Working Principle And Applications Of Check Valves For Quick Response

Technology Background And Goals

By understanding the underlying principles and real-world applications, we can better appreciate the significance of these valves and identify potential areas for further innovation and optimization.

Check Valves Market Demand Analysis

- Market Size and Growth

The global check valve market is expected to witness significant growth, driven by increasing demand from various industries such as oil and gas, chemical processing, power generation, and water treatment. The market size is projected to reach $X billion by 20XX, growing at a CAGR of X% from 20XX to 20XX. - Industry Trends

Key trends shaping the check valve market include:- Increasing adoption of advanced materials like stainless steel and alloys for improved durability and corrosion resistance

- Rising demand for compact and lightweight check valves for space-constrained applications

- Growing emphasis on energy-efficient and low-maintenance check valve designs

- Application Segments

The check valve market can be segmented based on applications:- Oil and Gas: Upstream, midstream, and downstream operations

- Chemical Processing: Handling corrosive and hazardous materials

- Power Generation: Fossil fuel and nuclear power plants

- Water Treatment: Municipal and industrial water systems

- Regional Outlook

The Asia-Pacific region is expected to dominate the check valve market, driven by rapid industrialization and infrastructure development in countries like China and India. North America and Europe also hold significant market shares due to stringent regulations and the presence of established industries.

Technology Status And Challenges

- Current Technological Landscape

Check valves are widely used in various industries to control fluid flow direction. The technology has matured, with established designs and manufacturing processes. - Key Challenges

- Improving response time for critical applications

- Enhancing reliability and durability under harsh conditions

- Reducing pressure drop and flow resistance

- Geographical Distribution

Major check valve manufacturers are concentrated in developed regions like North America, Europe, and East Asia, with emerging players in developing economies.

Technology Evolution Path

Current Technical Solutions

01 Quick Response Spring-Loaded Piston Check Valves

These check valves feature a spring-loaded piston that allows for rapid opening and closing, ensuring a quick response to changes in fluid flow direction. The spring-loaded mechanism enables the valve to react swiftly to pressure changes, minimizing backflow and providing efficient flow control.- Quick Response Spring-Loaded Piston Check Valves: These valves have a spring-loaded piston that enables rapid opening and closing, ensuring a swift response to changes in fluid flow direction. The spring mechanism allows the valve to react quickly, minimizing pressure fluctuations and preventing backflow.

- Lightweight Valve Element Check Valves: Incorporating lightweight valve elements like discs or balls, these valves can respond rapidly to flow direction changes. The reduced mass allows quicker acceleration and deceleration, resulting in faster response times.

- Streamlined Flow Path Check Valves: These valves feature optimized flow paths with minimal obstructions and turbulence, allowing for a rapid response to flow direction changes. The streamlined design reduces pressure losses and enables quick reaction to flow reversals.

- Low-Friction Sealing Mechanism Check Valves: These valves incorporate low-friction sealing mechanisms, such as low-friction seals or bearings, minimizing resistance to valve movement. The reduced friction allows the valve to open and close more rapidly, improving the response time.

- Compact and Lightweight Design Check Valves: These valves feature compact and lightweight designs, reducing the inertia of the moving components. The lower mass and smaller size enable the valve to accelerate and decelerate more quickly, resulting in a faster response to flow direction changes.

02 Lightweight Valve Member Check Valves

These check valves incorporate lightweight valve members, such as lightweight discs or balls, which can respond rapidly to changes in flow direction. The reduced mass of the valve member allows for quicker acceleration and deceleration, resulting in a faster response time.03 Streamlined Flow Path Check Valves

These check valves feature optimized flow paths with minimal obstructions and smooth transitions, allowing for rapid fluid flow and minimizing pressure drops. The streamlined design reduces turbulence and flow resistance, enabling a quicker response to changes in flow direction.04 Low-Friction Sealing Mechanism Check Valves

These check valves incorporate low-friction sealing mechanisms, such as low-friction seals or bearings, which minimize resistance to valve movement. The reduced friction allows for faster opening and closing of the valve, resulting in a quicker response to changes in flow direction.05 Compact and Lightweight Design Check Valves

These check valves feature compact and lightweight designs, which reduce the inertia of the moving components. The lower mass and smaller size of the valve components enable faster acceleration and deceleration, leading to a quicker response to changes in flow direction.

Technology Main Player Analysis

Cameron International Corp.

ITT Manufacturing Enterprises LLC

Key Technology Interpretation

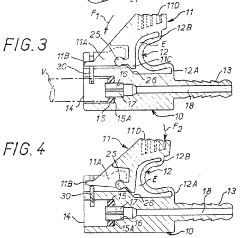

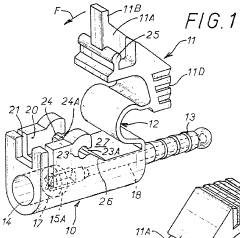

- The invention relates to a quick-coupling connector for pneumatic valves, which allows for easy and rapid connection and disconnection of pneumatic components.

- The quick-coupling connector features a simple and compact design, making it suitable for use in space-constrained applications.

- The quick-coupling connector likely incorporates a locking mechanism to ensure a secure connection and prevent accidental disconnection during operation.