The Influence of Consumer Demand on V12 Engine Development

AUG 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V12 Engine Evolution and Objectives

The V12 engine has a rich history dating back to the early 20th century, evolving from its initial applications in luxury automobiles and aircraft to becoming a symbol of power and prestige in high-performance vehicles. Throughout its development, consumer demand has played a crucial role in shaping the trajectory of V12 engine technology.

In the early stages, V12 engines were primarily designed for high-end luxury cars and racing vehicles, catering to a niche market of enthusiasts and wealthy consumers who demanded exceptional performance and exclusivity. As automotive technology advanced, the V12 engine became synonymous with superior power, smoothness, and refinement, attributes highly valued by discerning customers.

The 1960s and 1970s saw a surge in consumer interest for high-performance vehicles, leading to increased development and production of V12 engines. Iconic models from manufacturers like Ferrari, Lamborghini, and Jaguar showcased the V12's capabilities, further fueling consumer desire for these powerful powerplants.

However, as environmental concerns and fuel efficiency became more prominent in the late 20th and early 21st centuries, consumer preferences began to shift. This change in demand prompted engine manufacturers to focus on developing more efficient and environmentally friendly V12 engines, incorporating technologies such as direct injection, variable valve timing, and cylinder deactivation.

The luxury car market has continued to influence V12 engine development, with brands like Rolls-Royce and Bentley maintaining consumer interest in these engines by emphasizing their smooth operation and refined power delivery. Simultaneously, high-performance sports car manufacturers have pushed the boundaries of V12 technology to meet the demands of enthusiasts seeking ultimate performance.

Looking ahead, the objectives for V12 engine development are largely shaped by evolving consumer expectations and regulatory requirements. Key goals include further improving fuel efficiency, reducing emissions, and exploring hybridization to meet stringent environmental standards while preserving the unique characteristics that make V12 engines desirable to consumers.

Manufacturers are also focusing on enhancing power output and torque delivery to satisfy the performance demands of their target market. Additionally, there is a growing emphasis on weight reduction and compact design to improve overall vehicle dynamics and efficiency without compromising the V12's inherent advantages.

As the automotive industry transitions towards electrification, the future of V12 engines faces challenges. However, consumer demand for exclusive, high-performance vehicles continues to drive innovation in this space, with manufacturers exploring ways to integrate V12 engines into hybrid powertrains or develop fully electric alternatives that can replicate the distinctive qualities of a V12.

In the early stages, V12 engines were primarily designed for high-end luxury cars and racing vehicles, catering to a niche market of enthusiasts and wealthy consumers who demanded exceptional performance and exclusivity. As automotive technology advanced, the V12 engine became synonymous with superior power, smoothness, and refinement, attributes highly valued by discerning customers.

The 1960s and 1970s saw a surge in consumer interest for high-performance vehicles, leading to increased development and production of V12 engines. Iconic models from manufacturers like Ferrari, Lamborghini, and Jaguar showcased the V12's capabilities, further fueling consumer desire for these powerful powerplants.

However, as environmental concerns and fuel efficiency became more prominent in the late 20th and early 21st centuries, consumer preferences began to shift. This change in demand prompted engine manufacturers to focus on developing more efficient and environmentally friendly V12 engines, incorporating technologies such as direct injection, variable valve timing, and cylinder deactivation.

The luxury car market has continued to influence V12 engine development, with brands like Rolls-Royce and Bentley maintaining consumer interest in these engines by emphasizing their smooth operation and refined power delivery. Simultaneously, high-performance sports car manufacturers have pushed the boundaries of V12 technology to meet the demands of enthusiasts seeking ultimate performance.

Looking ahead, the objectives for V12 engine development are largely shaped by evolving consumer expectations and regulatory requirements. Key goals include further improving fuel efficiency, reducing emissions, and exploring hybridization to meet stringent environmental standards while preserving the unique characteristics that make V12 engines desirable to consumers.

Manufacturers are also focusing on enhancing power output and torque delivery to satisfy the performance demands of their target market. Additionally, there is a growing emphasis on weight reduction and compact design to improve overall vehicle dynamics and efficiency without compromising the V12's inherent advantages.

As the automotive industry transitions towards electrification, the future of V12 engines faces challenges. However, consumer demand for exclusive, high-performance vehicles continues to drive innovation in this space, with manufacturers exploring ways to integrate V12 engines into hybrid powertrains or develop fully electric alternatives that can replicate the distinctive qualities of a V12.

Consumer Demand Analysis for V12 Engines

The V12 engine, renowned for its smooth power delivery and prestigious status, has long been a symbol of luxury and high performance in the automotive industry. Consumer demand for V12 engines has been primarily driven by affluent buyers seeking the pinnacle of automotive engineering and exclusivity. This market segment values the unique characteristics of V12 engines, including their refined operation, impressive power output, and the prestige associated with owning such a sophisticated piece of machinery.

In recent years, the demand for V12 engines has been influenced by several factors. Luxury car manufacturers have observed a growing interest in high-end vehicles, particularly in emerging markets such as China and the Middle East. These regions have seen an increase in ultra-high-net-worth individuals who are willing to invest in premium automobiles that showcase their status and success. This trend has supported the continued development and production of V12 engines, despite their higher cost and complexity compared to smaller powerplants.

