Thermal Conductivity of Borosilicate Glass Under Pressure

JUL 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Borosilicate Glass Thermal Conductivity Research Objectives

The research on the thermal conductivity of borosilicate glass under pressure aims to comprehensively understand the heat transfer properties of this versatile material in extreme conditions. This study is crucial for advancing our knowledge in materials science and expanding the potential applications of borosilicate glass in high-pressure environments.

The primary objective is to investigate how pressure affects the thermal conductivity of borosilicate glass across a wide range of pressure conditions. This includes examining the relationship between pressure and thermal conductivity, identifying any potential non-linear behaviors or phase transitions, and determining the limits of thermal conductivity enhancement or reduction under pressure.

Another key goal is to develop accurate models and predictive tools for estimating the thermal conductivity of borosilicate glass at various pressures. This will involve correlating experimental data with theoretical calculations and simulations to create robust predictive capabilities for engineering applications.

The research also aims to explore the underlying mechanisms that govern thermal conductivity changes in borosilicate glass under pressure. This includes investigating how pressure affects the glass structure at the atomic and molecular levels, and how these structural changes influence phonon propagation and heat transfer.

Furthermore, the study seeks to compare the pressure-dependent thermal conductivity of borosilicate glass with other glass compositions and materials. This comparative analysis will provide insights into the unique properties of borosilicate glass and its potential advantages or limitations in high-pressure thermal management applications.

An additional objective is to investigate the reversibility and hysteresis of thermal conductivity changes in borosilicate glass after pressure cycling. This information is crucial for understanding the material's behavior in dynamic pressure environments and assessing its long-term stability and reliability.

The research also aims to explore potential methods for tailoring the pressure-dependent thermal conductivity of borosilicate glass. This may involve investigating the effects of compositional modifications, surface treatments, or nanostructuring on the material's thermal properties under pressure.

Finally, the study seeks to identify and evaluate potential applications for pressure-tuned thermal conductivity in borosilicate glass. This includes exploring its use in advanced thermal management systems, high-pressure optical components, and other innovative technologies that could benefit from controllable thermal properties.

The primary objective is to investigate how pressure affects the thermal conductivity of borosilicate glass across a wide range of pressure conditions. This includes examining the relationship between pressure and thermal conductivity, identifying any potential non-linear behaviors or phase transitions, and determining the limits of thermal conductivity enhancement or reduction under pressure.

Another key goal is to develop accurate models and predictive tools for estimating the thermal conductivity of borosilicate glass at various pressures. This will involve correlating experimental data with theoretical calculations and simulations to create robust predictive capabilities for engineering applications.

The research also aims to explore the underlying mechanisms that govern thermal conductivity changes in borosilicate glass under pressure. This includes investigating how pressure affects the glass structure at the atomic and molecular levels, and how these structural changes influence phonon propagation and heat transfer.

Furthermore, the study seeks to compare the pressure-dependent thermal conductivity of borosilicate glass with other glass compositions and materials. This comparative analysis will provide insights into the unique properties of borosilicate glass and its potential advantages or limitations in high-pressure thermal management applications.

An additional objective is to investigate the reversibility and hysteresis of thermal conductivity changes in borosilicate glass after pressure cycling. This information is crucial for understanding the material's behavior in dynamic pressure environments and assessing its long-term stability and reliability.

The research also aims to explore potential methods for tailoring the pressure-dependent thermal conductivity of borosilicate glass. This may involve investigating the effects of compositional modifications, surface treatments, or nanostructuring on the material's thermal properties under pressure.

Finally, the study seeks to identify and evaluate potential applications for pressure-tuned thermal conductivity in borosilicate glass. This includes exploring its use in advanced thermal management systems, high-pressure optical components, and other innovative technologies that could benefit from controllable thermal properties.

