Muriatic Acid in the Treatment of Semiconductor Industry Wastewater

JUL 18, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Muriatic Acid Treatment Background and Objectives

The semiconductor industry has been a cornerstone of technological advancement for decades, driving innovation in electronics, computing, and communications. However, this progress comes at an environmental cost, particularly in the form of wastewater generated during the manufacturing process. One of the most significant challenges in semiconductor wastewater treatment is the presence of hydrofluoric acid (HF), a highly corrosive and toxic substance used extensively in chip production.

Muriatic acid, also known as hydrochloric acid (HCl), has emerged as a potential solution for treating semiconductor industry wastewater. This research aims to explore the efficacy, safety, and sustainability of using muriatic acid in this context. The primary objective is to develop a comprehensive understanding of how muriatic acid can neutralize and remove harmful contaminants, particularly HF, from semiconductor wastewater.

The use of muriatic acid in wastewater treatment is not a new concept, but its application in the semiconductor industry presents unique challenges and opportunities. This research seeks to build upon existing knowledge of acid-base neutralization reactions and expand it to address the specific needs of semiconductor wastewater treatment. By doing so, we aim to contribute to the development of more efficient and environmentally friendly wastewater treatment processes for the semiconductor industry.

Another key objective of this research is to evaluate the potential of muriatic acid treatment to reduce the environmental impact of semiconductor manufacturing. This includes assessing its ability to meet increasingly stringent environmental regulations and standards, as well as its potential to improve the overall sustainability of semiconductor production processes.

Furthermore, this study aims to investigate the economic viability of implementing muriatic acid treatment systems in semiconductor facilities. This involves analyzing the costs associated with the treatment process, including equipment, chemicals, and operational expenses, and comparing them to the potential benefits, such as reduced environmental liabilities and improved resource recovery.

Lastly, this research seeks to identify any potential drawbacks or limitations of using muriatic acid in semiconductor wastewater treatment. This includes examining possible safety concerns, assessing the impact on downstream processes, and exploring any long-term effects on the treated water and the environment. By addressing these aspects, we aim to provide a balanced and comprehensive evaluation of muriatic acid as a treatment option for semiconductor industry wastewater.

Muriatic acid, also known as hydrochloric acid (HCl), has emerged as a potential solution for treating semiconductor industry wastewater. This research aims to explore the efficacy, safety, and sustainability of using muriatic acid in this context. The primary objective is to develop a comprehensive understanding of how muriatic acid can neutralize and remove harmful contaminants, particularly HF, from semiconductor wastewater.

The use of muriatic acid in wastewater treatment is not a new concept, but its application in the semiconductor industry presents unique challenges and opportunities. This research seeks to build upon existing knowledge of acid-base neutralization reactions and expand it to address the specific needs of semiconductor wastewater treatment. By doing so, we aim to contribute to the development of more efficient and environmentally friendly wastewater treatment processes for the semiconductor industry.

Another key objective of this research is to evaluate the potential of muriatic acid treatment to reduce the environmental impact of semiconductor manufacturing. This includes assessing its ability to meet increasingly stringent environmental regulations and standards, as well as its potential to improve the overall sustainability of semiconductor production processes.

Furthermore, this study aims to investigate the economic viability of implementing muriatic acid treatment systems in semiconductor facilities. This involves analyzing the costs associated with the treatment process, including equipment, chemicals, and operational expenses, and comparing them to the potential benefits, such as reduced environmental liabilities and improved resource recovery.

Lastly, this research seeks to identify any potential drawbacks or limitations of using muriatic acid in semiconductor wastewater treatment. This includes examining possible safety concerns, assessing the impact on downstream processes, and exploring any long-term effects on the treated water and the environment. By addressing these aspects, we aim to provide a balanced and comprehensive evaluation of muriatic acid as a treatment option for semiconductor industry wastewater.

Semiconductor Wastewater Market Analysis

The semiconductor wastewater treatment market has been experiencing significant growth in recent years, driven by the expanding semiconductor industry and increasing environmental regulations. As semiconductor manufacturing processes become more complex and production volumes rise, the generation of wastewater containing various pollutants, including heavy metals, organic compounds, and acids, has also increased.

The global semiconductor wastewater treatment market is expected to continue its upward trajectory, with Asia-Pacific region leading the growth. Countries like China, Taiwan, South Korea, and Japan are major contributors to this market due to their dominant position in semiconductor manufacturing. North America and Europe also hold substantial market shares, primarily due to stringent environmental regulations and the presence of established semiconductor companies.

