Muriatic Acid in the Treatment of Cosmetic Industry Wastewater

JUL 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Muriatic Acid in Wastewater Treatment: Background and Objectives

Muriatic acid, also known as hydrochloric acid, has been a subject of increasing interest in the field of wastewater treatment, particularly in the cosmetic industry. The use of this strong mineral acid in treating industrial effluents has evolved significantly over the past few decades, driven by the growing need for more effective and environmentally friendly water treatment solutions.

The cosmetic industry, with its diverse range of products and complex manufacturing processes, generates wastewater containing various organic and inorganic contaminants. These pollutants often include surfactants, dyes, preservatives, and heavy metals, which pose significant environmental and health risks if not properly treated before discharge. Traditional wastewater treatment methods have struggled to effectively remove all these contaminants, leading to the exploration of alternative approaches.

Muriatic acid has emerged as a promising agent in this context due to its strong acidic properties and ability to react with a wide range of substances. Its potential applications in wastewater treatment include pH adjustment, coagulation enhancement, and the breakdown of complex organic compounds. The acid's effectiveness in dissolving mineral deposits and its relatively low cost compared to other treatment chemicals have further contributed to its growing adoption in industrial wastewater management.

The primary objective of researching muriatic acid in cosmetic industry wastewater treatment is to develop more efficient and sustainable treatment processes. This involves optimizing the use of muriatic acid to maximize contaminant removal while minimizing environmental impact and operational costs. Researchers aim to understand the acid's interactions with various pollutants found in cosmetic wastewater and to determine the optimal conditions for its application.

Another key goal is to address the challenges associated with using muriatic acid in wastewater treatment. These include managing the corrosive nature of the acid, ensuring worker safety, and developing strategies to neutralize treated effluents before discharge. The research also seeks to explore potential synergies between muriatic acid and other treatment technologies, such as advanced oxidation processes or membrane filtration systems.

As environmental regulations become increasingly stringent, there is a growing emphasis on developing treatment solutions that not only meet current standards but also anticipate future requirements. This research into muriatic acid usage aligns with the broader trend towards circular economy principles in the cosmetic industry, aiming to minimize waste generation and maximize resource recovery from wastewater streams.

The cosmetic industry, with its diverse range of products and complex manufacturing processes, generates wastewater containing various organic and inorganic contaminants. These pollutants often include surfactants, dyes, preservatives, and heavy metals, which pose significant environmental and health risks if not properly treated before discharge. Traditional wastewater treatment methods have struggled to effectively remove all these contaminants, leading to the exploration of alternative approaches.

Muriatic acid has emerged as a promising agent in this context due to its strong acidic properties and ability to react with a wide range of substances. Its potential applications in wastewater treatment include pH adjustment, coagulation enhancement, and the breakdown of complex organic compounds. The acid's effectiveness in dissolving mineral deposits and its relatively low cost compared to other treatment chemicals have further contributed to its growing adoption in industrial wastewater management.

The primary objective of researching muriatic acid in cosmetic industry wastewater treatment is to develop more efficient and sustainable treatment processes. This involves optimizing the use of muriatic acid to maximize contaminant removal while minimizing environmental impact and operational costs. Researchers aim to understand the acid's interactions with various pollutants found in cosmetic wastewater and to determine the optimal conditions for its application.

Another key goal is to address the challenges associated with using muriatic acid in wastewater treatment. These include managing the corrosive nature of the acid, ensuring worker safety, and developing strategies to neutralize treated effluents before discharge. The research also seeks to explore potential synergies between muriatic acid and other treatment technologies, such as advanced oxidation processes or membrane filtration systems.

As environmental regulations become increasingly stringent, there is a growing emphasis on developing treatment solutions that not only meet current standards but also anticipate future requirements. This research into muriatic acid usage aligns with the broader trend towards circular economy principles in the cosmetic industry, aiming to minimize waste generation and maximize resource recovery from wastewater streams.