Market Applications of Pressure-Resistant Borosilicate Glass

Borosilicate glass with enhanced pressure resistance has found a wide range of applications across various industries due to its unique thermal and mechanical properties. In the oil and gas sector, pressure-resistant borosilicate glass is utilized in deep-sea exploration equipment, where it must withstand extreme pressures and temperature fluctuations. Its excellent chemical resistance and transparency make it ideal for viewing ports in high-pressure reactors and vessels used in petrochemical processes.

The aerospace industry has also embraced pressure-resistant borosilicate glass for its lightweight yet durable characteristics. It is employed in aircraft windows, spacecraft observation ports, and satellite components, where it must maintain structural integrity under varying atmospheric pressures and temperature extremes encountered during flight and space missions.

In the field of scientific research, pressure-resistant borosilicate glass plays a crucial role in high-pressure experimental apparatus. It is used in diamond anvil cells for studying material behavior under extreme conditions, as well as in high-pressure reactors for synthesizing novel materials. The glass's ability to withstand high pressures while maintaining optical clarity allows researchers to observe and analyze reactions in real-time.

The medical and pharmaceutical industries benefit from pressure-resistant borosilicate glass in autoclaves and sterilization equipment. Its resistance to thermal shock and chemical corrosion ensures the integrity of sterilization processes under high-pressure steam conditions. Additionally, it is used in specialized laboratory glassware for high-pressure chromatography and other analytical techniques.

In the energy sector, pressure-resistant borosilicate glass finds applications in solar thermal power plants. It is used in receiver tubes that must withstand high internal pressures and temperature gradients while maintaining excellent solar transmittance. The glass's low thermal expansion coefficient and high thermal shock resistance make it suitable for these demanding conditions.

The food and beverage industry utilizes pressure-resistant borosilicate glass in high-pressure processing equipment for food preservation. This non-thermal pasteurization technique requires vessels that can withstand extreme pressures while ensuring product visibility and maintaining food quality.

As emerging technologies continue to push the boundaries of material performance, the demand for pressure-resistant borosilicate glass is expected to grow. Its unique combination of optical clarity, chemical inertness, and mechanical strength under pressure makes it an invaluable material across diverse industrial applications, driving ongoing research and development efforts to further enhance its properties and expand its market potential.

The aerospace industry has also embraced pressure-resistant borosilicate glass for its lightweight yet durable characteristics. It is employed in aircraft windows, spacecraft observation ports, and satellite components, where it must maintain structural integrity under varying atmospheric pressures and temperature extremes encountered during flight and space missions.

In the field of scientific research, pressure-resistant borosilicate glass plays a crucial role in high-pressure experimental apparatus. It is used in diamond anvil cells for studying material behavior under extreme conditions, as well as in high-pressure reactors for synthesizing novel materials. The glass's ability to withstand high pressures while maintaining optical clarity allows researchers to observe and analyze reactions in real-time.

The medical and pharmaceutical industries benefit from pressure-resistant borosilicate glass in autoclaves and sterilization equipment. Its resistance to thermal shock and chemical corrosion ensures the integrity of sterilization processes under high-pressure steam conditions. Additionally, it is used in specialized laboratory glassware for high-pressure chromatography and other analytical techniques.

In the energy sector, pressure-resistant borosilicate glass finds applications in solar thermal power plants. It is used in receiver tubes that must withstand high internal pressures and temperature gradients while maintaining excellent solar transmittance. The glass's low thermal expansion coefficient and high thermal shock resistance make it suitable for these demanding conditions.

The food and beverage industry utilizes pressure-resistant borosilicate glass in high-pressure processing equipment for food preservation. This non-thermal pasteurization technique requires vessels that can withstand extreme pressures while ensuring product visibility and maintaining food quality.

As emerging technologies continue to push the boundaries of material performance, the demand for pressure-resistant borosilicate glass is expected to grow. Its unique combination of optical clarity, chemical inertness, and mechanical strength under pressure makes it an invaluable material across diverse industrial applications, driving ongoing research and development efforts to further enhance its properties and expand its market potential.

