Role of Sulphanilic Acid in Electrospinning of Nanofibrous Scaffolds

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sulphanilic Acid in Electrospinning: Background and Objectives

Electrospinning has emerged as a versatile technique for fabricating nanofibrous scaffolds with diverse applications in tissue engineering, drug delivery, and wound healing. The process involves the application of an electric field to draw charged polymer solutions into ultrafine fibers. In recent years, researchers have explored various additives to enhance the properties and functionality of electrospun nanofibers. Among these additives, sulphanilic acid has gained significant attention due to its unique chemical structure and potential to modify the characteristics of electrospun scaffolds.

Sulphanilic acid, also known as 4-aminobenzenesulfonic acid, is an aromatic compound containing both amino and sulfonic acid groups. Its molecular structure allows for interactions with polymer chains and the formation of hydrogen bonds, which can significantly influence the electrospinning process and the resulting nanofiber properties. The incorporation of sulphanilic acid into electrospinning solutions has been investigated to address several challenges in nanofiber fabrication and to impart novel functionalities to the scaffolds.

The primary objectives of exploring the role of sulphanilic acid in electrospinning are multifaceted. Firstly, researchers aim to improve the electrospinnability of polymer solutions, particularly for those that are challenging to process due to high viscosity or low conductivity. Sulphanilic acid can potentially act as a charge carrier, enhancing the conductivity of the spinning solution and facilitating the formation of a stable Taylor cone during the electrospinning process.

Secondly, the addition of sulphanilic acid is expected to modify the surface properties of the resulting nanofibers. The presence of sulfonic acid groups on the fiber surface can increase hydrophilicity, which is crucial for applications requiring improved wettability and cell adhesion. This modification can lead to enhanced biocompatibility and cell proliferation when used in tissue engineering scaffolds.

Another important objective is to investigate the potential of sulphanilic acid to act as a crosslinking agent or to promote the formation of intermolecular interactions within the nanofiber structure. Such interactions could lead to improved mechanical properties and stability of the scaffolds, addressing the common issue of poor mechanical strength in electrospun materials.

Furthermore, the incorporation of sulphanilic acid may enable the development of stimuli-responsive nanofibers. The pH-sensitive nature of the sulfonic acid groups could be exploited to create scaffolds that respond to changes in environmental pH, opening up possibilities for controlled drug release and smart wound dressings.

As research in this area progresses, it is anticipated that a deeper understanding of the role of sulphanilic acid in electrospinning will lead to the development of advanced nanofibrous scaffolds with tailored properties for specific biomedical and industrial applications. The exploration of this additive represents a step towards expanding the capabilities of electrospinning technology and pushing the boundaries of nanofiber engineering.

Sulphanilic acid, also known as 4-aminobenzenesulfonic acid, is an aromatic compound containing both amino and sulfonic acid groups. Its molecular structure allows for interactions with polymer chains and the formation of hydrogen bonds, which can significantly influence the electrospinning process and the resulting nanofiber properties. The incorporation of sulphanilic acid into electrospinning solutions has been investigated to address several challenges in nanofiber fabrication and to impart novel functionalities to the scaffolds.

The primary objectives of exploring the role of sulphanilic acid in electrospinning are multifaceted. Firstly, researchers aim to improve the electrospinnability of polymer solutions, particularly for those that are challenging to process due to high viscosity or low conductivity. Sulphanilic acid can potentially act as a charge carrier, enhancing the conductivity of the spinning solution and facilitating the formation of a stable Taylor cone during the electrospinning process.

Secondly, the addition of sulphanilic acid is expected to modify the surface properties of the resulting nanofibers. The presence of sulfonic acid groups on the fiber surface can increase hydrophilicity, which is crucial for applications requiring improved wettability and cell adhesion. This modification can lead to enhanced biocompatibility and cell proliferation when used in tissue engineering scaffolds.

Another important objective is to investigate the potential of sulphanilic acid to act as a crosslinking agent or to promote the formation of intermolecular interactions within the nanofiber structure. Such interactions could lead to improved mechanical properties and stability of the scaffolds, addressing the common issue of poor mechanical strength in electrospun materials.

Furthermore, the incorporation of sulphanilic acid may enable the development of stimuli-responsive nanofibers. The pH-sensitive nature of the sulfonic acid groups could be exploited to create scaffolds that respond to changes in environmental pH, opening up possibilities for controlled drug release and smart wound dressings.

