Strategies for Isopentane Emissions Reduction in Chemical Plants

JUL 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Isopentane Emissions Background and Objectives

Isopentane, a volatile organic compound (VOC) widely used in the chemical industry, has become a significant concern due to its environmental impact and potential health hazards. The chemical's high vapor pressure and low boiling point make it prone to emissions during various industrial processes, particularly in chemical plants. As global environmental regulations become increasingly stringent, the reduction of isopentane emissions has emerged as a critical challenge for the chemical industry.

The evolution of isopentane emission control technologies can be traced back to the late 20th century when awareness of VOC emissions and their environmental consequences began to grow. Initially, efforts focused on basic containment and ventilation systems. However, as understanding of the long-term effects of VOC emissions on air quality and human health improved, more sophisticated control strategies emerged.

In recent years, the chemical industry has witnessed a paradigm shift towards sustainable practices, driven by both regulatory pressures and corporate social responsibility initiatives. This shift has accelerated the development of innovative technologies and methodologies for isopentane emissions reduction. The industry now recognizes that effective emission control not only ensures compliance with environmental regulations but also contributes to operational efficiency and cost savings.

The primary objective of isopentane emissions reduction strategies is to minimize the release of this compound into the atmosphere while maintaining or improving production efficiency. This goal encompasses several key aspects, including the development of advanced capture and recovery systems, the implementation of leak detection and repair (LDAR) programs, and the exploration of alternative processes or substitutes that can reduce or eliminate isopentane usage.

Another critical objective is to establish best practices and industry standards for isopentane handling and storage. This involves improving containment systems, optimizing process conditions to minimize volatilization, and implementing robust monitoring and reporting mechanisms. Additionally, there is a growing emphasis on employee training and awareness programs to ensure that operational practices align with emissions reduction goals.

As the chemical industry continues to evolve, the focus on isopentane emissions reduction is expected to intensify. Future objectives may include the development of closed-loop systems that virtually eliminate emissions, the integration of artificial intelligence and machine learning for predictive maintenance and real-time emission control, and the exploration of bio-based alternatives to isopentane in various applications.

The evolution of isopentane emission control technologies can be traced back to the late 20th century when awareness of VOC emissions and their environmental consequences began to grow. Initially, efforts focused on basic containment and ventilation systems. However, as understanding of the long-term effects of VOC emissions on air quality and human health improved, more sophisticated control strategies emerged.

In recent years, the chemical industry has witnessed a paradigm shift towards sustainable practices, driven by both regulatory pressures and corporate social responsibility initiatives. This shift has accelerated the development of innovative technologies and methodologies for isopentane emissions reduction. The industry now recognizes that effective emission control not only ensures compliance with environmental regulations but also contributes to operational efficiency and cost savings.

The primary objective of isopentane emissions reduction strategies is to minimize the release of this compound into the atmosphere while maintaining or improving production efficiency. This goal encompasses several key aspects, including the development of advanced capture and recovery systems, the implementation of leak detection and repair (LDAR) programs, and the exploration of alternative processes or substitutes that can reduce or eliminate isopentane usage.

Another critical objective is to establish best practices and industry standards for isopentane handling and storage. This involves improving containment systems, optimizing process conditions to minimize volatilization, and implementing robust monitoring and reporting mechanisms. Additionally, there is a growing emphasis on employee training and awareness programs to ensure that operational practices align with emissions reduction goals.

As the chemical industry continues to evolve, the focus on isopentane emissions reduction is expected to intensify. Future objectives may include the development of closed-loop systems that virtually eliminate emissions, the integration of artificial intelligence and machine learning for predictive maintenance and real-time emission control, and the exploration of bio-based alternatives to isopentane in various applications.

Market Drivers for Emissions Reduction

The global drive towards environmental sustainability and regulatory compliance has become a significant market driver for emissions reduction in chemical plants, particularly concerning isopentane. As governments worldwide implement stricter environmental policies, chemical companies face increasing pressure to reduce their carbon footprint and volatile organic compound (VOC) emissions. This regulatory landscape has created a robust market demand for innovative solutions to mitigate isopentane emissions.

The chemical industry's growing awareness of corporate social responsibility and the potential for cost savings through improved efficiency has further fueled the market for emissions reduction technologies. Companies are recognizing that implementing effective strategies for isopentane emissions reduction not only ensures compliance with regulations but also enhances their reputation and competitive edge in an increasingly environmentally conscious market.

