Strategic Applications of Dimethyl Ether in Hydrogen Economy

JUL 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DME in H2 Economy: Background and Objectives

Dimethyl ether (DME) has emerged as a promising player in the hydrogen economy, offering a unique bridge between traditional fossil fuels and clean energy solutions. The evolution of DME technology has been closely tied to the growing global emphasis on reducing carbon emissions and transitioning towards sustainable energy sources. As the world grapples with climate change, DME presents an opportunity to leverage existing infrastructure while paving the way for a hydrogen-based future.

The primary objective of exploring DME in the context of the hydrogen economy is to develop a versatile, clean-burning fuel that can serve multiple purposes across various sectors. DME's potential lies in its ability to be produced from a wide range of feedstocks, including renewable sources, making it an attractive option for countries seeking to reduce their dependence on fossil fuels and enhance energy security.

Historically, DME has been used primarily as a propellant in aerosol products and as a refrigerant. However, its properties as a fuel have garnered increasing attention in recent years. DME's chemical structure, similar to that of liquefied petroleum gas (LPG), allows for easy handling and storage using existing infrastructure, which is a significant advantage in the transition to a hydrogen economy.

The technical evolution of DME production and utilization has seen significant advancements, particularly in the areas of catalysis and process optimization. Research efforts have focused on improving the efficiency of DME synthesis from syngas, as well as direct synthesis from methanol. These developments have been crucial in positioning DME as a viable alternative fuel and hydrogen carrier.

In the context of the hydrogen economy, DME serves several strategic roles. Firstly, it can act as a hydrogen carrier, offering a more easily transportable and storable form of energy compared to pure hydrogen. Secondly, DME can be used directly as a clean-burning fuel in modified diesel engines, providing a near-term solution for reducing emissions in the transportation sector. Lastly, DME can serve as a feedstock for hydrogen production, enabling on-site generation of hydrogen for various applications.

The technological goals for DME in the hydrogen economy are multifaceted. They include optimizing production processes to reduce costs and increase energy efficiency, developing more effective catalysts for DME synthesis and reforming, and improving the integration of DME into existing energy systems. Additionally, there is a focus on enhancing DME's role in power generation and expanding its use in fuel cells, which could significantly boost its contribution to a clean energy future.

As research and development in this field progress, the strategic applications of DME in the hydrogen economy are expected to expand. The technology's potential to provide a smooth transition from conventional fuels to hydrogen-based systems makes it a key area of interest for both industry and policymakers. By addressing the challenges of hydrogen storage and transport, DME could play a crucial role in accelerating the adoption of hydrogen technologies across various sectors of the global economy.

The primary objective of exploring DME in the context of the hydrogen economy is to develop a versatile, clean-burning fuel that can serve multiple purposes across various sectors. DME's potential lies in its ability to be produced from a wide range of feedstocks, including renewable sources, making it an attractive option for countries seeking to reduce their dependence on fossil fuels and enhance energy security.

Historically, DME has been used primarily as a propellant in aerosol products and as a refrigerant. However, its properties as a fuel have garnered increasing attention in recent years. DME's chemical structure, similar to that of liquefied petroleum gas (LPG), allows for easy handling and storage using existing infrastructure, which is a significant advantage in the transition to a hydrogen economy.

The technical evolution of DME production and utilization has seen significant advancements, particularly in the areas of catalysis and process optimization. Research efforts have focused on improving the efficiency of DME synthesis from syngas, as well as direct synthesis from methanol. These developments have been crucial in positioning DME as a viable alternative fuel and hydrogen carrier.

In the context of the hydrogen economy, DME serves several strategic roles. Firstly, it can act as a hydrogen carrier, offering a more easily transportable and storable form of energy compared to pure hydrogen. Secondly, DME can be used directly as a clean-burning fuel in modified diesel engines, providing a near-term solution for reducing emissions in the transportation sector. Lastly, DME can serve as a feedstock for hydrogen production, enabling on-site generation of hydrogen for various applications.