The market is characterized by a growing demand for advanced treatment technologies that can effectively remove contaminants while minimizing water and energy consumption. Membrane-based technologies, such as reverse osmosis and nanofiltration, are gaining popularity due to their high efficiency in removing dissolved solids and organic compounds. Additionally, there is an increasing focus on water recycling and reuse within semiconductor facilities to reduce overall water consumption and operational costs.

The use of muriatic acid (hydrochloric acid) in semiconductor wastewater treatment is part of a broader trend towards more efficient and cost-effective treatment solutions. Muriatic acid is primarily used for pH adjustment and as a cleaning agent in various stages of the treatment process. Its effectiveness in removing metal contaminants and its relatively low cost make it an attractive option for many semiconductor manufacturers.

Key market drivers include the growing awareness of environmental issues, stricter government regulations on industrial wastewater discharge, and the semiconductor industry's push towards sustainability. The increasing adoption of advanced process technologies in semiconductor manufacturing, such as extreme ultraviolet (EUV) lithography, is also contributing to the complexity of wastewater streams, necessitating more sophisticated treatment solutions.

However, the market also faces challenges, including the high initial investment required for advanced treatment systems and the need for skilled personnel to operate and maintain these systems. Additionally, the cyclical nature of the semiconductor industry can lead to fluctuations in demand for wastewater treatment solutions.

The global semiconductor wastewater treatment market is expected to continue its upward trajectory, with Asia-Pacific region leading the growth. Countries like China, Taiwan, South Korea, and Japan are major contributors to this market due to their dominant position in semiconductor manufacturing. North America and Europe also hold substantial market shares, primarily due to stringent environmental regulations and the presence of established semiconductor companies.

The market is characterized by a growing demand for advanced treatment technologies that can effectively remove contaminants while minimizing water and energy consumption. Membrane-based technologies, such as reverse osmosis and nanofiltration, are gaining popularity due to their high efficiency in removing dissolved solids and organic compounds. Additionally, there is an increasing focus on water recycling and reuse within semiconductor facilities to reduce overall water consumption and operational costs.

The use of muriatic acid (hydrochloric acid) in semiconductor wastewater treatment is part of a broader trend towards more efficient and cost-effective treatment solutions. Muriatic acid is primarily used for pH adjustment and as a cleaning agent in various stages of the treatment process. Its effectiveness in removing metal contaminants and its relatively low cost make it an attractive option for many semiconductor manufacturers.

Key market drivers include the growing awareness of environmental issues, stricter government regulations on industrial wastewater discharge, and the semiconductor industry's push towards sustainability. The increasing adoption of advanced process technologies in semiconductor manufacturing, such as extreme ultraviolet (EUV) lithography, is also contributing to the complexity of wastewater streams, necessitating more sophisticated treatment solutions.

However, the market also faces challenges, including the high initial investment required for advanced treatment systems and the need for skilled personnel to operate and maintain these systems. Additionally, the cyclical nature of the semiconductor industry can lead to fluctuations in demand for wastewater treatment solutions.

Current Challenges in Wastewater Treatment

The semiconductor industry's wastewater treatment faces several significant challenges due to the complex nature of the effluents and stringent environmental regulations. One of the primary issues is the high concentration of heavy metals, such as copper, lead, and zinc, which are toxic to aquatic life and can accumulate in the food chain. Traditional treatment methods often struggle to remove these metals effectively, especially at low concentrations.

Another major challenge is the presence of organic compounds, including photoresists and solvents, which are difficult to break down and can interfere with biological treatment processes. These compounds may also form recalcitrant complexes with metals, further complicating their removal. The high variability in wastewater composition, due to batch processes and changing production lines, makes it challenging to design a single, effective treatment system.

The semiconductor industry also generates large volumes of ultra-pure water, which, after use, contains trace contaminants that are hard to detect and remove. This requires advanced analytical techniques and treatment technologies to ensure compliance with increasingly strict discharge limits. The presence of fluoride, a common etchant, poses additional treatment difficulties due to its high solubility and potential to form stable complexes with other contaminants.

Energy consumption and cost-effectiveness remain significant concerns in wastewater treatment. Many advanced treatment technologies, such as reverse osmosis and advanced oxidation processes, are energy-intensive and expensive to operate. Balancing treatment efficacy with operational costs is a constant challenge for semiconductor facilities.