Consumer demand for eco-friendly products has also played a crucial role in driving the market for emissions reduction. End-users across various industries, from automotive to consumer goods, are seeking products manufactured with minimal environmental impact. This shift in consumer preferences has cascaded up the supply chain, compelling chemical plants to adopt cleaner production processes and reduce their isopentane emissions.

The potential for energy recovery and cost savings associated with emissions reduction technologies has emerged as another significant market driver. By capturing and reusing isopentane that would otherwise be released into the atmosphere, chemical plants can improve their operational efficiency and reduce raw material costs. This economic incentive has spurred investment in advanced emissions control systems and process optimization techniques.

International climate agreements and carbon pricing mechanisms have further intensified the market focus on emissions reduction. As countries strive to meet their commitments under agreements like the Paris Accord, industries, including chemical manufacturing, are under increasing pressure to adopt low-emission technologies. The potential for carbon credits or avoiding carbon taxes has created additional financial incentives for companies to invest in isopentane emissions reduction strategies.

The growing emphasis on sustainable development goals (SDGs) by both public and private sectors has also contributed to the market demand for emissions reduction solutions. Chemical companies are aligning their operations with these global objectives, recognizing that effective emissions management is crucial for long-term sustainability and stakeholder value creation.

The chemical industry's growing awareness of corporate social responsibility and the potential for cost savings through improved efficiency has further fueled the market for emissions reduction technologies. Companies are recognizing that implementing effective strategies for isopentane emissions reduction not only ensures compliance with regulations but also enhances their reputation and competitive edge in an increasingly environmentally conscious market.

Consumer demand for eco-friendly products has also played a crucial role in driving the market for emissions reduction. End-users across various industries, from automotive to consumer goods, are seeking products manufactured with minimal environmental impact. This shift in consumer preferences has cascaded up the supply chain, compelling chemical plants to adopt cleaner production processes and reduce their isopentane emissions.

The potential for energy recovery and cost savings associated with emissions reduction technologies has emerged as another significant market driver. By capturing and reusing isopentane that would otherwise be released into the atmosphere, chemical plants can improve their operational efficiency and reduce raw material costs. This economic incentive has spurred investment in advanced emissions control systems and process optimization techniques.

International climate agreements and carbon pricing mechanisms have further intensified the market focus on emissions reduction. As countries strive to meet their commitments under agreements like the Paris Accord, industries, including chemical manufacturing, are under increasing pressure to adopt low-emission technologies. The potential for carbon credits or avoiding carbon taxes has created additional financial incentives for companies to invest in isopentane emissions reduction strategies.

The growing emphasis on sustainable development goals (SDGs) by both public and private sectors has also contributed to the market demand for emissions reduction solutions. Chemical companies are aligning their operations with these global objectives, recognizing that effective emissions management is crucial for long-term sustainability and stakeholder value creation.

Current Challenges in Isopentane Emissions Control

Isopentane emissions control in chemical plants faces several significant challenges that hinder effective reduction strategies. One of the primary obstacles is the volatile nature of isopentane, which easily vaporizes at room temperature. This characteristic makes containment and capture of emissions particularly difficult, especially during storage, transfer, and processing operations.

The complexity of chemical plant processes further complicates emissions control efforts. Isopentane is often used in various stages of production, and each stage may have different emission sources and rates. Identifying and addressing all these sources requires comprehensive monitoring systems and tailored solutions, which can be both technically challenging and cost-intensive.

Another major challenge is the limitation of current emission control technologies. While there are several methods available, such as vapor recovery systems and thermal oxidizers, each has its drawbacks. Vapor recovery systems may not be efficient enough to capture all emissions, especially during high-pressure operations. Thermal oxidizers, while effective, consume significant energy and may contribute to other environmental concerns through increased CO2 emissions.

The economic feasibility of implementing advanced emission control technologies poses another hurdle. Many chemical plants, particularly smaller operations, may find it financially challenging to invest in state-of-the-art emission reduction systems. This economic barrier can lead to slower adoption of more effective control measures across the industry.

Regulatory compliance adds another layer of complexity to isopentane emissions control. Varying standards across different regions and countries can make it difficult for multinational companies to implement consistent strategies. Moreover, keeping up with evolving regulations requires continuous adaptation of control measures, which can be resource-intensive.

The lack of real-time, accurate emission monitoring technologies specific to isopentane is another significant challenge. Without precise data on emission rates and sources, it becomes difficult to design and implement targeted reduction strategies. This gap in monitoring capabilities also hampers the ability to assess the effectiveness of implemented control measures accurately.

