Muriatic Acid in the Treatment of Textile Mill Effluents

JUL 18, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Muriatic Acid in Textile Effluents: Background and Objectives

The textile industry has long been recognized as a significant contributor to water pollution due to its extensive use of chemicals and water-intensive processes. Among the various pollutants found in textile mill effluents, acidic waste poses a particular challenge. In recent years, the use of muriatic acid, also known as hydrochloric acid (HCl), has emerged as a potential solution for treating these effluents. This research aims to explore the efficacy and implications of using muriatic acid in the treatment of textile mill wastewater.

The textile industry's historical reliance on chemical processes has led to the discharge of effluents containing a complex mixture of dyes, heavy metals, and other pollutants. These discharges have severe environmental consequences, affecting aquatic ecosystems and human health. As global awareness of environmental issues has grown, so too has the pressure on the textile industry to adopt more sustainable practices and effective treatment methods.

Muriatic acid, a strong mineral acid, has been traditionally used in various industrial applications, including metal cleaning and pH adjustment. Its potential in textile effluent treatment lies in its ability to neutralize alkaline waste streams, precipitate certain metals, and potentially aid in the breakdown of complex organic compounds found in dyes. The exploration of muriatic acid as a treatment option aligns with the industry's ongoing efforts to find cost-effective and efficient methods for wastewater management.

The objectives of this research are multifaceted. Primarily, it seeks to evaluate the effectiveness of muriatic acid in reducing the pollutant load of textile mill effluents, focusing on parameters such as pH, chemical oxygen demand (COD), biological oxygen demand (BOD), and color removal. Additionally, the study aims to assess the optimal conditions for muriatic acid application, including dosage, contact time, and integration with other treatment processes.

Furthermore, this research intends to investigate the potential environmental impacts of using muriatic acid in wastewater treatment. This includes examining the fate of chloride ions introduced into the effluent and their potential effects on receiving water bodies. The economic feasibility of implementing muriatic acid treatment on an industrial scale will also be evaluated, considering factors such as operational costs, equipment requirements, and potential savings from improved effluent quality.

As the textile industry continues to evolve, driven by both technological advancements and environmental regulations, the exploration of innovative treatment methods becomes increasingly crucial. This research on muriatic acid treatment not only addresses current challenges in textile effluent management but also contributes to the broader discourse on sustainable industrial practices and water conservation in the textile sector.

The textile industry's historical reliance on chemical processes has led to the discharge of effluents containing a complex mixture of dyes, heavy metals, and other pollutants. These discharges have severe environmental consequences, affecting aquatic ecosystems and human health. As global awareness of environmental issues has grown, so too has the pressure on the textile industry to adopt more sustainable practices and effective treatment methods.

Muriatic acid, a strong mineral acid, has been traditionally used in various industrial applications, including metal cleaning and pH adjustment. Its potential in textile effluent treatment lies in its ability to neutralize alkaline waste streams, precipitate certain metals, and potentially aid in the breakdown of complex organic compounds found in dyes. The exploration of muriatic acid as a treatment option aligns with the industry's ongoing efforts to find cost-effective and efficient methods for wastewater management.

The objectives of this research are multifaceted. Primarily, it seeks to evaluate the effectiveness of muriatic acid in reducing the pollutant load of textile mill effluents, focusing on parameters such as pH, chemical oxygen demand (COD), biological oxygen demand (BOD), and color removal. Additionally, the study aims to assess the optimal conditions for muriatic acid application, including dosage, contact time, and integration with other treatment processes.

Furthermore, this research intends to investigate the potential environmental impacts of using muriatic acid in wastewater treatment. This includes examining the fate of chloride ions introduced into the effluent and their potential effects on receiving water bodies. The economic feasibility of implementing muriatic acid treatment on an industrial scale will also be evaluated, considering factors such as operational costs, equipment requirements, and potential savings from improved effluent quality.

As the textile industry continues to evolve, driven by both technological advancements and environmental regulations, the exploration of innovative treatment methods becomes increasingly crucial. This research on muriatic acid treatment not only addresses current challenges in textile effluent management but also contributes to the broader discourse on sustainable industrial practices and water conservation in the textile sector.

Market Demand for Eco-Friendly Textile Wastewater Treatment

The textile industry's growing awareness of environmental sustainability has led to a significant increase in demand for eco-friendly wastewater treatment solutions. This shift is driven by several factors, including stricter environmental regulations, consumer preferences for sustainable products, and the industry's own commitment to reducing its ecological footprint.

