The Effect of Altitude on V12 Engine Performance

AUG 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V12 Engine Altitude Performance Background

The V12 engine, renowned for its smooth operation and high power output, has been a hallmark of luxury and high-performance vehicles for decades. However, its performance characteristics can be significantly affected by changes in altitude. This phenomenon has been a subject of interest for automotive engineers and enthusiasts alike, as it impacts the engine's efficiency, power delivery, and overall performance across various geographical locations.

At sea level, where atmospheric pressure is at its highest, V12 engines typically perform at their optimal level. The dense air provides ample oxygen for combustion, allowing the engine to generate maximum power. As altitude increases, the air becomes thinner, leading to a decrease in oxygen concentration. This reduction in available oxygen has a direct impact on the combustion process, resulting in decreased engine performance.

The effect of altitude on V12 engine performance is particularly noticeable in naturally aspirated engines. These engines rely solely on atmospheric pressure to draw air into the combustion chamber. As the air density decreases with altitude, less oxygen enters the engine, leading to a lean air-fuel mixture. This can result in reduced power output, decreased fuel efficiency, and potential engine knock or detonation.

Historically, this challenge has been addressed through various engineering solutions. Carbureted engines required manual adjustments to compensate for altitude changes, often necessitating specialized high-altitude jets. With the advent of electronic fuel injection systems, adaptive algorithms were developed to automatically adjust fuel delivery based on air density and other environmental factors.

Modern V12 engines often incorporate forced induction systems, such as turbochargers or superchargers, to mitigate the effects of altitude. These systems compress the incoming air, effectively increasing its density and ensuring a more consistent air-fuel mixture across different altitudes. However, even forced induction engines experience some performance loss at extreme altitudes due to the overall reduction in atmospheric pressure.

The impact of altitude on V12 engine performance extends beyond power output. It also affects emissions, as the altered air-fuel mixture can lead to incomplete combustion and increased pollutant production. This has implications for both environmental regulations and vehicle certification processes, particularly for markets in high-altitude regions.

Understanding the relationship between altitude and V12 engine performance is crucial for automotive manufacturers, especially those targeting global markets with diverse geographical conditions. It influences not only engine design and calibration but also vehicle marketing strategies and performance claims. As such, extensive research and development efforts continue to focus on optimizing V12 engine performance across a wide range of altitudes, ensuring consistent power delivery and efficiency in various operating environments.

At sea level, where atmospheric pressure is at its highest, V12 engines typically perform at their optimal level. The dense air provides ample oxygen for combustion, allowing the engine to generate maximum power. As altitude increases, the air becomes thinner, leading to a decrease in oxygen concentration. This reduction in available oxygen has a direct impact on the combustion process, resulting in decreased engine performance.

The effect of altitude on V12 engine performance is particularly noticeable in naturally aspirated engines. These engines rely solely on atmospheric pressure to draw air into the combustion chamber. As the air density decreases with altitude, less oxygen enters the engine, leading to a lean air-fuel mixture. This can result in reduced power output, decreased fuel efficiency, and potential engine knock or detonation.

Historically, this challenge has been addressed through various engineering solutions. Carbureted engines required manual adjustments to compensate for altitude changes, often necessitating specialized high-altitude jets. With the advent of electronic fuel injection systems, adaptive algorithms were developed to automatically adjust fuel delivery based on air density and other environmental factors.

Modern V12 engines often incorporate forced induction systems, such as turbochargers or superchargers, to mitigate the effects of altitude. These systems compress the incoming air, effectively increasing its density and ensuring a more consistent air-fuel mixture across different altitudes. However, even forced induction engines experience some performance loss at extreme altitudes due to the overall reduction in atmospheric pressure.

The impact of altitude on V12 engine performance extends beyond power output. It also affects emissions, as the altered air-fuel mixture can lead to incomplete combustion and increased pollutant production. This has implications for both environmental regulations and vehicle certification processes, particularly for markets in high-altitude regions.