Lastly, the integration of emission control systems with existing plant infrastructure presents technical challenges. Retrofitting older facilities with modern emission control equipment can be complex, requiring careful planning to avoid disruptions to production processes. This integration challenge often leads to compromises in system design or efficiency, potentially limiting the overall effectiveness of emission reduction efforts.

The complexity of chemical plant processes further complicates emissions control efforts. Isopentane is often used in various stages of production, and each stage may have different emission sources and rates. Identifying and addressing all these sources requires comprehensive monitoring systems and tailored solutions, which can be both technically challenging and cost-intensive.

Another major challenge is the limitation of current emission control technologies. While there are several methods available, such as vapor recovery systems and thermal oxidizers, each has its drawbacks. Vapor recovery systems may not be efficient enough to capture all emissions, especially during high-pressure operations. Thermal oxidizers, while effective, consume significant energy and may contribute to other environmental concerns through increased CO2 emissions.

The economic feasibility of implementing advanced emission control technologies poses another hurdle. Many chemical plants, particularly smaller operations, may find it financially challenging to invest in state-of-the-art emission reduction systems. This economic barrier can lead to slower adoption of more effective control measures across the industry.

Regulatory compliance adds another layer of complexity to isopentane emissions control. Varying standards across different regions and countries can make it difficult for multinational companies to implement consistent strategies. Moreover, keeping up with evolving regulations requires continuous adaptation of control measures, which can be resource-intensive.

The lack of real-time, accurate emission monitoring technologies specific to isopentane is another significant challenge. Without precise data on emission rates and sources, it becomes difficult to design and implement targeted reduction strategies. This gap in monitoring capabilities also hampers the ability to assess the effectiveness of implemented control measures accurately.

Lastly, the integration of emission control systems with existing plant infrastructure presents technical challenges. Retrofitting older facilities with modern emission control equipment can be complex, requiring careful planning to avoid disruptions to production processes. This integration challenge often leads to compromises in system design or efficiency, potentially limiting the overall effectiveness of emission reduction efforts.

Existing Isopentane Emissions Reduction Strategies

01 Isopentane emission reduction in industrial processes

Various industrial processes have been developed to reduce isopentane emissions. These include methods for recovering isopentane from waste streams, improving separation techniques, and optimizing production processes to minimize losses. Such approaches help in reducing environmental impact and improving resource efficiency in industries that use or produce isopentane.- Isopentane emission reduction in industrial processes: Various industrial processes involve the use of isopentane, which can lead to emissions. Techniques have been developed to reduce these emissions, including improved sealing systems, vapor recovery units, and process optimization. These methods aim to capture and recycle isopentane vapors, minimizing their release into the environment.

- Isopentane as a blowing agent in foam production: Isopentane is used as a blowing agent in the production of foams, particularly in the manufacture of insulation materials. Efforts have been made to develop processes that minimize isopentane emissions during foam production and use. This includes improved encapsulation techniques and the development of alternative blowing agents with lower emission profiles.

- Isopentane in refrigeration and air conditioning systems: Isopentane is used as a refrigerant in some cooling systems. Research has focused on developing more efficient systems that reduce isopentane leakage and emissions. This includes improved sealing technologies, leak detection systems, and the exploration of alternative refrigerants with similar thermodynamic properties but lower environmental impact.

- Isopentane emissions in fuel systems: Isopentane is a component of some fuel blends and can contribute to evaporative emissions from fuel systems. Technologies have been developed to reduce these emissions, including improved fuel tank designs, vapor recovery systems, and the use of low-permeation materials in fuel system components.

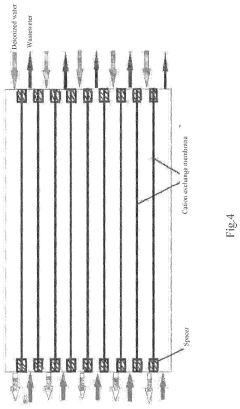

- Monitoring and control of isopentane emissions: Advanced monitoring and control systems have been developed to detect, measure, and manage isopentane emissions in various industrial settings. These systems employ sensors, data analytics, and automated control mechanisms to identify potential emission sources and implement real-time mitigation strategies, ensuring compliance with environmental regulations.

