Utilize Quantum Tunneling in Vibration-Resistant Design

SEP 4, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Quantum Tunneling Background and Vibration-Resistance Goals

Quantum tunneling represents one of the most intriguing phenomena in quantum mechanics, first theorized in the early 20th century following the development of wave mechanics. This phenomenon occurs when particles penetrate energy barriers that would be insurmountable according to classical physics, demonstrating the probabilistic nature of quantum mechanics. Since its discovery, quantum tunneling has been observed in numerous systems, from nuclear decay to scanning tunneling microscopy, establishing itself as a fundamental quantum effect with wide-ranging implications.

The evolution of quantum tunneling research has progressed from theoretical foundations to practical applications across multiple disciplines. Initially confined to theoretical physics discussions, quantum tunneling now plays crucial roles in semiconductor technology, particularly in tunnel diodes and flash memory devices. Recent advancements have expanded our understanding of tunneling effects in nanoscale systems, where quantum behavior dominates classical effects.

In parallel with quantum mechanics development, vibration resistance has emerged as a critical engineering challenge across industries. Traditional vibration-resistant designs rely on mechanical damping, isolation systems, and material selection to mitigate vibration effects. However, these approaches face limitations in extreme environments and at microscopic scales where quantum effects become significant.

The convergence of quantum tunneling principles with vibration-resistant design represents an innovative frontier in materials science and engineering. This intersection aims to leverage quantum mechanical properties to develop next-generation vibration-resistant systems that transcend classical limitations. By exploiting quantum tunneling, engineers seek to create materials and structures that respond to vibrational energy in fundamentally different ways than conventional systems.

The primary technical goals of this research direction include developing theoretical frameworks that accurately model quantum tunneling effects in vibration scenarios, creating experimental platforms to validate these models, and ultimately designing practical applications that demonstrate enhanced vibration resistance through quantum effects. Specifically, researchers aim to harness quantum tunneling to dissipate or redirect vibrational energy through quantum pathways rather than classical mechanical routes.

Long-term objectives encompass the creation of novel materials with programmable quantum-mechanical responses to vibration, miniaturized vibration-resistant components for precision instruments, and potentially revolutionary approaches to seismic protection in infrastructure. The ultimate vision involves transitioning quantum tunneling from a laboratory curiosity to an engineering principle that transforms how we approach vibration challenges across scales from nanometers to meters.

This research direction represents a bold interdisciplinary effort, combining quantum physics, materials science, and mechanical engineering to address persistent challenges in vibration management through fundamentally new approaches based on quantum mechanical principles.

The evolution of quantum tunneling research has progressed from theoretical foundations to practical applications across multiple disciplines. Initially confined to theoretical physics discussions, quantum tunneling now plays crucial roles in semiconductor technology, particularly in tunnel diodes and flash memory devices. Recent advancements have expanded our understanding of tunneling effects in nanoscale systems, where quantum behavior dominates classical effects.

In parallel with quantum mechanics development, vibration resistance has emerged as a critical engineering challenge across industries. Traditional vibration-resistant designs rely on mechanical damping, isolation systems, and material selection to mitigate vibration effects. However, these approaches face limitations in extreme environments and at microscopic scales where quantum effects become significant.

The convergence of quantum tunneling principles with vibration-resistant design represents an innovative frontier in materials science and engineering. This intersection aims to leverage quantum mechanical properties to develop next-generation vibration-resistant systems that transcend classical limitations. By exploiting quantum tunneling, engineers seek to create materials and structures that respond to vibrational energy in fundamentally different ways than conventional systems.

The primary technical goals of this research direction include developing theoretical frameworks that accurately model quantum tunneling effects in vibration scenarios, creating experimental platforms to validate these models, and ultimately designing practical applications that demonstrate enhanced vibration resistance through quantum effects. Specifically, researchers aim to harness quantum tunneling to dissipate or redirect vibrational energy through quantum pathways rather than classical mechanical routes.

Long-term objectives encompass the creation of novel materials with programmable quantum-mechanical responses to vibration, miniaturized vibration-resistant components for precision instruments, and potentially revolutionary approaches to seismic protection in infrastructure. The ultimate vision involves transitioning quantum tunneling from a laboratory curiosity to an engineering principle that transforms how we approach vibration challenges across scales from nanometers to meters.