However, the market for V12 engines remains niche and faces challenges. Environmental concerns and stricter emissions regulations have put pressure on manufacturers to improve fuel efficiency and reduce carbon emissions. This has led to a shift in consumer preferences towards more environmentally friendly options, including hybrid and electric powertrains, even in the luxury segment. As a result, some automakers have begun to phase out V12 engines in favor of smaller, turbocharged engines or electrified powertrains that offer similar performance with improved efficiency.

Despite these challenges, there remains a dedicated consumer base for V12 engines. Enthusiasts and collectors continue to value the heritage and engineering prowess represented by these powerplants. Limited edition models and bespoke vehicles featuring V12 engines often command premium prices and generate significant interest among automotive connoisseurs. This sustained demand has encouraged manufacturers to invest in refining V12 technology, focusing on weight reduction, improved thermal efficiency, and integration with hybrid systems to meet both performance expectations and regulatory requirements.

The future of V12 engine development is likely to be shaped by evolving consumer preferences and technological advancements. As the automotive industry transitions towards electrification, the role of V12 engines may shift towards ultra-luxury and collector vehicles. Manufacturers may focus on producing smaller numbers of highly specialized V12 engines, catering to a discerning clientele that values the unique characteristics and emotional appeal of these powerplants. This approach could see V12 engines becoming even more exclusive, potentially increasing their desirability among certain consumer segments.

In recent years, the demand for V12 engines has been influenced by several factors. Luxury car manufacturers have observed a growing interest in high-end vehicles, particularly in emerging markets such as China and the Middle East. These regions have seen an increase in ultra-high-net-worth individuals who are willing to invest in premium automobiles that showcase their status and success. This trend has supported the continued development and production of V12 engines, despite their higher cost and complexity compared to smaller powerplants.

However, the market for V12 engines remains niche and faces challenges. Environmental concerns and stricter emissions regulations have put pressure on manufacturers to improve fuel efficiency and reduce carbon emissions. This has led to a shift in consumer preferences towards more environmentally friendly options, including hybrid and electric powertrains, even in the luxury segment. As a result, some automakers have begun to phase out V12 engines in favor of smaller, turbocharged engines or electrified powertrains that offer similar performance with improved efficiency.

Despite these challenges, there remains a dedicated consumer base for V12 engines. Enthusiasts and collectors continue to value the heritage and engineering prowess represented by these powerplants. Limited edition models and bespoke vehicles featuring V12 engines often command premium prices and generate significant interest among automotive connoisseurs. This sustained demand has encouraged manufacturers to invest in refining V12 technology, focusing on weight reduction, improved thermal efficiency, and integration with hybrid systems to meet both performance expectations and regulatory requirements.

The future of V12 engine development is likely to be shaped by evolving consumer preferences and technological advancements. As the automotive industry transitions towards electrification, the role of V12 engines may shift towards ultra-luxury and collector vehicles. Manufacturers may focus on producing smaller numbers of highly specialized V12 engines, catering to a discerning clientele that values the unique characteristics and emotional appeal of these powerplants. This approach could see V12 engines becoming even more exclusive, potentially increasing their desirability among certain consumer segments.

V12 Technology Status and Challenges

The V12 engine, once a symbol of automotive luxury and performance, faces significant challenges in the current automotive landscape. Despite its historical prominence, the V12 engine's development has been heavily influenced by shifting consumer demands and stringent environmental regulations.

Currently, V12 engines are primarily confined to ultra-luxury and high-performance vehicles, with limited production numbers. Major manufacturers like Ferrari, Lamborghini, and Rolls-Royce continue to produce V12 engines, but their applications are becoming increasingly niche. The main technical challenge lies in meeting ever-tightening emissions standards while maintaining the power and prestige associated with V12 engines.

Fuel efficiency remains a critical hurdle for V12 engines. Their large displacement and high cylinder count inherently lead to increased fuel consumption, which conflicts with growing consumer and regulatory demands for better fuel economy. Engineers are exploring various technologies to address this, including cylinder deactivation, advanced fuel injection systems, and lightweight materials to reduce overall vehicle weight.

Another significant challenge is the integration of hybrid and electric technologies with V12 engines. As the automotive industry shifts towards electrification, manufacturers are under pressure to incorporate these technologies into their flagship models. This presents complex engineering challenges in terms of packaging, weight distribution, and power management.

The geographical distribution of V12 engine development is primarily concentrated in Europe, particularly in Italy, Germany, and the UK, where luxury and sports car manufacturers have traditionally been based. However, with the global shift towards sustainable mobility, even these strongholds are reevaluating their commitment to V12 technology.

From a consumer perspective, the demand for V12 engines is increasingly driven by exclusivity and heritage rather than practical performance benefits. This shift has led to a focus on enhancing the emotional and sensory aspects of V12 engines, such as their distinctive sound and smooth power delivery, rather than purely chasing higher power outputs.

Looking ahead, the future of V12 engine development is uncertain. While there is still a small but passionate market for these engines, the technical challenges and regulatory pressures may eventually outweigh the benefits of continued development. Some manufacturers are exploring alternative configurations, such as high-output V8 or even V6 engines with electrification, to deliver comparable performance with improved efficiency.