02 Isopentane as a blowing agent alternative

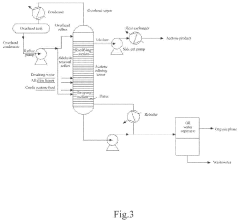

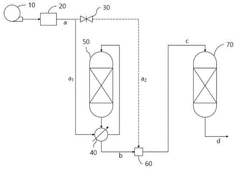

Isopentane is used as an alternative blowing agent in foam production, replacing ozone-depleting substances. However, its volatile nature requires careful handling to minimize emissions. Techniques have been developed to improve the efficiency of isopentane use in foam production, reducing overall emissions while maintaining product quality.Expand Specific Solutions03 Emission control in isopentane storage and transportation

Specialized equipment and methods have been designed to control isopentane emissions during storage and transportation. These include vapor recovery systems, improved sealing technologies, and advanced monitoring techniques to detect and prevent leaks. Such measures are crucial in reducing fugitive emissions from storage tanks and during transfer operations.Expand Specific Solutions04 Isopentane emission reduction in fuel systems

In the context of fuel systems, particularly in vehicles and fuel storage facilities, various technologies have been developed to reduce isopentane emissions. These include improved fuel tank designs, enhanced vapor recovery systems, and advanced fuel injection technologies that minimize evaporative losses of volatile compounds like isopentane.Expand Specific Solutions05 Analytical methods for isopentane emission monitoring

Advanced analytical techniques have been developed for accurate monitoring and quantification of isopentane emissions. These methods include improved gas chromatography techniques, real-time monitoring systems, and novel sensor technologies. Such advancements enable better emission control strategies and compliance with environmental regulations.Expand Specific Solutions

Key Players in Emissions Control Industry

The strategies for isopentane emissions reduction in chemical plants are at a mature stage of development, with ongoing refinement and optimization. The market for these solutions is substantial, driven by stringent environmental regulations and industry-wide sustainability initiatives. Technologically, the field is well-established, with major players like BASF Corp., Phillips 66, and SINOPEC Engineering (Group) Co., Ltd. leading innovation. These companies have developed advanced capture and control systems, process modifications, and leak detection technologies. The University of California and North Carolina State University contribute to research, while industry giants such as PetroChina Co., Ltd. and China Petroleum & Chemical Corp. implement large-scale solutions, demonstrating the technology's commercial viability and widespread adoption across the chemical sector.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a comprehensive strategy for isopentane emissions reduction in chemical plants. Their approach includes advanced process optimization, leak detection and repair (LDAR) programs, and the implementation of vapor recovery systems. Sinopec has implemented a closed-loop system for isopentane handling, which significantly reduces fugitive emissions[1]. They have also invested in state-of-the-art monitoring technologies, such as infrared cameras and portable VOC detectors, to quickly identify and address potential leaks[2]. Additionally, Sinopec has developed proprietary catalysts and processes that minimize isopentane formation during refining operations, thereby reducing overall emissions[3].

Strengths: Comprehensive approach combining process optimization, advanced monitoring, and innovative catalysts. Weaknesses: High initial investment costs and potential production disruptions during implementation.

BASF Corp.

Technical Solution: BASF Corp. has implemented a multi-faceted approach to reduce isopentane emissions in their chemical plants. Their strategy includes the use of advanced process control systems to optimize production and minimize waste. BASF has developed a proprietary vapor recovery unit (VRU) specifically designed for isopentane capture, which has shown efficiency rates of up to 99.5%[4]. The company has also invested in floating roof tanks with advanced sealing systems to reduce evaporative losses during storage. BASF's emissions reduction efforts extend to their transportation operations, where they have implemented vapor balancing systems for loading and unloading operations[5]. Furthermore, BASF has developed innovative materials for improved sealing in valves and flanges, significantly reducing fugitive emissions throughout their facilities.

Strengths: High-efficiency vapor recovery technology and comprehensive approach covering production, storage, and transportation. Weaknesses: Potential high costs associated with retrofitting existing facilities and implementing new technologies across all operations.

Innovative Approaches to Emissions Mitigation

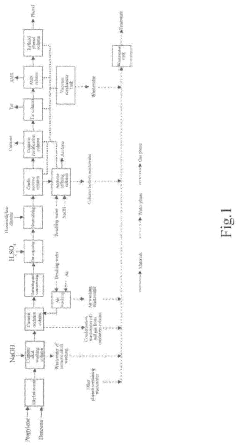

Method for reducing pollutant discharge in phenol and acetone production

PatentInactiveUS20200346959A1

Innovation

- A method that includes collecting and adjusting phenol-containing wastewater, using cumene as an extracting agent, optimizing the acetone refining column process, treating with a permselective membrane for alkali recovery, neutralizing and detoxifying wastewater, and subjecting it to oil separation and biological or degradation treatments to reduce pollutant concentrations and toxicity.

