The Application of Carbolic Acid in Developing Renewable Polymers

JUL 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbolic Acid Polymers: Background and Objectives

Carbolic acid, also known as phenol, has been a cornerstone in the chemical industry for over a century. Its versatile properties have made it an essential component in various applications, from disinfectants to plastics. In recent years, the focus on sustainable and renewable materials has brought carbolic acid to the forefront of polymer research, particularly in the development of renewable polymers.

The evolution of carbolic acid-based polymers can be traced back to the early 20th century when Leo Baekeland invented Bakelite, the first fully synthetic plastic. This breakthrough marked the beginning of the modern plastics era and demonstrated the potential of carbolic acid in polymer synthesis. Since then, the field has witnessed significant advancements, with researchers exploring novel ways to harness the unique properties of carbolic acid for creating more sustainable and environmentally friendly polymers.

The current technological landscape is characterized by a growing emphasis on reducing dependence on fossil fuels and minimizing environmental impact. This shift has led to increased interest in bio-based and renewable resources for polymer production. Carbolic acid, which can be derived from both petrochemical and renewable sources, presents an intriguing opportunity to bridge the gap between traditional and sustainable polymer manufacturing.

The primary objective of research in this field is to develop innovative methods for synthesizing renewable polymers using carbolic acid as a key building block. This involves exploring various renewable sources of carbolic acid, such as lignin-derived compounds, and optimizing extraction and purification processes. Additionally, researchers aim to enhance the properties of carbolic acid-based polymers to match or exceed those of conventional petroleum-based plastics.

Another crucial goal is to improve the biodegradability and recyclability of these polymers, addressing the growing concern over plastic waste accumulation. By focusing on the entire lifecycle of carbolic acid polymers, from production to disposal, scientists and engineers strive to create materials that are not only renewable but also environmentally benign throughout their use and after-life phases.

The technological trajectory in this field is expected to lead to the development of a new generation of high-performance, sustainable polymers. These materials could potentially replace traditional plastics in various applications, ranging from packaging to automotive components, contributing to a more circular and sustainable economy.

As research progresses, it is anticipated that advancements in carbolic acid polymer technology will play a significant role in addressing global challenges related to resource depletion and environmental pollution. The successful implementation of these technologies could revolutionize the polymer industry, offering a viable path towards more sustainable material production and consumption patterns.

The evolution of carbolic acid-based polymers can be traced back to the early 20th century when Leo Baekeland invented Bakelite, the first fully synthetic plastic. This breakthrough marked the beginning of the modern plastics era and demonstrated the potential of carbolic acid in polymer synthesis. Since then, the field has witnessed significant advancements, with researchers exploring novel ways to harness the unique properties of carbolic acid for creating more sustainable and environmentally friendly polymers.

The current technological landscape is characterized by a growing emphasis on reducing dependence on fossil fuels and minimizing environmental impact. This shift has led to increased interest in bio-based and renewable resources for polymer production. Carbolic acid, which can be derived from both petrochemical and renewable sources, presents an intriguing opportunity to bridge the gap between traditional and sustainable polymer manufacturing.

The primary objective of research in this field is to develop innovative methods for synthesizing renewable polymers using carbolic acid as a key building block. This involves exploring various renewable sources of carbolic acid, such as lignin-derived compounds, and optimizing extraction and purification processes. Additionally, researchers aim to enhance the properties of carbolic acid-based polymers to match or exceed those of conventional petroleum-based plastics.

Another crucial goal is to improve the biodegradability and recyclability of these polymers, addressing the growing concern over plastic waste accumulation. By focusing on the entire lifecycle of carbolic acid polymers, from production to disposal, scientists and engineers strive to create materials that are not only renewable but also environmentally benign throughout their use and after-life phases.

The technological trajectory in this field is expected to lead to the development of a new generation of high-performance, sustainable polymers. These materials could potentially replace traditional plastics in various applications, ranging from packaging to automotive components, contributing to a more circular and sustainable economy.