Understanding the relationship between altitude and V12 engine performance is crucial for automotive manufacturers, especially those targeting global markets with diverse geographical conditions. It influences not only engine design and calibration but also vehicle marketing strategies and performance claims. As such, extensive research and development efforts continue to focus on optimizing V12 engine performance across a wide range of altitudes, ensuring consistent power delivery and efficiency in various operating environments.

Market Analysis for High-Altitude V12 Applications

The market for high-altitude V12 applications presents a niche yet potentially lucrative segment within the automotive and aerospace industries. As altitude increases, the performance of traditional engines, including V12s, typically decreases due to reduced air density. This creates a unique demand for specialized V12 engines capable of maintaining optimal performance at high altitudes.

In the automotive sector, luxury and high-performance vehicle manufacturers are showing increased interest in developing altitude-optimized V12 engines. This trend is driven by the growing popularity of luxury SUVs and performance cars in mountainous regions and high-altitude urban areas. Markets such as Colorado in the United States, parts of South America, and certain regions in Asia have become focal points for these specialized engines.

The aerospace industry also presents significant opportunities for high-altitude V12 applications. While jet engines dominate commercial aviation, there is a renewed interest in piston engines for certain niche applications, including high-altitude reconnaissance aircraft and specialized cargo planes designed to operate in challenging environments.

The market size for high-altitude V12 engines is relatively small compared to standard automotive engines, but it commands premium pricing due to its specialized nature. Current estimates suggest a global market value in the hundreds of millions of dollars, with potential for growth as more manufacturers enter this space and new applications are developed.

Key market drivers include the increasing demand for luxury vehicles in high-altitude regions, the expansion of infrastructure and tourism in mountainous areas, and the need for specialized aircraft capable of operating efficiently at high altitudes. Additionally, as environmental regulations become stricter, there is a growing emphasis on developing more efficient high-altitude engines, which could further stimulate market growth.

Challenges in this market include the high development costs associated with altitude-optimized engines, limited production volumes, and competition from alternative technologies such as turbocharged smaller engines or electric powertrains. However, for certain applications where the unique characteristics of V12 engines are valued, such as their smooth power delivery and prestigious status, there remains a strong market potential.

Looking ahead, the market for high-altitude V12 applications is expected to evolve with advancements in materials science, turbocharging technology, and engine management systems. These developments could expand the capabilities of V12 engines at high altitudes, potentially opening up new market segments and applications.

In the automotive sector, luxury and high-performance vehicle manufacturers are showing increased interest in developing altitude-optimized V12 engines. This trend is driven by the growing popularity of luxury SUVs and performance cars in mountainous regions and high-altitude urban areas. Markets such as Colorado in the United States, parts of South America, and certain regions in Asia have become focal points for these specialized engines.

The aerospace industry also presents significant opportunities for high-altitude V12 applications. While jet engines dominate commercial aviation, there is a renewed interest in piston engines for certain niche applications, including high-altitude reconnaissance aircraft and specialized cargo planes designed to operate in challenging environments.

The market size for high-altitude V12 engines is relatively small compared to standard automotive engines, but it commands premium pricing due to its specialized nature. Current estimates suggest a global market value in the hundreds of millions of dollars, with potential for growth as more manufacturers enter this space and new applications are developed.

Key market drivers include the increasing demand for luxury vehicles in high-altitude regions, the expansion of infrastructure and tourism in mountainous areas, and the need for specialized aircraft capable of operating efficiently at high altitudes. Additionally, as environmental regulations become stricter, there is a growing emphasis on developing more efficient high-altitude engines, which could further stimulate market growth.

Challenges in this market include the high development costs associated with altitude-optimized engines, limited production volumes, and competition from alternative technologies such as turbocharged smaller engines or electric powertrains. However, for certain applications where the unique characteristics of V12 engines are valued, such as their smooth power delivery and prestigious status, there remains a strong market potential.

Looking ahead, the market for high-altitude V12 applications is expected to evolve with advancements in materials science, turbocharging technology, and engine management systems. These developments could expand the capabilities of V12 engines at high altitudes, potentially opening up new market segments and applications.