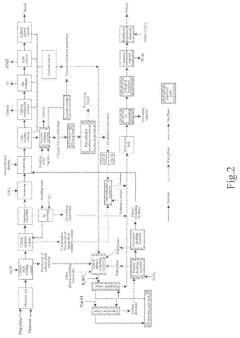

Process for simultaneously reducing isopropanol and ammonia

PatentWO2022245078A1

Innovation

- A process involving a two-reactor system where industrial exhaust gas containing isopropanol and ammonia is first oxidized in a reactor, followed by a second reactor that produces nitrogen, carbon dioxide, and water, minimizing secondary pollutant emissions without the need for a separate reducing agent by optimizing the stoichiometry and using specific catalysts and operating conditions.

Environmental Regulations and Compliance

Environmental regulations and compliance play a crucial role in shaping strategies for isopentane emissions reduction in chemical plants. The regulatory landscape for volatile organic compounds (VOCs) like isopentane has become increasingly stringent in recent years, driven by growing concerns over air quality and climate change.

In the United States, the Environmental Protection Agency (EPA) sets national standards for VOC emissions under the Clean Air Act. The National Emission Standards for Hazardous Air Pollutants (NESHAP) specifically addresses emissions from chemical manufacturing facilities. These regulations mandate the use of Maximum Achievable Control Technology (MACT) to reduce emissions from various processes, including those involving isopentane.

At the state level, regulations can be even more stringent. For instance, California's Air Resources Board (CARB) has implemented strict VOC emission limits for industrial facilities, including chemical plants. These regulations often require the use of best available control technologies (BACT) and continuous monitoring systems to ensure compliance.

In the European Union, the Industrial Emissions Directive (IED) sets the framework for regulating emissions from industrial activities. This directive requires chemical plants to obtain permits based on the application of Best Available Techniques (BAT). The BAT reference documents (BREFs) for the chemical sector provide detailed guidance on emission reduction strategies, including those applicable to isopentane.

Compliance with these regulations often necessitates significant investments in emission control technologies. Common approaches include the installation of vapor recovery systems, leak detection and repair (LDAR) programs, and the use of low-emission valves and seals. Many chemical plants are also implementing advanced process control systems to optimize operations and minimize emissions.

The regulatory landscape is not static, and chemical plants must stay abreast of evolving requirements. For example, there is a growing trend towards more stringent monitoring and reporting requirements, with some jurisdictions mandating real-time emission monitoring systems. This shift towards continuous monitoring is driving the adoption of advanced sensor technologies and data analytics in chemical plants.

International agreements, such as the Paris Agreement on climate change, are also influencing national and regional regulations on VOC emissions. As countries strive to meet their greenhouse gas reduction targets, chemical plants can expect increased pressure to reduce emissions of compounds like isopentane, which has a high global warming potential.

To ensure compliance and avoid penalties, chemical plants are increasingly adopting proactive environmental management strategies. This includes regular audits, employee training programs, and the implementation of environmental management systems (EMS) certified to standards such as ISO 14001. These systems help plants systematically identify and address environmental risks, including those related to isopentane emissions.

In the United States, the Environmental Protection Agency (EPA) sets national standards for VOC emissions under the Clean Air Act. The National Emission Standards for Hazardous Air Pollutants (NESHAP) specifically addresses emissions from chemical manufacturing facilities. These regulations mandate the use of Maximum Achievable Control Technology (MACT) to reduce emissions from various processes, including those involving isopentane.

At the state level, regulations can be even more stringent. For instance, California's Air Resources Board (CARB) has implemented strict VOC emission limits for industrial facilities, including chemical plants. These regulations often require the use of best available control technologies (BACT) and continuous monitoring systems to ensure compliance.

In the European Union, the Industrial Emissions Directive (IED) sets the framework for regulating emissions from industrial activities. This directive requires chemical plants to obtain permits based on the application of Best Available Techniques (BAT). The BAT reference documents (BREFs) for the chemical sector provide detailed guidance on emission reduction strategies, including those applicable to isopentane.

Compliance with these regulations often necessitates significant investments in emission control technologies. Common approaches include the installation of vapor recovery systems, leak detection and repair (LDAR) programs, and the use of low-emission valves and seals. Many chemical plants are also implementing advanced process control systems to optimize operations and minimize emissions.