As research in this area progresses, it is anticipated that a deeper understanding of the role of sulphanilic acid in electrospinning will lead to the development of advanced nanofibrous scaffolds with tailored properties for specific biomedical and industrial applications. The exploration of this additive represents a step towards expanding the capabilities of electrospinning technology and pushing the boundaries of nanofiber engineering.

Market Analysis for Nanofibrous Scaffolds

The market for nanofibrous scaffolds has been experiencing significant growth in recent years, driven by advancements in tissue engineering, regenerative medicine, and drug delivery systems. The global nanofibrous scaffolds market is expected to continue its upward trajectory, with a compound annual growth rate (CAGR) projected to remain strong over the next five years.

One of the key factors contributing to this market expansion is the increasing prevalence of chronic diseases and the growing aging population worldwide. These demographic shifts have led to a rising demand for advanced wound healing solutions and tissue regeneration therapies, where nanofibrous scaffolds play a crucial role. Additionally, the expanding applications of nanofibrous scaffolds in various biomedical fields, including orthopedics, cardiology, and neurology, are further fueling market growth.

The healthcare sector remains the primary end-user of nanofibrous scaffolds, with hospitals, research institutions, and pharmaceutical companies being the major consumers. However, there is a growing interest from other industries, such as cosmetics and environmental remediation, which are exploring the potential applications of these advanced materials.

Geographically, North America and Europe currently dominate the nanofibrous scaffolds market, owing to their well-established healthcare infrastructure, substantial research and development investments, and favorable regulatory environments. However, the Asia-Pacific region is emerging as a lucrative market, with countries like China, Japan, and South Korea making significant strides in nanofibrous scaffold research and development.

The market landscape is characterized by intense competition among key players, including both established multinational corporations and innovative start-ups. These companies are focusing on developing novel nanofibrous scaffold materials and manufacturing techniques to gain a competitive edge. The role of sulphanilic acid in electrospinning of nanofibrous scaffolds is of particular interest, as it offers potential improvements in scaffold properties and functionality.

Despite the positive market outlook, several challenges persist. These include high production costs, scalability issues, and regulatory hurdles associated with the approval of nanofibrous scaffold-based medical products. Additionally, concerns regarding the long-term safety and biocompatibility of certain nanomaterials used in scaffold fabrication need to be addressed to ensure widespread market acceptance.

In conclusion, the nanofibrous scaffolds market presents significant opportunities for growth and innovation. As research continues to uncover new applications and improve existing technologies, such as the use of sulphanilic acid in electrospinning, the market is poised for further expansion. Companies that can effectively navigate the regulatory landscape, reduce production costs, and develop cutting-edge solutions are likely to emerge as leaders in this dynamic and promising market.

One of the key factors contributing to this market expansion is the increasing prevalence of chronic diseases and the growing aging population worldwide. These demographic shifts have led to a rising demand for advanced wound healing solutions and tissue regeneration therapies, where nanofibrous scaffolds play a crucial role. Additionally, the expanding applications of nanofibrous scaffolds in various biomedical fields, including orthopedics, cardiology, and neurology, are further fueling market growth.

The healthcare sector remains the primary end-user of nanofibrous scaffolds, with hospitals, research institutions, and pharmaceutical companies being the major consumers. However, there is a growing interest from other industries, such as cosmetics and environmental remediation, which are exploring the potential applications of these advanced materials.

Geographically, North America and Europe currently dominate the nanofibrous scaffolds market, owing to their well-established healthcare infrastructure, substantial research and development investments, and favorable regulatory environments. However, the Asia-Pacific region is emerging as a lucrative market, with countries like China, Japan, and South Korea making significant strides in nanofibrous scaffold research and development.

The market landscape is characterized by intense competition among key players, including both established multinational corporations and innovative start-ups. These companies are focusing on developing novel nanofibrous scaffold materials and manufacturing techniques to gain a competitive edge. The role of sulphanilic acid in electrospinning of nanofibrous scaffolds is of particular interest, as it offers potential improvements in scaffold properties and functionality.

Despite the positive market outlook, several challenges persist. These include high production costs, scalability issues, and regulatory hurdles associated with the approval of nanofibrous scaffold-based medical products. Additionally, concerns regarding the long-term safety and biocompatibility of certain nanomaterials used in scaffold fabrication need to be addressed to ensure widespread market acceptance.

