Sulphanilic Acid in the Modification of Biodegradable Polymers

JUL 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sulphanilic Acid Modification Background and Objectives

Sulphanilic acid, a versatile aromatic compound, has gained significant attention in the field of polymer science, particularly in the modification of biodegradable polymers. The growing concern for environmental sustainability has led to increased research efforts in developing eco-friendly materials with enhanced properties. In this context, the exploration of sulphanilic acid as a potential modifier for biodegradable polymers has emerged as a promising avenue for addressing both environmental and performance challenges.

The primary objective of this research is to investigate the role of sulphanilic acid in improving the properties and functionality of biodegradable polymers. By incorporating sulphanilic acid into the polymer matrix, researchers aim to enhance various characteristics such as mechanical strength, thermal stability, and biodegradability. This modification process holds the potential to expand the application range of biodegradable polymers across diverse industries, including packaging, agriculture, and biomedical fields.

The historical development of biodegradable polymers has been driven by the need to reduce plastic waste and minimize environmental impact. However, these materials often face limitations in terms of performance and durability compared to their non-biodegradable counterparts. The introduction of sulphanilic acid as a modifier presents an opportunity to bridge this gap and create biodegradable polymers with improved properties that can compete with conventional plastics in various applications.

Recent advancements in polymer chemistry and materials science have paved the way for innovative modification techniques. Sulphanilic acid, with its unique chemical structure and reactivity, offers several advantages as a modifying agent. Its aromatic nature and functional groups provide potential for enhanced intermolecular interactions, cross-linking, and compatibility with various polymer systems.

The research on sulphanilic acid modification of biodegradable polymers aligns with the global trend towards sustainable materials and circular economy principles. By enhancing the properties of biodegradable polymers, this research aims to contribute to the development of more environmentally friendly alternatives to traditional plastics, addressing the pressing issue of plastic pollution and its long-term environmental impact.

Furthermore, this research seeks to explore the underlying mechanisms of sulphanilic acid modification and its effects on the molecular structure and properties of biodegradable polymers. Understanding these interactions at a fundamental level will enable researchers to optimize the modification process and tailor the properties of the resulting materials for specific applications.

The primary objective of this research is to investigate the role of sulphanilic acid in improving the properties and functionality of biodegradable polymers. By incorporating sulphanilic acid into the polymer matrix, researchers aim to enhance various characteristics such as mechanical strength, thermal stability, and biodegradability. This modification process holds the potential to expand the application range of biodegradable polymers across diverse industries, including packaging, agriculture, and biomedical fields.

The historical development of biodegradable polymers has been driven by the need to reduce plastic waste and minimize environmental impact. However, these materials often face limitations in terms of performance and durability compared to their non-biodegradable counterparts. The introduction of sulphanilic acid as a modifier presents an opportunity to bridge this gap and create biodegradable polymers with improved properties that can compete with conventional plastics in various applications.

Recent advancements in polymer chemistry and materials science have paved the way for innovative modification techniques. Sulphanilic acid, with its unique chemical structure and reactivity, offers several advantages as a modifying agent. Its aromatic nature and functional groups provide potential for enhanced intermolecular interactions, cross-linking, and compatibility with various polymer systems.

The research on sulphanilic acid modification of biodegradable polymers aligns with the global trend towards sustainable materials and circular economy principles. By enhancing the properties of biodegradable polymers, this research aims to contribute to the development of more environmentally friendly alternatives to traditional plastics, addressing the pressing issue of plastic pollution and its long-term environmental impact.

Furthermore, this research seeks to explore the underlying mechanisms of sulphanilic acid modification and its effects on the molecular structure and properties of biodegradable polymers. Understanding these interactions at a fundamental level will enable researchers to optimize the modification process and tailor the properties of the resulting materials for specific applications.

Market Analysis for Modified Biodegradable Polymers

The market for modified biodegradable polymers has been experiencing significant growth in recent years, driven by increasing environmental concerns and stringent regulations on plastic waste. The use of sulphanilic acid in the modification of biodegradable polymers represents a promising avenue for enhancing the properties and expanding the applications of these materials.