Regulatory pressures have become a major driver for the adoption of eco-friendly textile wastewater treatment methods. Governments worldwide are implementing more stringent environmental policies, forcing textile manufacturers to seek effective and sustainable solutions for treating their effluents. This regulatory landscape has created a robust market for innovative treatment technologies that can effectively remove pollutants while minimizing environmental impact.

Consumer awareness and demand for sustainably produced textiles have also played a crucial role in shaping the market. As end-users become more environmentally conscious, they are increasingly choosing products from companies that demonstrate responsible water management practices. This trend has pushed textile manufacturers to invest in advanced wastewater treatment systems, not only to comply with regulations but also to enhance their brand image and meet consumer expectations.

The textile industry itself has recognized the long-term benefits of adopting eco-friendly wastewater treatment methods. These benefits include reduced water consumption through recycling, lower operational costs, and improved resource efficiency. As a result, many textile companies are proactively seeking innovative solutions that can treat their effluents effectively while aligning with their sustainability goals.

The market for eco-friendly textile wastewater treatment is experiencing rapid growth, with a particular focus on technologies that can address the complex mixture of pollutants found in textile effluents. There is a strong demand for solutions that can remove dyes, heavy metals, and other contaminants while being energy-efficient and cost-effective. This has led to increased research and development in areas such as advanced oxidation processes, membrane filtration, and biological treatment methods.

The use of muriatic acid (hydrochloric acid) in textile wastewater treatment has garnered attention as part of this eco-friendly trend. While traditionally used in various industrial processes, its potential in wastewater treatment is being explored as a more environmentally compatible option compared to some conventional chemical treatments. The market is showing interest in understanding how muriatic acid can be integrated into treatment processes to enhance efficiency and reduce environmental impact.

Regulatory pressures have become a major driver for the adoption of eco-friendly textile wastewater treatment methods. Governments worldwide are implementing more stringent environmental policies, forcing textile manufacturers to seek effective and sustainable solutions for treating their effluents. This regulatory landscape has created a robust market for innovative treatment technologies that can effectively remove pollutants while minimizing environmental impact.

Consumer awareness and demand for sustainably produced textiles have also played a crucial role in shaping the market. As end-users become more environmentally conscious, they are increasingly choosing products from companies that demonstrate responsible water management practices. This trend has pushed textile manufacturers to invest in advanced wastewater treatment systems, not only to comply with regulations but also to enhance their brand image and meet consumer expectations.

The textile industry itself has recognized the long-term benefits of adopting eco-friendly wastewater treatment methods. These benefits include reduced water consumption through recycling, lower operational costs, and improved resource efficiency. As a result, many textile companies are proactively seeking innovative solutions that can treat their effluents effectively while aligning with their sustainability goals.

The market for eco-friendly textile wastewater treatment is experiencing rapid growth, with a particular focus on technologies that can address the complex mixture of pollutants found in textile effluents. There is a strong demand for solutions that can remove dyes, heavy metals, and other contaminants while being energy-efficient and cost-effective. This has led to increased research and development in areas such as advanced oxidation processes, membrane filtration, and biological treatment methods.

The use of muriatic acid (hydrochloric acid) in textile wastewater treatment has garnered attention as part of this eco-friendly trend. While traditionally used in various industrial processes, its potential in wastewater treatment is being explored as a more environmentally compatible option compared to some conventional chemical treatments. The market is showing interest in understanding how muriatic acid can be integrated into treatment processes to enhance efficiency and reduce environmental impact.

Current Challenges in Textile Effluent Treatment

The textile industry faces significant challenges in treating its effluents, particularly when considering the use of muriatic acid (hydrochloric acid) as a treatment method. One of the primary concerns is the high volume of wastewater generated by textile mills, which can contain a complex mixture of dyes, chemicals, and other pollutants. This effluent often has extreme pH levels, high chemical oxygen demand (COD), and elevated levels of suspended solids, making treatment a complex and multifaceted process.

The use of muriatic acid in effluent treatment presents its own set of challenges. While it can be effective in neutralizing alkaline wastewater and aiding in the precipitation of certain pollutants, its corrosive nature poses risks to treatment infrastructure and requires careful handling. Additionally, the potential for chloride contamination in treated water must be carefully managed to meet environmental regulations and prevent ecological damage.