In conclusion, the nanofibrous scaffolds market presents significant opportunities for growth and innovation. As research continues to uncover new applications and improve existing technologies, such as the use of sulphanilic acid in electrospinning, the market is poised for further expansion. Companies that can effectively navigate the regulatory landscape, reduce production costs, and develop cutting-edge solutions are likely to emerge as leaders in this dynamic and promising market.

Current Challenges in Electrospinning with Sulphanilic Acid

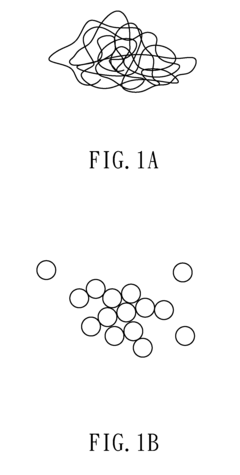

Electrospinning with sulphanilic acid presents several significant challenges that researchers and industry professionals are currently grappling with. One of the primary issues is the stability of the electrospinning solution. Sulphanilic acid, being a zwitterionic compound, can significantly alter the solution properties, leading to inconsistencies in the electrospinning process. The pH-dependent behavior of sulphanilic acid can cause variations in solution conductivity and viscosity, which directly impact the fiber formation and morphology.

Another major challenge is the control of fiber diameter and uniformity. The incorporation of sulphanilic acid into the polymer solution can affect the surface tension and viscoelastic properties, making it difficult to achieve consistent fiber diameters across the scaffold. This variability can lead to non-uniform mechanical properties and potentially compromise the scaffold's intended functionality in biomedical applications.

The interaction between sulphanilic acid and the polymer matrix poses additional complications. Depending on the polymer used, sulphanilic acid may interfere with the chain entanglement and molecular orientation during fiber formation. This can result in reduced mechanical strength of the resulting nanofibers or even lead to the formation of beads or other structural defects in the scaffold.

Scalability and reproducibility remain significant hurdles in the electrospinning process involving sulphanilic acid. The sensitive nature of the electrospinning parameters, combined with the unique properties of sulphanilic acid, makes it challenging to maintain consistent results when scaling up production. This issue is particularly critical for industrial applications where large-scale, uniform production of nanofibrous scaffolds is required.

Environmental and safety concerns also present challenges in working with sulphanilic acid in electrospinning. The compound's potential for irritation and its environmental impact necessitate careful handling and disposal procedures. This adds complexity to the manufacturing process and may limit the widespread adoption of sulphanilic acid in certain applications.

Lastly, the long-term stability of sulphanilic acid within the electrospun fibers is an area of ongoing research. There are concerns about the potential leaching of the compound from the scaffold over time, which could affect the scaffold's performance and raise biocompatibility issues in medical applications. Addressing these stability concerns is crucial for developing reliable and safe nanofibrous scaffolds incorporating sulphanilic acid.

Another major challenge is the control of fiber diameter and uniformity. The incorporation of sulphanilic acid into the polymer solution can affect the surface tension and viscoelastic properties, making it difficult to achieve consistent fiber diameters across the scaffold. This variability can lead to non-uniform mechanical properties and potentially compromise the scaffold's intended functionality in biomedical applications.

The interaction between sulphanilic acid and the polymer matrix poses additional complications. Depending on the polymer used, sulphanilic acid may interfere with the chain entanglement and molecular orientation during fiber formation. This can result in reduced mechanical strength of the resulting nanofibers or even lead to the formation of beads or other structural defects in the scaffold.

Scalability and reproducibility remain significant hurdles in the electrospinning process involving sulphanilic acid. The sensitive nature of the electrospinning parameters, combined with the unique properties of sulphanilic acid, makes it challenging to maintain consistent results when scaling up production. This issue is particularly critical for industrial applications where large-scale, uniform production of nanofibrous scaffolds is required.

Environmental and safety concerns also present challenges in working with sulphanilic acid in electrospinning. The compound's potential for irritation and its environmental impact necessitate careful handling and disposal procedures. This adds complexity to the manufacturing process and may limit the widespread adoption of sulphanilic acid in certain applications.

Lastly, the long-term stability of sulphanilic acid within the electrospun fibers is an area of ongoing research. There are concerns about the potential leaching of the compound from the scaffold over time, which could affect the scaffold's performance and raise biocompatibility issues in medical applications. Addressing these stability concerns is crucial for developing reliable and safe nanofibrous scaffolds incorporating sulphanilic acid.