Market Analysis of Cosmetic Industry Wastewater Treatment

The cosmetic industry wastewater treatment market has been experiencing significant growth due to increasing environmental regulations and the rising awareness of sustainable practices within the beauty sector. The global market for cosmetic industry wastewater treatment is projected to expand at a compound annual growth rate (CAGR) of 5.8% from 2021 to 2026, driven by the growing demand for eco-friendly cosmetic products and stringent water quality standards.

The cosmetic industry generates substantial amounts of wastewater containing various pollutants, including surfactants, emulsifiers, preservatives, and coloring agents. This has created a pressing need for effective treatment solutions, particularly in regions with high cosmetic production, such as Asia-Pacific, North America, and Europe. The market demand is further fueled by the implementation of zero liquid discharge (ZLD) policies in several countries, compelling cosmetic manufacturers to invest in advanced wastewater treatment technologies.

In terms of treatment technologies, biological treatment methods currently dominate the market, accounting for approximately 40% of the total market share. However, chemical treatment processes, including the use of muriatic acid, are gaining traction due to their effectiveness in removing specific contaminants and their ability to complement other treatment methods.

The market for muriatic acid in cosmetic industry wastewater treatment is expected to grow steadily, driven by its cost-effectiveness and versatility in addressing various pollutants. Muriatic acid, also known as hydrochloric acid, is particularly effective in pH adjustment, heavy metal removal, and scale prevention in treatment systems. Its use is becoming increasingly popular in small to medium-sized cosmetic manufacturing facilities seeking affordable yet efficient wastewater treatment solutions.

Key market players in the cosmetic industry wastewater treatment sector include Suez Water Technologies & Solutions, Veolia Water Technologies, and Evoqua Water Technologies. These companies are investing heavily in research and development to improve treatment efficiencies and develop innovative solutions tailored to the specific needs of the cosmetic industry.

The market is also witnessing a trend towards the adoption of integrated treatment systems that combine multiple technologies, including chemical treatment with muriatic acid, to achieve optimal results. This approach is particularly appealing to large-scale cosmetic manufacturers looking to minimize their environmental footprint while ensuring compliance with regulatory standards.

In conclusion, the market for cosmetic industry wastewater treatment, including the use of muriatic acid, presents significant opportunities for growth and innovation. As the beauty industry continues to expand and environmental regulations become more stringent, the demand for effective and sustainable wastewater treatment solutions is expected to rise, driving further advancements in treatment technologies and market expansion.

The cosmetic industry generates substantial amounts of wastewater containing various pollutants, including surfactants, emulsifiers, preservatives, and coloring agents. This has created a pressing need for effective treatment solutions, particularly in regions with high cosmetic production, such as Asia-Pacific, North America, and Europe. The market demand is further fueled by the implementation of zero liquid discharge (ZLD) policies in several countries, compelling cosmetic manufacturers to invest in advanced wastewater treatment technologies.

In terms of treatment technologies, biological treatment methods currently dominate the market, accounting for approximately 40% of the total market share. However, chemical treatment processes, including the use of muriatic acid, are gaining traction due to their effectiveness in removing specific contaminants and their ability to complement other treatment methods.

The market for muriatic acid in cosmetic industry wastewater treatment is expected to grow steadily, driven by its cost-effectiveness and versatility in addressing various pollutants. Muriatic acid, also known as hydrochloric acid, is particularly effective in pH adjustment, heavy metal removal, and scale prevention in treatment systems. Its use is becoming increasingly popular in small to medium-sized cosmetic manufacturing facilities seeking affordable yet efficient wastewater treatment solutions.

Key market players in the cosmetic industry wastewater treatment sector include Suez Water Technologies & Solutions, Veolia Water Technologies, and Evoqua Water Technologies. These companies are investing heavily in research and development to improve treatment efficiencies and develop innovative solutions tailored to the specific needs of the cosmetic industry.

The market is also witnessing a trend towards the adoption of integrated treatment systems that combine multiple technologies, including chemical treatment with muriatic acid, to achieve optimal results. This approach is particularly appealing to large-scale cosmetic manufacturers looking to minimize their environmental footprint while ensuring compliance with regulatory standards.