In conclusion, while V12 engines continue to hold a special place in automotive engineering, their development is increasingly constrained by external factors. The challenge for manufacturers is to balance the heritage and emotional appeal of V12 engines with the practical realities of modern automotive requirements.

Currently, V12 engines are primarily confined to ultra-luxury and high-performance vehicles, with limited production numbers. Major manufacturers like Ferrari, Lamborghini, and Rolls-Royce continue to produce V12 engines, but their applications are becoming increasingly niche. The main technical challenge lies in meeting ever-tightening emissions standards while maintaining the power and prestige associated with V12 engines.

Fuel efficiency remains a critical hurdle for V12 engines. Their large displacement and high cylinder count inherently lead to increased fuel consumption, which conflicts with growing consumer and regulatory demands for better fuel economy. Engineers are exploring various technologies to address this, including cylinder deactivation, advanced fuel injection systems, and lightweight materials to reduce overall vehicle weight.

Another significant challenge is the integration of hybrid and electric technologies with V12 engines. As the automotive industry shifts towards electrification, manufacturers are under pressure to incorporate these technologies into their flagship models. This presents complex engineering challenges in terms of packaging, weight distribution, and power management.

The geographical distribution of V12 engine development is primarily concentrated in Europe, particularly in Italy, Germany, and the UK, where luxury and sports car manufacturers have traditionally been based. However, with the global shift towards sustainable mobility, even these strongholds are reevaluating their commitment to V12 technology.

From a consumer perspective, the demand for V12 engines is increasingly driven by exclusivity and heritage rather than practical performance benefits. This shift has led to a focus on enhancing the emotional and sensory aspects of V12 engines, such as their distinctive sound and smooth power delivery, rather than purely chasing higher power outputs.

Looking ahead, the future of V12 engine development is uncertain. While there is still a small but passionate market for these engines, the technical challenges and regulatory pressures may eventually outweigh the benefits of continued development. Some manufacturers are exploring alternative configurations, such as high-output V8 or even V6 engines with electrification, to deliver comparable performance with improved efficiency.

In conclusion, while V12 engines continue to hold a special place in automotive engineering, their development is increasingly constrained by external factors. The challenge for manufacturers is to balance the heritage and emotional appeal of V12 engines with the practical realities of modern automotive requirements.

Current V12 Engine Designs

01 V12 Engine Design and Configuration

V12 engines are typically designed with two banks of six cylinders arranged in a V-shape. This configuration allows for a compact engine layout while providing high power output and smooth operation. The design often incorporates advanced materials and manufacturing techniques to optimize performance and efficiency.- V12 Engine Design and Configuration: V12 engines are typically designed with two banks of six cylinders arranged in a V-shape. This configuration allows for a compact engine layout while providing high power output and smooth operation. The design often includes advanced features for improved performance, fuel efficiency, and reduced emissions.

- V12 Engine Control Systems: Modern V12 engines incorporate sophisticated control systems to optimize performance and efficiency. These systems may include electronic fuel injection, variable valve timing, and advanced engine management units. They help regulate fuel consumption, monitor engine parameters, and adjust operation for various driving conditions.

- V12 Engine Applications: V12 engines are commonly used in high-performance vehicles, luxury cars, and specialized applications. They are prized for their power output, smoothness, and prestige. These engines may also be adapted for use in marine vessels, aircraft, and industrial equipment where high power and reliability are required.

- V12 Engine Cooling and Lubrication: Effective cooling and lubrication systems are crucial for V12 engines due to their high power output and complex design. These systems may include advanced oil circulation methods, multiple radiators, and precision-engineered cooling channels to maintain optimal operating temperatures and ensure longevity of engine components.

- V12 Engine Exhaust Systems: Exhaust systems for V12 engines are designed to efficiently remove combustion gases while enhancing performance and meeting emissions standards. These systems may incorporate variable valve exhaust, multiple catalytic converters, and tuned exhaust manifolds to optimize back pressure and improve engine efficiency.

02 V12 Engine Control Systems

Modern V12 engines utilize sophisticated control systems to manage fuel injection, ignition timing, and other parameters. These systems often incorporate advanced sensors and electronic control units to optimize performance, fuel efficiency, and emissions across various operating conditions.Expand Specific Solutions03 V12 Engine Cooling and Lubrication

Effective cooling and lubrication systems are crucial for V12 engines due to their high power output and thermal loads. These systems may include advanced coolant circulation designs, oil cooling systems, and specialized lubricants to maintain optimal operating temperatures and reduce wear on engine components.Expand Specific Solutions04 V12 Engine Applications

V12 engines are commonly used in high-performance vehicles, luxury cars, marine applications, and some industrial settings. Their application often requires specialized integration techniques to accommodate the engine's size and power characteristics within the vehicle or equipment design.Expand Specific Solutions05 V12 Engine Emissions and Efficiency Improvements

To meet increasingly stringent emissions regulations and improve fuel efficiency, V12 engine designs often incorporate advanced technologies such as direct fuel injection, variable valve timing, and cylinder deactivation. These improvements aim to reduce emissions and fuel consumption while maintaining the high performance expected from V12 engines.Expand Specific Solutions

Major V12 Engine Manufacturers

The development of V12 engines is influenced by a complex interplay of consumer demand, market dynamics, and technological advancements. The industry is in a mature stage, with a relatively niche market size due to the specialized nature of V12 engines. Technological maturity varies among key players, with luxury automakers like BMW, Mercedes-Benz, and Ferrari leading in innovation. Companies such as GM Global Technology Operations LLC, Honda Motor Co., Ltd., and Toyota Motor Corp. are also significant contributors to V12 engine development, focusing on performance and efficiency improvements. The market is characterized by a balance between traditional combustion engine expertise and the growing trend towards electrification, with companies like Tesla, Inc. indirectly influencing the sector through advancements in electric powertrains.