The management of concentrated waste streams, such as spent etchants and plating baths, presents another hurdle. These streams often require specialized treatment or disposal methods, which can be costly and potentially hazardous. Additionally, the recovery and reuse of valuable materials from wastewater, such as precious metals and rare earth elements, is becoming increasingly important but technologically challenging.

Emerging contaminants, including nanomaterials and per- and polyfluoroalkyl substances (PFAS), are raising new concerns in semiconductor wastewater treatment. These substances have unknown long-term environmental impacts and are not effectively removed by conventional treatment methods. Developing new technologies to address these contaminants while maintaining treatment efficiency for existing pollutants is a pressing challenge.

Another major challenge is the presence of organic compounds, including photoresists and solvents, which are difficult to break down and can interfere with biological treatment processes. These compounds may also form recalcitrant complexes with metals, further complicating their removal. The high variability in wastewater composition, due to batch processes and changing production lines, makes it challenging to design a single, effective treatment system.

The semiconductor industry also generates large volumes of ultra-pure water, which, after use, contains trace contaminants that are hard to detect and remove. This requires advanced analytical techniques and treatment technologies to ensure compliance with increasingly strict discharge limits. The presence of fluoride, a common etchant, poses additional treatment difficulties due to its high solubility and potential to form stable complexes with other contaminants.

Energy consumption and cost-effectiveness remain significant concerns in wastewater treatment. Many advanced treatment technologies, such as reverse osmosis and advanced oxidation processes, are energy-intensive and expensive to operate. Balancing treatment efficacy with operational costs is a constant challenge for semiconductor facilities.

The management of concentrated waste streams, such as spent etchants and plating baths, presents another hurdle. These streams often require specialized treatment or disposal methods, which can be costly and potentially hazardous. Additionally, the recovery and reuse of valuable materials from wastewater, such as precious metals and rare earth elements, is becoming increasingly important but technologically challenging.

Emerging contaminants, including nanomaterials and per- and polyfluoroalkyl substances (PFAS), are raising new concerns in semiconductor wastewater treatment. These substances have unknown long-term environmental impacts and are not effectively removed by conventional treatment methods. Developing new technologies to address these contaminants while maintaining treatment efficiency for existing pollutants is a pressing challenge.

Existing Muriatic Acid Treatment Techniques

01 Industrial applications of muriatic acid

Muriatic acid, also known as hydrochloric acid, has various industrial applications. It is used in metal cleaning and pickling processes, particularly in the steel industry. The acid is also employed in the production of chemicals, water treatment, and as a pH regulator in various industrial processes.- Production and purification of muriatic acid: Muriatic acid, also known as hydrochloric acid, can be produced and purified through various industrial processes. These methods may involve the reaction of hydrogen and chlorine gases, or the treatment of chloride salts with sulfuric acid. Purification techniques can include distillation or membrane separation to remove impurities and achieve desired concentrations.

- Applications in metal treatment and surface cleaning: Muriatic acid is widely used in metal treatment processes, such as pickling, etching, and surface cleaning. It can effectively remove rust, scale, and other contaminants from metal surfaces. The acid is particularly useful in preparing metal surfaces for further processing, such as painting or plating.

- Use in construction and building materials: Muriatic acid finds applications in the construction industry, particularly in the treatment of concrete and masonry surfaces. It can be used for cleaning, etching, or preparing surfaces for further treatment. The acid is also employed in the production of certain building materials and in the maintenance of swimming pools.

- Environmental and safety considerations: Handling and disposal of muriatic acid require careful consideration of environmental and safety factors. Proper storage, transportation, and use of the acid are essential to prevent accidents and minimize environmental impact. Neutralization techniques and specialized equipment may be necessary for safe handling and disposal of the acid.

- Industrial and chemical processing applications: Muriatic acid is a versatile chemical used in various industrial processes. It serves as a reagent in chemical synthesis, pH adjustment, and as a catalyst in certain reactions. The acid is also employed in the production of pharmaceuticals, food additives, and in water treatment processes.