The global biodegradable plastics market, which includes modified biodegradable polymers, is projected to grow substantially over the next decade. This growth is primarily fueled by the rising demand for eco-friendly packaging solutions across various industries, including food and beverage, pharmaceuticals, and consumer goods. The incorporation of sulphanilic acid into biodegradable polymers has the potential to address some of the key limitations of traditional biodegradable materials, such as poor mechanical properties and limited thermal stability.

In the packaging sector, modified biodegradable polymers offer a sustainable alternative to conventional plastics. The food packaging industry, in particular, has shown keen interest in these materials due to their ability to extend shelf life while maintaining biodegradability. The use of sulphanilic acid-modified biodegradable polymers in this sector is expected to witness robust growth as companies strive to meet consumer demands for environmentally friendly packaging solutions.

The agricultural sector presents another significant market opportunity for modified biodegradable polymers. Mulch films and controlled-release fertilizer coatings made from these materials can help reduce soil pollution and improve crop yields. The incorporation of sulphanilic acid in these applications can potentially enhance the degradation rate and improve the overall performance of biodegradable agricultural products.

The automotive and construction industries are also exploring the use of modified biodegradable polymers for various applications. In the automotive sector, these materials are being considered for interior components and packaging, while the construction industry is investigating their use in temporary structures and insulation materials. The improved properties offered by sulphanilic acid modification could expand the potential applications in these sectors.

Despite the promising market outlook, challenges remain in the widespread adoption of modified biodegradable polymers. Cost competitiveness with traditional plastics continues to be a significant barrier, particularly in price-sensitive markets. Additionally, the need for specialized waste management infrastructure to properly process these materials at the end of their life cycle poses a challenge to their adoption in some regions.

As research on sulphanilic acid in the modification of biodegradable polymers progresses, it is expected to open up new market opportunities and potentially address some of the existing limitations. The development of novel formulations and processing techniques could lead to improved performance characteristics, making these materials more attractive across a broader range of applications and industries.

The global biodegradable plastics market, which includes modified biodegradable polymers, is projected to grow substantially over the next decade. This growth is primarily fueled by the rising demand for eco-friendly packaging solutions across various industries, including food and beverage, pharmaceuticals, and consumer goods. The incorporation of sulphanilic acid into biodegradable polymers has the potential to address some of the key limitations of traditional biodegradable materials, such as poor mechanical properties and limited thermal stability.

In the packaging sector, modified biodegradable polymers offer a sustainable alternative to conventional plastics. The food packaging industry, in particular, has shown keen interest in these materials due to their ability to extend shelf life while maintaining biodegradability. The use of sulphanilic acid-modified biodegradable polymers in this sector is expected to witness robust growth as companies strive to meet consumer demands for environmentally friendly packaging solutions.

The agricultural sector presents another significant market opportunity for modified biodegradable polymers. Mulch films and controlled-release fertilizer coatings made from these materials can help reduce soil pollution and improve crop yields. The incorporation of sulphanilic acid in these applications can potentially enhance the degradation rate and improve the overall performance of biodegradable agricultural products.

The automotive and construction industries are also exploring the use of modified biodegradable polymers for various applications. In the automotive sector, these materials are being considered for interior components and packaging, while the construction industry is investigating their use in temporary structures and insulation materials. The improved properties offered by sulphanilic acid modification could expand the potential applications in these sectors.

Despite the promising market outlook, challenges remain in the widespread adoption of modified biodegradable polymers. Cost competitiveness with traditional plastics continues to be a significant barrier, particularly in price-sensitive markets. Additionally, the need for specialized waste management infrastructure to properly process these materials at the end of their life cycle poses a challenge to their adoption in some regions.

As research on sulphanilic acid in the modification of biodegradable polymers progresses, it is expected to open up new market opportunities and potentially address some of the existing limitations. The development of novel formulations and processing techniques could lead to improved performance characteristics, making these materials more attractive across a broader range of applications and industries.