As research progresses, it is anticipated that advancements in carbolic acid polymer technology will play a significant role in addressing global challenges related to resource depletion and environmental pollution. The successful implementation of these technologies could revolutionize the polymer industry, offering a viable path towards more sustainable material production and consumption patterns.

Market Analysis for Renewable Polymer Materials

The renewable polymer market has experienced significant growth in recent years, driven by increasing environmental concerns and the push for sustainable alternatives to traditional petroleum-based plastics. The global market for renewable polymers is projected to reach substantial value in the coming years, with a compound annual growth rate outpacing many other sectors in the chemical industry.

Carbolic acid, also known as phenol, plays a crucial role in the development of renewable polymers. Its application in this field has gained traction due to its versatility and potential to replace fossil-based raw materials. The market for phenol-based renewable polymers is particularly strong in industries such as packaging, automotive, and consumer goods, where there is a growing demand for eco-friendly materials.

The packaging industry represents the largest market segment for renewable polymers, with a focus on biodegradable and compostable solutions. Carbolic acid-derived polymers offer excellent barrier properties and durability, making them suitable for food packaging and other applications requiring extended shelf life. The automotive sector is another key market, driven by the need for lightweight, high-performance materials that can reduce vehicle weight and improve fuel efficiency.

Consumer goods manufacturers are increasingly adopting renewable polymers to meet the growing consumer demand for sustainable products. This trend is particularly evident in personal care and household items, where carbolic acid-based polymers can provide both functionality and environmental benefits.

Geographically, North America and Europe lead the market for renewable polymers, with stringent regulations promoting the use of sustainable materials. However, the Asia-Pacific region is expected to witness the fastest growth, driven by rapid industrialization, increasing environmental awareness, and supportive government policies.

The market for carbolic acid in renewable polymer development faces some challenges, including higher production costs compared to conventional polymers and the need for improved recycling infrastructure. However, ongoing research and development efforts are focused on addressing these issues, with innovations in production processes and material properties expected to drive down costs and improve overall performance.

As sustainability becomes a key focus for businesses and consumers alike, the market for renewable polymers, including those derived from carbolic acid, is poised for continued growth. This expansion is supported by increasing investments in research and development, as well as collaborations between industry players and academic institutions to develop novel applications and improve existing technologies.

Carbolic acid, also known as phenol, plays a crucial role in the development of renewable polymers. Its application in this field has gained traction due to its versatility and potential to replace fossil-based raw materials. The market for phenol-based renewable polymers is particularly strong in industries such as packaging, automotive, and consumer goods, where there is a growing demand for eco-friendly materials.

The packaging industry represents the largest market segment for renewable polymers, with a focus on biodegradable and compostable solutions. Carbolic acid-derived polymers offer excellent barrier properties and durability, making them suitable for food packaging and other applications requiring extended shelf life. The automotive sector is another key market, driven by the need for lightweight, high-performance materials that can reduce vehicle weight and improve fuel efficiency.

Consumer goods manufacturers are increasingly adopting renewable polymers to meet the growing consumer demand for sustainable products. This trend is particularly evident in personal care and household items, where carbolic acid-based polymers can provide both functionality and environmental benefits.

Geographically, North America and Europe lead the market for renewable polymers, with stringent regulations promoting the use of sustainable materials. However, the Asia-Pacific region is expected to witness the fastest growth, driven by rapid industrialization, increasing environmental awareness, and supportive government policies.

The market for carbolic acid in renewable polymer development faces some challenges, including higher production costs compared to conventional polymers and the need for improved recycling infrastructure. However, ongoing research and development efforts are focused on addressing these issues, with innovations in production processes and material properties expected to drive down costs and improve overall performance.

As sustainability becomes a key focus for businesses and consumers alike, the market for renewable polymers, including those derived from carbolic acid, is poised for continued growth. This expansion is supported by increasing investments in research and development, as well as collaborations between industry players and academic institutions to develop novel applications and improve existing technologies.