The technological goals for DME in the hydrogen economy are multifaceted. They include optimizing production processes to reduce costs and increase energy efficiency, developing more effective catalysts for DME synthesis and reforming, and improving the integration of DME into existing energy systems. Additionally, there is a focus on enhancing DME's role in power generation and expanding its use in fuel cells, which could significantly boost its contribution to a clean energy future.

As research and development in this field progress, the strategic applications of DME in the hydrogen economy are expected to expand. The technology's potential to provide a smooth transition from conventional fuels to hydrogen-based systems makes it a key area of interest for both industry and policymakers. By addressing the challenges of hydrogen storage and transport, DME could play a crucial role in accelerating the adoption of hydrogen technologies across various sectors of the global economy.

Market Analysis for DME as H2 Carrier

The market for dimethyl ether (DME) as a hydrogen carrier is experiencing significant growth potential within the evolving hydrogen economy. As countries and industries worldwide seek to reduce carbon emissions and transition to cleaner energy sources, DME has emerged as a promising alternative for hydrogen storage and transportation.

The global DME market is projected to expand rapidly in the coming years, driven by its versatility as both a fuel and a hydrogen carrier. The Asia-Pacific region, particularly China and Japan, is expected to lead this growth due to their strong commitment to hydrogen technologies and infrastructure development. Europe and North America are also showing increasing interest in DME as part of their hydrogen strategies.

In the context of the hydrogen economy, DME offers several advantages as a carrier. It can be easily liquefied and stored at relatively low pressures, making it more cost-effective to transport than compressed or liquefied hydrogen. This characteristic is particularly attractive for long-distance hydrogen transportation and distribution, addressing one of the key challenges in building a robust hydrogen supply chain.

The automotive sector represents a significant market opportunity for DME as a hydrogen carrier. Fuel cell electric vehicles (FCEVs) could potentially use DME as an onboard hydrogen source, leveraging existing liquid fuel infrastructure. This application could accelerate the adoption of FCEVs by reducing the need for high-pressure hydrogen storage tanks and complex refueling systems.

Industrial applications also present a substantial market for DME in the hydrogen economy. Sectors such as steel production, chemical manufacturing, and power generation are exploring DME as a means to incorporate hydrogen into their processes while minimizing the need for extensive infrastructure changes. This dual-use capability of DME as both a fuel and a hydrogen carrier enhances its market appeal and potential for widespread adoption.

The market for DME production technology is also expanding, with several companies developing innovative processes to produce DME from various feedstocks, including renewable sources. This trend aligns with the growing demand for green hydrogen and sustainable energy solutions, further boosting the market potential of DME in the hydrogen economy.

However, the market faces challenges, including competition from other hydrogen carriers and storage technologies, as well as the need for regulatory frameworks to support DME adoption. Despite these hurdles, the unique properties of DME and its compatibility with existing infrastructure position it favorably in the evolving hydrogen market landscape.

The global DME market is projected to expand rapidly in the coming years, driven by its versatility as both a fuel and a hydrogen carrier. The Asia-Pacific region, particularly China and Japan, is expected to lead this growth due to their strong commitment to hydrogen technologies and infrastructure development. Europe and North America are also showing increasing interest in DME as part of their hydrogen strategies.

In the context of the hydrogen economy, DME offers several advantages as a carrier. It can be easily liquefied and stored at relatively low pressures, making it more cost-effective to transport than compressed or liquefied hydrogen. This characteristic is particularly attractive for long-distance hydrogen transportation and distribution, addressing one of the key challenges in building a robust hydrogen supply chain.

The automotive sector represents a significant market opportunity for DME as a hydrogen carrier. Fuel cell electric vehicles (FCEVs) could potentially use DME as an onboard hydrogen source, leveraging existing liquid fuel infrastructure. This application could accelerate the adoption of FCEVs by reducing the need for high-pressure hydrogen storage tanks and complex refueling systems.