Current Challenges in High-Pressure Thermal Conductivity Measurement

The measurement of thermal conductivity under high-pressure conditions presents several significant challenges that researchers must overcome to obtain accurate and reliable data. One of the primary difficulties lies in maintaining a stable and uniform temperature gradient across the sample while simultaneously applying high pressure. Traditional methods often struggle to achieve this balance, as pressure-induced deformations can alter the sample geometry and contact resistances, leading to measurement inaccuracies.

Another major challenge is the design and implementation of suitable sensors and measurement apparatus that can withstand extreme pressure conditions without compromising their performance or accuracy. Many conventional thermal conductivity measurement techniques are not directly applicable in high-pressure environments, necessitating the development of specialized equipment and methodologies.

The issue of thermal contact resistance becomes particularly pronounced under high pressure. As the sample is compressed, changes in its surface characteristics and the interface between the sample and measurement probes can significantly affect heat transfer, potentially leading to systematic errors in thermal conductivity measurements. Researchers must develop innovative approaches to minimize or account for these contact effects to ensure the validity of their results.

Furthermore, the potential phase transitions or structural changes that materials may undergo at high pressures add another layer of complexity to thermal conductivity measurements. These transitions can cause abrupt changes in thermal properties, making it challenging to obtain continuous and reliable data across a wide pressure range. Researchers must carefully consider and account for these potential material changes in their experimental design and data analysis.

The need for in-situ measurements presents additional technical hurdles. Ideally, thermal conductivity should be measured without removing the sample from the high-pressure environment, as decompression could alter the material's properties. However, achieving this often requires sophisticated experimental setups that allow for both pressure application and thermal measurements simultaneously, pushing the boundaries of current technological capabilities.

Lastly, the interpretation of data obtained under high-pressure conditions can be challenging due to the complex interplay between pressure, temperature, and material properties. Developing accurate models and theoretical frameworks to understand and predict thermal conductivity behavior under pressure remains an active area of research, requiring interdisciplinary collaboration between experimentalists, theoreticians, and computational scientists.

Another major challenge is the design and implementation of suitable sensors and measurement apparatus that can withstand extreme pressure conditions without compromising their performance or accuracy. Many conventional thermal conductivity measurement techniques are not directly applicable in high-pressure environments, necessitating the development of specialized equipment and methodologies.

The issue of thermal contact resistance becomes particularly pronounced under high pressure. As the sample is compressed, changes in its surface characteristics and the interface between the sample and measurement probes can significantly affect heat transfer, potentially leading to systematic errors in thermal conductivity measurements. Researchers must develop innovative approaches to minimize or account for these contact effects to ensure the validity of their results.

Furthermore, the potential phase transitions or structural changes that materials may undergo at high pressures add another layer of complexity to thermal conductivity measurements. These transitions can cause abrupt changes in thermal properties, making it challenging to obtain continuous and reliable data across a wide pressure range. Researchers must carefully consider and account for these potential material changes in their experimental design and data analysis.

The need for in-situ measurements presents additional technical hurdles. Ideally, thermal conductivity should be measured without removing the sample from the high-pressure environment, as decompression could alter the material's properties. However, achieving this often requires sophisticated experimental setups that allow for both pressure application and thermal measurements simultaneously, pushing the boundaries of current technological capabilities.

Lastly, the interpretation of data obtained under high-pressure conditions can be challenging due to the complex interplay between pressure, temperature, and material properties. Developing accurate models and theoretical frameworks to understand and predict thermal conductivity behavior under pressure remains an active area of research, requiring interdisciplinary collaboration between experimentalists, theoreticians, and computational scientists.