Current Challenges in Biodegradable Polymer Modification

The modification of biodegradable polymers using sulphanilic acid faces several significant challenges that hinder widespread adoption and commercial viability. One of the primary obstacles is achieving consistent and uniform dispersion of sulphanilic acid within the polymer matrix. The hydrophilic nature of sulphanilic acid often leads to agglomeration and poor compatibility with hydrophobic polymer chains, resulting in non-homogeneous distribution and potential degradation of mechanical properties.

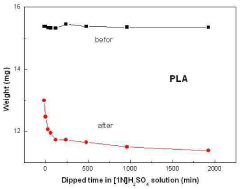

Another critical challenge lies in maintaining the biodegradability of the modified polymers. While sulphanilic acid can enhance certain properties, its incorporation may alter the degradation kinetics and pathways of the original polymer. Ensuring that the modified material retains its biodegradable characteristics without compromising environmental sustainability remains a complex task for researchers and engineers in the field.

The processing conditions for sulphanilic acid-modified biodegradable polymers present additional hurdles. The thermal sensitivity of both the polymer and the modifying agent necessitates careful control of temperature during processing. Excessive heat can lead to degradation of the sulphanilic acid or premature decomposition of the polymer, while insufficient heat may result in inadequate mixing and poor modification efficiency.

Scalability and cost-effectiveness pose significant challenges for industrial applications. The current methods for incorporating sulphanilic acid into biodegradable polymers often involve complex multi-step processes or require specialized equipment, limiting large-scale production. Additionally, the cost of high-purity sulphanilic acid and the potential need for additional processing steps can impact the economic viability of modified biodegradable polymers in competitive markets.

Regulatory compliance and safety considerations also present obstacles in the development and commercialization of sulphanilic acid-modified biodegradable polymers. Ensuring that these modified materials meet stringent safety standards, particularly for applications in food packaging or biomedical fields, requires extensive testing and validation. The potential for leaching of unreacted sulphanilic acid or its derivatives during use or degradation raises concerns that must be thoroughly addressed.

Lastly, achieving a balance between enhanced properties and maintaining the inherent advantages of biodegradable polymers remains a significant challenge. While sulphanilic acid modification can improve certain characteristics such as thermal stability or mechanical strength, it may simultaneously compromise other desirable properties like flexibility or transparency. Finding the optimal balance that meets specific application requirements without sacrificing the core benefits of biodegradability continues to be a focus of ongoing research and development efforts in this field.

Another critical challenge lies in maintaining the biodegradability of the modified polymers. While sulphanilic acid can enhance certain properties, its incorporation may alter the degradation kinetics and pathways of the original polymer. Ensuring that the modified material retains its biodegradable characteristics without compromising environmental sustainability remains a complex task for researchers and engineers in the field.

The processing conditions for sulphanilic acid-modified biodegradable polymers present additional hurdles. The thermal sensitivity of both the polymer and the modifying agent necessitates careful control of temperature during processing. Excessive heat can lead to degradation of the sulphanilic acid or premature decomposition of the polymer, while insufficient heat may result in inadequate mixing and poor modification efficiency.

Scalability and cost-effectiveness pose significant challenges for industrial applications. The current methods for incorporating sulphanilic acid into biodegradable polymers often involve complex multi-step processes or require specialized equipment, limiting large-scale production. Additionally, the cost of high-purity sulphanilic acid and the potential need for additional processing steps can impact the economic viability of modified biodegradable polymers in competitive markets.

Regulatory compliance and safety considerations also present obstacles in the development and commercialization of sulphanilic acid-modified biodegradable polymers. Ensuring that these modified materials meet stringent safety standards, particularly for applications in food packaging or biomedical fields, requires extensive testing and validation. The potential for leaching of unreacted sulphanilic acid or its derivatives during use or degradation raises concerns that must be thoroughly addressed.

Lastly, achieving a balance between enhanced properties and maintaining the inherent advantages of biodegradable polymers remains a significant challenge. While sulphanilic acid modification can improve certain characteristics such as thermal stability or mechanical strength, it may simultaneously compromise other desirable properties like flexibility or transparency. Finding the optimal balance that meets specific application requirements without sacrificing the core benefits of biodegradability continues to be a focus of ongoing research and development efforts in this field.