Honda Motor Co., Ltd.

Technical Solution: Honda has been developing V12 engines primarily for high-performance and luxury applications. Their approach focuses on combining power with efficiency, utilizing advanced materials and precision engineering. Honda's V12 engines feature direct fuel injection, variable valve timing, and cylinder deactivation technology to optimize performance and fuel economy[1]. The company has also explored hybrid V12 powertrains to meet increasing consumer demand for eco-friendly luxury vehicles[2]. Honda's V12 engines typically displace between 3.5 to 5.0 liters, producing power outputs ranging from 400 to 600 horsepower, catering to the premium segment of the automotive market[3].

Strengths: Advanced technology integration, balance of performance and efficiency. Weaknesses: Limited market share in the V12 segment, higher production costs compared to smaller engines.

Toyota Motor Corp.

Technical Solution: Toyota's approach to V12 engine development has been primarily focused on their luxury brand, Lexus. The company's V12 engines are designed to deliver smooth, refined power for high-end luxury vehicles. Toyota's V12 engines typically feature a 5.0-liter displacement, producing around 450-500 horsepower[4]. The company has implemented technologies such as dual VVT-i (Variable Valve Timing with intelligence) and D-4S direct injection system to enhance performance and fuel efficiency[5]. Toyota has also been exploring the integration of hybrid technology with V12 engines to meet evolving consumer demands for both power and environmental consciousness[6]. The company's V12 engines are known for their reliability and longevity, aligning with Toyota's overall brand image.

Strengths: Renowned reliability, smooth power delivery, and luxury brand association. Weaknesses: Limited model range featuring V12 engines, potentially higher fuel consumption compared to smaller engines.