In conclusion, the market for cosmetic industry wastewater treatment, including the use of muriatic acid, presents significant opportunities for growth and innovation. As the beauty industry continues to expand and environmental regulations become more stringent, the demand for effective and sustainable wastewater treatment solutions is expected to rise, driving further advancements in treatment technologies and market expansion.

Current Challenges in Cosmetic Wastewater Treatment

The cosmetic industry faces significant challenges in treating its wastewater due to the complex nature of the effluents produced. These wastewaters often contain a wide range of pollutants, including surfactants, emulsifiers, preservatives, dyes, and various organic and inorganic compounds. The high concentration of these substances makes traditional treatment methods less effective and more costly.

One of the primary challenges is the removal of persistent organic pollutants (POPs) and emerging contaminants of concern (ECCs). These compounds are often resistant to conventional biological treatment processes and can pass through traditional wastewater treatment plants unchanged. Their presence in treated effluents poses potential risks to aquatic ecosystems and human health.

Another significant issue is the high chemical oxygen demand (COD) and biochemical oxygen demand (BOD) of cosmetic wastewater. These parameters indicate the amount of organic matter present, which can lead to oxygen depletion in receiving water bodies if not adequately treated. The high COD and BOD levels also make it difficult to meet increasingly stringent discharge regulations.

The presence of color in cosmetic wastewater presents an additional challenge. Many cosmetic products contain dyes and pigments that are difficult to remove through conventional treatment methods. These colorants not only affect the aesthetic quality of the receiving water bodies but can also interfere with photosynthetic processes in aquatic ecosystems.

Emulsified oils and fats, commonly found in cosmetic formulations, create another hurdle in wastewater treatment. These substances can form stable emulsions that are resistant to separation, making oil-water separation techniques less effective. The presence of emulsified oils can also interfere with biological treatment processes by coating microbial populations and reducing their efficiency.

The variability in wastewater composition poses a significant challenge for treatment plant operators. The cosmetic industry produces a wide range of products, each with its unique formulation. This diversity results in fluctuating wastewater characteristics, making it difficult to design and operate a single, effective treatment system that can handle all variations.

Lastly, the increasing focus on sustainability and environmental regulations has put pressure on the cosmetic industry to adopt more advanced and eco-friendly wastewater treatment technologies. This shift requires significant investment in research and development, as well as the implementation of new treatment processes, which can be costly and time-consuming for manufacturers.

One of the primary challenges is the removal of persistent organic pollutants (POPs) and emerging contaminants of concern (ECCs). These compounds are often resistant to conventional biological treatment processes and can pass through traditional wastewater treatment plants unchanged. Their presence in treated effluents poses potential risks to aquatic ecosystems and human health.

Another significant issue is the high chemical oxygen demand (COD) and biochemical oxygen demand (BOD) of cosmetic wastewater. These parameters indicate the amount of organic matter present, which can lead to oxygen depletion in receiving water bodies if not adequately treated. The high COD and BOD levels also make it difficult to meet increasingly stringent discharge regulations.

The presence of color in cosmetic wastewater presents an additional challenge. Many cosmetic products contain dyes and pigments that are difficult to remove through conventional treatment methods. These colorants not only affect the aesthetic quality of the receiving water bodies but can also interfere with photosynthetic processes in aquatic ecosystems.

Emulsified oils and fats, commonly found in cosmetic formulations, create another hurdle in wastewater treatment. These substances can form stable emulsions that are resistant to separation, making oil-water separation techniques less effective. The presence of emulsified oils can also interfere with biological treatment processes by coating microbial populations and reducing their efficiency.

The variability in wastewater composition poses a significant challenge for treatment plant operators. The cosmetic industry produces a wide range of products, each with its unique formulation. This diversity results in fluctuating wastewater characteristics, making it difficult to design and operate a single, effective treatment system that can handle all variations.

Lastly, the increasing focus on sustainability and environmental regulations has put pressure on the cosmetic industry to adopt more advanced and eco-friendly wastewater treatment technologies. This shift requires significant investment in research and development, as well as the implementation of new treatment processes, which can be costly and time-consuming for manufacturers.