02 Cleaning and etching applications

Muriatic acid is widely used in cleaning and etching applications. It is effective in removing rust, scale, and other deposits from metal surfaces. In the construction industry, it is used for cleaning masonry and concrete surfaces. The acid is also utilized in pool maintenance to balance pH levels and remove stains.Expand Specific Solutions03 Production and handling of muriatic acid

The production of muriatic acid involves various processes, including the reaction of hydrogen and chlorine gases. Specialized equipment and safety measures are required for its production, storage, and handling due to its corrosive nature. Innovations in production methods focus on improving efficiency and reducing environmental impact.Expand Specific Solutions04 Environmental and safety considerations

Due to its corrosive nature, the use of muriatic acid requires strict safety protocols. Proper handling, storage, and disposal methods are essential to prevent environmental contamination and ensure worker safety. Innovations in this area include the development of safer formulations and improved containment systems.Expand Specific Solutions05 Alternative applications and formulations

Research is ongoing to develop alternative applications and formulations of muriatic acid. This includes its use in specialized chemical processes, such as the production of pharmaceuticals and advanced materials. Modified formulations aim to reduce corrosiveness while maintaining effectiveness for specific applications.Expand Specific Solutions

Key Players in Semiconductor Wastewater Management

The semiconductor industry's wastewater treatment using muriatic acid is in a mature stage, with a growing market due to increasing environmental regulations and sustainability concerns. The global market size for semiconductor wastewater treatment is estimated to be in the billions of dollars, driven by the expanding semiconductor industry. Technologically, the field is well-developed, with companies like Samsung Electronics, SCREEN Holdings, and Lam Research offering advanced solutions. However, there's ongoing research to improve efficiency and reduce environmental impact. Companies such as Mega Union Technology and Nomura Micro Science specialize in water treatment systems for the semiconductor industry, indicating a competitive and specialized market landscape.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung Electronics has developed a comprehensive wastewater treatment system for its semiconductor facilities that incorporates muriatic acid treatment. Their approach begins with a pre-treatment stage using muriatic acid to adjust pH and precipitate heavy metals. This is followed by a biological treatment process using specially adapted microorganisms capable of degrading semiconductor-specific pollutants. The final stage involves advanced membrane technologies, including reverse osmosis and nanofiltration, to produce high-quality water suitable for reuse[7][9]. Samsung has reported achieving water recovery rates of up to 90% in some of its facilities, significantly reducing freshwater consumption[8]. The company has also implemented real-time monitoring systems to optimize muriatic acid dosing and overall treatment efficiency.

Strengths: High water recovery rate, integration of biological and physical treatment methods. Weaknesses: Complex system requiring skilled operation, potential for membrane fouling in the final treatment stage.

Lam Research Corp.

Technical Solution: Lam Research Corp. has pioneered a novel approach to semiconductor wastewater treatment incorporating muriatic acid. Their system integrates muriatic acid treatment with advanced oxidation processes (AOPs) and electrochemical methods. The process begins with a precise dosing of muriatic acid to optimize pH for subsequent treatment steps. This is followed by an AOP stage using UV light and hydrogen peroxide to break down complex organic compounds. The final stage employs electrochemical oxidation to further degrade recalcitrant pollutants and polish the effluent[2][4]. Lam Research reports that this integrated approach can reduce chemical oxygen demand (COD) by up to 95% and achieve near-complete removal of perfluoroalkyl substances (PFAS), which are common in semiconductor manufacturing[6].

Strengths: Effective removal of both organic and inorganic contaminants, including emerging pollutants like PFAS. Weaknesses: High energy consumption due to UV and electrochemical processes, potential formation of byproducts during oxidation.

Innovative Approaches in Acid-Based Wastewater Treatment

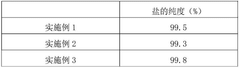

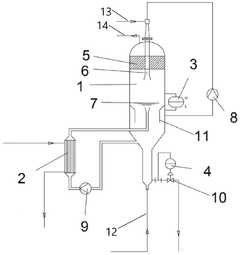

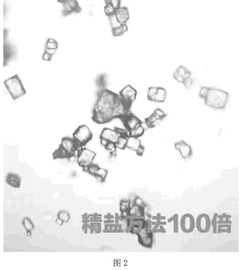

Self-consistent resourceful treatment apparatus and method for salt-containing wastewater and hydrochloric acid-containing waste gas

PatentWO2024074057A9

Innovation

- By using a self-consistent absorption reactor, the salt-containing wastewater and hydrochloric acid-containing waste gas are simultaneously passed into the reactor, and the self-consistent absorption reaction is carried out. The circulation cooler and cooling force circulation pump are used to cool, so as to achieve efficient absorption of HCl and complete precipitation of NaCl, and industrial-grade hydrochloric acid is obtained.