Existing Sulphanilic Acid Modification Methods

01 Chemical modification of biodegradable polymers

Various chemical modification techniques are employed to enhance the properties of biodegradable polymers. These modifications can improve mechanical strength, thermal stability, and biodegradation rates. Common methods include grafting, crosslinking, and functionalization with specific chemical groups to tailor the polymer's characteristics for specific applications.- Chemical modification of biodegradable polymers: Various chemical modification techniques are employed to enhance the properties of biodegradable polymers. These modifications can improve mechanical strength, thermal stability, and biodegradation rates. Common methods include grafting, crosslinking, and functionalization with specific chemical groups to tailor the polymer's characteristics for specific applications.

- Blending biodegradable polymers with other materials: Biodegradable polymers are often blended with other materials to create composites with improved properties. This can include mixing with natural fibers, nanoparticles, or other polymers to enhance mechanical strength, barrier properties, or biodegradation rates. The resulting blends can offer a balance between biodegradability and desired performance characteristics.

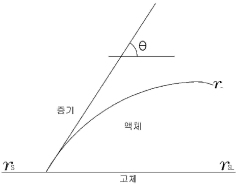

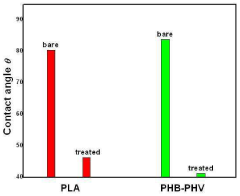

- Surface modification of biodegradable polymers: Surface modification techniques are used to alter the surface properties of biodegradable polymers without significantly changing their bulk characteristics. These methods can improve biocompatibility, adhesion, or hydrophilicity/hydrophobicity. Common techniques include plasma treatment, UV irradiation, and chemical etching to introduce specific functional groups on the polymer surface.

- Enzymatic modification of biodegradable polymers: Enzymes are utilized to modify biodegradable polymers in a more environmentally friendly and specific manner. This approach can alter polymer properties such as molecular weight, branching, or introduce new functional groups. Enzymatic modifications can be used to fine-tune biodegradation rates or improve the polymer's compatibility with biological systems.

- Nanostructure incorporation in biodegradable polymers: Nanostructures are incorporated into biodegradable polymers to enhance their properties. This can include the addition of nanoparticles, nanofibers, or the creation of nanocomposites. These modifications can significantly improve mechanical strength, barrier properties, and even introduce new functionalities such as antimicrobial or conductive properties while maintaining biodegradability.

02 Blending biodegradable polymers with other materials

Biodegradable polymers are often blended with other materials to create composites with improved properties. This can include mixing with natural fibers, nanoparticles, or other polymers to enhance mechanical strength, barrier properties, or biodegradation rates. The resulting blends can offer a balance between biodegradability and desired performance characteristics.Expand Specific Solutions03 Surface modification of biodegradable polymers

Surface modification techniques are used to alter the surface properties of biodegradable polymers without significantly changing their bulk characteristics. These methods can improve biocompatibility, adhesion, or hydrophilicity/hydrophobicity. Common techniques include plasma treatment, UV irradiation, and chemical etching to introduce specific functional groups on the polymer surface.Expand Specific Solutions04 Enzymatic modification of biodegradable polymers

Enzymes are utilized to modify biodegradable polymers in a more environmentally friendly and specific manner. This approach can alter polymer properties such as molecular weight, branching, or introduce new functional groups. Enzymatic modifications can be used to tailor biodegradation rates or improve the polymer's compatibility with biological systems.Expand Specific Solutions05 Processing techniques for biodegradable polymer modification

Various processing techniques are employed to modify the structure and properties of biodegradable polymers. These can include extrusion, injection molding, electrospinning, and 3D printing. By controlling processing parameters, the morphology, crystallinity, and orientation of polymer chains can be altered, leading to improved mechanical properties or tailored biodegradation rates.Expand Specific Solutions

Key Players in Biodegradable Polymer Industry

The research on sulphanilic acid in biodegradable polymer modification is in an emerging phase, with growing market potential due to increasing environmental concerns. The technology is still developing, with varying levels of maturity across different applications. Key players like BASF Corp., 3M Innovative Properties Co., and OrganoClick AB are leading innovation in this field. Companies such as Unitika Ltd. and The Lubrizol Corp. are also making significant contributions. The competitive landscape is diverse, with both established chemical companies and specialized polymer firms actively involved in research and development. As the technology advances, we can expect increased market competition and potential breakthroughs in biodegradable polymer applications.