Existing Muriatic Acid Treatment Solutions

01 Acid treatment for metal surface preparation

Muriatic acid, also known as hydrochloric acid, is used for metal surface preparation, particularly in the treatment of steel and other metals. The acid effectively removes rust, scale, and other contaminants, improving the surface quality for subsequent processes such as coating or welding. The treatment efficiency can be enhanced by controlling factors like acid concentration, temperature, and exposure time.- Acid treatment for metal surface preparation: Muriatic acid, also known as hydrochloric acid, is used for metal surface preparation, particularly in the treatment of steel and other metals. The acid effectively removes rust, scale, and other contaminants, improving the surface quality for subsequent processes such as coating or welding. The treatment efficiency can be enhanced by controlling factors like acid concentration, temperature, and exposure time.

- Wastewater treatment using muriatic acid: Muriatic acid is employed in wastewater treatment processes to adjust pH levels and remove contaminants. The acid's efficiency in neutralizing alkaline wastewater and precipitating certain pollutants makes it valuable in industrial and municipal water treatment applications. Proper dosing and mixing techniques are crucial for optimizing the treatment efficiency.

- Acid cleaning in industrial processes: Muriatic acid is widely used for cleaning and descaling in various industrial processes, including heat exchangers, boilers, and pipelines. The acid's effectiveness in dissolving mineral deposits and removing scale improves equipment efficiency and extends operational life. Factors such as acid concentration, circulation rate, and temperature influence the cleaning efficiency.

- Acid etching for concrete and masonry: Muriatic acid is utilized for etching concrete and masonry surfaces to improve adhesion for coatings or to achieve decorative effects. The acid treatment opens up the pores of the surface, creating a better bond for subsequent applications. Proper dilution, application techniques, and safety measures are essential for achieving optimal etching efficiency.

- Acid treatment in oil and gas industry: Muriatic acid plays a crucial role in the oil and gas industry, particularly in well stimulation and formation damage removal. The acid is used to dissolve carbonate minerals and increase permeability in reservoir rocks, enhancing oil and gas production. Treatment efficiency depends on factors such as acid concentration, injection rate, and formation characteristics.

02 Wastewater treatment using muriatic acid

Muriatic acid is employed in wastewater treatment processes to adjust pH levels and remove contaminants. The acid's efficiency in neutralizing alkaline wastewater and precipitating certain pollutants makes it valuable in industrial and municipal water treatment applications. Proper dosing and mixing techniques are crucial for optimizing the treatment efficiency.Expand Specific Solutions03 Acid cleaning of heat exchangers and industrial equipment

Muriatic acid is widely used for cleaning heat exchangers, boilers, and other industrial equipment. The acid effectively dissolves mineral deposits, scale, and fouling, improving heat transfer efficiency and equipment performance. Treatment efficiency can be enhanced by using appropriate acid concentrations, circulation methods, and inhibitors to protect metal surfaces.Expand Specific Solutions04 Acid treatment in oil and gas industry

In the oil and gas industry, muriatic acid treatment is used for well stimulation and formation damage removal. The acid dissolves carbonate minerals, increasing permeability and production rates. Treatment efficiency depends on factors such as acid concentration, pumping rate, and the use of additives to control reaction rates and protect equipment from corrosion.Expand Specific Solutions05 Acid etching for concrete and masonry surfaces

Muriatic acid is used for etching concrete and masonry surfaces to improve adhesion of coatings or to achieve decorative effects. The treatment efficiency is influenced by the acid concentration, application method, and surface preparation. Proper safety measures and neutralization techniques are essential for optimal results and environmental protection.Expand Specific Solutions