Another significant challenge is the variability in effluent composition due to the diverse range of processes and chemicals used in textile production. This variability makes it difficult to implement a one-size-fits-all treatment approach, necessitating adaptive and flexible treatment systems. The presence of recalcitrant dyes and other organic compounds further complicates treatment efforts, as these substances can be resistant to conventional treatment methods, including acid-based treatments.

The energy-intensive nature of many textile effluent treatment processes, including those involving acid treatments, presents both economic and environmental challenges. Balancing the need for effective treatment with energy efficiency and cost-effectiveness is an ongoing struggle for the industry. Moreover, the disposal of sludge generated during the treatment process, which may contain concentrated levels of pollutants and acid residues, requires careful management and often incurs significant costs.

Regulatory compliance presents another layer of complexity. Stringent environmental regulations regarding effluent quality are becoming increasingly common worldwide, pushing textile manufacturers to adopt more advanced treatment technologies. However, the implementation of these technologies, especially in developing countries where much of the textile production occurs, is often hindered by economic constraints and lack of technical expertise.

The potential for resource recovery from textile effluents, such as the reclamation of water, dyes, or chemicals, is an area of growing interest but faces technical and economic barriers. While acid treatments can play a role in some recovery processes, integrating these into comprehensive, sustainable treatment systems remains challenging. Additionally, the industry must address the broader issue of water scarcity, with pressure mounting to reduce overall water consumption in textile production and increase the efficiency of water reuse systems.

The use of muriatic acid in effluent treatment presents its own set of challenges. While it can be effective in neutralizing alkaline wastewater and aiding in the precipitation of certain pollutants, its corrosive nature poses risks to treatment infrastructure and requires careful handling. Additionally, the potential for chloride contamination in treated water must be carefully managed to meet environmental regulations and prevent ecological damage.

Another significant challenge is the variability in effluent composition due to the diverse range of processes and chemicals used in textile production. This variability makes it difficult to implement a one-size-fits-all treatment approach, necessitating adaptive and flexible treatment systems. The presence of recalcitrant dyes and other organic compounds further complicates treatment efforts, as these substances can be resistant to conventional treatment methods, including acid-based treatments.

The energy-intensive nature of many textile effluent treatment processes, including those involving acid treatments, presents both economic and environmental challenges. Balancing the need for effective treatment with energy efficiency and cost-effectiveness is an ongoing struggle for the industry. Moreover, the disposal of sludge generated during the treatment process, which may contain concentrated levels of pollutants and acid residues, requires careful management and often incurs significant costs.

Regulatory compliance presents another layer of complexity. Stringent environmental regulations regarding effluent quality are becoming increasingly common worldwide, pushing textile manufacturers to adopt more advanced treatment technologies. However, the implementation of these technologies, especially in developing countries where much of the textile production occurs, is often hindered by economic constraints and lack of technical expertise.

The potential for resource recovery from textile effluents, such as the reclamation of water, dyes, or chemicals, is an area of growing interest but faces technical and economic barriers. While acid treatments can play a role in some recovery processes, integrating these into comprehensive, sustainable treatment systems remains challenging. Additionally, the industry must address the broader issue of water scarcity, with pressure mounting to reduce overall water consumption in textile production and increase the efficiency of water reuse systems.

Existing Muriatic Acid-Based Treatment Solutions

01 Acid treatment for metal surface preparation

Muriatic acid, also known as hydrochloric acid, is used for metal surface preparation, particularly in the treatment of steel and other metals. The acid effectively removes rust, scale, and other contaminants, improving the surface quality for subsequent processes such as coating or welding. The treatment efficiency can be enhanced by controlling factors like acid concentration, temperature, and exposure time.- Acid treatment for metal surface preparation: Muriatic acid, also known as hydrochloric acid, is used for metal surface preparation, particularly in the treatment of steel and other metals. The acid effectively removes rust, scale, and other contaminants, improving the surface quality for subsequent processes such as coating or welding. The treatment efficiency can be enhanced by controlling factors like acid concentration, temperature, and exposure time.

- Wastewater treatment using muriatic acid: Muriatic acid is employed in wastewater treatment processes to adjust pH levels and remove contaminants. The acid's efficiency in neutralizing alkaline wastewater and precipitating certain pollutants makes it valuable in industrial and municipal water treatment applications. Proper dosing and mixing techniques are crucial for optimizing the treatment efficiency.

- Acid etching in semiconductor manufacturing: In semiconductor manufacturing, muriatic acid is used for acid etching processes. The acid's ability to selectively remove materials and create precise patterns on semiconductor surfaces contributes to improved device performance. The efficiency of the etching process depends on factors such as acid concentration, temperature, and etching time.