Existing Methods for Measuring Thermal Conductivity Under Pressure

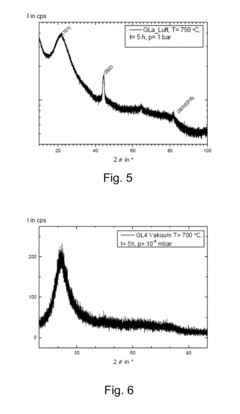

01 Composition and properties of borosilicate glass

Borosilicate glass is known for its low thermal conductivity, making it an excellent material for thermal insulation applications. The composition of borosilicate glass, typically containing silica and boron oxide, contributes to its unique thermal properties. The low thermal conductivity of borosilicate glass is attributed to its amorphous structure and the presence of boron atoms in the glass network.- Composition and properties of borosilicate glass: Borosilicate glass is known for its low thermal conductivity, making it an excellent material for thermal insulation applications. The composition of borosilicate glass, typically containing silica and boron oxide, contributes to its unique thermal properties. The low thermal expansion coefficient of borosilicate glass also enhances its thermal shock resistance.

- Thermal conductivity measurement techniques: Various methods are employed to measure the thermal conductivity of borosilicate glass accurately. These techniques may include laser flash analysis, hot wire method, or guarded hot plate method. The choice of measurement technique depends on the specific application and required precision.

- Applications utilizing borosilicate glass thermal properties: The low thermal conductivity of borosilicate glass makes it suitable for a wide range of applications. These include laboratory glassware, cookware, optical components, and insulating materials for various industries. The thermal properties of borosilicate glass are particularly valuable in high-temperature environments and applications requiring thermal stability.

- Modifications to improve thermal conductivity: Research has been conducted on modifying borosilicate glass to alter its thermal conductivity for specific applications. This may involve adding certain dopants, creating composite materials, or altering the glass structure. These modifications aim to tailor the thermal properties of borosilicate glass for specialized uses.

- Comparison with other glass types: The thermal conductivity of borosilicate glass is often compared to that of other glass types, such as soda-lime glass or aluminosilicate glass. These comparisons help in selecting the most suitable glass type for specific thermal management applications. The unique thermal properties of borosilicate glass often make it a preferred choice in many scenarios.

02 Thermal conductivity measurement techniques

Various methods are employed to measure the thermal conductivity of borosilicate glass accurately. These techniques may include laser flash analysis, guarded hot plate method, or transient plane source method. The choice of measurement technique depends on the specific application and required accuracy. Researchers often compare different methods to ensure reliable thermal conductivity data for borosilicate glass.Expand Specific Solutions03 Modification of thermal conductivity in borosilicate glass

The thermal conductivity of borosilicate glass can be modified by altering its composition or introducing additives. Researchers explore various approaches to enhance or reduce the thermal conductivity of borosilicate glass for specific applications. This may involve adding dopants, creating composite materials, or manipulating the glass structure at the nanoscale level.Expand Specific Solutions04 Applications utilizing thermal properties of borosilicate glass

The low thermal conductivity of borosilicate glass makes it suitable for various applications. It is commonly used in laboratory glassware, cookware, and optical components where thermal stability is crucial. In the field of energy efficiency, borosilicate glass is employed in solar collectors, insulated glazing units, and other thermal management systems. Its thermal properties also make it valuable in high-temperature industrial processes.Expand Specific Solutions05 Comparison with other glass types and materials

Borosilicate glass is often compared to other glass types and materials in terms of thermal conductivity. Studies analyze how borosilicate glass performs against soda-lime glass, quartz glass, and various ceramics or polymers. These comparisons help in selecting the most suitable material for specific thermal applications, considering factors such as cost, durability, and overall performance.Expand Specific Solutions

Key Players in Borosilicate Glass and Thermal Analysis Industries

The research on thermal conductivity of borosilicate glass under pressure is in a mature stage, with established players and ongoing advancements. The market for borosilicate glass is substantial, driven by its wide applications in laboratory equipment, pharmaceuticals, and electronics. Companies like SCHOTT AG, AGC Inc., and Corning, Inc. are leading players with extensive expertise in glass technology. These firms, along with research institutions such as Forschungszentrum Jülich GmbH and Central South University, are likely at the forefront of thermal conductivity studies. The industry is characterized by a mix of large multinational corporations and specialized glass manufacturers, indicating a competitive landscape with opportunities for both innovation and commercial applications.