Key Players in Cosmetic Wastewater Treatment

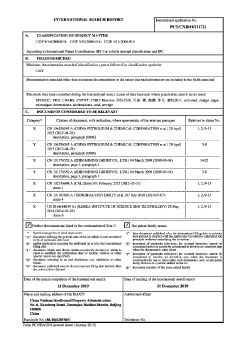

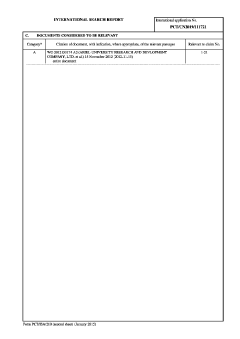

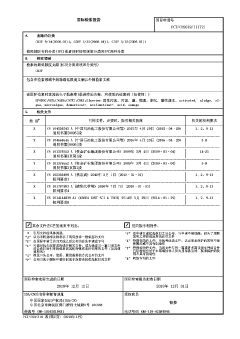

The research on using Muriatic Acid in cosmetic industry wastewater treatment is in an early development stage, with a relatively small but growing market. The technology's maturity is still evolving, with key players like BASF Corp., Zhejiang Qicai Environmental Technology Co Ltd., and China Petroleum & Chemical Corp. leading research efforts. As environmental regulations tighten, this niche is expected to expand, driven by the cosmetic industry's need for more effective and sustainable wastewater treatment solutions. The involvement of major chemical companies suggests potential for rapid advancements in this field.

BASF Corp.

Technical Solution: BASF Corp. has developed an advanced wastewater treatment system specifically for the cosmetic industry that incorporates muriatic acid (hydrochloric acid) in a multi-stage process. The system utilizes a pH adjustment step where muriatic acid is carefully dosed to optimize the removal of organic compounds and heavy metals[1]. This is followed by a coagulation-flocculation process enhanced by the acid treatment, which improves the settling of suspended solids. BASF's technology also includes an innovative membrane filtration stage that benefits from the acid pre-treatment, allowing for more efficient separation of contaminants[3]. The company has reported that this integrated approach can achieve up to 95% reduction in chemical oxygen demand (COD) and 99% removal of suspended solids in cosmetic industry wastewater[5].

Strengths: High efficiency in contaminant removal, versatile application in various cosmetic wastewater streams, and reduced chemical consumption. Weaknesses: Potential for corrosion in equipment due to acid use, and the need for careful pH control throughout the process.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has implemented a comprehensive wastewater treatment strategy for the cosmetic industry that incorporates muriatic acid. Their approach involves a preliminary acid treatment stage using muriatic acid to break down emulsions and facilitate the separation of oil and water phases[2]. This is followed by an advanced oxidation process (AOP) that benefits from the acidic conditions, enhancing the degradation of recalcitrant organic compounds. Sinopec's system also includes a novel electrocoagulation unit that operates more efficiently in the acid-treated wastewater, promoting the removal of colloidal particles and dissolved metals[4]. The company reports that this integrated system can achieve COD reduction rates of up to 98% and reduce total suspended solids by 99.5% in cosmetic industry effluents[6].

Strengths: High contaminant removal efficiency, effective handling of complex cosmetic wastewater compositions, and potential for water reuse. Weaknesses: Higher initial investment costs and the need for specialized operator training due to the complexity of the system.

Innovations in Muriatic Acid Application

Method for treating acidic organic wastewater and recycling

PatentActiveJP2022512024A

Innovation

- A method combining activated sludge treatment with microalgae treatment, utilizing specific bacterial compositions in the sludge to adapt to acidic conditions, self-adjust pH, and integrate CO2 utilization for resource recovery, simplifying the process and enhancing COD removal.

Method for purifying wastewater from reprocessing of crude aromatic nitro compounds

PatentWO2013020961A1

Innovation

- A process involving multiple washing stages with demulsifiers, using amphiphilic anionic copolymers to enhance phase separation and reduce the need for thermal and oxidative treatments, allowing for direct biological wastewater treatment of the resulting waste water.

Environmental Impact Assessment

The use of muriatic acid in the treatment of cosmetic industry wastewater presents both potential benefits and environmental concerns that require careful assessment. This treatment method can effectively neutralize alkaline wastewater and remove certain contaminants, but it also poses risks to ecosystems and human health if not properly managed.

One of the primary environmental impacts of using muriatic acid in wastewater treatment is the potential for pH alteration in receiving water bodies. If the treated effluent is not adequately neutralized before discharge, it can lead to acidification of aquatic ecosystems, disrupting the delicate balance of flora and fauna. This pH change can affect the survival and reproduction of various aquatic species, potentially causing long-term ecological damage.