Industrial applications also present a substantial market for DME in the hydrogen economy. Sectors such as steel production, chemical manufacturing, and power generation are exploring DME as a means to incorporate hydrogen into their processes while minimizing the need for extensive infrastructure changes. This dual-use capability of DME as both a fuel and a hydrogen carrier enhances its market appeal and potential for widespread adoption.

The market for DME production technology is also expanding, with several companies developing innovative processes to produce DME from various feedstocks, including renewable sources. This trend aligns with the growing demand for green hydrogen and sustainable energy solutions, further boosting the market potential of DME in the hydrogen economy.

However, the market faces challenges, including competition from other hydrogen carriers and storage technologies, as well as the need for regulatory frameworks to support DME adoption. Despite these hurdles, the unique properties of DME and its compatibility with existing infrastructure position it favorably in the evolving hydrogen market landscape.

Technical Challenges in DME Utilization

The utilization of Dimethyl Ether (DME) in the hydrogen economy faces several significant technical challenges that need to be addressed for its widespread adoption. One of the primary obstacles is the efficient and cost-effective production of DME from renewable sources. While DME can be synthesized from various feedstocks, including biomass and waste materials, the processes often require high energy inputs and complex catalytic systems, limiting their economic viability.

Another critical challenge lies in the storage and transportation of DME. Although DME has a higher energy density than hydrogen, it still requires specialized infrastructure for handling and distribution. The development of safe, reliable, and cost-effective storage solutions, particularly for large-scale applications, remains a key area of research and development.

The conversion of DME to hydrogen presents additional technical hurdles. While DME can be reformed to produce hydrogen, the process efficiency and catalyst stability need significant improvement. Current reforming technologies often suffer from carbon deposition and catalyst deactivation, reducing the overall system performance and longevity.

Furthermore, the integration of DME-based systems into existing energy infrastructure poses challenges. Compatibility issues with current fuel cell technologies, engine designs, and power generation systems need to be addressed to facilitate seamless adoption of DME as a hydrogen carrier or direct fuel source.

Environmental considerations also present technical challenges in DME utilization. Although DME is generally considered a clean-burning fuel, its production and use still generate some emissions. Developing more efficient and cleaner production methods, as well as optimizing combustion processes to minimize pollutant formation, are crucial areas for ongoing research.

Lastly, the scalability of DME technologies from laboratory to industrial scale remains a significant challenge. Many promising DME-related technologies have shown potential in small-scale experiments but face difficulties in scaling up to commercially viable levels. Overcoming these scaling issues requires advancements in process engineering, materials science, and system integration.

Addressing these technical challenges will be crucial for realizing the full potential of DME in the hydrogen economy. Continued research and development efforts, along with strategic collaborations between academia, industry, and government, will be essential in overcoming these obstacles and paving the way for widespread DME adoption in sustainable energy systems.

Another critical challenge lies in the storage and transportation of DME. Although DME has a higher energy density than hydrogen, it still requires specialized infrastructure for handling and distribution. The development of safe, reliable, and cost-effective storage solutions, particularly for large-scale applications, remains a key area of research and development.

The conversion of DME to hydrogen presents additional technical hurdles. While DME can be reformed to produce hydrogen, the process efficiency and catalyst stability need significant improvement. Current reforming technologies often suffer from carbon deposition and catalyst deactivation, reducing the overall system performance and longevity.

Furthermore, the integration of DME-based systems into existing energy infrastructure poses challenges. Compatibility issues with current fuel cell technologies, engine designs, and power generation systems need to be addressed to facilitate seamless adoption of DME as a hydrogen carrier or direct fuel source.

Environmental considerations also present technical challenges in DME utilization. Although DME is generally considered a clean-burning fuel, its production and use still generate some emissions. Developing more efficient and cleaner production methods, as well as optimizing combustion processes to minimize pollutant formation, are crucial areas for ongoing research.