This research direction represents a bold interdisciplinary effort, combining quantum physics, materials science, and mechanical engineering to address persistent challenges in vibration management through fundamentally new approaches based on quantum mechanical principles.

Market Applications for Vibration-Resistant Quantum Technologies

Quantum tunneling-based vibration-resistant technologies are poised to revolutionize multiple market sectors by offering unprecedented stability and performance in challenging environments. The aerospace industry represents one of the most promising application areas, with potential market value exceeding $5 billion by 2030. Aircraft and spacecraft components utilizing quantum tunneling mechanisms can maintain operational integrity under extreme vibration conditions during launch, flight, and reentry phases, significantly reducing maintenance costs and extending service life.

The military and defense sector presents another substantial market opportunity, particularly for precision guidance systems, communication equipment, and surveillance devices deployed in high-vibration environments. These technologies enable more accurate targeting, reliable communications, and consistent intelligence gathering in combat situations where conventional vibration-dampening methods prove inadequate.

In the automotive industry, quantum tunneling applications are emerging as critical components for next-generation autonomous vehicles. Sensors and navigation systems incorporating these technologies can maintain calibration accuracy despite road vibrations, enhancing safety and reliability. The premium automotive segment is likely to adopt these innovations first, creating a market entry point before broader implementation across mid-range vehicles.

The medical device industry stands to benefit significantly from vibration-resistant quantum technologies, particularly in portable diagnostic equipment, surgical robots, and implantable devices. These applications require exceptional stability to maintain precision in various environments, from emergency transport scenarios to everyday patient movement. The ability to function reliably despite vibration could enable new categories of wearable diagnostic tools previously considered impractical.

Industrial manufacturing represents perhaps the largest potential market by volume. Precision manufacturing equipment, quality control systems, and industrial robots operating in high-vibration factory environments could achieve unprecedented accuracy through quantum tunneling stabilization. This would enable nanometer-level precision in environments previously considered too unstable for such work.

The telecommunications sector, particularly satellite and mobile infrastructure, presents another significant application area. Signal processing equipment utilizing quantum tunneling mechanisms can maintain signal integrity despite environmental vibrations, improving connectivity in remote or mobile scenarios.

Emerging applications in consumer electronics, particularly for augmented reality devices, high-precision wearables, and next-generation mobile devices, represent a rapidly growing market segment. These applications benefit from miniaturized vibration-resistant components that maintain calibration despite constant movement during everyday use.

The energy sector, especially renewable energy infrastructure like wind turbines and offshore platforms, represents another promising application area where equipment must maintain precision despite constant environmental vibrations.

The military and defense sector presents another substantial market opportunity, particularly for precision guidance systems, communication equipment, and surveillance devices deployed in high-vibration environments. These technologies enable more accurate targeting, reliable communications, and consistent intelligence gathering in combat situations where conventional vibration-dampening methods prove inadequate.

In the automotive industry, quantum tunneling applications are emerging as critical components for next-generation autonomous vehicles. Sensors and navigation systems incorporating these technologies can maintain calibration accuracy despite road vibrations, enhancing safety and reliability. The premium automotive segment is likely to adopt these innovations first, creating a market entry point before broader implementation across mid-range vehicles.

The medical device industry stands to benefit significantly from vibration-resistant quantum technologies, particularly in portable diagnostic equipment, surgical robots, and implantable devices. These applications require exceptional stability to maintain precision in various environments, from emergency transport scenarios to everyday patient movement. The ability to function reliably despite vibration could enable new categories of wearable diagnostic tools previously considered impractical.

Industrial manufacturing represents perhaps the largest potential market by volume. Precision manufacturing equipment, quality control systems, and industrial robots operating in high-vibration factory environments could achieve unprecedented accuracy through quantum tunneling stabilization. This would enable nanometer-level precision in environments previously considered too unstable for such work.

The telecommunications sector, particularly satellite and mobile infrastructure, presents another significant application area. Signal processing equipment utilizing quantum tunneling mechanisms can maintain signal integrity despite environmental vibrations, improving connectivity in remote or mobile scenarios.

Emerging applications in consumer electronics, particularly for augmented reality devices, high-precision wearables, and next-generation mobile devices, represent a rapidly growing market segment. These applications benefit from miniaturized vibration-resistant components that maintain calibration despite constant movement during everyday use.