The introduction of chloride ions from muriatic acid treatment into water systems is another significant concern. Elevated chloride levels can be toxic to freshwater organisms and may alter the overall salinity of water bodies, affecting the distribution and abundance of aquatic species. Furthermore, increased chloride concentrations can lead to the mobilization of heavy metals from sediments, exacerbating water pollution issues.

Air quality is also a consideration in the environmental impact assessment of muriatic acid use. The volatile nature of hydrochloric acid can result in the release of acidic fumes during the treatment process. These emissions may contribute to local air pollution and pose health risks to workers and nearby communities if not properly controlled through adequate ventilation and safety measures.

The potential for accidental spills or leaks during transportation, storage, or handling of muriatic acid presents another environmental hazard. Such incidents can lead to soil contamination, groundwater pollution, and damage to vegetation. The corrosive nature of the acid can also pose risks to infrastructure and equipment, necessitating proper containment and handling protocols.

On the positive side, the effective treatment of cosmetic industry wastewater using muriatic acid can significantly reduce the overall environmental footprint of these facilities. By removing contaminants such as heavy metals, organic compounds, and excess alkalinity, the treated water can be safely discharged or potentially reused, conserving water resources and minimizing the impact on natural water systems.

To mitigate the environmental risks associated with muriatic acid use, comprehensive monitoring and control measures must be implemented. This includes regular testing of treated effluent, installation of pH adjustment systems, proper acid storage and handling facilities, and the development of emergency response plans for potential spills or accidents. Additionally, exploring alternative treatment methods or combining muriatic acid treatment with other technologies may help optimize the process and reduce environmental impacts.

One of the primary environmental impacts of using muriatic acid in wastewater treatment is the potential for pH alteration in receiving water bodies. If the treated effluent is not adequately neutralized before discharge, it can lead to acidification of aquatic ecosystems, disrupting the delicate balance of flora and fauna. This pH change can affect the survival and reproduction of various aquatic species, potentially causing long-term ecological damage.

The introduction of chloride ions from muriatic acid treatment into water systems is another significant concern. Elevated chloride levels can be toxic to freshwater organisms and may alter the overall salinity of water bodies, affecting the distribution and abundance of aquatic species. Furthermore, increased chloride concentrations can lead to the mobilization of heavy metals from sediments, exacerbating water pollution issues.

Air quality is also a consideration in the environmental impact assessment of muriatic acid use. The volatile nature of hydrochloric acid can result in the release of acidic fumes during the treatment process. These emissions may contribute to local air pollution and pose health risks to workers and nearby communities if not properly controlled through adequate ventilation and safety measures.

The potential for accidental spills or leaks during transportation, storage, or handling of muriatic acid presents another environmental hazard. Such incidents can lead to soil contamination, groundwater pollution, and damage to vegetation. The corrosive nature of the acid can also pose risks to infrastructure and equipment, necessitating proper containment and handling protocols.

On the positive side, the effective treatment of cosmetic industry wastewater using muriatic acid can significantly reduce the overall environmental footprint of these facilities. By removing contaminants such as heavy metals, organic compounds, and excess alkalinity, the treated water can be safely discharged or potentially reused, conserving water resources and minimizing the impact on natural water systems.

To mitigate the environmental risks associated with muriatic acid use, comprehensive monitoring and control measures must be implemented. This includes regular testing of treated effluent, installation of pH adjustment systems, proper acid storage and handling facilities, and the development of emergency response plans for potential spills or accidents. Additionally, exploring alternative treatment methods or combining muriatic acid treatment with other technologies may help optimize the process and reduce environmental impacts.

Regulatory Compliance and Safety Measures

The use of muriatic acid in treating cosmetic industry wastewater requires strict adherence to regulatory compliance and implementation of robust safety measures. Regulatory bodies such as the Environmental Protection Agency (EPA) and Occupational Safety and Health Administration (OSHA) in the United States, and similar organizations worldwide, have established guidelines for the handling and disposal of hazardous chemicals, including muriatic acid.