Lastly, the scalability of DME technologies from laboratory to industrial scale remains a significant challenge. Many promising DME-related technologies have shown potential in small-scale experiments but face difficulties in scaling up to commercially viable levels. Overcoming these scaling issues requires advancements in process engineering, materials science, and system integration.

Addressing these technical challenges will be crucial for realizing the full potential of DME in the hydrogen economy. Continued research and development efforts, along with strategic collaborations between academia, industry, and government, will be essential in overcoming these obstacles and paving the way for widespread DME adoption in sustainable energy systems.

Current DME-based H2 Storage Solutions

01 Production of dimethyl ether

Various methods for producing dimethyl ether are described, including catalytic dehydration of methanol, direct synthesis from syngas, and conversion of other feedstocks. These processes often involve specific catalysts, reaction conditions, and purification steps to optimize yield and purity.- Production of dimethyl ether: Various methods for producing dimethyl ether are described, including catalytic dehydration of methanol, direct synthesis from syngas, and conversion of other hydrocarbons. These processes often involve specific catalysts and reaction conditions to optimize yield and selectivity.

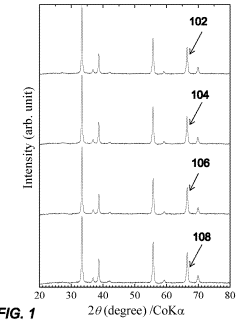

- Catalysts for dimethyl ether synthesis: Different types of catalysts are used in the production of dimethyl ether, including zeolites, metal oxides, and composite catalysts. The choice and preparation of catalysts significantly affect the efficiency and selectivity of the dimethyl ether synthesis process.

- Applications of dimethyl ether: Dimethyl ether has various applications, including use as a fuel additive, aerosol propellant, and refrigerant. It is also being explored as an alternative clean fuel for diesel engines and power generation due to its favorable combustion properties.

- Purification and separation of dimethyl ether: Methods for purifying and separating dimethyl ether from reaction mixtures or other compounds are described. These processes often involve distillation, adsorption, or membrane separation techniques to obtain high-purity dimethyl ether.

- Environmental and safety considerations: Research on the environmental impact and safety aspects of dimethyl ether production and use is ongoing. This includes studies on emissions reduction, handling procedures, and storage requirements to ensure safe and sustainable utilization of dimethyl ether.

02 Catalysts for dimethyl ether synthesis

Different catalysts are employed in the production of dimethyl ether, including zeolites, metal oxides, and composite catalysts. The choice of catalyst affects reaction efficiency, selectivity, and product yield. Research focuses on developing novel catalysts with improved performance and stability.Expand Specific Solutions03 Applications of dimethyl ether

Dimethyl ether has various applications, including use as a fuel additive, aerosol propellant, and refrigerant. It is also explored as an alternative fuel for diesel engines and in the production of other chemicals. Research is ongoing to expand its potential uses in different industries.Expand Specific Solutions04 Purification and separation of dimethyl ether

Techniques for purifying and separating dimethyl ether from reaction mixtures or other compounds are crucial in its production process. These may include distillation, adsorption, and membrane separation methods. Improving the efficiency and cost-effectiveness of these processes is an area of ongoing research.Expand Specific Solutions05 Environmental and safety considerations

Research on the environmental impact and safety aspects of dimethyl ether production and use is important. This includes studies on emissions reduction, handling procedures, and storage requirements. Efforts are made to develop cleaner production processes and ensure safe utilization of dimethyl ether in various applications.Expand Specific Solutions