Current State and Challenges in Carbolic Acid Polymerization

The current state of carbolic acid polymerization presents both promising advancements and significant challenges. Globally, researchers have made substantial progress in developing renewable polymers from carbolic acid, also known as phenol. These efforts align with the growing demand for sustainable materials in various industries, including packaging, automotive, and construction.

One of the primary achievements in this field is the successful synthesis of polycarbonates using carbolic acid derivatives. These polymers exhibit excellent thermal and mechanical properties, making them potential alternatives to petroleum-based plastics. However, the scalability of these processes remains a major hurdle, as current production methods are often energy-intensive and costly.

Another area of focus has been the development of phenol-formaldehyde resins with improved environmental profiles. Researchers have made strides in reducing the toxicity of these resins by incorporating bio-based components and optimizing curing processes. Despite these advancements, challenges persist in achieving comparable performance to traditional formulations while maintaining cost-effectiveness.

The geographical distribution of carbolic acid polymerization research shows concentrations in North America, Europe, and Asia, with emerging contributions from South America and Australia. This global effort has led to diverse approaches and innovations, but also highlights the need for increased collaboration to overcome shared challenges.

A significant technical obstacle in carbolic acid polymerization is the control of molecular weight and polydispersity. Current polymerization techniques often result in polymers with broad molecular weight distributions, which can negatively impact material properties. Researchers are exploring various catalysts and reaction conditions to achieve better control, but progress has been incremental.

Environmental concerns also pose challenges to the widespread adoption of carbolic acid-based polymers. While these materials offer potential sustainability benefits, the production of carbolic acid itself often relies on petroleum sources. Efforts to develop bio-based routes for carbolic acid production are ongoing but face obstacles in terms of yield and economic viability.

Lastly, the regulatory landscape surrounding carbolic acid and its derivatives presents additional complexities. Stringent safety regulations and varying global standards create barriers to commercialization and international trade of carbolic acid-based polymers. Industry stakeholders are working towards harmonizing standards and developing safer handling protocols to address these challenges.

One of the primary achievements in this field is the successful synthesis of polycarbonates using carbolic acid derivatives. These polymers exhibit excellent thermal and mechanical properties, making them potential alternatives to petroleum-based plastics. However, the scalability of these processes remains a major hurdle, as current production methods are often energy-intensive and costly.

Another area of focus has been the development of phenol-formaldehyde resins with improved environmental profiles. Researchers have made strides in reducing the toxicity of these resins by incorporating bio-based components and optimizing curing processes. Despite these advancements, challenges persist in achieving comparable performance to traditional formulations while maintaining cost-effectiveness.

The geographical distribution of carbolic acid polymerization research shows concentrations in North America, Europe, and Asia, with emerging contributions from South America and Australia. This global effort has led to diverse approaches and innovations, but also highlights the need for increased collaboration to overcome shared challenges.

A significant technical obstacle in carbolic acid polymerization is the control of molecular weight and polydispersity. Current polymerization techniques often result in polymers with broad molecular weight distributions, which can negatively impact material properties. Researchers are exploring various catalysts and reaction conditions to achieve better control, but progress has been incremental.

Environmental concerns also pose challenges to the widespread adoption of carbolic acid-based polymers. While these materials offer potential sustainability benefits, the production of carbolic acid itself often relies on petroleum sources. Efforts to develop bio-based routes for carbolic acid production are ongoing but face obstacles in terms of yield and economic viability.

Lastly, the regulatory landscape surrounding carbolic acid and its derivatives presents additional complexities. Stringent safety regulations and varying global standards create barriers to commercialization and international trade of carbolic acid-based polymers. Industry stakeholders are working towards harmonizing standards and developing safer handling protocols to address these challenges.