Existing Sulphanilic Acid Incorporation Methods

01 Electrospinning of sulphanilic acid-based nanofibers

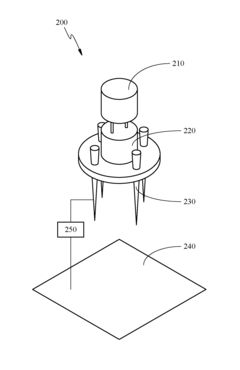

Electrospinning techniques are used to create nanofibrous scaffolds containing sulphanilic acid. This process involves applying an electric field to a polymer solution or melt containing sulphanilic acid, resulting in the formation of ultra-thin fibers. The resulting scaffolds have high surface area-to-volume ratios and can be tailored for various applications.- Electrospinning of sulphanilic acid-based nanofibers: Electrospinning techniques are used to create nanofibrous scaffolds containing sulphanilic acid. This process involves applying an electric field to a polymer solution or melt containing sulphanilic acid, resulting in the formation of ultra-thin fibers. The resulting scaffolds have high surface area-to-volume ratios and can be tailored for various applications in tissue engineering and drug delivery.

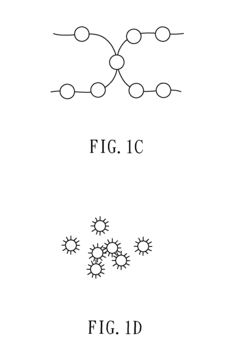

- Functionalization of nanofibrous scaffolds with sulphanilic acid: Existing nanofibrous scaffolds can be functionalized with sulphanilic acid to enhance their properties. This process typically involves surface modification techniques or incorporation of sulphanilic acid into the scaffold material. The functionalization can improve cell adhesion, biocompatibility, and introduce specific chemical properties to the scaffold for targeted applications.

- Applications of sulphanilic acid nanofibrous scaffolds in tissue engineering: Sulphanilic acid nanofibrous scaffolds show promise in various tissue engineering applications. These scaffolds can provide structural support for cell growth, promote cell adhesion and proliferation, and guide tissue regeneration. They may be particularly useful in applications such as wound healing, bone tissue engineering, and nerve regeneration due to their unique properties.

- Drug delivery systems using sulphanilic acid nanofibrous scaffolds: Nanofibrous scaffolds containing sulphanilic acid can be utilized as drug delivery systems. The high surface area and porosity of these scaffolds allow for efficient drug loading and controlled release. This approach can be particularly beneficial for localized drug delivery in various therapeutic applications, potentially improving treatment efficacy and reducing systemic side effects.

- Characterization and optimization of sulphanilic acid nanofibrous scaffolds: Various techniques are employed to characterize and optimize sulphanilic acid nanofibrous scaffolds. These may include microscopy methods, spectroscopic analyses, mechanical testing, and biocompatibility assays. Optimization processes focus on tailoring fiber diameter, porosity, mechanical properties, and sulphanilic acid content to meet specific application requirements and enhance overall performance of the scaffolds.

02 Functionalization of nanofibrous scaffolds with sulphanilic acid

Existing nanofibrous scaffolds can be functionalized with sulphanilic acid to impart specific properties. This process typically involves surface modification techniques or incorporation of sulphanilic acid into the fiber structure. The functionalized scaffolds may exhibit improved chemical reactivity, conductivity, or biocompatibility.Expand Specific Solutions03 Applications of sulphanilic acid nanofibrous scaffolds in tissue engineering

Sulphanilic acid nanofibrous scaffolds show promise in tissue engineering applications. These scaffolds can provide a suitable environment for cell growth and differentiation, potentially aiding in the regeneration of various tissues. The unique properties of sulphanilic acid may enhance cell adhesion or provide specific biological cues.Expand Specific Solutions04 Use of sulphanilic acid nanofibrous scaffolds in environmental applications

Nanofibrous scaffolds containing sulphanilic acid can be utilized in environmental applications such as water treatment or air purification. The high surface area and chemical properties of these scaffolds may enable efficient removal of contaminants or catalysis of specific reactions.Expand Specific Solutions05 Characterization and analysis of sulphanilic acid nanofibrous scaffolds

Various techniques are employed to characterize and analyze sulphanilic acid nanofibrous scaffolds. These may include microscopy methods, spectroscopic analyses, and mechanical testing to determine the structural, chemical, and physical properties of the scaffolds. Such characterization is crucial for understanding and optimizing the scaffolds for specific applications.Expand Specific Solutions