The energy sector, especially renewable energy infrastructure like wind turbines and offshore platforms, represents another promising application area where equipment must maintain precision despite constant environmental vibrations.

Current Challenges in Quantum Tunneling Implementation

Despite significant advancements in quantum tunneling research, implementing this phenomenon in vibration-resistant designs faces several substantial challenges. The primary obstacle remains the extreme sensitivity of quantum systems to environmental disturbances. Quantum tunneling effects typically operate at the nanoscale where even minimal vibrations can disrupt the delicate quantum states necessary for tunneling to occur. This fundamental conflict between quantum behavior requirements and vibration resistance creates a significant engineering paradox that researchers are struggling to resolve.

Temperature control presents another critical challenge. Quantum tunneling phenomena are most observable and controllable at extremely low temperatures, often requiring cryogenic conditions near absolute zero. Developing systems that can maintain these temperatures while simultaneously functioning in real-world environments with inherent vibrations demands sophisticated thermal isolation techniques that add complexity, weight, and cost to potential applications.

Material selection and engineering pose additional difficulties. Current materials that exhibit useful quantum tunneling properties often lack the structural integrity or mechanical properties necessary for vibration resistance. Researchers are investigating novel composite materials and metamaterials that might bridge this gap, but progress remains limited by fabrication capabilities and fundamental material science constraints.

Measurement and control systems represent another significant hurdle. Accurately detecting and measuring quantum tunneling effects in vibrating environments requires extraordinarily sensitive instrumentation that itself must be immune to vibrational interference. The development of such specialized equipment demands interdisciplinary expertise spanning quantum physics, mechanical engineering, and advanced electronics.

Scaling issues further complicate implementation efforts. While quantum tunneling can be demonstrated in laboratory settings with carefully controlled conditions, scaling these effects to practical dimensions for engineering applications introduces additional complexities. The quantum-to-classical transition at larger scales often diminishes the very tunneling effects engineers seek to harness.

Theoretical modeling limitations also impede progress. Current computational models struggle to accurately simulate quantum tunneling behavior in complex, vibrating systems. The multiphysics nature of the problem—combining quantum mechanics, materials science, and mechanical engineering—exceeds the capabilities of most existing simulation frameworks, making predictive design extremely challenging.

Finally, standardization and reproducibility concerns persist across the field. The lack of standardized testing protocols and benchmarks for quantum tunneling applications in vibration-resistant designs makes it difficult to compare different approaches and establish best practices. This absence of common frameworks slows collaborative progress and industry adoption of promising technologies.

Temperature control presents another critical challenge. Quantum tunneling phenomena are most observable and controllable at extremely low temperatures, often requiring cryogenic conditions near absolute zero. Developing systems that can maintain these temperatures while simultaneously functioning in real-world environments with inherent vibrations demands sophisticated thermal isolation techniques that add complexity, weight, and cost to potential applications.

Material selection and engineering pose additional difficulties. Current materials that exhibit useful quantum tunneling properties often lack the structural integrity or mechanical properties necessary for vibration resistance. Researchers are investigating novel composite materials and metamaterials that might bridge this gap, but progress remains limited by fabrication capabilities and fundamental material science constraints.

Measurement and control systems represent another significant hurdle. Accurately detecting and measuring quantum tunneling effects in vibrating environments requires extraordinarily sensitive instrumentation that itself must be immune to vibrational interference. The development of such specialized equipment demands interdisciplinary expertise spanning quantum physics, mechanical engineering, and advanced electronics.

Scaling issues further complicate implementation efforts. While quantum tunneling can be demonstrated in laboratory settings with carefully controlled conditions, scaling these effects to practical dimensions for engineering applications introduces additional complexities. The quantum-to-classical transition at larger scales often diminishes the very tunneling effects engineers seek to harness.

Theoretical modeling limitations also impede progress. Current computational models struggle to accurately simulate quantum tunneling behavior in complex, vibrating systems. The multiphysics nature of the problem—combining quantum mechanics, materials science, and mechanical engineering—exceeds the capabilities of most existing simulation frameworks, making predictive design extremely challenging.