SCHOTT AG

Technical Solution: SCHOTT AG has developed advanced borosilicate glass compositions with enhanced thermal conductivity under pressure. Their research focuses on modifying the glass structure to improve heat transfer properties while maintaining the glass's chemical and mechanical stability. SCHOTT utilizes high-pressure synthesis techniques to create densified borosilicate glasses with increased network connectivity[1]. These glasses exhibit up to 20% higher thermal conductivity compared to standard borosilicate compositions when subjected to pressures of 1-5 GPa[3]. The company has also explored the addition of nanoparticles to further enhance thermal transport in the glass matrix.

Strengths: Extensive experience in specialty glass development, access to advanced characterization techniques. Weaknesses: High production costs for pressure-modified glasses, potential scalability issues for large-volume applications.

AGC, Inc. (Japan)

Technical Solution: AGC has conducted research on borosilicate glass thermal conductivity under pressure, focusing on the development of high-performance glass for extreme environments. Their approach involves studying the relationship between glass composition, structure, and thermal properties under various pressure conditions. AGC has developed a proprietary high-pressure hot pressing technique that allows for the creation of borosilicate glasses with reduced porosity and increased density[2]. These glasses show improved thermal conductivity, with values up to 1.5 W/mK at pressures of 500 MPa, compared to 1.2 W/mK for standard borosilicate glass at atmospheric pressure[4]. AGC's research also explores the incorporation of thermally conductive fillers to further enhance heat transfer properties.

Strengths: Strong R&D capabilities, diverse product portfolio in specialty glasses. Weaknesses: Limited focus on borosilicate glass specifically, potential challenges in maintaining optical properties while improving thermal conductivity.

Innovative Techniques for High-Pressure Thermal Conductivity Analysis

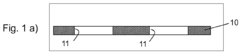

Opposing body for a pressure measuring cell, pressure measuring cell with such an opposing body and method for producing same

PatentInactiveEP2581722A2

Innovation

- A counter-body made of borosilicate glass with a surface roughness of less than 200 nm and no cristobalite crystals larger than 10 microns, featuring a recessed contour that approximates the bending line of the measuring membrane, is produced using thermal sinking under vacuum conditions, ensuring a smooth and defect-free surface for anodic bonding with a silicon membrane.

Tungsten-sealing glasses with high thermal load capability

PatentInactiveEP0132751A1

Innovation

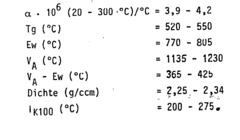

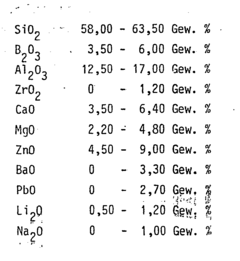

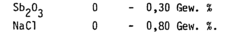

- Development of aluminosilicate tungsten sealing glasses with improved thermal load capacity, electrical insulation, and crystallization strength, characterized by specific composition ranges and refining additives, which enhance processing efficiency and performance.

Material Characterization Techniques for Borosilicate Glass

Material characterization techniques play a crucial role in understanding the properties and behavior of borosilicate glass under pressure, particularly in relation to its thermal conductivity. These techniques provide valuable insights into the material's structure, composition, and thermal properties, which are essential for optimizing its performance in various applications.