Key V12 Engine Innovations

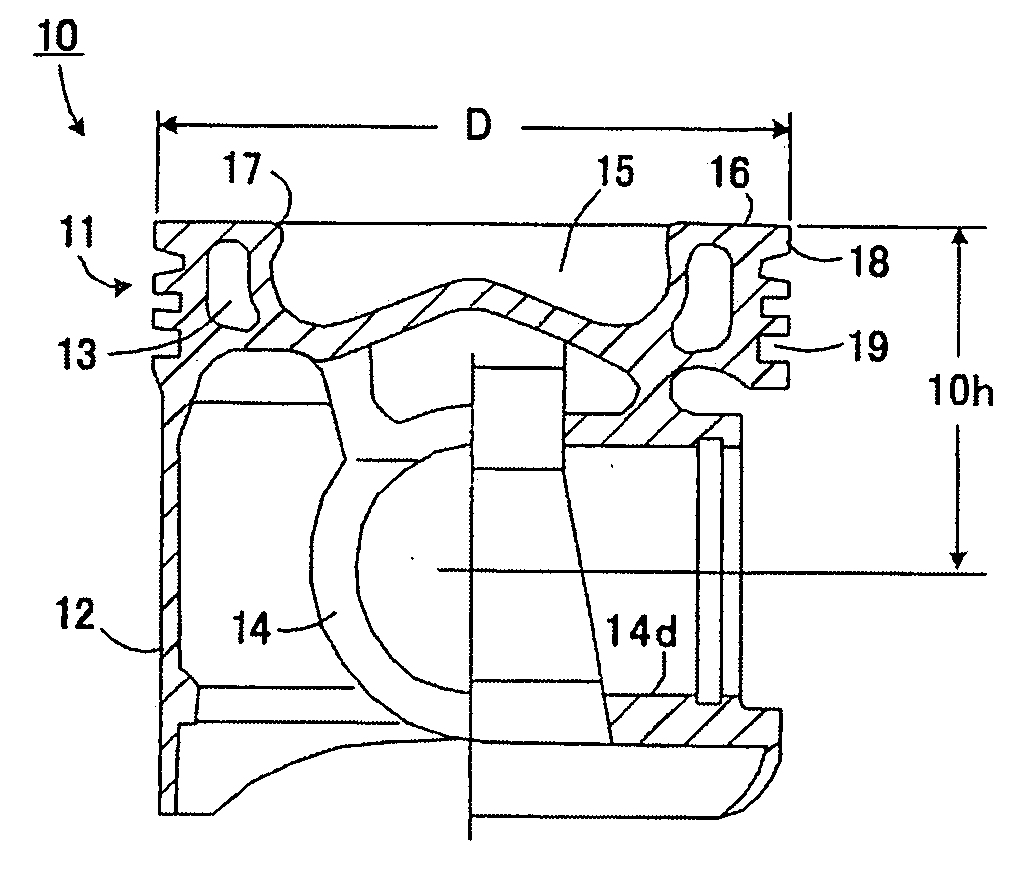

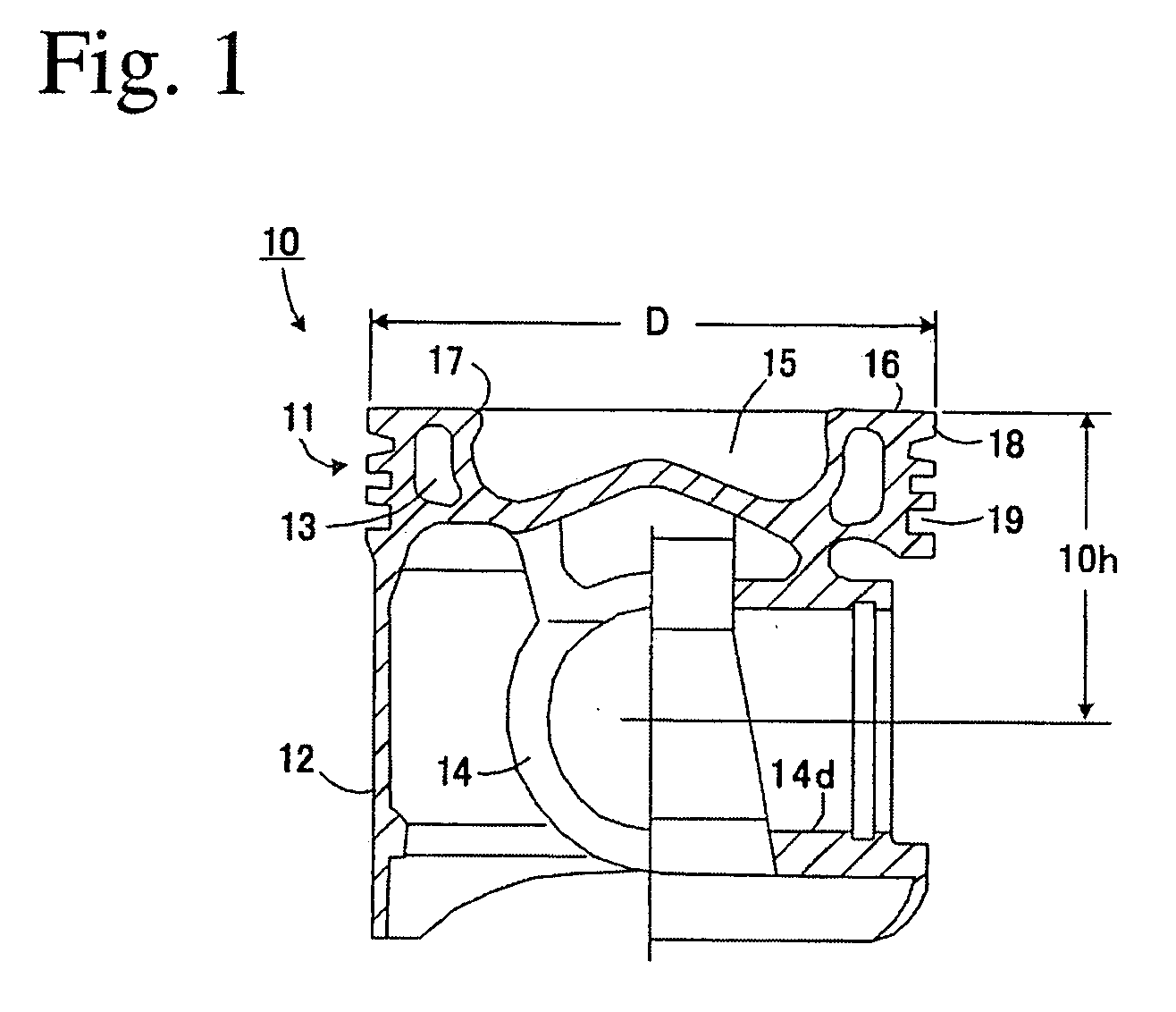

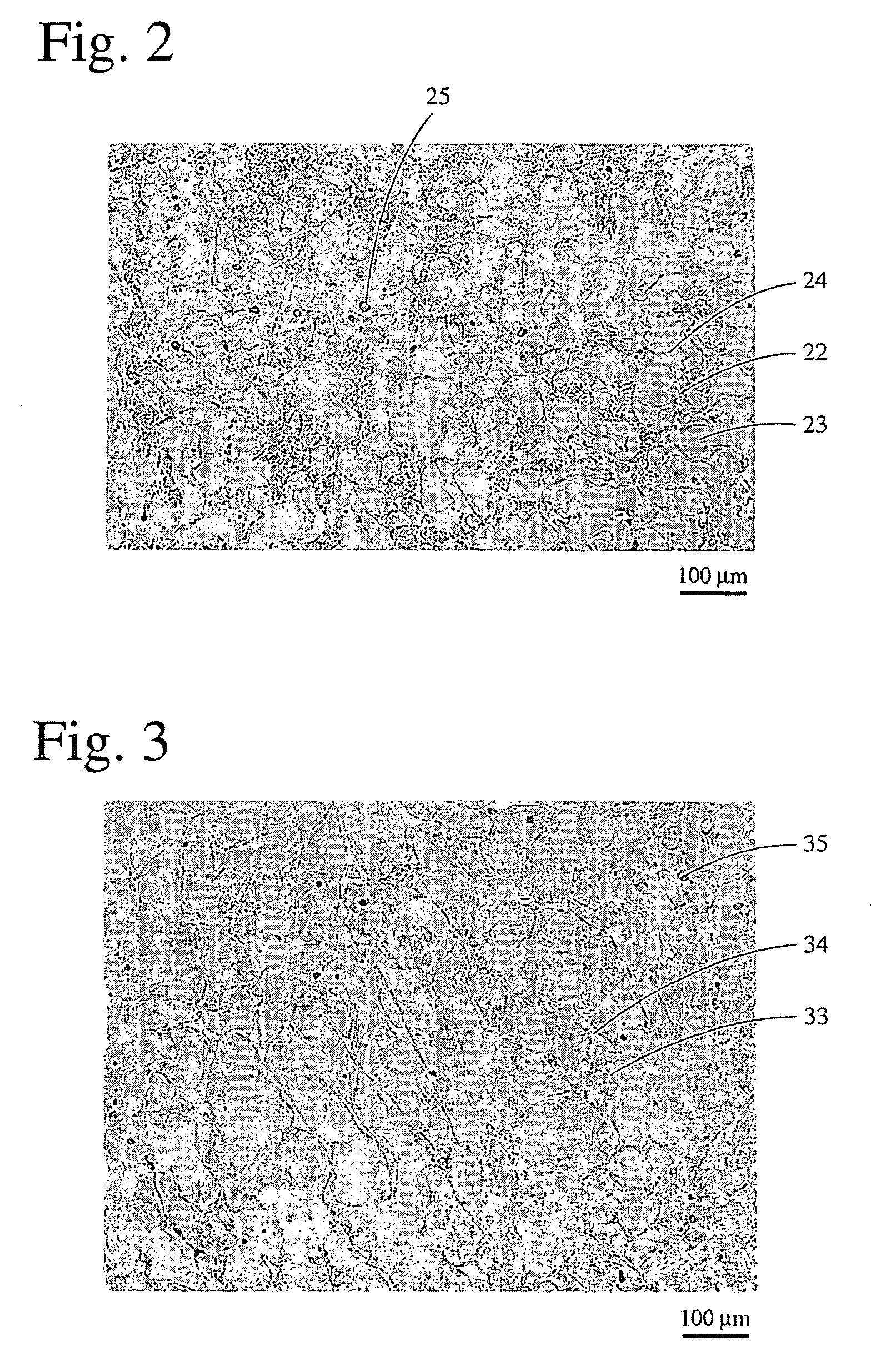

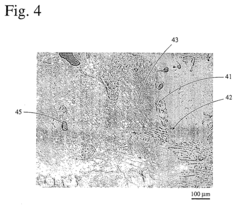

Internal engine piston and its production method

PatentInactiveUS20060191508A1

Innovation

- An integrally cast steel piston with a specific composition and microstructure, including eutectic carbides and a δ-M cast steel matrix, providing high-temperature yield strength, thermal cracking resistance, and excellent seizure resistance, while allowing for lighter weight and reduced production costs.