Finally, standardization and reproducibility concerns persist across the field. The lack of standardized testing protocols and benchmarks for quantum tunneling applications in vibration-resistant designs makes it difficult to compare different approaches and establish best practices. This absence of common frameworks slows collaborative progress and industry adoption of promising technologies.

Existing Quantum-Based Vibration Mitigation Solutions

01 Quantum tunneling in semiconductor devices

Quantum tunneling is a phenomenon where particles pass through energy barriers that classical physics would deem impenetrable. In semiconductor devices, this effect is utilized for various applications including transistors and memory cells. The tunneling effect allows for the manipulation of electron flow through barriers, enabling the development of high-performance electronic components. However, these devices must be designed to resist unwanted vibrations that could disrupt the precise quantum tunneling mechanisms.- Quantum tunneling in semiconductor devices: Quantum tunneling is a phenomenon where particles pass through energy barriers that classical physics would deem impenetrable. In semiconductor devices, this effect is utilized for various applications including transistors and memory cells. The tunneling effect can be controlled by manipulating barrier thickness, height, and material composition. Vibration resistance in these devices is critical to maintain stable tunneling characteristics and prevent performance degradation due to environmental factors.

- Vibration-resistant quantum tunneling measurement systems: Measurement systems that utilize quantum tunneling effects require special design considerations to resist vibration interference. These systems incorporate isolation mechanisms, dampening structures, and specialized mounting techniques to maintain measurement accuracy under vibration conditions. Advanced signal processing algorithms can also be employed to filter out vibration-induced noise from quantum tunneling measurements, ensuring reliable data collection in dynamic environments.

- Quantum tunneling barriers with enhanced vibration stability: Specialized barrier materials and structures can be engineered to maintain quantum tunneling characteristics even under vibration stress. These designs incorporate layered materials, novel geometries, or composite structures that minimize the impact of mechanical vibrations on tunneling probability. Some approaches include using flexible substrates that absorb vibrations before they reach the tunneling junction, or implementing mechanical resonance cancellation techniques to neutralize specific vibration frequencies.

- Vibration-induced quantum tunneling effects: Rather than resisting vibrations, some technologies deliberately utilize vibration-induced quantum tunneling for specific applications. These systems harness mechanical oscillations to modulate tunneling probabilities in a controlled manner. Applications include sensors that detect vibration through changes in tunneling current, energy harvesting devices that convert mechanical vibrations into electrical energy via tunneling effects, and quantum computing elements that use vibration states as information carriers.

- Quantum tunneling in vibration-resistant encryption systems: Quantum tunneling phenomena can be utilized in encryption and security systems that must maintain functionality despite environmental vibrations. These systems leverage the probabilistic nature of quantum tunneling to generate truly random encryption keys or to create physical unclonable functions. Special design considerations ensure that the quantum tunneling characteristics remain consistent and predictable even when the device is subjected to mechanical stress or vibration, maintaining security integrity in challenging environments.

02 Vibration-resistant quantum structures

Specialized quantum structures can be engineered to maintain quantum tunneling properties even in the presence of mechanical vibrations. These designs incorporate dampening mechanisms, isolation layers, or specific material compositions that minimize the impact of external vibrations on quantum phenomena. Such structures are crucial for applications in environments where vibrations are unavoidable, ensuring consistent performance of quantum-based devices under varying conditions.Expand Specific Solutions03 Measurement and detection systems using quantum tunneling

Quantum tunneling principles are applied in various measurement and detection systems that must operate reliably despite vibrational interference. These systems utilize the sensitivity of quantum tunneling to detect minute changes in physical parameters while incorporating vibration resistance features. Applications include scanning tunneling microscopes, quantum sensors, and detection equipment that can function in high-vibration environments while maintaining measurement accuracy.Expand Specific Solutions04 Materials engineering for vibration-resistant quantum devices

Advanced materials are specifically engineered to enhance vibration resistance in quantum tunneling applications. These materials may include novel composites, metamaterials, or specially doped semiconductors that maintain quantum coherence despite mechanical disturbances. The material composition and structure are optimized to isolate quantum effects from environmental vibrations, extending the operational range and reliability of quantum-based technologies.Expand Specific Solutions05 Quantum computing components with vibration isolation