Existing Carbolic Acid Polymerization Methods

01 Historical use in medical and industrial applications

Carbolic acid, also known as phenol, has a long history of use in medical and industrial applications. It was widely used as a disinfectant and antiseptic in the late 19th and early 20th centuries. Its properties made it valuable for sterilization in medical settings and for various industrial processes.- Historical use in medical applications: Carbolic acid, also known as phenol, has a long history of use in medical applications. It was widely used as an antiseptic and disinfectant in the late 19th and early 20th centuries. Its properties made it valuable for sterilizing surgical instruments and treating wounds, although its use has since been largely replaced by safer alternatives.

- Industrial applications and manufacturing processes: Carbolic acid has various industrial applications, including in the production of plastics, resins, and other chemical compounds. Patents in this area focus on improved manufacturing processes, purification methods, and novel applications in industrial settings.

- Environmental and waste treatment applications: Several patents describe the use of carbolic acid or its derivatives in environmental applications, particularly in waste treatment and water purification processes. These innovations aim to improve the efficiency of pollutant removal and reduce environmental impact.

- Pharmaceutical and cosmetic formulations: Carbolic acid and its derivatives are used in various pharmaceutical and cosmetic formulations. Patents in this category describe novel compositions, delivery systems, and applications in topical treatments, oral care products, and other personal care items.

- Safety and handling improvements: Given the toxic nature of carbolic acid, several patents focus on improving safety measures in its handling, storage, and application. These innovations include specialized containers, protective equipment, and methods for reducing exposure risks in various settings.

02 Incorporation in cleaning and disinfecting products

Carbolic acid is utilized in the formulation of various cleaning and disinfecting products. Its antimicrobial properties make it effective in household cleaners, industrial degreasers, and sanitizing solutions. These products often combine carbolic acid with other ingredients to enhance their cleaning and disinfecting capabilities.Expand Specific Solutions03 Use in polymer and resin production

Carbolic acid serves as a key raw material in the production of various polymers and resins. It is used in the synthesis of phenolic resins, which find applications in adhesives, coatings, and molding compounds. The chemical properties of carbolic acid make it valuable in creating durable and heat-resistant materials.Expand Specific Solutions04 Application in water treatment systems

Carbolic acid is employed in water treatment processes due to its disinfectant properties. It can be used in industrial and municipal water treatment systems to eliminate harmful microorganisms and improve water quality. The compound's effectiveness in controlling bacterial growth makes it useful in maintaining clean water supplies.Expand Specific Solutions05 Innovations in safe handling and application methods

Given the potentially hazardous nature of carbolic acid, there have been innovations in developing safer handling and application methods. These include improved containment systems, specialized dispensing equipment, and formulations that reduce risks associated with exposure. Such advancements aim to enhance safety while maintaining the compound's effectiveness in various applications.Expand Specific Solutions

Key Players in Renewable Polymer Industry

The application of carbolic acid in developing renewable polymers is an emerging field in the sustainable materials industry. The market is in its early growth stage, with increasing demand for eco-friendly alternatives to traditional petroleum-based polymers. The global market for renewable polymers is projected to expand significantly in the coming years, driven by environmental concerns and regulatory pressures. Technologically, the field is rapidly evolving, with key players like DSM IP Assets BV, Arkema France SA, and Evonik Operations GmbH leading research and development efforts. Universities such as the University of Florida and Zhejiang University are also contributing to advancements in this area. While the technology is promising, it is still in the process of scaling up for commercial applications, indicating a moderate level of technological maturity.

DSM IP Assets BV

Technical Solution: DSM has developed a novel approach to utilizing carbolic acid in the production of renewable polymers. Their method involves the catalytic oxidation of lignin-derived phenols to produce carbolic acid, which is then used as a building block for bio-based polymers [1]. This process allows for the creation of high-performance materials with reduced environmental impact. DSM's technology incorporates a unique catalyst system that enhances the selectivity and yield of carbolic acid production, resulting in a more efficient and cost-effective process [2]. The company has also implemented advanced polymerization techniques to optimize the properties of the final renewable polymers, such as improved thermal stability and mechanical strength [3].

Strengths: Utilizes lignin, a renewable resource; High efficiency in carbolic acid production; Produces high-performance bio-based polymers. Weaknesses: May require specialized equipment; Potential scalability challenges for large-scale production.