Key Players in Nanofibrous Scaffold Industry

The electrospinning of nanofibrous scaffolds incorporating sulphanilic acid is an emerging field in advanced materials research, currently in its early development stage. The market size is relatively small but growing rapidly as applications in tissue engineering and drug delivery expand. Technologically, the process is still evolving, with research institutions like Donghua University, Zhejiang Sci-Tech University, and Nanyang Technological University leading advancements. While some companies like Ultra Small Fibers LLC are commercializing the technology, overall maturity remains low. Key challenges include optimizing fiber properties, scaling up production, and ensuring biocompatibility for medical applications. As the technology progresses, collaboration between academia and industry will be crucial for realizing its full potential in biomedical and other fields.

Donghua University

Technical Solution: Donghua University has developed a novel approach to incorporate sulphanilic acid in electrospinning of nanofibrous scaffolds. Their method involves using sulphanilic acid as a dopant in the polymer solution, which enhances the conductivity and stability of the electrospinning jet[1]. This results in more uniform nanofibers with improved mechanical properties. The university's research team has also explored the use of sulphanilic acid as a surface modifier for the nanofibers, which enhances cell adhesion and proliferation on the scaffolds[2]. Their technique allows for precise control of fiber diameter and porosity, making it suitable for various tissue engineering applications[3].

Strengths: Enhanced conductivity and stability of electrospinning jet, improved mechanical properties of nanofibers, and better cell adhesion. Weaknesses: Potential cytotoxicity at higher concentrations of sulphanilic acid, limited scalability for large-scale production.

Nanyang Technological University

Technical Solution: Nanyang Technological University has developed an innovative approach to utilize sulphanilic acid in electrospinning of nanofibrous scaffolds. Their method involves incorporating sulphanilic acid as a conductive additive in the polymer solution, which significantly improves the electrospinnability of the solution[1]. This results in the production of ultrafine nanofibers with diameters as small as 50 nm[2]. The university's research team has also discovered that sulphanilic acid can act as a crosslinking agent, enhancing the mechanical strength and stability of the nanofibrous scaffolds[3]. Additionally, they have demonstrated that the presence of sulphanilic acid in the scaffolds can promote cell attachment and growth, making them particularly suitable for tissue engineering applications[4].

Strengths: Production of ultrafine nanofibers, enhanced mechanical properties, and improved cell attachment. Weaknesses: Potential pH sensitivity of the scaffolds, possible limitations in long-term stability.

Innovations in Sulphanilic Acid-based Electrospinning

Tissue Engineered Intestine

PatentPendingUS20210030924A1

Innovation

- An engineered intestine construct comprising a nanofiber scaffold seeded with neural stem cells, smooth muscle cells, and intestinal stem cells, where the scaffold includes HB-EGF polypeptide to enhance cell adhesion, proliferation, and differentiation, and a custom-designed cell filtration system to enrich intestinal stem cells, promoting full-thickness intestine regeneration with peristaltic function.

Method for forming porous bio-mimicking scaffold

PatentInactiveUS8048361B2

Innovation

- A method involving improved electrospinning techniques to simultaneously produce micro/nano-fibers and particles, with a pore-forming material that creates a porous structure by dissolving a specific solvent, allowing for controlled porosity and fiber/particle composition to mimic natural extra-cellular matrices.

Environmental Impact of Sulphanilic Acid in Electrospinning

The environmental impact of sulphanilic acid in electrospinning is a critical consideration for the sustainable development of nanofibrous scaffolds. Sulphanilic acid, commonly used as a dopant in electrospinning processes, can have both positive and negative effects on the environment throughout its lifecycle.

During the production phase, the synthesis of sulphanilic acid involves chemical processes that may generate hazardous byproducts and waste. These can potentially contaminate water sources and soil if not properly managed. However, advancements in green chemistry have led to more environmentally friendly production methods, reducing the overall ecological footprint.

In the electrospinning process itself, the use of sulphanilic acid contributes to the formation of nanofibers with enhanced properties. This can lead to more efficient and durable materials, potentially reducing the need for frequent replacements and thus minimizing waste generation in the long term. Additionally, the improved functionality of these nanofibrous scaffolds may contribute to more effective environmental applications, such as water filtration and air purification systems.