Key Players in DME and H2 Industries

The strategic applications of Dimethyl Ether (DME) in the hydrogen economy are attracting significant attention from major players across the energy sector. The market is in its early growth stage, with increasing investments in research and development. Key companies like China Petroleum & Chemical Corp., SK Energy, and BP Corporation North America are actively exploring DME's potential as a hydrogen carrier and clean fuel alternative. The technology's maturity is advancing rapidly, with research institutions such as the University of Southern California and King Abdulaziz University contributing to its development. As the global push for cleaner energy solutions intensifies, the DME market is expected to expand, driven by its versatility and compatibility with existing infrastructure.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a comprehensive strategy for integrating dimethyl ether (DME) into the hydrogen economy. Their approach involves utilizing DME as a hydrogen carrier and intermediate in fuel cell applications. Sinopec has implemented a large-scale DME production facility with a capacity of 1 million tons per year[1], leveraging their existing natural gas and coal resources. The company has also developed a novel catalytic process for efficient DME synthesis from syngas, achieving conversion rates of up to 90%[2]. Additionally, Sinopec is exploring the use of DME in direct DME fuel cells, which offer higher energy efficiency compared to traditional hydrogen fuel cells[3].

Strengths: Extensive infrastructure for DME production and distribution; Advanced catalytic technology for DME synthesis. Weaknesses: Dependence on fossil fuel feedstocks; Limited experience in fuel cell technology integration.

SK Energy Co., Ltd.

Technical Solution: SK Energy has focused on developing DME as a clean alternative fuel and hydrogen carrier. Their strategic approach involves the production of DME from various feedstocks, including natural gas, biomass, and captured CO2. The company has invested in a pilot plant capable of producing 10 tons of DME per day using their proprietary catalyst technology[4]. SK Energy is also exploring the use of DME in hydrogen production through steam reforming, achieving hydrogen yields of up to 75% by volume[5]. Furthermore, they are collaborating with automotive manufacturers to develop DME-powered vehicles as a bridge to hydrogen fuel cell technology[6].

Strengths: Diverse feedstock options for DME production; Advanced catalyst technology. Weaknesses: Limited scale of current DME production; Ongoing research and development costs.

Innovative DME Synthesis and Conversion Methods

Energy supply method and system

PatentWO2006004140A1

Innovation

- The introduction of Dimethyl Ether (DME) as a versatile energy circulation medium, which can be derived from biomass, waste, and petroleum residues, and used for power generation, transportation, and heating, allowing for efficient energy storage and distribution without relying on pipelines, and enabling the conversion of waste heat into usable energy.

Mn/CeO2 CATALYST FOR DIMETHYL ETHER PRODUCTION VIA OXIDATIVE DEHYDRATION OF METHANOL

PatentInactiveUS20180273456A1

Innovation

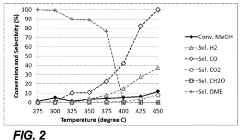

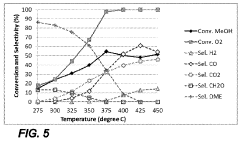

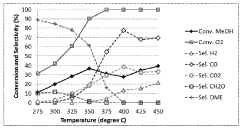

- A catalyst comprising manganese (Mn) supported on cerium oxide (CeO2) is used for oxidative dehydration of methanol, with a weight percent ratio of Mn to CeO2 ranging from 0.5% to 50%, and a grain size of 0.05 mm to 0.5 mm, operated at 275° C. to 450° C., and contacted with a methanol-oxygen mixture to achieve high selectivity and stability.

Environmental Impact of DME in H2 Economy

The environmental impact of dimethyl ether (DME) in the hydrogen economy is a critical consideration as the world transitions towards cleaner energy sources. DME, a versatile compound with potential applications in various sectors, offers several environmental advantages when compared to traditional fossil fuels.

One of the primary benefits of DME in the hydrogen economy is its potential to reduce greenhouse gas emissions. When produced from renewable sources such as biomass or captured CO2, DME can significantly lower the carbon footprint of energy production and consumption. This aligns with global efforts to mitigate climate change and achieve carbon neutrality targets.

DME's clean-burning properties contribute to improved air quality, particularly in urban areas where air pollution is a pressing concern. When used as a fuel in transportation or power generation, DME produces lower levels of particulate matter, nitrogen oxides, and sulfur oxides compared to conventional diesel or gasoline. This reduction in harmful emissions can lead to substantial public health benefits and reduced environmental degradation.