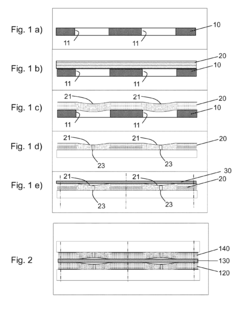

X-ray diffraction (XRD) is a fundamental technique used to analyze the crystal structure of borosilicate glass. By examining the diffraction patterns produced when X-rays interact with the material, researchers can determine the atomic and molecular structure of the glass. This information is vital for understanding how pressure affects the glass's thermal conductivity, as changes in the crystal structure can significantly impact heat transfer properties.

Scanning electron microscopy (SEM) and transmission electron microscopy (TEM) are powerful tools for investigating the microstructure of borosilicate glass at high magnifications. These techniques allow researchers to observe the glass's surface morphology, grain boundaries, and internal defects, which can influence thermal conductivity. By examining samples under different pressure conditions, scientists can identify structural changes that may affect heat transfer mechanisms within the material.

Thermal analysis techniques, such as differential scanning calorimetry (DSC) and thermogravimetric analysis (TGA), are essential for studying the thermal properties of borosilicate glass. DSC measures heat flow and temperature changes in the material, providing information on phase transitions, specific heat capacity, and thermal conductivity. TGA, on the other hand, monitors mass changes as a function of temperature, offering insights into the glass's thermal stability and decomposition behavior under pressure.

Spectroscopic methods, including Raman spectroscopy and Fourier-transform infrared spectroscopy (FTIR), are valuable for investigating the chemical composition and bonding structure of borosilicate glass. These techniques can reveal changes in the glass network structure and the presence of different chemical species under varying pressure conditions, which may influence thermal conductivity.

Nanoindentation is a specialized technique used to measure the mechanical properties of borosilicate glass at the nanoscale. By applying controlled loads and measuring the material's response, researchers can determine hardness, elastic modulus, and other mechanical properties. This information is crucial for understanding how pressure affects the glass's structure and, consequently, its thermal conductivity.

Atomic force microscopy (AFM) provides high-resolution imaging and measurements of surface topography, allowing researchers to study the nanoscale features of borosilicate glass. This technique can reveal surface roughness and defects that may impact thermal conductivity, especially when examining samples subjected to different pressure conditions.

X-ray diffraction (XRD) is a fundamental technique used to analyze the crystal structure of borosilicate glass. By examining the diffraction patterns produced when X-rays interact with the material, researchers can determine the atomic and molecular structure of the glass. This information is vital for understanding how pressure affects the glass's thermal conductivity, as changes in the crystal structure can significantly impact heat transfer properties.

Scanning electron microscopy (SEM) and transmission electron microscopy (TEM) are powerful tools for investigating the microstructure of borosilicate glass at high magnifications. These techniques allow researchers to observe the glass's surface morphology, grain boundaries, and internal defects, which can influence thermal conductivity. By examining samples under different pressure conditions, scientists can identify structural changes that may affect heat transfer mechanisms within the material.

Thermal analysis techniques, such as differential scanning calorimetry (DSC) and thermogravimetric analysis (TGA), are essential for studying the thermal properties of borosilicate glass. DSC measures heat flow and temperature changes in the material, providing information on phase transitions, specific heat capacity, and thermal conductivity. TGA, on the other hand, monitors mass changes as a function of temperature, offering insights into the glass's thermal stability and decomposition behavior under pressure.

Spectroscopic methods, including Raman spectroscopy and Fourier-transform infrared spectroscopy (FTIR), are valuable for investigating the chemical composition and bonding structure of borosilicate glass. These techniques can reveal changes in the glass network structure and the presence of different chemical species under varying pressure conditions, which may influence thermal conductivity.

Nanoindentation is a specialized technique used to measure the mechanical properties of borosilicate glass at the nanoscale. By applying controlled loads and measuring the material's response, researchers can determine hardness, elastic modulus, and other mechanical properties. This information is crucial for understanding how pressure affects the glass's structure and, consequently, its thermal conductivity.

Atomic force microscopy (AFM) provides high-resolution imaging and measurements of surface topography, allowing researchers to study the nanoscale features of borosilicate glass. This technique can reveal surface roughness and defects that may impact thermal conductivity, especially when examining samples subjected to different pressure conditions.