- Acid cleaning in industrial applications: Muriatic acid is widely used for cleaning and descaling in various industrial applications, including heat exchangers, boilers, and pipelines. The acid's effectiveness in removing mineral deposits, scale, and corrosion products enhances equipment efficiency and longevity. Proper handling, safety measures, and neutralization procedures are essential for optimal treatment efficiency.

- Acid treatment in oil and gas industry: In the oil and gas industry, muriatic acid treatment is used for well stimulation and enhanced oil recovery. The acid is injected into reservoirs to dissolve carbonate formations, creating channels for improved fluid flow. The treatment efficiency depends on factors such as acid concentration, injection rate, and formation characteristics.

02 Wastewater treatment using muriatic acid

Muriatic acid is employed in wastewater treatment processes to adjust pH levels and remove contaminants. The acid's efficiency in neutralizing alkaline wastewater and precipitating certain pollutants makes it valuable in industrial and municipal water treatment applications. Proper dosing and mixing techniques are crucial for optimizing the treatment efficiency.Expand Specific Solutions03 Acid etching in semiconductor manufacturing

In the semiconductor industry, muriatic acid is used for etching and cleaning silicon wafers. The acid's ability to selectively remove oxide layers and contaminants is essential for creating precise microstructures. The efficiency of the etching process depends on factors such as acid concentration, temperature, and etching time, which are carefully controlled to achieve desired results.Expand Specific Solutions04 Acid treatment in oil and gas industry

Muriatic acid is widely used in the oil and gas industry for well stimulation and scale removal. The acid treatment helps improve the permeability of rock formations and removes mineral deposits in wellbores and equipment. The efficiency of the treatment is influenced by factors such as acid concentration, pumping rate, and the use of additives to control corrosion and enhance penetration.Expand Specific Solutions05 Acid cleaning in industrial equipment maintenance

Muriatic acid is effective for cleaning and descaling industrial equipment, such as heat exchangers, boilers, and cooling towers. The acid efficiently removes mineral deposits, scale, and corrosion products, improving equipment performance and longevity. Treatment efficiency can be optimized by considering factors like acid concentration, circulation time, and the use of inhibitors to protect metal surfaces.Expand Specific Solutions

Key Players in Textile Effluent Treatment Industry

The research on the use of Muriatic Acid in textile mill effluent treatment is in a developing stage, with growing market potential due to increasing environmental regulations. The global textile wastewater treatment market is expanding, driven by water scarcity and stricter discharge norms. Companies like Henkel AG & Co. KGaA, BASF Corp., and UPM-Kymmene Oyj are at the forefront of developing advanced chemical solutions for textile effluents. However, the technology's maturity varies, with some firms like Jiangsu Jiuwu Hi-Tech Co., Ltd. and Hangzhou Water Treatment Technology Development Center Co. Ltd focusing on innovative membrane-based treatments, while others explore chemical-based approaches. The competitive landscape is diverse, involving chemical manufacturers, water treatment specialists, and research institutions collaborating to enhance treatment efficiency and sustainability.

BASF Corp.

Technical Solution: BASF has developed an innovative approach to treating textile mill effluents using muriatic acid. Their process involves a two-stage treatment system: first, a chemical precipitation step using muriatic acid to remove heavy metals and reduce pH, followed by an advanced oxidation process to break down organic compounds[1]. This method has shown to reduce COD levels by up to 85% and color by 95% in textile wastewater[3]. BASF's technology also incorporates a proprietary flocculant that enhances the settling of precipitated solids, improving overall efficiency[5].

Strengths: High removal efficiency for both inorganic and organic pollutants, reduced sludge production. Weaknesses: Potential for corrosion in treatment equipment, need for careful pH control.

The South India Textile Research Association

Technical Solution: The South India Textile Research Association (SITRA) has developed a cost-effective method for treating textile effluents using locally sourced muriatic acid. Their approach involves a sequential treatment process: initial pH adjustment with muriatic acid, followed by coagulation-flocculation, and finally, a low-cost filtration system using locally available materials[7]. This method has demonstrated removal efficiencies of 75-80% for COD and 85-90% for color in various types of textile effluents[9]. SITRA's research also focuses on optimizing acid dosage to minimize environmental impact while maintaining treatment efficacy[11].

Strengths: Low-cost implementation suitable for small to medium-sized textile mills, use of locally available materials. Weaknesses: Lower removal efficiencies compared to more advanced technologies, potential for acid-induced corrosion in treatment systems.