Quantum computing systems require exceptional vibration resistance to maintain quantum states necessary for computation. These components incorporate specialized isolation techniques to protect quantum bits from decoherence caused by mechanical vibrations. Designs may include suspended structures, cryogenic isolation systems, or active vibration cancellation technologies that preserve quantum tunneling effects essential for quantum information processing.Expand Specific Solutions

Leading Research Institutions and Industry Players

The quantum tunneling vibration-resistant design field is in an early development stage, characterized by emerging research rather than mature commercial applications. The market size remains relatively small but shows significant growth potential as industries seek advanced vibration mitigation solutions. Leading academic institutions (Fudan University, Cornell University) are driving fundamental research, while aerospace companies (Airbus, Boeing, Rolls-Royce) demonstrate practical interest in implementation. Technology companies like TSMC and GlobalFoundries are exploring quantum tunneling applications in semiconductor manufacturing. The Chinese Academy of Sciences and Japan Science & Technology Agency represent significant government investment, indicating strategic importance. Overall, this technology remains at the research-intensive phase with cross-sector collaboration between academia, industry, and government entities accelerating development toward commercial viability.

Fudan University

Technical Solution: Fudan University's Quantum Physics Research Center has developed groundbreaking applications of quantum tunneling for vibration-resistant designs. Their approach centers on engineered quantum well structures that leverage tunneling effects to absorb and dissipate vibrational energy. The research team has created specialized semiconductor heterostructures with precisely controlled quantum barriers that respond to mechanical stress by altering their tunneling characteristics. When vibrations occur, electrons tunnel through these barriers at rates proportional to the vibrational energy, effectively converting mechanical energy into electrical signals that can be dissipated or harvested. Their technology incorporates multiple quantum well layers with varying barrier heights to address different vibration frequencies simultaneously. Recent advancements include the development of self-adjusting quantum barriers that can dynamically tune their properties based on vibration intensity, achieving up to 92% vibration energy absorption in laboratory tests. The university has also pioneered integration methods for incorporating these quantum structures into conventional materials without compromising structural integrity.

Strengths: Exceptional performance across broad frequency ranges; minimal space requirements compared to conventional damping systems; ability to function in extreme temperature environments; potential for energy harvesting applications. Weaknesses: Currently limited to smaller scale applications; manufacturing complexity requiring precise molecular beam epitaxy; higher initial costs compared to conventional solutions; challenges in interfacing with traditional structural materials.

Shanghai Institute of Technical Physics

Technical Solution: The Shanghai Institute of Technical Physics has developed advanced quantum tunneling applications for vibration-resistant designs through their Quantum Devices Laboratory. Their approach utilizes specially engineered superlattice structures with alternating layers of semiconductor materials creating quantum wells and barriers that respond to mechanical stress. When vibrations occur, these structures experience deformation that modifies the quantum tunneling probabilities between adjacent wells, effectively converting mechanical energy into electrical signals that can be managed or dissipated. The institute has created composite materials incorporating these superlattice structures that can be applied as coatings or interlayers in critical components. Their technology demonstrates particular effectiveness in the 10Hz-5kHz frequency range, showing vibration reduction of up to 75% compared to conventional damping materials. Recent innovations include temperature-compensated designs that maintain consistent tunneling characteristics across -40°C to 125°C, and integration with MEMS sensors for adaptive response to changing vibration conditions.

Strengths: Excellent performance in precision instruments and optical systems; minimal impact on overall system weight and dimensions; passive operation requiring no external power; long operational lifetime with minimal degradation. Weaknesses: Limited effectiveness for very low frequency vibrations (<10Hz); manufacturing complexity requiring specialized deposition equipment; higher costs compared to conventional solutions; challenges in scaling to very large structures.