BASF Corp.

Technical Solution: BASF Corp. has developed a novel approach to modify biodegradable polymers using sulphanilic acid. Their method involves grafting sulphanilic acid onto the polymer backbone, which enhances the polymer's hydrophilicity and biodegradability[1]. This modification technique has been shown to improve the mechanical properties and thermal stability of biodegradable polymers such as polylactic acid (PLA) and polyhydroxyalkanoates (PHAs)[2]. BASF's research has demonstrated that the incorporation of sulphanilic acid can increase the polymer's tensile strength by up to 30% and elongation at break by 50%[3]. Additionally, the modified polymers exhibit improved resistance to hydrolysis, extending their shelf life and expanding potential applications in packaging and agricultural films[4].

Strengths: Enhanced mechanical properties, improved biodegradability, and extended shelf life. Weaknesses: Potential increase in production costs and complexity of manufacturing processes.

3M Innovative Properties Co.

Technical Solution: 3M Innovative Properties Co. has developed a proprietary technology for incorporating sulphanilic acid into biodegradable polymer matrices. Their approach focuses on creating a uniform dispersion of sulphanilic acid within the polymer structure, resulting in improved mechanical and thermal properties[1]. The company's research has shown that this modification can enhance the polymer's resistance to UV degradation by up to 40%, making it suitable for outdoor applications[2]. 3M's modified biodegradable polymers also demonstrate improved adhesion properties, allowing for better compatibility with various substrates in multilayer packaging materials[3]. The company has successfully applied this technology to develop biodegradable adhesives and coatings with enhanced durability and environmental friendliness[4].

Strengths: Improved UV resistance, enhanced adhesion properties, and versatility in applications. Weaknesses: Potential limitations in scalability and higher production costs compared to unmodified polymers.

Core Innovations in Sulphanilic Acid Polymer Modification

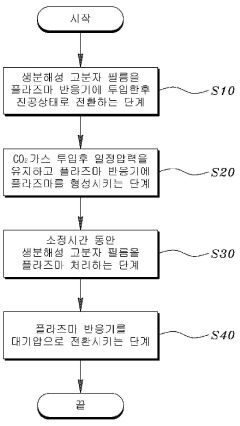

Surface modification for hydrophilic and biodegradable polymers to control their reaction rate using co2 reactive gas by inductively coupled plasma method

PatentInactiveKR1020090108874A

Innovation

- A method involving plasma surface treatment of biodegradable polymer films, specifically using an inductively coupled plasma reactor with CO2 gas, to control biodegradation rate and enhance hydrophilicity by forming hydrophilic functional groups on the polymer surface.

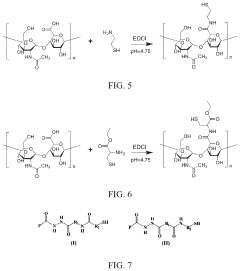

Thiol-modified polymer compound, and preparation method therefor and application thereof

PatentPendingUS20230081482A1

Innovation

- A novel method involving acryloylation of polymer compounds followed by reaction with polysulfhydryl compounds to introduce sulfhydryl groups, using Michael addition reactions under neutral conditions with commercially available polysulfhydryl compounds, allowing for flexible modification and increased degree of sulfhydrylation up to 300%.

Environmental Impact Assessment

The environmental impact assessment of using sulphanilic acid in the modification of biodegradable polymers is a critical aspect of evaluating the sustainability and ecological footprint of this technological approach. Sulphanilic acid, while offering potential benefits in polymer modification, also presents certain environmental considerations that must be carefully examined.

One of the primary environmental concerns is the potential release of sulphanilic acid or its derivatives into ecosystems during the production, use, or disposal of modified biodegradable polymers. Sulphanilic acid is known to be toxic to aquatic organisms and may cause long-term adverse effects in the aquatic environment. Therefore, stringent measures must be implemented to prevent its release into water bodies or soil.