Current Challenges in High-Altitude V12 Operation

Operating V12 engines at high altitudes presents several significant challenges that impact performance and reliability. As air density decreases with altitude, the amount of oxygen available for combustion reduces, leading to a decrease in engine power output. This power loss can be substantial, with some estimates suggesting a 3% reduction in power for every 1,000 feet of elevation gain.

Fuel mixture management becomes increasingly critical at higher altitudes. The lower air density can result in an overly rich fuel mixture, leading to inefficient combustion, increased fuel consumption, and potential engine damage. Advanced fuel injection systems and altitude-compensating carburetors are necessary to maintain optimal air-fuel ratios across varying altitudes.

Cooling system efficiency is another major concern in high-altitude operations. The thinner air reduces the cooling capacity of radiators and intercoolers, potentially leading to overheating issues. This problem is exacerbated by the fact that V12 engines, with their large displacement and high power output, generate significant heat even under normal conditions.

Turbocharging and supercharging systems, often used to mitigate altitude-related power loss, face their own challenges. These forced induction systems must be carefully calibrated to provide consistent boost pressure across a wide range of altitudes without over-stressing the engine components or exceeding safe operating limits.

Lubricant performance is also affected by high-altitude conditions. Lower atmospheric pressure can cause oil to foam or aerate more easily, potentially reducing its lubricating properties and increasing the risk of engine wear. Specialized high-altitude lubricants may be required to maintain proper engine protection.

The complexity of V12 engines, with their multiple cylinders and intricate valve trains, adds another layer of difficulty to high-altitude operation. Ensuring consistent combustion and balanced performance across all cylinders becomes more challenging as atmospheric conditions change rapidly with altitude variations.

Emissions control is an additional concern, as the altered combustion characteristics at high altitudes can lead to increased pollutant production. Meeting stringent emissions standards while maintaining performance across a wide range of operating altitudes requires sophisticated engine management systems and potentially additional emissions control technologies.

Fuel mixture management becomes increasingly critical at higher altitudes. The lower air density can result in an overly rich fuel mixture, leading to inefficient combustion, increased fuel consumption, and potential engine damage. Advanced fuel injection systems and altitude-compensating carburetors are necessary to maintain optimal air-fuel ratios across varying altitudes.

Cooling system efficiency is another major concern in high-altitude operations. The thinner air reduces the cooling capacity of radiators and intercoolers, potentially leading to overheating issues. This problem is exacerbated by the fact that V12 engines, with their large displacement and high power output, generate significant heat even under normal conditions.

Turbocharging and supercharging systems, often used to mitigate altitude-related power loss, face their own challenges. These forced induction systems must be carefully calibrated to provide consistent boost pressure across a wide range of altitudes without over-stressing the engine components or exceeding safe operating limits.

Lubricant performance is also affected by high-altitude conditions. Lower atmospheric pressure can cause oil to foam or aerate more easily, potentially reducing its lubricating properties and increasing the risk of engine wear. Specialized high-altitude lubricants may be required to maintain proper engine protection.

The complexity of V12 engines, with their multiple cylinders and intricate valve trains, adds another layer of difficulty to high-altitude operation. Ensuring consistent combustion and balanced performance across all cylinders becomes more challenging as atmospheric conditions change rapidly with altitude variations.

Emissions control is an additional concern, as the altered combustion characteristics at high altitudes can lead to increased pollutant production. Meeting stringent emissions standards while maintaining performance across a wide range of operating altitudes requires sophisticated engine management systems and potentially additional emissions control technologies.

Existing High-Altitude V12 Compensation Methods

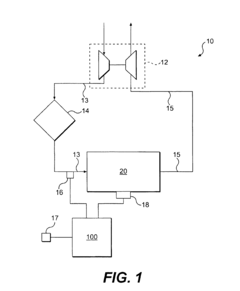

01 Engine Control and Management Systems

Advanced control systems are implemented to optimize V12 engine performance. These systems manage various aspects such as fuel injection, ignition timing, and valve timing to enhance power output, fuel efficiency, and overall engine responsiveness. Electronic control units (ECUs) play a crucial role in monitoring and adjusting engine parameters in real-time.- Engine Management Systems: Advanced engine management systems are crucial for optimizing V12 engine performance. These systems control various aspects such as fuel injection, ignition timing, and valve timing to enhance power output, fuel efficiency, and emissions control. They often incorporate sophisticated sensors and algorithms to adapt to different driving conditions and engine loads.