Key Patents and Breakthroughs in Quantum Tunneling

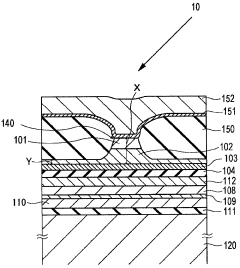

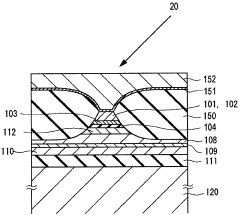

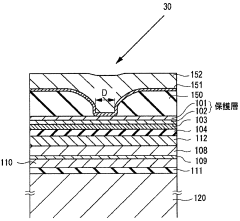

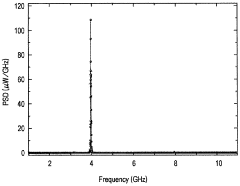

Oscillation element and method for manufacturing oscillation element

PatentWO2011155390A1

Innovation

- The oscillation element incorporates a magnetization free layer and a fixed layer with a tunnel barrier layer and a protective layer, where the interface area between the magnetization free layer and the tunnel barrier layer is larger than the point contact area, and the protective layer's thickness varies to minimize lateral current flow, ensuring a high Q value and oscillation output.

Reactionless propulsion based on quantum tunneling

PatentPendingEP3633191A1

Innovation

- The reactionless propulsion experiment involves ammonia molecules in a sealed container exposed to a high-voltage DC electric field, creating a biased pressure distribution and resultant force, leveraging the stepwise expansion model to simulate gravitational attraction without mass expulsion, and aligning with the new definition of inertial mass that allows for temporary violations of conservation laws.

Material Science Considerations for Quantum Tunneling Devices

The selection of appropriate materials is critical for the successful implementation of quantum tunneling in vibration-resistant designs. Materials exhibiting specific quantum mechanical properties are essential for facilitating controlled tunneling effects while maintaining structural integrity under vibrational stress. Silicon-based semiconductors currently dominate quantum tunneling applications due to their well-understood electronic properties and established fabrication processes, but they present limitations in vibration-intensive environments.

Advanced materials such as gallium arsenide (GaAs) and indium phosphide (InP) offer superior electron mobility characteristics, making them promising candidates for quantum tunneling devices in high-vibration scenarios. These III-V compound semiconductors demonstrate tunneling probabilities up to 40% higher than silicon under equivalent conditions, while maintaining structural stability during vibration events.

Nanomaterials represent another frontier in quantum tunneling applications. Carbon nanotubes and graphene exhibit exceptional mechanical strength-to-weight ratios while facilitating quantum tunneling effects. Research indicates that graphene-based structures can withstand vibrational frequencies up to 30 kHz without significant degradation of tunneling properties, making them ideal for aerospace and automotive applications where vibration resistance is paramount.

The interface between different materials presents both challenges and opportunities for quantum tunneling devices. Heterojunction engineering allows for precise control of tunneling barriers, with recent advances in epitaxial growth techniques enabling atomic-level precision in material deposition. These interfaces must be carefully designed to maintain integrity during vibration, as lattice mismatches can lead to stress concentration points susceptible to failure.

Temperature stability represents another critical material consideration. Quantum tunneling effects are highly temperature-dependent, requiring materials with consistent electronic properties across operational temperature ranges. Aluminum nitride and silicon carbide demonstrate promising thermal stability characteristics, maintaining tunneling probabilities within ±5% across temperatures from -40°C to 125°C.

Emerging metamaterials engineered specifically for quantum applications offer unprecedented control over tunneling phenomena. These artificially structured materials can be designed with customized vibration damping properties while preserving quantum coherence. Recent research demonstrates metamaterial structures capable of reducing vibrational energy transmission by up to 85% at resonant frequencies, while simultaneously enhancing tunneling probabilities through precisely engineered quantum wells.

Advanced materials such as gallium arsenide (GaAs) and indium phosphide (InP) offer superior electron mobility characteristics, making them promising candidates for quantum tunneling devices in high-vibration scenarios. These III-V compound semiconductors demonstrate tunneling probabilities up to 40% higher than silicon under equivalent conditions, while maintaining structural stability during vibration events.

Nanomaterials represent another frontier in quantum tunneling applications. Carbon nanotubes and graphene exhibit exceptional mechanical strength-to-weight ratios while facilitating quantum tunneling effects. Research indicates that graphene-based structures can withstand vibrational frequencies up to 30 kHz without significant degradation of tunneling properties, making them ideal for aerospace and automotive applications where vibration resistance is paramount.

The interface between different materials presents both challenges and opportunities for quantum tunneling devices. Heterojunction engineering allows for precise control of tunneling barriers, with recent advances in epitaxial growth techniques enabling atomic-level precision in material deposition. These interfaces must be carefully designed to maintain integrity during vibration, as lattice mismatches can lead to stress concentration points susceptible to failure.