The regulatory landscape is not static, and chemical plants must stay abreast of evolving requirements. For example, there is a growing trend towards more stringent monitoring and reporting requirements, with some jurisdictions mandating real-time emission monitoring systems. This shift towards continuous monitoring is driving the adoption of advanced sensor technologies and data analytics in chemical plants.

International agreements, such as the Paris Agreement on climate change, are also influencing national and regional regulations on VOC emissions. As countries strive to meet their greenhouse gas reduction targets, chemical plants can expect increased pressure to reduce emissions of compounds like isopentane, which has a high global warming potential.

To ensure compliance and avoid penalties, chemical plants are increasingly adopting proactive environmental management strategies. This includes regular audits, employee training programs, and the implementation of environmental management systems (EMS) certified to standards such as ISO 14001. These systems help plants systematically identify and address environmental risks, including those related to isopentane emissions.

Economic Impact of Emissions Reduction Measures

The implementation of isopentane emissions reduction strategies in chemical plants can have significant economic implications for the industry. These measures often require substantial initial investments in equipment upgrades, process modifications, and monitoring systems. However, the long-term financial benefits can outweigh the upfront costs, leading to improved operational efficiency and reduced environmental liabilities.

One of the primary economic impacts is the potential for cost savings through the recovery and reuse of isopentane. By implementing advanced capture and recycling technologies, chemical plants can reduce their raw material costs and minimize waste. This circular approach not only lowers operational expenses but also enhances resource efficiency, contributing to a more sustainable and economically viable production process.

Compliance with increasingly stringent environmental regulations is another crucial factor affecting the economic landscape. Proactive adoption of emissions reduction measures can help companies avoid hefty fines and penalties associated with non-compliance. Moreover, it can position them favorably in markets where environmental performance is a key differentiator, potentially leading to increased market share and customer loyalty.

The implementation of emissions reduction strategies can also drive innovation within the chemical industry. As companies invest in research and development to find novel solutions, they may create new intellectual property and technological advancements. These innovations can open up additional revenue streams through licensing or the development of new products and services related to emissions control.

Labor market dynamics are another economic consideration. The shift towards more environmentally friendly practices may require workforce retraining and the creation of new job roles focused on emissions management and sustainable operations. While this may incur short-term costs, it can lead to a more skilled and adaptable workforce, potentially increasing productivity and competitiveness in the long run.

Energy efficiency improvements often accompany emissions reduction efforts, resulting in lower utility costs for chemical plants. By optimizing processes and implementing energy recovery systems, companies can significantly reduce their energy consumption, leading to substantial savings over time. This not only improves the bottom line but also enhances resilience against energy price volatility.

The adoption of emissions reduction measures can also impact a company's access to capital. Financial institutions and investors are increasingly considering environmental performance in their lending and investment decisions. Companies demonstrating strong commitment to emissions reduction may benefit from improved access to green financing options, potentially at more favorable terms.

One of the primary economic impacts is the potential for cost savings through the recovery and reuse of isopentane. By implementing advanced capture and recycling technologies, chemical plants can reduce their raw material costs and minimize waste. This circular approach not only lowers operational expenses but also enhances resource efficiency, contributing to a more sustainable and economically viable production process.

Compliance with increasingly stringent environmental regulations is another crucial factor affecting the economic landscape. Proactive adoption of emissions reduction measures can help companies avoid hefty fines and penalties associated with non-compliance. Moreover, it can position them favorably in markets where environmental performance is a key differentiator, potentially leading to increased market share and customer loyalty.

The implementation of emissions reduction strategies can also drive innovation within the chemical industry. As companies invest in research and development to find novel solutions, they may create new intellectual property and technological advancements. These innovations can open up additional revenue streams through licensing or the development of new products and services related to emissions control.

Labor market dynamics are another economic consideration. The shift towards more environmentally friendly practices may require workforce retraining and the creation of new job roles focused on emissions management and sustainable operations. While this may incur short-term costs, it can lead to a more skilled and adaptable workforce, potentially increasing productivity and competitiveness in the long run.

Energy efficiency improvements often accompany emissions reduction efforts, resulting in lower utility costs for chemical plants. By optimizing processes and implementing energy recovery systems, companies can significantly reduce their energy consumption, leading to substantial savings over time. This not only improves the bottom line but also enhances resilience against energy price volatility.

The adoption of emissions reduction measures can also impact a company's access to capital. Financial institutions and investors are increasingly considering environmental performance in their lending and investment decisions. Companies demonstrating strong commitment to emissions reduction may benefit from improved access to green financing options, potentially at more favorable terms.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!