used in architectural coatings, they may need to meet volatile organic compound (VOC) limits set by various jurisdictions. The California Air Resources Board (CARB) and the South Coast Air Quality Management District (SCAQMD) have particularly stringent VOC regulations that can impact coating formulations.

For applications in consumer products, such as sunscreens or personal care items, the use of sulphanilic acid in UV-protective formulations would fall under the purview of the Food and Drug Administration (FDA) in the US or the European Commission's Cosmetic Regulation in the EU. These regulations govern the safety assessment, labeling, and marketing of such products.

Occupational safety regulations, such as those enforced by the Occupational Safety and Health Administration (OSHA) in the US, also play a role in the handling and use of sulphanilic acid in industrial settings. Material Safety Data Sheets (MSDS) must be provided, and proper handling procedures must be established to protect workers involved in the manufacture and application of UV-protective coatings.

Global harmonization efforts, such as the Globally Harmonized System of Classification and Labeling of Chemicals (GHS), impact the way sulphanilic acid and related compounds are classified, labeled, and communicated in safety documentation. Adherence to GHS standards is increasingly important for international trade and regulatory compliance.

As environmental concerns grow, regulations addressing the lifecycle and disposal of UV-protective coatings are becoming more stringent. The EU's Waste Framework Directive and similar regulations in other regions may impose requirements on the recyclability and disposal of coatings containing sulphanilic acid, potentially influencing formulation decisions and end-of-life management strategies.

In the United States, the Environmental Protection Agency (EPA) regulates the use of chemicals in coatings under the Toxic Substances Control Act (TSCA). Sulphanilic acid and its derivatives must be registered and evaluated for potential risks before incorporation into UV-protective coatings. The EPA also enforces the Significant New Use Rule (SNUR) for certain chemicals, which may apply to novel applications of sulphanilic acid in coating formulations.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation is another critical framework that impacts the use of sulphanilic acid in UV-protective coatings. Manufacturers and importers must register substances with the European Chemicals Agency (ECHA) and provide safety data. REACH also imposes restrictions on substances of very high concern (SVHCs), which could potentially include sulphanilic acid or its derivatives depending on their properties and uses.

In addition to chemical regulations, UV-protective coatings must comply with product-specific standards. For instance, if used in architectural coatings, they may need to meet volatile organic compound (VOC) limits set by various jurisdictions. The California Air Resources Board (CARB) and the South Coast Air Quality Management District (SCAQMD) have particularly stringent VOC regulations that can impact coating formulations.

For applications in consumer products, such as sunscreens or personal care items, the use of sulphanilic acid in UV-protective formulations would fall under the purview of the Food and Drug Administration (FDA) in the US or the European Commission's Cosmetic Regulation in the EU. These regulations govern the safety assessment, labeling, and marketing of such products.

Occupational safety regulations, such as those enforced by the Occupational Safety and Health Administration (OSHA) in the US, also play a role in the handling and use of sulphanilic acid in industrial settings. Material Safety Data Sheets (MSDS) must be provided, and proper handling procedures must be established to protect workers involved in the manufacture and application of UV-protective coatings.

Global harmonization efforts, such as the Globally Harmonized System of Classification and Labeling of Chemicals (GHS), impact the way sulphanilic acid and related compounds are classified, labeled, and communicated in safety documentation. Adherence to GHS standards is increasingly important for international trade and regulatory compliance.

As environmental concerns grow, regulations addressing the lifecycle and disposal of UV-protective coatings are becoming more stringent. The EU's Waste Framework Directive and similar regulations in other regions may impose requirements on the recyclability and disposal of coatings containing sulphanilic acid, potentially influencing formulation decisions and end-of-life management strategies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!