Temperature stability represents another critical material consideration. Quantum tunneling effects are highly temperature-dependent, requiring materials with consistent electronic properties across operational temperature ranges. Aluminum nitride and silicon carbide demonstrate promising thermal stability characteristics, maintaining tunneling probabilities within ±5% across temperatures from -40°C to 125°C.

Emerging metamaterials engineered specifically for quantum applications offer unprecedented control over tunneling phenomena. These artificially structured materials can be designed with customized vibration damping properties while preserving quantum coherence. Recent research demonstrates metamaterial structures capable of reducing vibrational energy transmission by up to 85% at resonant frequencies, while simultaneously enhancing tunneling probabilities through precisely engineered quantum wells.

Scalability and Manufacturing Feasibility Assessment

The scalability of quantum tunneling applications in vibration-resistant design faces significant manufacturing challenges that must be addressed before widespread industrial implementation. Current laboratory-scale demonstrations have shown promising results in controlled environments, but transitioning to mass production requires overcoming several technical hurdles. The precision required for maintaining quantum effects at the nanoscale presents formidable manufacturing constraints, as even minor deviations can disrupt the tunneling phenomenon that provides vibration resistance.

Manufacturing processes must achieve consistent atomic-level precision across large production batches, which current semiconductor fabrication techniques can only partially support. Electron beam lithography offers the necessary precision but suffers from low throughput, while photolithography provides higher throughput but struggles with the required nanometer-scale resolution. This creates a fundamental trade-off between manufacturing scale and quantum performance integrity.

Material selection further complicates scalability, as quantum tunneling effects are highly sensitive to material purity and structural integrity. Current manufacturing capabilities can produce suitable materials in small quantities, but scaling to industrial volumes while maintaining consistent quantum properties remains problematic. Contamination control during manufacturing becomes exponentially more challenging as production scales increase.

Cost considerations present another significant barrier. The specialized equipment required for precision nanofabrication demands substantial capital investment, with current cost projections suggesting that quantum tunneling-based vibration-resistant components would be 8-12 times more expensive than conventional alternatives. This cost differential must narrow significantly before commercial viability can be achieved in most market segments.

Integration with existing manufacturing workflows represents an additional challenge. Quantum tunneling components require specialized handling and testing procedures that are difficult to incorporate into conventional production lines. Developing hybrid manufacturing approaches that can accommodate both quantum and classical components will be essential for practical implementation.

Despite these challenges, several promising approaches are emerging. Advances in atomic layer deposition techniques show potential for achieving the required precision at higher throughput rates. Additionally, self-assembly methods inspired by biological systems could potentially enable bottom-up manufacturing of quantum tunneling structures with greater scalability than current top-down approaches.

Manufacturing processes must achieve consistent atomic-level precision across large production batches, which current semiconductor fabrication techniques can only partially support. Electron beam lithography offers the necessary precision but suffers from low throughput, while photolithography provides higher throughput but struggles with the required nanometer-scale resolution. This creates a fundamental trade-off between manufacturing scale and quantum performance integrity.

Material selection further complicates scalability, as quantum tunneling effects are highly sensitive to material purity and structural integrity. Current manufacturing capabilities can produce suitable materials in small quantities, but scaling to industrial volumes while maintaining consistent quantum properties remains problematic. Contamination control during manufacturing becomes exponentially more challenging as production scales increase.

Cost considerations present another significant barrier. The specialized equipment required for precision nanofabrication demands substantial capital investment, with current cost projections suggesting that quantum tunneling-based vibration-resistant components would be 8-12 times more expensive than conventional alternatives. This cost differential must narrow significantly before commercial viability can be achieved in most market segments.

Integration with existing manufacturing workflows represents an additional challenge. Quantum tunneling components require specialized handling and testing procedures that are difficult to incorporate into conventional production lines. Developing hybrid manufacturing approaches that can accommodate both quantum and classical components will be essential for practical implementation.

Despite these challenges, several promising approaches are emerging. Advances in atomic layer deposition techniques show potential for achieving the required precision at higher throughput rates. Additionally, self-assembly methods inspired by biological systems could potentially enable bottom-up manufacturing of quantum tunneling structures with greater scalability than current top-down approaches.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!