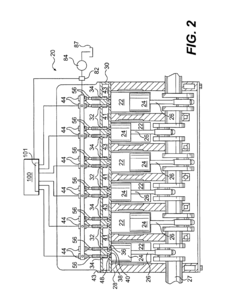

- Turbocharging and Supercharging: Forced induction systems, including turbochargers and superchargers, are frequently used to boost V12 engine performance. These systems increase the amount of air entering the combustion chambers, allowing for more fuel to be burned and resulting in higher power output. Advanced designs can minimize turbo lag and provide better low-end torque.

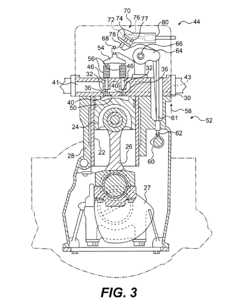

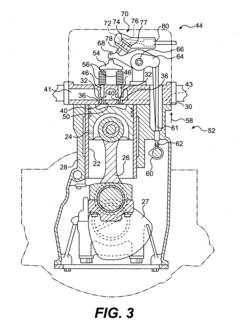

- Combustion Chamber Design: Optimizing the combustion chamber design is essential for improving V12 engine performance. This includes factors such as piston crown shape, valve positioning, and cylinder head design. Advanced designs aim to enhance fuel mixture distribution, flame propagation, and thermal efficiency, leading to increased power output and reduced emissions.

- Variable Valve Timing and Lift: Implementing variable valve timing and lift systems can significantly enhance V12 engine performance across different RPM ranges. These systems allow for optimal valve operation at both low and high engine speeds, improving power delivery, fuel efficiency, and emissions control. Advanced designs may incorporate electronic control for precise adjustment.

- Lightweight Materials and Construction: Utilizing lightweight materials and advanced construction techniques can improve V12 engine performance by reducing overall weight and enhancing structural rigidity. This may include the use of materials such as aluminum alloys, titanium, or carbon fiber composites for engine components. Reduced weight can lead to improved power-to-weight ratios and better fuel efficiency.

02 Turbocharging and Supercharging

Forced induction systems, including turbochargers and superchargers, are employed to boost V12 engine performance. These systems increase air intake, allowing for more fuel combustion and resulting in higher power output. Advanced designs focus on reducing turbo lag and improving overall engine efficiency across various RPM ranges.Expand Specific Solutions03 Combustion Chamber Design

Innovative combustion chamber designs are developed to enhance V12 engine performance. These designs focus on improving fuel-air mixture, optimizing flame propagation, and reducing heat loss. Advanced materials and manufacturing techniques are used to create more efficient and durable combustion chambers, contributing to increased power output and reduced emissions.Expand Specific Solutions04 Variable Valve Timing and Lift

Variable valve timing and lift systems are implemented to optimize V12 engine performance across different operating conditions. These systems allow for precise control of valve opening and closing times, as well as lift height, resulting in improved power delivery, fuel efficiency, and reduced emissions throughout the engine's RPM range.Expand Specific Solutions05 Engine Testing and Simulation

Advanced testing and simulation techniques are utilized to enhance V12 engine performance. These methods include computer-aided simulations, dynamometer testing, and real-world performance evaluations. By analyzing data from these tests, engineers can fine-tune engine parameters, identify areas for improvement, and validate design changes before implementation.Expand Specific Solutions

Key V12 Engine Manufacturers and Developers

The competition in altitude effects on V12 engine performance is at a mature stage, with established players and ongoing research. The market size is significant, driven by high-end automotive, aviation, and marine applications. Technologically, companies like Ford, Toyota, Honda, and GM are at the forefront, leveraging their extensive R&D capabilities. Caterpillar and Cummins bring expertise from heavy-duty and industrial engines, while specialized firms like Progress Rail and Transportation IP Holdings contribute niche knowledge. Academic institutions such as Kunming University of Science & Technology also play a role in advancing the field through research collaborations.