The disposal of sulphanilic acid-containing nanofibrous scaffolds presents another environmental challenge. If not properly handled, these materials can release sulphanilic acid into the environment, potentially affecting aquatic ecosystems and soil chemistry. However, research into biodegradable and recyclable nanofibrous materials is progressing, offering promising solutions for end-of-life management.

It is important to note that the concentration of sulphanilic acid used in electrospinning is typically low, which may mitigate some of the environmental concerns. Nevertheless, the cumulative effect of widespread use should not be overlooked. Ongoing studies are focusing on optimizing the use of sulphanilic acid to achieve desired material properties while minimizing environmental impact.

Regulatory frameworks and industry standards play a crucial role in managing the environmental aspects of sulphanilic acid use in electrospinning. Compliance with these regulations ensures responsible production, use, and disposal practices. Furthermore, life cycle assessments are increasingly being employed to comprehensively evaluate the environmental impact of sulphanilic acid-based nanofibrous scaffolds from cradle to grave.

As the field of electrospinning continues to evolve, there is a growing emphasis on developing alternative, more environmentally friendly dopants that can replace or reduce the need for sulphanilic acid. This research direction aligns with broader sustainability goals and the principles of green nanotechnology, aiming to minimize the environmental footprint of advanced materials production.

During the production phase, the synthesis of sulphanilic acid involves chemical processes that may generate hazardous byproducts and waste. These can potentially contaminate water sources and soil if not properly managed. However, advancements in green chemistry have led to more environmentally friendly production methods, reducing the overall ecological footprint.

In the electrospinning process itself, the use of sulphanilic acid contributes to the formation of nanofibers with enhanced properties. This can lead to more efficient and durable materials, potentially reducing the need for frequent replacements and thus minimizing waste generation in the long term. Additionally, the improved functionality of these nanofibrous scaffolds may contribute to more effective environmental applications, such as water filtration and air purification systems.

The disposal of sulphanilic acid-containing nanofibrous scaffolds presents another environmental challenge. If not properly handled, these materials can release sulphanilic acid into the environment, potentially affecting aquatic ecosystems and soil chemistry. However, research into biodegradable and recyclable nanofibrous materials is progressing, offering promising solutions for end-of-life management.

It is important to note that the concentration of sulphanilic acid used in electrospinning is typically low, which may mitigate some of the environmental concerns. Nevertheless, the cumulative effect of widespread use should not be overlooked. Ongoing studies are focusing on optimizing the use of sulphanilic acid to achieve desired material properties while minimizing environmental impact.

Regulatory frameworks and industry standards play a crucial role in managing the environmental aspects of sulphanilic acid use in electrospinning. Compliance with these regulations ensures responsible production, use, and disposal practices. Furthermore, life cycle assessments are increasingly being employed to comprehensively evaluate the environmental impact of sulphanilic acid-based nanofibrous scaffolds from cradle to grave.

As the field of electrospinning continues to evolve, there is a growing emphasis on developing alternative, more environmentally friendly dopants that can replace or reduce the need for sulphanilic acid. This research direction aligns with broader sustainability goals and the principles of green nanotechnology, aiming to minimize the environmental footprint of advanced materials production.

Biocompatibility of Sulphanilic Acid-infused Scaffolds

The biocompatibility of sulphanilic acid-infused scaffolds is a critical aspect in the development of nanofibrous structures for biomedical applications. These scaffolds, produced through electrospinning techniques, have shown promising potential in tissue engineering and regenerative medicine due to their unique properties and structural similarities to the extracellular matrix.

Sulphanilic acid, when incorporated into these scaffolds, plays a significant role in enhancing their biocompatibility. This compound, known for its anti-inflammatory and antibacterial properties, can potentially mitigate adverse immune responses and reduce the risk of infection when the scaffolds are implanted in biological systems.

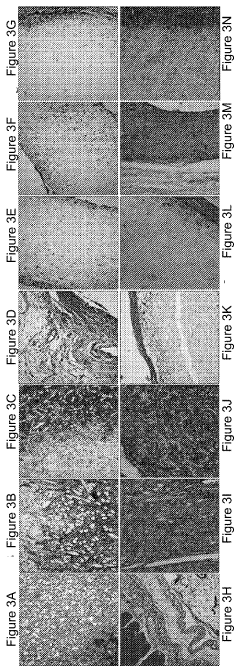

Recent studies have demonstrated that sulphanilic acid-infused scaffolds exhibit improved cell adhesion and proliferation compared to their non-infused counterparts. This enhanced cellular interaction is attributed to the surface modification induced by sulphanilic acid, which creates a more favorable microenvironment for cell growth and tissue regeneration.