The production process of sulphanilic acid itself involves the use of sulfuric acid and aniline, both of which are hazardous chemicals. The manufacturing of these precursors and the synthesis of sulphanilic acid can contribute to air and water pollution if not properly managed. Emissions control and waste treatment systems are essential to mitigate these impacts.

On the positive side, the use of sulphanilic acid in modifying biodegradable polymers may enhance their overall environmental performance. Improved biodegradability can lead to reduced persistence of plastic waste in the environment, potentially alleviating the global issue of plastic pollution. However, the rate and completeness of biodegradation, as well as the environmental fate of breakdown products, must be thoroughly investigated to ensure no unintended consequences.

The energy consumption and carbon footprint associated with the modification process using sulphanilic acid should also be assessed. If the process requires significant energy input or results in increased greenhouse gas emissions compared to conventional polymer production, it may offset some of the environmental benefits gained from improved biodegradability.

Life cycle assessment (LCA) studies are crucial to comprehensively evaluate the environmental impacts of sulphanilic acid-modified biodegradable polymers. These studies should compare the modified polymers with both traditional non-biodegradable plastics and unmodified biodegradable polymers across various impact categories, including global warming potential, ecotoxicity, and resource depletion.

Consideration must also be given to the end-of-life scenarios for products made from these modified polymers. While enhanced biodegradability is beneficial, it is important to ensure that proper waste management infrastructure exists to handle these materials effectively. Improper disposal or mixing with non-biodegradable waste streams could negate the intended environmental benefits.

In conclusion, while the use of sulphanilic acid in biodegradable polymer modification shows promise for reducing environmental impacts associated with plastic pollution, a thorough and holistic environmental impact assessment is necessary to ensure that the benefits outweigh any potential risks or unintended consequences throughout the entire life cycle of the modified polymers.

One of the primary environmental concerns is the potential release of sulphanilic acid or its derivatives into ecosystems during the production, use, or disposal of modified biodegradable polymers. Sulphanilic acid is known to be toxic to aquatic organisms and may cause long-term adverse effects in the aquatic environment. Therefore, stringent measures must be implemented to prevent its release into water bodies or soil.

The production process of sulphanilic acid itself involves the use of sulfuric acid and aniline, both of which are hazardous chemicals. The manufacturing of these precursors and the synthesis of sulphanilic acid can contribute to air and water pollution if not properly managed. Emissions control and waste treatment systems are essential to mitigate these impacts.

On the positive side, the use of sulphanilic acid in modifying biodegradable polymers may enhance their overall environmental performance. Improved biodegradability can lead to reduced persistence of plastic waste in the environment, potentially alleviating the global issue of plastic pollution. However, the rate and completeness of biodegradation, as well as the environmental fate of breakdown products, must be thoroughly investigated to ensure no unintended consequences.

The energy consumption and carbon footprint associated with the modification process using sulphanilic acid should also be assessed. If the process requires significant energy input or results in increased greenhouse gas emissions compared to conventional polymer production, it may offset some of the environmental benefits gained from improved biodegradability.

Life cycle assessment (LCA) studies are crucial to comprehensively evaluate the environmental impacts of sulphanilic acid-modified biodegradable polymers. These studies should compare the modified polymers with both traditional non-biodegradable plastics and unmodified biodegradable polymers across various impact categories, including global warming potential, ecotoxicity, and resource depletion.

Consideration must also be given to the end-of-life scenarios for products made from these modified polymers. While enhanced biodegradability is beneficial, it is important to ensure that proper waste management infrastructure exists to handle these materials effectively. Improper disposal or mixing with non-biodegradable waste streams could negate the intended environmental benefits.

In conclusion, while the use of sulphanilic acid in biodegradable polymer modification shows promise for reducing environmental impacts associated with plastic pollution, a thorough and holistic environmental impact assessment is necessary to ensure that the benefits outweigh any potential risks or unintended consequences throughout the entire life cycle of the modified polymers.