In the context of the hydrogen economy, DME can serve as an efficient hydrogen carrier. Its ability to be easily liquefied and stored at relatively low pressures makes it an attractive option for hydrogen transport and distribution. This characteristic can potentially reduce the energy and infrastructure requirements associated with hydrogen storage and transportation, thereby minimizing the overall environmental impact of the hydrogen supply chain.

Furthermore, DME's versatility allows for its integration into existing infrastructure with minimal modifications. This adaptability can lead to a smoother transition towards a hydrogen-based economy, reducing the environmental impact associated with large-scale infrastructure overhauls.

However, it is essential to consider the full lifecycle environmental impact of DME production and utilization. While DME offers numerous advantages, its production process, especially when derived from fossil fuels, can still contribute to carbon emissions. Therefore, emphasis should be placed on developing and scaling up sustainable DME production methods to maximize its environmental benefits.

The use of DME in the hydrogen economy also presents opportunities for waste valorization and circular economy principles. DME can be produced from various waste streams, including agricultural residues and municipal solid waste, potentially addressing multiple environmental challenges simultaneously.

In conclusion, the strategic application of DME in the hydrogen economy holds promise for reducing environmental impacts across various sectors. Its potential to lower emissions, improve air quality, and facilitate efficient hydrogen distribution positions DME as a valuable component in the transition towards a more sustainable energy landscape. However, ongoing research and development efforts are crucial to optimize DME production and utilization processes, ensuring that its full environmental benefits are realized within the broader context of the hydrogen economy.

One of the primary benefits of DME in the hydrogen economy is its potential to reduce greenhouse gas emissions. When produced from renewable sources such as biomass or captured CO2, DME can significantly lower the carbon footprint of energy production and consumption. This aligns with global efforts to mitigate climate change and achieve carbon neutrality targets.

DME's clean-burning properties contribute to improved air quality, particularly in urban areas where air pollution is a pressing concern. When used as a fuel in transportation or power generation, DME produces lower levels of particulate matter, nitrogen oxides, and sulfur oxides compared to conventional diesel or gasoline. This reduction in harmful emissions can lead to substantial public health benefits and reduced environmental degradation.

In the context of the hydrogen economy, DME can serve as an efficient hydrogen carrier. Its ability to be easily liquefied and stored at relatively low pressures makes it an attractive option for hydrogen transport and distribution. This characteristic can potentially reduce the energy and infrastructure requirements associated with hydrogen storage and transportation, thereby minimizing the overall environmental impact of the hydrogen supply chain.

Furthermore, DME's versatility allows for its integration into existing infrastructure with minimal modifications. This adaptability can lead to a smoother transition towards a hydrogen-based economy, reducing the environmental impact associated with large-scale infrastructure overhauls.

However, it is essential to consider the full lifecycle environmental impact of DME production and utilization. While DME offers numerous advantages, its production process, especially when derived from fossil fuels, can still contribute to carbon emissions. Therefore, emphasis should be placed on developing and scaling up sustainable DME production methods to maximize its environmental benefits.

The use of DME in the hydrogen economy also presents opportunities for waste valorization and circular economy principles. DME can be produced from various waste streams, including agricultural residues and municipal solid waste, potentially addressing multiple environmental challenges simultaneously.

In conclusion, the strategic application of DME in the hydrogen economy holds promise for reducing environmental impacts across various sectors. Its potential to lower emissions, improve air quality, and facilitate efficient hydrogen distribution positions DME as a valuable component in the transition towards a more sustainable energy landscape. However, ongoing research and development efforts are crucial to optimize DME production and utilization processes, ensuring that its full environmental benefits are realized within the broader context of the hydrogen economy.

Policy Framework for DME Adoption

The adoption of dimethyl ether (DME) as a strategic component in the hydrogen economy requires a comprehensive policy framework to facilitate its integration and widespread use. This framework should address various aspects, including regulatory measures, economic incentives, and infrastructure development.