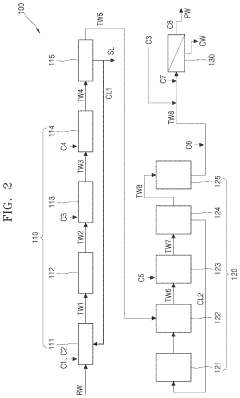

Method and apparatus for reusing wastewater

PatentActiveUS11945744B2

Innovation

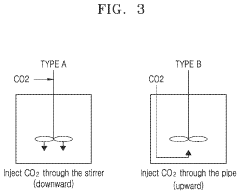

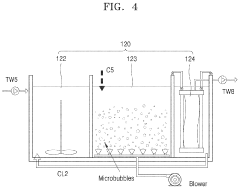

- A method and apparatus that combines flocculation-sedimentation, membrane bioreactor, and reverse-osmosis processes to treat mixed wastewaters, using slack lime, hydrogen peroxide scavengers, pH control agents, and anionic polymers to reduce fluoride and calcium concentrations, and carbon dioxide to minimize chemical usage and enhance operational safety.

Environmental Regulations and Compliance

The treatment of semiconductor industry wastewater using muriatic acid is subject to stringent environmental regulations and compliance requirements. These regulations are designed to protect human health and the environment from potential hazards associated with the use and disposal of hazardous chemicals.

At the federal level in the United States, the Environmental Protection Agency (EPA) regulates the use of muriatic acid in industrial processes under the Clean Water Act and the Resource Conservation and Recovery Act. The Clean Water Act establishes limits on the discharge of pollutants into water bodies, while the Resource Conservation and Recovery Act governs the management and disposal of hazardous waste.

Semiconductor manufacturers must obtain National Pollutant Discharge Elimination System (NPDES) permits, which set specific limits on the concentration of pollutants in wastewater discharges. These permits often require regular monitoring and reporting of effluent quality to ensure compliance with established standards.

The Occupational Safety and Health Administration (OSHA) also plays a crucial role in regulating the use of muriatic acid in industrial settings. OSHA standards mandate proper handling, storage, and disposal procedures to protect workers from potential exposure to hazardous chemicals.

At the state and local levels, additional regulations may apply. Many states have implemented their own environmental protection agencies and regulations that are often more stringent than federal standards. Local municipalities may also impose specific requirements for wastewater treatment and disposal.

Compliance with these regulations requires semiconductor manufacturers to implement comprehensive wastewater treatment systems and management practices. This typically involves the use of neutralization processes to adjust the pH of acidic wastewater, as well as advanced treatment technologies to remove other contaminants such as heavy metals and organic compounds.

Companies must also maintain detailed records of their wastewater treatment processes, including chemical usage, effluent quality, and disposal methods. Regular audits and inspections by regulatory agencies are conducted to ensure ongoing compliance with environmental regulations.

Failure to comply with these regulations can result in severe penalties, including fines, legal action, and potential shutdown of operations. As such, semiconductor manufacturers must prioritize environmental compliance in their wastewater treatment strategies, including the use of muriatic acid.

At the federal level in the United States, the Environmental Protection Agency (EPA) regulates the use of muriatic acid in industrial processes under the Clean Water Act and the Resource Conservation and Recovery Act. The Clean Water Act establishes limits on the discharge of pollutants into water bodies, while the Resource Conservation and Recovery Act governs the management and disposal of hazardous waste.

Semiconductor manufacturers must obtain National Pollutant Discharge Elimination System (NPDES) permits, which set specific limits on the concentration of pollutants in wastewater discharges. These permits often require regular monitoring and reporting of effluent quality to ensure compliance with established standards.

The Occupational Safety and Health Administration (OSHA) also plays a crucial role in regulating the use of muriatic acid in industrial settings. OSHA standards mandate proper handling, storage, and disposal procedures to protect workers from potential exposure to hazardous chemicals.

At the state and local levels, additional regulations may apply. Many states have implemented their own environmental protection agencies and regulations that are often more stringent than federal standards. Local municipalities may also impose specific requirements for wastewater treatment and disposal.

Compliance with these regulations requires semiconductor manufacturers to implement comprehensive wastewater treatment systems and management practices. This typically involves the use of neutralization processes to adjust the pH of acidic wastewater, as well as advanced treatment technologies to remove other contaminants such as heavy metals and organic compounds.

Companies must also maintain detailed records of their wastewater treatment processes, including chemical usage, effluent quality, and disposal methods. Regular audits and inspections by regulatory agencies are conducted to ensure ongoing compliance with environmental regulations.