Ford Global Technologies LLC

Technical Solution: Ford has developed an innovative approach to address the effect of altitude on V12 engine performance. Their system incorporates a variable geometry turbocharger and advanced engine control unit (ECU) that dynamically adjusts boost pressure and fuel injection timing based on altitude sensors[1]. This allows the engine to maintain optimal performance across a wide range of elevations. Additionally, Ford has implemented a unique intercooler design that compensates for the reduced air density at higher altitudes, ensuring consistent charge air temperatures[3]. The system also features an adaptive exhaust gas recirculation (EGR) strategy that optimizes combustion efficiency and emissions control at various altitudes[5].

Strengths: Maintains consistent performance across diverse altitudes; Optimizes fuel efficiency and emissions. Weaknesses: Increased system complexity; Potential higher manufacturing costs.

Toyota Motor Corp.

Technical Solution: Toyota's approach to mitigating altitude effects on V12 engine performance involves a multi-faceted strategy. They have developed a high-altitude compensation system that utilizes a combination of twin-scroll turbochargers and an electric supercharger[2]. This hybrid forced induction system provides rapid boost at low engine speeds and maintains high power output at altitude. Toyota's ECU incorporates an advanced algorithm that factors in barometric pressure and oxygen sensors to precisely adjust fuel injection and ignition timing[4]. Furthermore, they have implemented a variable valve timing and lift system that optimizes airflow characteristics across different altitudes, ensuring efficient combustion and power delivery[6].

Strengths: Excellent low-end torque and high-altitude performance; Adaptive system for various driving conditions. Weaknesses: Increased mechanical complexity; Higher initial cost due to advanced technologies.

Innovative Altitude Adaptation Technologies

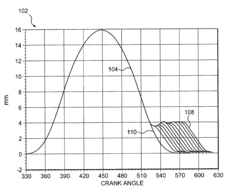

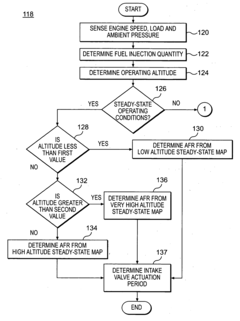

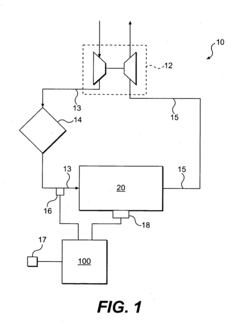

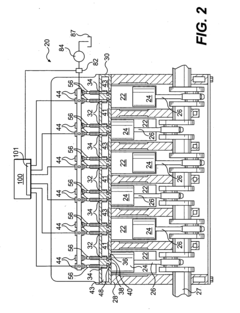

Variable valve actuation control for operation at altitude

PatentInactiveUS6912458B2

Innovation

- A variable valve actuation system that adjusts the intake valve actuation period based on sensed altitude, using lookup maps to determine optimal air-fuel ratios and extending the intake valve opening to maintain efficient combustion at varying altitudes.

Variable valve actuation control for operation at altitude

PatentInactiveUS20050279329A1

Innovation

- A variable valve actuation system that senses altitude and adjusts the intake valve actuation period based on lookup maps to maintain an optimal air-fuel ratio, using a cam assembly and valve actuator to control the intake valve's opening and closing times.

Environmental Impact of High-Altitude Engine Operation

The operation of V12 engines at high altitudes presents significant environmental challenges that warrant careful consideration. As the altitude increases, the air density decreases, leading to a reduction in oxygen concentration. This phenomenon directly impacts the combustion process in V12 engines, resulting in incomplete fuel burning and increased emissions of harmful pollutants.

One of the primary environmental concerns is the elevated production of carbon monoxide (CO) and unburned hydrocarbons (HC) at higher altitudes. The reduced oxygen availability compromises the engine's ability to achieve complete combustion, leading to higher levels of these pollutants in the exhaust gases. This increase in emissions can contribute to air pollution and potentially exacerbate climate change effects in high-altitude regions.