Arkema France SA

Technical Solution: Arkema has pioneered a groundbreaking approach to incorporating carbolic acid in renewable polymer development. Their technology focuses on the synthesis of bio-based epoxy resins using carbolic acid derivatives obtained from renewable resources [4]. The process involves a two-step reaction: first, the conversion of plant-based phenolic compounds to carbolic acid, and second, the epoxidation of carbolic acid to create renewable epoxy monomers [5]. Arkema's method utilizes a proprietary catalyst system that enhances the selectivity of the epoxidation reaction, resulting in higher yields and purity of the final product. The company has also developed innovative curing agents specifically designed for these bio-based epoxy resins, ensuring optimal performance in various applications [6].

Strengths: Production of high-value epoxy resins; Tailored curing agents for optimal performance; Versatile applications in coatings and composites. Weaknesses: Potentially higher production costs compared to petroleum-based alternatives; Limited by availability of renewable phenolic precursors.

Innovative Approaches in Carbolic Acid Polymer Synthesis

Renewable polymers and resins and methods of making the same

PatentInactiveUS20210347949A1

Innovation

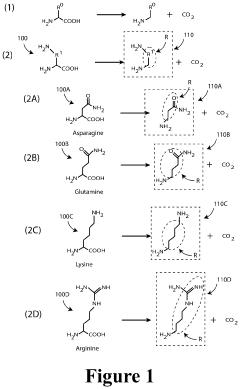

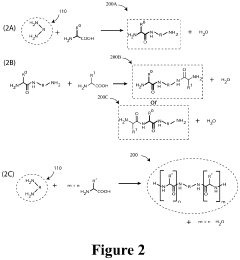

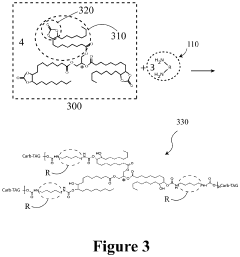

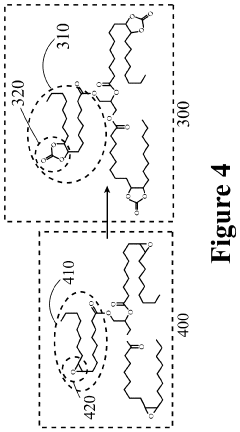

- The method involves reacting amino acids, peptides, or polypeptides with carbonated lipids using diamines to produce polymers and resins, and employing electrophoresis for cost-effective PUFA enrichment, allowing for the production of bio-derived polymers and resins that eliminate the use of toxic isocyanates and enable scalable PUFA purification.

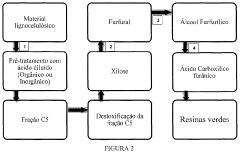

process FOR THE PRODUCTION OF FURANIC CARBOXYLIC ACID COMPOUND DERIVED FROM A PLANT BIOMASS AND COMPOUND

PatentInactiveBR102013019462A2

Innovation

- A process is developed to obtain furanic carboxylic acid from plant biomass, specifically sugarcane bagasse, by pre-treating the biomass with diluted acid to separate xylose, converting it to furfural, then to furfuryl alcohol, and finally reacting it with pyruvic acid or alkyne ester to form furanic carboxylic acid, which can be used as a polymerization monomer for renewable polymers and resins.

Environmental Impact Assessment

The application of carbolic acid in developing renewable polymers presents both opportunities and challenges from an environmental perspective. The use of renewable resources in polymer production aligns with sustainability goals, potentially reducing reliance on fossil fuels and mitigating greenhouse gas emissions. However, the environmental impact of carbolic acid production and its incorporation into polymers requires careful consideration.

Carbolic acid, also known as phenol, can be derived from renewable sources such as lignin, a by-product of the paper and pulp industry. This approach offers a more sustainable alternative to traditional petrochemical-based phenol production. The utilization of waste biomass for carbolic acid synthesis contributes to circular economy principles, reducing overall waste and maximizing resource efficiency.