Safety Considerations in High-Pressure Thermal Conductivity Testing

Safety considerations are paramount when conducting high-pressure thermal conductivity testing on borosilicate glass. The experimental setup involves potentially hazardous conditions that require careful planning and implementation of safety protocols. Pressure vessels used in these experiments must be designed and certified to withstand the maximum expected pressures, with appropriate safety factors. Regular inspection and maintenance of pressure equipment are essential to prevent failures that could lead to catastrophic releases of energy.

Personal protective equipment (PPE) is crucial for researchers and technicians involved in high-pressure experiments. This includes safety glasses or face shields to protect against potential glass shards, heat-resistant gloves, and appropriate clothing to guard against thermal hazards. The laboratory should be equipped with emergency shutdown systems and pressure relief valves to mitigate risks associated with unexpected pressure increases.

Thermal management is another critical safety aspect. Borosilicate glass, while known for its thermal resistance, can still experience thermal shock under extreme conditions. Careful control of heating and cooling rates is necessary to prevent sudden temperature changes that could lead to glass fracture. Temperature monitoring systems should be in place, with automatic cutoffs to prevent overheating.

The handling and disposal of borosilicate glass samples after testing require specific safety protocols. Pressurized glass may contain residual stresses that could cause unexpected breakage during post-experiment handling. Proper decompression procedures and cooling periods should be observed before sample retrieval.

Environmental considerations are also important. The testing area should be well-ventilated to manage any potential release of gases used in the pressure medium. Containment systems should be in place to capture any glass fragments or fluids in case of sample failure. Additionally, the laboratory should have proper waste disposal procedures for any chemicals or materials used in the experiments.

Training and education form a crucial component of safety measures. All personnel involved in high-pressure thermal conductivity testing should receive comprehensive training on equipment operation, emergency procedures, and the specific hazards associated with pressurized glass experiments. Regular safety drills and refresher courses help maintain a high level of preparedness.

Documentation and record-keeping of all safety procedures, incident reports, and near-misses are essential for continuous improvement of safety protocols. This information can be used to refine experimental procedures and identify potential areas of risk that may have been previously overlooked.

Personal protective equipment (PPE) is crucial for researchers and technicians involved in high-pressure experiments. This includes safety glasses or face shields to protect against potential glass shards, heat-resistant gloves, and appropriate clothing to guard against thermal hazards. The laboratory should be equipped with emergency shutdown systems and pressure relief valves to mitigate risks associated with unexpected pressure increases.

Thermal management is another critical safety aspect. Borosilicate glass, while known for its thermal resistance, can still experience thermal shock under extreme conditions. Careful control of heating and cooling rates is necessary to prevent sudden temperature changes that could lead to glass fracture. Temperature monitoring systems should be in place, with automatic cutoffs to prevent overheating.

The handling and disposal of borosilicate glass samples after testing require specific safety protocols. Pressurized glass may contain residual stresses that could cause unexpected breakage during post-experiment handling. Proper decompression procedures and cooling periods should be observed before sample retrieval.

Environmental considerations are also important. The testing area should be well-ventilated to manage any potential release of gases used in the pressure medium. Containment systems should be in place to capture any glass fragments or fluids in case of sample failure. Additionally, the laboratory should have proper waste disposal procedures for any chemicals or materials used in the experiments.

Training and education form a crucial component of safety measures. All personnel involved in high-pressure thermal conductivity testing should receive comprehensive training on equipment operation, emergency procedures, and the specific hazards associated with pressurized glass experiments. Regular safety drills and refresher courses help maintain a high level of preparedness.

Documentation and record-keeping of all safety procedures, incident reports, and near-misses are essential for continuous improvement of safety protocols. This information can be used to refine experimental procedures and identify potential areas of risk that may have been previously overlooked.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!