Furthermore, the altered air-fuel mixture at high altitudes can lead to increased nitrogen oxide (NOx) emissions. While NOx formation typically decreases with altitude due to lower combustion temperatures, the engine's compensatory mechanisms to maintain power output may counteract this effect, potentially resulting in higher NOx emissions than expected.

The environmental impact extends beyond air quality concerns. The reduced engine efficiency at high altitudes necessitates higher fuel consumption to maintain performance, leading to increased carbon dioxide (CO2) emissions. This not only contributes to the global carbon footprint but also places additional stress on fuel resources in often remote and ecologically sensitive high-altitude areas.

Moreover, the unique ecosystems found at high altitudes are particularly vulnerable to the effects of engine emissions. Alpine and subalpine environments, characterized by fragile flora and fauna, may suffer disproportionately from the increased pollution levels associated with V12 engine operation. The deposition of pollutants can affect soil chemistry, disrupt plant growth, and impact local wildlife populations.

The noise pollution generated by V12 engines operating at high altitudes is another environmental concern. Sound travels differently in the thinner air, potentially carrying engine noise over greater distances and disturbing wildlife habitats. This acoustic impact can disrupt breeding patterns, communication, and overall ecosystem balance in high-altitude regions.

To address these environmental challenges, engine manufacturers and researchers are exploring various technological solutions. These include adaptive engine control systems that optimize combustion processes for high-altitude conditions, advanced catalytic converters designed to function effectively in low-oxygen environments, and the development of alternative fuel systems that produce fewer emissions at high altitudes. Additionally, there is growing interest in electric and hybrid powertrains for high-altitude applications, which could significantly reduce the environmental footprint of vehicle operations in these sensitive areas.

One of the primary environmental concerns is the elevated production of carbon monoxide (CO) and unburned hydrocarbons (HC) at higher altitudes. The reduced oxygen availability compromises the engine's ability to achieve complete combustion, leading to higher levels of these pollutants in the exhaust gases. This increase in emissions can contribute to air pollution and potentially exacerbate climate change effects in high-altitude regions.

Furthermore, the altered air-fuel mixture at high altitudes can lead to increased nitrogen oxide (NOx) emissions. While NOx formation typically decreases with altitude due to lower combustion temperatures, the engine's compensatory mechanisms to maintain power output may counteract this effect, potentially resulting in higher NOx emissions than expected.

The environmental impact extends beyond air quality concerns. The reduced engine efficiency at high altitudes necessitates higher fuel consumption to maintain performance, leading to increased carbon dioxide (CO2) emissions. This not only contributes to the global carbon footprint but also places additional stress on fuel resources in often remote and ecologically sensitive high-altitude areas.

Moreover, the unique ecosystems found at high altitudes are particularly vulnerable to the effects of engine emissions. Alpine and subalpine environments, characterized by fragile flora and fauna, may suffer disproportionately from the increased pollution levels associated with V12 engine operation. The deposition of pollutants can affect soil chemistry, disrupt plant growth, and impact local wildlife populations.

The noise pollution generated by V12 engines operating at high altitudes is another environmental concern. Sound travels differently in the thinner air, potentially carrying engine noise over greater distances and disturbing wildlife habitats. This acoustic impact can disrupt breeding patterns, communication, and overall ecosystem balance in high-altitude regions.

To address these environmental challenges, engine manufacturers and researchers are exploring various technological solutions. These include adaptive engine control systems that optimize combustion processes for high-altitude conditions, advanced catalytic converters designed to function effectively in low-oxygen environments, and the development of alternative fuel systems that produce fewer emissions at high altitudes. Additionally, there is growing interest in electric and hybrid powertrains for high-altitude applications, which could significantly reduce the environmental footprint of vehicle operations in these sensitive areas.

Regulatory Framework for Altitude-Specific Engines

The regulatory framework for altitude-specific engines is a complex and evolving landscape that addresses the unique challenges posed by operating V12 engines at varying altitudes. These regulations are primarily driven by environmental concerns, safety considerations, and performance optimization requirements.