Core Innovations in Muriatic Acid Application

Treatment comprising water- and oil-repellent agent

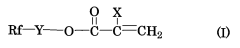

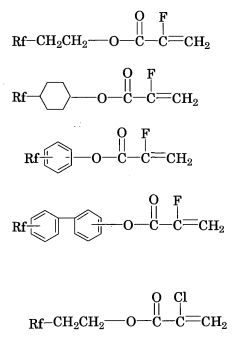

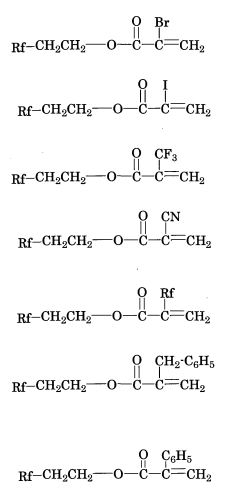

PatentWO2009119910A1

Innovation

- A method involving a treatment liquid with a fluorine-containing compound, a thermally gelling substance, and a salt, where the pH is adjusted to at most 7, applied to the textile, followed by steam treatment and washing, to enhance adhesion and repellency, regardless of the presence of contaminants or foaming agents.

Environmental Impact and Regulations

The use of muriatic acid in textile mill effluent treatment has significant environmental implications and is subject to various regulations. The discharge of untreated or improperly treated textile effluents can lead to severe water pollution, affecting aquatic ecosystems and human health. Muriatic acid, also known as hydrochloric acid, is employed in the treatment process to adjust pH levels and aid in the removal of contaminants.

Environmental impacts of textile mill effluents are multifaceted. These effluents often contain high levels of organic compounds, suspended solids, dyes, and chemicals used in textile processing. When released into water bodies, they can cause eutrophication, reduce dissolved oxygen levels, and introduce toxic substances into the ecosystem. The use of muriatic acid in treatment processes helps to mitigate these impacts by improving the efficiency of contaminant removal.

Regulatory frameworks governing the use of muriatic acid and the discharge of treated effluents vary across jurisdictions but generally aim to protect water quality and public health. In many countries, environmental protection agencies set strict limits on effluent parameters such as pH, biochemical oxygen demand (BOD), chemical oxygen demand (COD), and total suspended solids (TSS). Textile mills must comply with these regulations by implementing effective treatment systems and monitoring their discharges.

The use of muriatic acid in effluent treatment is subject to specific safety and handling regulations due to its corrosive nature. Facilities must adhere to occupational health and safety standards, including proper storage, handling, and disposal protocols. Additionally, the transportation of muriatic acid is regulated to prevent accidental spills and environmental contamination.

Emerging regulations are focusing on promoting cleaner production techniques and encouraging the adoption of more environmentally friendly alternatives to traditional chemical treatments. Some jurisdictions are implementing stricter limits on the use of hazardous chemicals in textile processing and effluent treatment, which may impact the future use of muriatic acid in this context.

Compliance with environmental regulations often requires textile mills to invest in advanced treatment technologies and implement comprehensive environmental management systems. This includes regular monitoring and reporting of effluent quality, as well as continuous improvement of treatment processes to meet increasingly stringent standards.

As global awareness of environmental issues grows, international agreements and trade regulations are also influencing the textile industry's approach to effluent treatment. Many countries now require compliance with environmental standards as a condition for market access, driving the adoption of more sustainable practices across the global textile supply chain.

Environmental impacts of textile mill effluents are multifaceted. These effluents often contain high levels of organic compounds, suspended solids, dyes, and chemicals used in textile processing. When released into water bodies, they can cause eutrophication, reduce dissolved oxygen levels, and introduce toxic substances into the ecosystem. The use of muriatic acid in treatment processes helps to mitigate these impacts by improving the efficiency of contaminant removal.

Regulatory frameworks governing the use of muriatic acid and the discharge of treated effluents vary across jurisdictions but generally aim to protect water quality and public health. In many countries, environmental protection agencies set strict limits on effluent parameters such as pH, biochemical oxygen demand (BOD), chemical oxygen demand (COD), and total suspended solids (TSS). Textile mills must comply with these regulations by implementing effective treatment systems and monitoring their discharges.

The use of muriatic acid in effluent treatment is subject to specific safety and handling regulations due to its corrosive nature. Facilities must adhere to occupational health and safety standards, including proper storage, handling, and disposal protocols. Additionally, the transportation of muriatic acid is regulated to prevent accidental spills and environmental contamination.