The production process of renewable carbolic acid generally has a lower carbon footprint compared to conventional methods. This reduction in greenhouse gas emissions is a significant environmental benefit, particularly in the context of global climate change mitigation efforts. Additionally, the use of renewable feedstocks helps preserve non-renewable resources, promoting long-term environmental sustainability.

However, the environmental impact of carbolic acid-based renewable polymers extends beyond production. The biodegradability and end-of-life management of these polymers are crucial factors to consider. While some renewable polymers may offer improved biodegradability compared to their petrochemical counterparts, others may persist in the environment, potentially contributing to plastic pollution if not properly managed.

The toxicity of carbolic acid itself is another environmental concern. Proper handling, storage, and disposal protocols must be implemented to prevent accidental releases into ecosystems. Occupational safety measures are also essential to protect workers involved in the production and processing of carbolic acid and its derived polymers.

Water usage and potential contamination are additional environmental aspects to evaluate. The production of carbolic acid and its subsequent polymerization may require significant water resources. Implementing water-efficient processes and effective wastewater treatment systems is crucial to minimize the environmental impact on local water bodies and aquatic ecosystems.

Land use changes associated with the cultivation of biomass for carbolic acid production must also be considered. Sustainable land management practices are essential to prevent deforestation, preserve biodiversity, and maintain soil health. Balancing the demand for renewable feedstocks with food security and ecosystem conservation is a complex challenge that requires careful planning and policy implementation.

In conclusion, while the application of carbolic acid in developing renewable polymers offers promising environmental benefits, a comprehensive life cycle assessment is necessary to fully understand and mitigate potential negative impacts. Continued research and development in this field should focus on optimizing production processes, enhancing polymer biodegradability, and implementing robust environmental management systems to ensure the sustainable growth of this innovative technology.

Carbolic acid, also known as phenol, can be derived from renewable sources such as lignin, a by-product of the paper and pulp industry. This approach offers a more sustainable alternative to traditional petrochemical-based phenol production. The utilization of waste biomass for carbolic acid synthesis contributes to circular economy principles, reducing overall waste and maximizing resource efficiency.

The production process of renewable carbolic acid generally has a lower carbon footprint compared to conventional methods. This reduction in greenhouse gas emissions is a significant environmental benefit, particularly in the context of global climate change mitigation efforts. Additionally, the use of renewable feedstocks helps preserve non-renewable resources, promoting long-term environmental sustainability.

However, the environmental impact of carbolic acid-based renewable polymers extends beyond production. The biodegradability and end-of-life management of these polymers are crucial factors to consider. While some renewable polymers may offer improved biodegradability compared to their petrochemical counterparts, others may persist in the environment, potentially contributing to plastic pollution if not properly managed.

The toxicity of carbolic acid itself is another environmental concern. Proper handling, storage, and disposal protocols must be implemented to prevent accidental releases into ecosystems. Occupational safety measures are also essential to protect workers involved in the production and processing of carbolic acid and its derived polymers.

Water usage and potential contamination are additional environmental aspects to evaluate. The production of carbolic acid and its subsequent polymerization may require significant water resources. Implementing water-efficient processes and effective wastewater treatment systems is crucial to minimize the environmental impact on local water bodies and aquatic ecosystems.

Land use changes associated with the cultivation of biomass for carbolic acid production must also be considered. Sustainable land management practices are essential to prevent deforestation, preserve biodiversity, and maintain soil health. Balancing the demand for renewable feedstocks with food security and ecosystem conservation is a complex challenge that requires careful planning and policy implementation.

In conclusion, while the application of carbolic acid in developing renewable polymers offers promising environmental benefits, a comprehensive life cycle assessment is necessary to fully understand and mitigate potential negative impacts. Continued research and development in this field should focus on optimizing production processes, enhancing polymer biodegradability, and implementing robust environmental management systems to ensure the sustainable growth of this innovative technology.