Regulatory policies play a crucial role in creating an enabling environment for DME adoption. Governments need to establish clear standards and guidelines for DME production, storage, and utilization. These regulations should ensure safety, quality, and environmental compliance throughout the DME value chain. Additionally, policies should be implemented to streamline the approval process for DME-related projects and technologies, reducing bureaucratic barriers and accelerating market entry.

Economic incentives are essential to promote investment in DME technologies and infrastructure. Tax credits, subsidies, and grants can be offered to companies engaged in DME production, distribution, and end-use applications. These financial incentives can help offset initial costs and improve the economic viability of DME projects. Furthermore, carbon pricing mechanisms and emissions trading schemes can be designed to favor DME as a low-carbon alternative, enhancing its competitiveness in the energy market.

Infrastructure development is a critical component of the policy framework. Governments should support the establishment of DME production facilities, storage terminals, and distribution networks. This can be achieved through public-private partnerships, targeted funding programs, and streamlined permitting processes. Policies should also encourage the retrofitting of existing infrastructure to accommodate DME, such as modifying fuel stations and industrial facilities.

Research and development (R&D) initiatives should be prioritized within the policy framework. Governments can allocate funding for DME-related research, focusing on improving production efficiency, exploring novel applications, and addressing technical challenges. Collaborative research programs between academia, industry, and government institutions can accelerate innovation and knowledge sharing in the DME sector.

Public awareness and education campaigns are crucial for successful DME adoption. Policies should support outreach programs to inform stakeholders about the benefits and applications of DME in the hydrogen economy. This can include targeted information campaigns for industries, policymakers, and the general public, as well as incorporating DME-related topics into educational curricula.

International cooperation and harmonization of standards are essential aspects of the policy framework. Governments should engage in bilateral and multilateral agreements to facilitate cross-border trade and technology transfer related to DME. Harmonized standards and regulations can help create a global market for DME, fostering economies of scale and promoting widespread adoption.

Regulatory policies play a crucial role in creating an enabling environment for DME adoption. Governments need to establish clear standards and guidelines for DME production, storage, and utilization. These regulations should ensure safety, quality, and environmental compliance throughout the DME value chain. Additionally, policies should be implemented to streamline the approval process for DME-related projects and technologies, reducing bureaucratic barriers and accelerating market entry.

Economic incentives are essential to promote investment in DME technologies and infrastructure. Tax credits, subsidies, and grants can be offered to companies engaged in DME production, distribution, and end-use applications. These financial incentives can help offset initial costs and improve the economic viability of DME projects. Furthermore, carbon pricing mechanisms and emissions trading schemes can be designed to favor DME as a low-carbon alternative, enhancing its competitiveness in the energy market.

Infrastructure development is a critical component of the policy framework. Governments should support the establishment of DME production facilities, storage terminals, and distribution networks. This can be achieved through public-private partnerships, targeted funding programs, and streamlined permitting processes. Policies should also encourage the retrofitting of existing infrastructure to accommodate DME, such as modifying fuel stations and industrial facilities.

Research and development (R&D) initiatives should be prioritized within the policy framework. Governments can allocate funding for DME-related research, focusing on improving production efficiency, exploring novel applications, and addressing technical challenges. Collaborative research programs between academia, industry, and government institutions can accelerate innovation and knowledge sharing in the DME sector.

Public awareness and education campaigns are crucial for successful DME adoption. Policies should support outreach programs to inform stakeholders about the benefits and applications of DME in the hydrogen economy. This can include targeted information campaigns for industries, policymakers, and the general public, as well as incorporating DME-related topics into educational curricula.

International cooperation and harmonization of standards are essential aspects of the policy framework. Governments should engage in bilateral and multilateral agreements to facilitate cross-border trade and technology transfer related to DME. Harmonized standards and regulations can help create a global market for DME, fostering economies of scale and promoting widespread adoption.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!