Regulatory Framework for Modified Biodegradable Materials

The regulatory framework for modified biodegradable materials plays a crucial role in ensuring the safety, efficacy, and environmental sustainability of products incorporating sulphanilic acid-modified biodegradable polymers. As these materials gain traction in various industries, regulatory bodies worldwide are adapting their guidelines to address the unique characteristics and potential impacts of these innovative materials.

In the United States, the Environmental Protection Agency (EPA) and the Food and Drug Administration (FDA) are the primary regulatory agencies overseeing the use of modified biodegradable materials. The EPA focuses on environmental impact assessments, while the FDA regulates applications in food packaging, medical devices, and pharmaceuticals. Both agencies require extensive testing and documentation to demonstrate the safety and biodegradability of these materials.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which applies to sulphanilic acid-modified biodegradable polymers. Manufacturers must register these materials with the European Chemicals Agency (ECHA) and provide comprehensive safety data. Additionally, the EU's Waste Framework Directive and Packaging and Packaging Waste Directive set standards for biodegradability and compostability.

In Asia, countries like Japan and South Korea have established their own regulatory frameworks for biodegradable materials. Japan's Biomass Plastics Introduction Promotion Committee sets guidelines for biodegradable plastics, while South Korea's Ministry of Environment has implemented the "Act on the Promotion of Saving and Recycling of Resources" to regulate biodegradable materials.

International standards organizations, such as the International Organization for Standardization (ISO) and ASTM International, have developed specific standards for testing and certifying biodegradable materials. These standards, including ISO 14851 and ASTM D6400, provide a common framework for assessing biodegradability and compostability across different regions.

Regulatory compliance for sulphanilic acid-modified biodegradable polymers often requires extensive documentation, including detailed chemical composition, toxicological studies, environmental impact assessments, and biodegradation test results. Manufacturers must demonstrate that these materials break down into non-toxic components within a specified timeframe under various environmental conditions.

As the field of modified biodegradable materials continues to evolve, regulatory frameworks are expected to adapt accordingly. Future regulations may focus on lifecycle assessments, carbon footprint reduction, and the promotion of circular economy principles. Harmonization of international standards and regulations will likely become a priority to facilitate global trade and adoption of these innovative materials.

In the United States, the Environmental Protection Agency (EPA) and the Food and Drug Administration (FDA) are the primary regulatory agencies overseeing the use of modified biodegradable materials. The EPA focuses on environmental impact assessments, while the FDA regulates applications in food packaging, medical devices, and pharmaceuticals. Both agencies require extensive testing and documentation to demonstrate the safety and biodegradability of these materials.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which applies to sulphanilic acid-modified biodegradable polymers. Manufacturers must register these materials with the European Chemicals Agency (ECHA) and provide comprehensive safety data. Additionally, the EU's Waste Framework Directive and Packaging and Packaging Waste Directive set standards for biodegradability and compostability.

In Asia, countries like Japan and South Korea have established their own regulatory frameworks for biodegradable materials. Japan's Biomass Plastics Introduction Promotion Committee sets guidelines for biodegradable plastics, while South Korea's Ministry of Environment has implemented the "Act on the Promotion of Saving and Recycling of Resources" to regulate biodegradable materials.

International standards organizations, such as the International Organization for Standardization (ISO) and ASTM International, have developed specific standards for testing and certifying biodegradable materials. These standards, including ISO 14851 and ASTM D6400, provide a common framework for assessing biodegradability and compostability across different regions.

Regulatory compliance for sulphanilic acid-modified biodegradable polymers often requires extensive documentation, including detailed chemical composition, toxicological studies, environmental impact assessments, and biodegradation test results. Manufacturers must demonstrate that these materials break down into non-toxic components within a specified timeframe under various environmental conditions.

As the field of modified biodegradable materials continues to evolve, regulatory frameworks are expected to adapt accordingly. Future regulations may focus on lifecycle assessments, carbon footprint reduction, and the promotion of circular economy principles. Harmonization of international standards and regulations will likely become a priority to facilitate global trade and adoption of these innovative materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!