Regulatory Framework for Bio-based Polymers

The regulatory framework for bio-based polymers, including those derived from carbolic acid, is evolving rapidly to address the growing demand for sustainable materials. At the international level, organizations such as the International Organization for Standardization (ISO) have developed standards for bio-based products, including ISO 16620 series for the determination of bio-based content. These standards provide a common language and methodology for assessing the renewable content of polymers, crucial for market acceptance and regulatory compliance.

In the European Union, the regulatory landscape is particularly advanced. The EU's Bioeconomy Strategy and Circular Economy Action Plan provide overarching policy frameworks that encourage the development and use of bio-based polymers. The European Committee for Standardization (CEN) has established specific standards for bio-based products, including CEN/TS 16137 for the determination of bio-based carbon content. Additionally, the EU's Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation applies to bio-based polymers, ensuring their safety for human health and the environment.

In the United States, the regulatory approach is more fragmented. The U.S. Department of Agriculture's BioPreferred program promotes the purchase and use of bio-based products, including polymers. The Environmental Protection Agency (EPA) regulates bio-based polymers under the Toxic Substances Control Act (TSCA), which requires manufacturers to submit premanufacture notices for new chemical substances.

Many countries have implemented or are developing eco-labeling schemes that include criteria for bio-based content. For instance, Japan's Eco Mark and Germany's Blue Angel have specific categories for products containing bio-based polymers. These schemes help consumers identify environmentally preferable products and incentivize manufacturers to increase their use of renewable materials.

Regulatory challenges remain, particularly in harmonizing standards across different jurisdictions and addressing end-of-life issues for bio-based polymers. The lack of consistent definitions and methodologies for assessing biodegradability and compostability across regions can create market barriers. Furthermore, regulations governing waste management and recycling infrastructure often lag behind the development of new bio-based materials, potentially limiting their environmental benefits.

As the field of renewable polymers continues to advance, regulatory frameworks are likely to evolve. Future regulations may focus on life cycle assessments, carbon footprint reduction, and the promotion of closed-loop systems for bio-based polymers. The development of these regulations will require ongoing collaboration between policymakers, industry stakeholders, and scientific experts to ensure that the regulatory landscape supports innovation while protecting public health and the environment.

In the European Union, the regulatory landscape is particularly advanced. The EU's Bioeconomy Strategy and Circular Economy Action Plan provide overarching policy frameworks that encourage the development and use of bio-based polymers. The European Committee for Standardization (CEN) has established specific standards for bio-based products, including CEN/TS 16137 for the determination of bio-based carbon content. Additionally, the EU's Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation applies to bio-based polymers, ensuring their safety for human health and the environment.

In the United States, the regulatory approach is more fragmented. The U.S. Department of Agriculture's BioPreferred program promotes the purchase and use of bio-based products, including polymers. The Environmental Protection Agency (EPA) regulates bio-based polymers under the Toxic Substances Control Act (TSCA), which requires manufacturers to submit premanufacture notices for new chemical substances.

Many countries have implemented or are developing eco-labeling schemes that include criteria for bio-based content. For instance, Japan's Eco Mark and Germany's Blue Angel have specific categories for products containing bio-based polymers. These schemes help consumers identify environmentally preferable products and incentivize manufacturers to increase their use of renewable materials.

Regulatory challenges remain, particularly in harmonizing standards across different jurisdictions and addressing end-of-life issues for bio-based polymers. The lack of consistent definitions and methodologies for assessing biodegradability and compostability across regions can create market barriers. Furthermore, regulations governing waste management and recycling infrastructure often lag behind the development of new bio-based materials, potentially limiting their environmental benefits.

As the field of renewable polymers continues to advance, regulatory frameworks are likely to evolve. Future regulations may focus on life cycle assessments, carbon footprint reduction, and the promotion of closed-loop systems for bio-based polymers. The development of these regulations will require ongoing collaboration between policymakers, industry stakeholders, and scientific experts to ensure that the regulatory landscape supports innovation while protecting public health and the environment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!