Compliance with the Clean Water Act is paramount when treating wastewater. This legislation sets standards for the discharge of pollutants into water bodies and requires facilities to obtain permits for wastewater treatment processes. The National Pollutant Discharge Elimination System (NPDES) permit program is a crucial component of this regulatory framework, mandating specific treatment standards and monitoring requirements.

Safety measures for handling muriatic acid are extensive and must be rigorously followed. Personal protective equipment (PPE) is essential, including chemical-resistant gloves, goggles, face shields, and appropriate respiratory protection. Proper storage facilities with adequate ventilation and secondary containment systems are necessary to prevent accidental spills and exposure.

Emergency response plans must be in place, including eyewash stations, safety showers, and spill containment kits. Regular training of personnel on the safe handling of muriatic acid and emergency procedures is crucial. Material Safety Data Sheets (MSDS) should be readily available, and all containers must be properly labeled according to the Globally Harmonized System of Classification and Labeling of Chemicals (GHS).

Monitoring and record-keeping are vital aspects of regulatory compliance. Regular testing of treated wastewater to ensure it meets discharge standards is mandatory. Documentation of treatment processes, chemical usage, and disposal methods must be maintained and made available for regulatory inspections.

The transportation of muriatic acid is subject to Department of Transportation (DOT) regulations, requiring proper packaging, labeling, and documentation. Facilities must also comply with the Resource Conservation and Recovery Act (RCRA) for the proper disposal of hazardous waste generated during the treatment process.

Risk assessments and regular audits should be conducted to identify potential hazards and ensure ongoing compliance with evolving regulations. Implementing a comprehensive environmental management system, such as ISO 14001, can help organizations systematically manage their environmental responsibilities and demonstrate commitment to regulatory compliance.

Collaboration with local authorities and regulatory agencies is essential to stay informed about changes in regulations and to ensure that the wastewater treatment processes remain in compliance. This proactive approach can help prevent violations and associated penalties while fostering a positive relationship with regulatory bodies.

Compliance with the Clean Water Act is paramount when treating wastewater. This legislation sets standards for the discharge of pollutants into water bodies and requires facilities to obtain permits for wastewater treatment processes. The National Pollutant Discharge Elimination System (NPDES) permit program is a crucial component of this regulatory framework, mandating specific treatment standards and monitoring requirements.

Safety measures for handling muriatic acid are extensive and must be rigorously followed. Personal protective equipment (PPE) is essential, including chemical-resistant gloves, goggles, face shields, and appropriate respiratory protection. Proper storage facilities with adequate ventilation and secondary containment systems are necessary to prevent accidental spills and exposure.

Emergency response plans must be in place, including eyewash stations, safety showers, and spill containment kits. Regular training of personnel on the safe handling of muriatic acid and emergency procedures is crucial. Material Safety Data Sheets (MSDS) should be readily available, and all containers must be properly labeled according to the Globally Harmonized System of Classification and Labeling of Chemicals (GHS).

Monitoring and record-keeping are vital aspects of regulatory compliance. Regular testing of treated wastewater to ensure it meets discharge standards is mandatory. Documentation of treatment processes, chemical usage, and disposal methods must be maintained and made available for regulatory inspections.

The transportation of muriatic acid is subject to Department of Transportation (DOT) regulations, requiring proper packaging, labeling, and documentation. Facilities must also comply with the Resource Conservation and Recovery Act (RCRA) for the proper disposal of hazardous waste generated during the treatment process.

Risk assessments and regular audits should be conducted to identify potential hazards and ensure ongoing compliance with evolving regulations. Implementing a comprehensive environmental management system, such as ISO 14001, can help organizations systematically manage their environmental responsibilities and demonstrate commitment to regulatory compliance.

Collaboration with local authorities and regulatory agencies is essential to stay informed about changes in regulations and to ensure that the wastewater treatment processes remain in compliance. This proactive approach can help prevent violations and associated penalties while fostering a positive relationship with regulatory bodies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!