At the international level, organizations such as the International Civil Aviation Organization (ICAO) have established guidelines for aircraft engine performance at different altitudes. These standards often serve as a basis for national and regional regulations. The ICAO's Annex 16 to the Convention on International Civil Aviation specifically addresses environmental protection, including emissions standards for aircraft engines at various altitudes.

In the United States, the Federal Aviation Administration (FAA) has implemented regulations that require engine manufacturers to demonstrate compliance with altitude-specific performance standards. These regulations are outlined in the Code of Federal Regulations (CFR) Title 14, Part 33, which covers airworthiness standards for aircraft engines. Manufacturers must provide data on engine performance across a range of altitudes, typically from sea level to the engine's certified ceiling.

The European Union Aviation Safety Agency (EASA) has similar regulations in place, outlined in Certification Specifications for Engines (CS-E). These specifications require manufacturers to demonstrate engine performance and reliability at different altitudes, including extreme conditions such as high-altitude takeoffs and landings.

For automotive applications, regulatory bodies such as the Environmental Protection Agency (EPA) in the United States and the European Commission in the EU have established emissions standards that indirectly affect altitude-specific engine performance. While these regulations do not explicitly address altitude, they require manufacturers to ensure compliance across a range of operating conditions, including varying altitudes.

Some regions with high-altitude environments have implemented specific regulations to address the unique challenges posed by operating engines in these conditions. For example, Colorado in the United States has adopted the High Altitude Testing Protocol, which requires additional emissions testing for vehicles sold in the state due to its elevated terrain.

As environmental concerns continue to grow, regulatory bodies are increasingly focusing on the impact of altitude on engine emissions. This has led to the development of more stringent testing procedures and performance requirements for engines operating at different altitudes. Manufacturers are now required to provide more comprehensive data on engine performance across a wider range of altitudes and operating conditions.

The regulatory framework also extends to maintenance and inspection requirements for altitude-specific engines. Operators are often required to follow specific maintenance schedules and procedures to ensure optimal engine performance and safety at varying altitudes. These requirements are typically outlined in aircraft maintenance manuals and regulatory guidance documents.

At the international level, organizations such as the International Civil Aviation Organization (ICAO) have established guidelines for aircraft engine performance at different altitudes. These standards often serve as a basis for national and regional regulations. The ICAO's Annex 16 to the Convention on International Civil Aviation specifically addresses environmental protection, including emissions standards for aircraft engines at various altitudes.

In the United States, the Federal Aviation Administration (FAA) has implemented regulations that require engine manufacturers to demonstrate compliance with altitude-specific performance standards. These regulations are outlined in the Code of Federal Regulations (CFR) Title 14, Part 33, which covers airworthiness standards for aircraft engines. Manufacturers must provide data on engine performance across a range of altitudes, typically from sea level to the engine's certified ceiling.

The European Union Aviation Safety Agency (EASA) has similar regulations in place, outlined in Certification Specifications for Engines (CS-E). These specifications require manufacturers to demonstrate engine performance and reliability at different altitudes, including extreme conditions such as high-altitude takeoffs and landings.

For automotive applications, regulatory bodies such as the Environmental Protection Agency (EPA) in the United States and the European Commission in the EU have established emissions standards that indirectly affect altitude-specific engine performance. While these regulations do not explicitly address altitude, they require manufacturers to ensure compliance across a range of operating conditions, including varying altitudes.

Some regions with high-altitude environments have implemented specific regulations to address the unique challenges posed by operating engines in these conditions. For example, Colorado in the United States has adopted the High Altitude Testing Protocol, which requires additional emissions testing for vehicles sold in the state due to its elevated terrain.

As environmental concerns continue to grow, regulatory bodies are increasingly focusing on the impact of altitude on engine emissions. This has led to the development of more stringent testing procedures and performance requirements for engines operating at different altitudes. Manufacturers are now required to provide more comprehensive data on engine performance across a wider range of altitudes and operating conditions.

The regulatory framework also extends to maintenance and inspection requirements for altitude-specific engines. Operators are often required to follow specific maintenance schedules and procedures to ensure optimal engine performance and safety at varying altitudes. These requirements are typically outlined in aircraft maintenance manuals and regulatory guidance documents.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!