Emerging regulations are focusing on promoting cleaner production techniques and encouraging the adoption of more environmentally friendly alternatives to traditional chemical treatments. Some jurisdictions are implementing stricter limits on the use of hazardous chemicals in textile processing and effluent treatment, which may impact the future use of muriatic acid in this context.

Compliance with environmental regulations often requires textile mills to invest in advanced treatment technologies and implement comprehensive environmental management systems. This includes regular monitoring and reporting of effluent quality, as well as continuous improvement of treatment processes to meet increasingly stringent standards.

As global awareness of environmental issues grows, international agreements and trade regulations are also influencing the textile industry's approach to effluent treatment. Many countries now require compliance with environmental standards as a condition for market access, driving the adoption of more sustainable practices across the global textile supply chain.

Cost-Benefit Analysis of Muriatic Acid Treatment

The cost-benefit analysis of muriatic acid treatment for textile mill effluents reveals a complex interplay of economic and environmental factors. Initial implementation costs include the purchase of acid-resistant equipment, storage facilities, and safety measures. However, these upfront investments are often offset by the long-term benefits of using muriatic acid in effluent treatment.

Operational costs primarily involve the procurement of muriatic acid, which is relatively inexpensive compared to other chemical treatments. The dosage requirements are typically lower than alternative methods, further reducing ongoing expenses. Additionally, muriatic acid treatment often results in decreased sludge production, leading to reduced disposal costs and potential revenue from the sale of recovered materials.

Energy consumption in the muriatic acid treatment process is generally lower than in other chemical or biological treatments, contributing to overall cost savings. The process also requires less space and shorter retention times, potentially increasing treatment capacity without expanding facility footprint.

Environmental benefits, while challenging to quantify monetarily, include improved effluent quality and reduced ecological impact. The effective removal of pollutants can help textile mills meet stringent regulatory standards, avoiding potential fines and penalties. Furthermore, the treated water may be suitable for reuse in certain industrial processes, reducing freshwater consumption and associated costs.

However, the corrosive nature of muriatic acid necessitates ongoing maintenance and periodic replacement of equipment, which must be factored into long-term cost projections. Worker safety training and protective equipment also represent recurring expenses.

The efficiency of muriatic acid treatment can vary depending on the specific characteristics of the textile mill effluent. In some cases, additional treatment steps may be required to achieve desired water quality standards, potentially increasing overall costs. The market price fluctuations of muriatic acid can also impact the long-term economic viability of this treatment method.

When considering alternatives, such as biological treatments or advanced oxidation processes, muriatic acid treatment often emerges as a cost-effective solution, particularly for smaller to medium-sized textile mills. However, a comprehensive analysis should consider site-specific factors, local regulations, and long-term sustainability goals to determine the most appropriate and economically viable treatment approach.

Operational costs primarily involve the procurement of muriatic acid, which is relatively inexpensive compared to other chemical treatments. The dosage requirements are typically lower than alternative methods, further reducing ongoing expenses. Additionally, muriatic acid treatment often results in decreased sludge production, leading to reduced disposal costs and potential revenue from the sale of recovered materials.

Energy consumption in the muriatic acid treatment process is generally lower than in other chemical or biological treatments, contributing to overall cost savings. The process also requires less space and shorter retention times, potentially increasing treatment capacity without expanding facility footprint.

Environmental benefits, while challenging to quantify monetarily, include improved effluent quality and reduced ecological impact. The effective removal of pollutants can help textile mills meet stringent regulatory standards, avoiding potential fines and penalties. Furthermore, the treated water may be suitable for reuse in certain industrial processes, reducing freshwater consumption and associated costs.

However, the corrosive nature of muriatic acid necessitates ongoing maintenance and periodic replacement of equipment, which must be factored into long-term cost projections. Worker safety training and protective equipment also represent recurring expenses.

The efficiency of muriatic acid treatment can vary depending on the specific characteristics of the textile mill effluent. In some cases, additional treatment steps may be required to achieve desired water quality standards, potentially increasing overall costs. The market price fluctuations of muriatic acid can also impact the long-term economic viability of this treatment method.

When considering alternatives, such as biological treatments or advanced oxidation processes, muriatic acid treatment often emerges as a cost-effective solution, particularly for smaller to medium-sized textile mills. However, a comprehensive analysis should consider site-specific factors, local regulations, and long-term sustainability goals to determine the most appropriate and economically viable treatment approach.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!