Failure to comply with these regulations can result in severe penalties, including fines, legal action, and potential shutdown of operations. As such, semiconductor manufacturers must prioritize environmental compliance in their wastewater treatment strategies, including the use of muriatic acid.

Cost-Benefit Analysis of Muriatic Acid Treatment

The cost-benefit analysis of muriatic acid treatment in semiconductor industry wastewater management is a critical consideration for manufacturers seeking to optimize their operations. This analysis encompasses both direct and indirect costs associated with the implementation of muriatic acid treatment systems, as well as the potential benefits derived from improved wastewater quality and regulatory compliance.

Initial capital expenditures for muriatic acid treatment systems can be substantial, including equipment costs for storage tanks, dosing pumps, and monitoring devices. Additionally, facility modifications may be necessary to accommodate the treatment process, further increasing upfront investments. Ongoing operational expenses include the procurement of muriatic acid, maintenance of treatment equipment, and training of personnel to handle the corrosive substance safely.

However, these costs must be weighed against the potential benefits of implementing muriatic acid treatment. One significant advantage is the effective removal of metal contaminants from wastewater, which can lead to improved effluent quality and reduced environmental impact. This, in turn, may result in lower discharge fees and a decreased risk of regulatory non-compliance penalties.

Furthermore, the use of muriatic acid can enhance the efficiency of subsequent treatment processes, potentially reducing overall treatment costs in the long term. By effectively neutralizing alkaline wastewater and removing metal ions, muriatic acid treatment can extend the lifespan of downstream equipment and minimize the need for additional chemical treatments.

Another consideration is the potential for resource recovery. Muriatic acid treatment can facilitate the precipitation of valuable metals from wastewater, which may be recovered and sold, offsetting some of the treatment costs. This aspect of the process aligns with circular economy principles and can contribute to a company's sustainability goals.

It is important to note that the cost-benefit ratio of muriatic acid treatment can vary significantly depending on factors such as wastewater composition, treatment volume, and local regulations. Semiconductor manufacturers must conduct thorough site-specific analyses to determine the economic viability of implementing this treatment method.

In conclusion, while the initial costs of muriatic acid treatment systems may be substantial, the long-term benefits in terms of improved wastewater quality, regulatory compliance, and potential resource recovery can justify the investment for many semiconductor manufacturers. A comprehensive cost-benefit analysis, taking into account both quantitative and qualitative factors, is essential for making informed decisions regarding the adoption of muriatic acid treatment in semiconductor industry wastewater management.

Initial capital expenditures for muriatic acid treatment systems can be substantial, including equipment costs for storage tanks, dosing pumps, and monitoring devices. Additionally, facility modifications may be necessary to accommodate the treatment process, further increasing upfront investments. Ongoing operational expenses include the procurement of muriatic acid, maintenance of treatment equipment, and training of personnel to handle the corrosive substance safely.

However, these costs must be weighed against the potential benefits of implementing muriatic acid treatment. One significant advantage is the effective removal of metal contaminants from wastewater, which can lead to improved effluent quality and reduced environmental impact. This, in turn, may result in lower discharge fees and a decreased risk of regulatory non-compliance penalties.

Furthermore, the use of muriatic acid can enhance the efficiency of subsequent treatment processes, potentially reducing overall treatment costs in the long term. By effectively neutralizing alkaline wastewater and removing metal ions, muriatic acid treatment can extend the lifespan of downstream equipment and minimize the need for additional chemical treatments.

Another consideration is the potential for resource recovery. Muriatic acid treatment can facilitate the precipitation of valuable metals from wastewater, which may be recovered and sold, offsetting some of the treatment costs. This aspect of the process aligns with circular economy principles and can contribute to a company's sustainability goals.

It is important to note that the cost-benefit ratio of muriatic acid treatment can vary significantly depending on factors such as wastewater composition, treatment volume, and local regulations. Semiconductor manufacturers must conduct thorough site-specific analyses to determine the economic viability of implementing this treatment method.

In conclusion, while the initial costs of muriatic acid treatment systems may be substantial, the long-term benefits in terms of improved wastewater quality, regulatory compliance, and potential resource recovery can justify the investment for many semiconductor manufacturers. A comprehensive cost-benefit analysis, taking into account both quantitative and qualitative factors, is essential for making informed decisions regarding the adoption of muriatic acid treatment in semiconductor industry wastewater management.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!