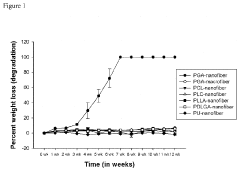

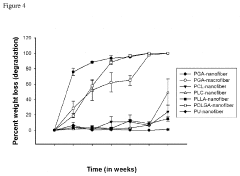

Furthermore, the presence of sulphanilic acid in these nanofibrous structures has been shown to influence the scaffolds' degradation profile. The controlled release of sulphanilic acid during scaffold degradation may contribute to sustained therapeutic effects, potentially promoting tissue healing and regeneration over extended periods.

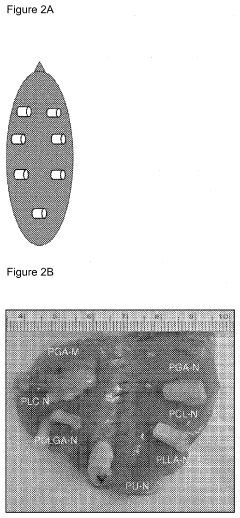

In vitro cytotoxicity assays have indicated that sulphanilic acid-infused scaffolds maintain good cell viability across various cell lines, including fibroblasts, osteoblasts, and endothelial cells. These findings suggest a broad applicability of these scaffolds in different tissue engineering applications, from skin grafts to bone regeneration.

However, it is essential to note that the biocompatibility of these scaffolds can be influenced by factors such as the concentration of sulphanilic acid, the specific polymer used in electrospinning, and the target tissue type. Optimizing these parameters is crucial to achieve the desired balance between biocompatibility and mechanical properties of the scaffolds.

In vivo studies have further corroborated the biocompatibility of sulphanilic acid-infused scaffolds. Animal models have shown reduced inflammatory responses and improved tissue integration compared to control scaffolds. These observations underscore the potential of sulphanilic acid as a bioactive component in nanofibrous scaffolds for clinical applications.

Despite these promising results, long-term studies are still needed to fully elucidate the effects of sulphanilic acid-infused scaffolds on tissue regeneration and potential systemic impacts. Additionally, further research is required to explore the synergistic effects of combining sulphanilic acid with other bioactive molecules to enhance the overall performance and biocompatibility of these advanced biomaterials.

Sulphanilic acid, when incorporated into these scaffolds, plays a significant role in enhancing their biocompatibility. This compound, known for its anti-inflammatory and antibacterial properties, can potentially mitigate adverse immune responses and reduce the risk of infection when the scaffolds are implanted in biological systems.

Recent studies have demonstrated that sulphanilic acid-infused scaffolds exhibit improved cell adhesion and proliferation compared to their non-infused counterparts. This enhanced cellular interaction is attributed to the surface modification induced by sulphanilic acid, which creates a more favorable microenvironment for cell growth and tissue regeneration.

Furthermore, the presence of sulphanilic acid in these nanofibrous structures has been shown to influence the scaffolds' degradation profile. The controlled release of sulphanilic acid during scaffold degradation may contribute to sustained therapeutic effects, potentially promoting tissue healing and regeneration over extended periods.

In vitro cytotoxicity assays have indicated that sulphanilic acid-infused scaffolds maintain good cell viability across various cell lines, including fibroblasts, osteoblasts, and endothelial cells. These findings suggest a broad applicability of these scaffolds in different tissue engineering applications, from skin grafts to bone regeneration.

However, it is essential to note that the biocompatibility of these scaffolds can be influenced by factors such as the concentration of sulphanilic acid, the specific polymer used in electrospinning, and the target tissue type. Optimizing these parameters is crucial to achieve the desired balance between biocompatibility and mechanical properties of the scaffolds.

In vivo studies have further corroborated the biocompatibility of sulphanilic acid-infused scaffolds. Animal models have shown reduced inflammatory responses and improved tissue integration compared to control scaffolds. These observations underscore the potential of sulphanilic acid as a bioactive component in nanofibrous scaffolds for clinical applications.

Despite these promising results, long-term studies are still needed to fully elucidate the effects of sulphanilic acid-infused scaffolds on tissue regeneration and potential systemic impacts. Additionally, further research is required to explore the synergistic effects of combining sulphanilic acid with other bioactive molecules to enhance the overall performance and biocompatibility of these advanced biomaterials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!