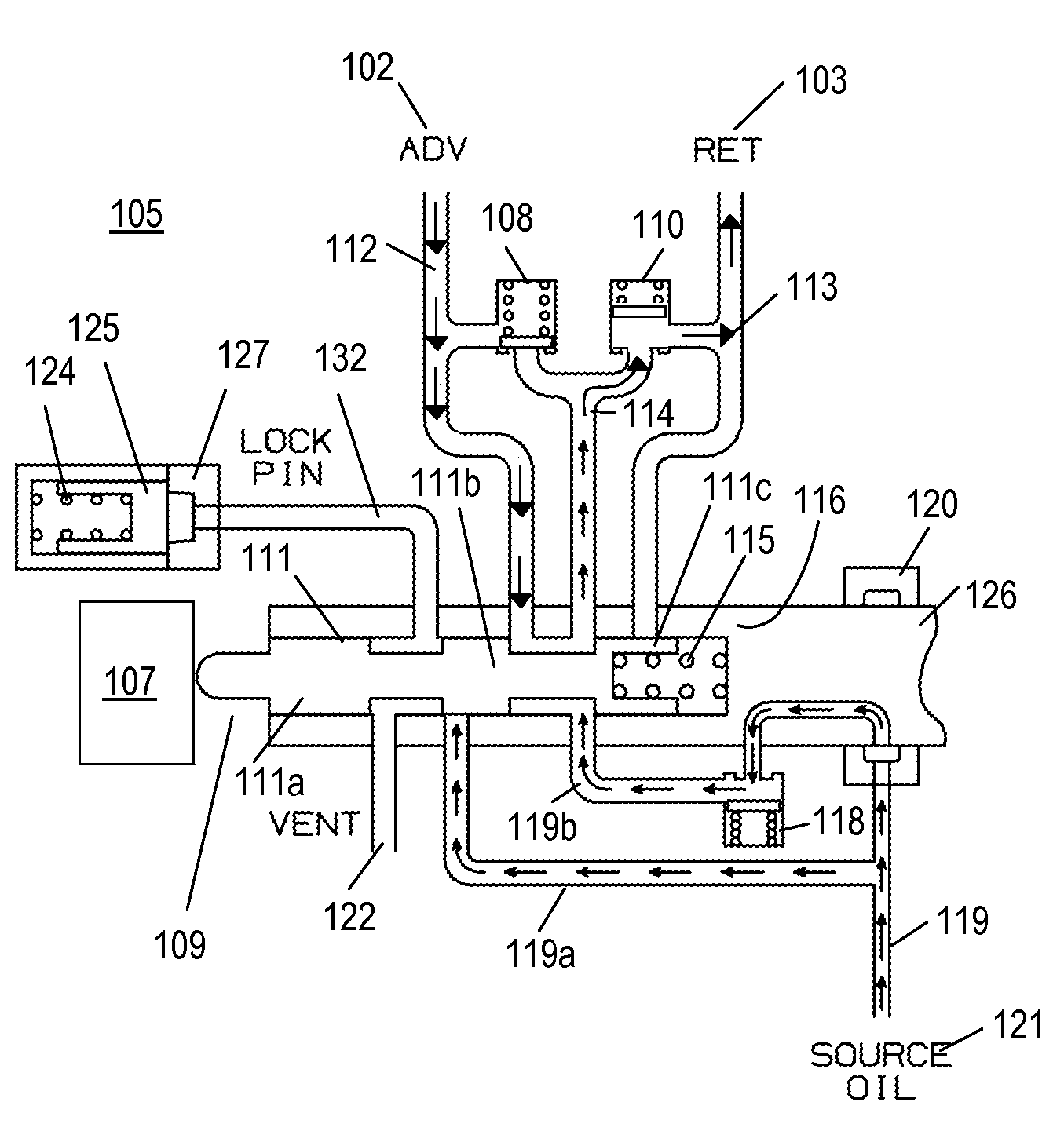

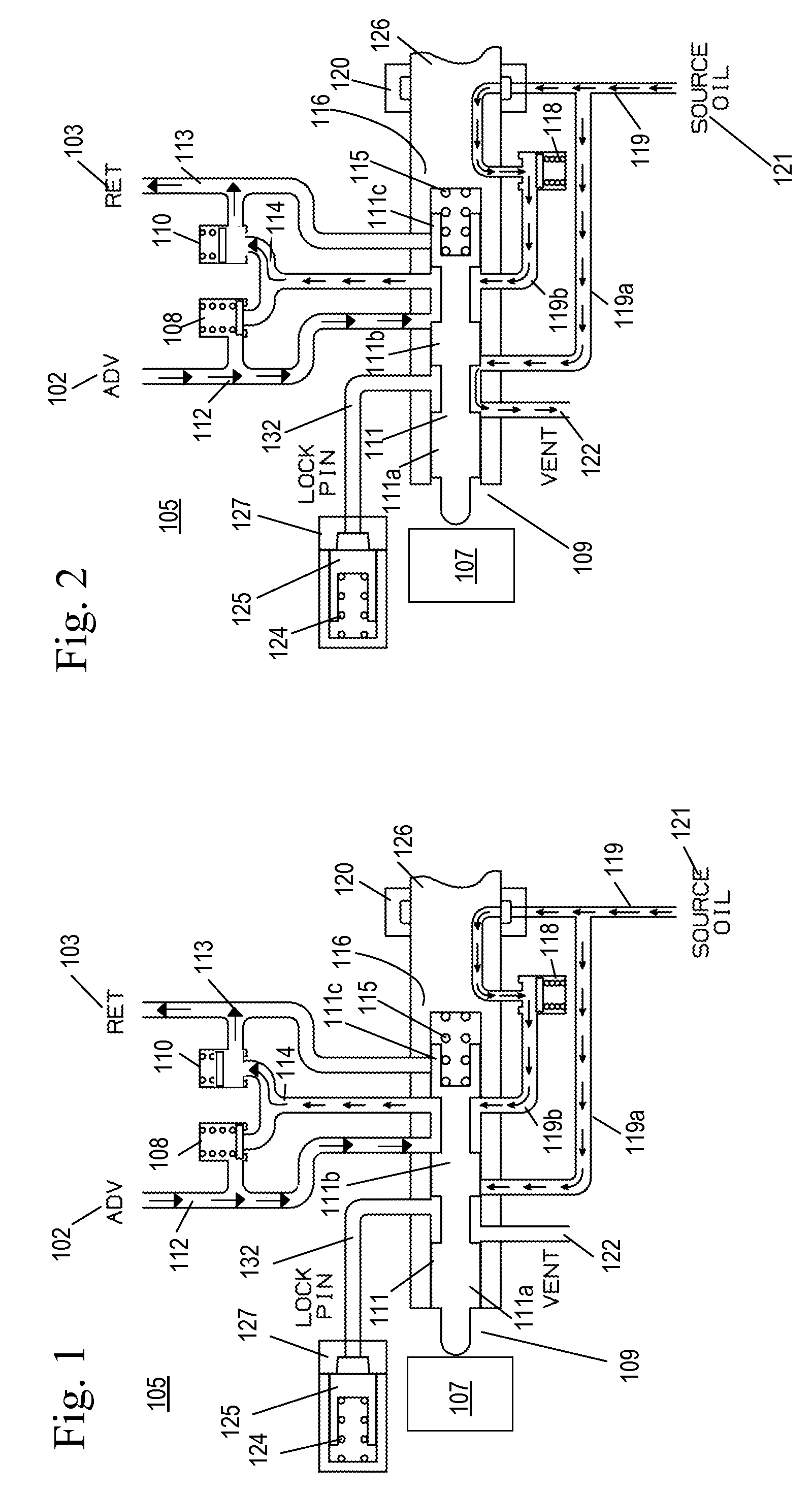

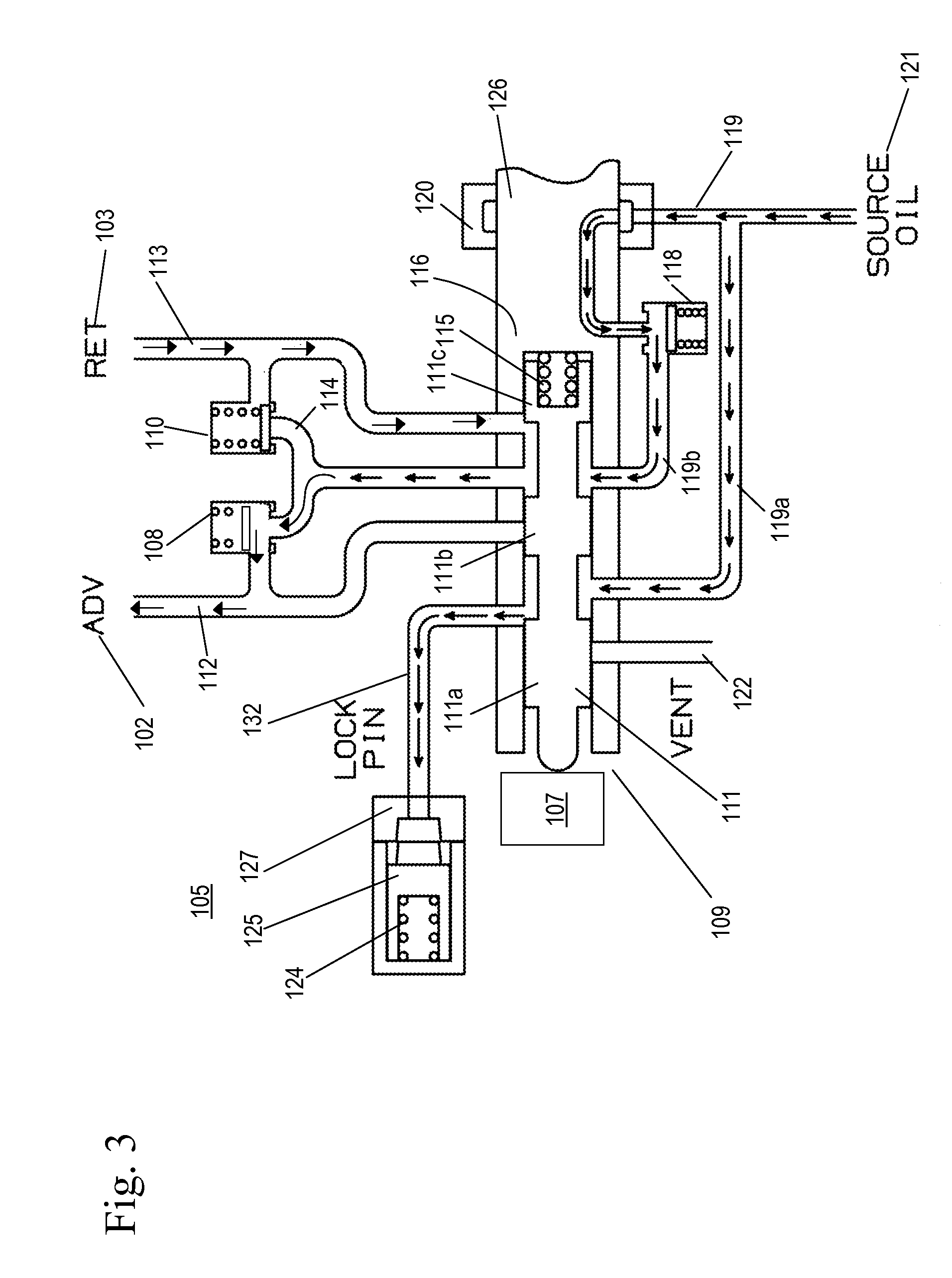

Venting mechanism to enhance warming of a varible CAM timing mechanism

PatentActiveUS20100251981A1

Innovation

- The VCT phaser is designed to enhance oil flow by allowing simultaneous venting and oil supply, reducing oil flow once hot, and increasing flow at low temperatures to introduce warmer oil sooner, using a spool valve system that controls the lock pin and venting passage to facilitate quicker warming.

Environmental Regulations Impact

Environmental regulations have played a significant role in shaping the development and future of V12 engines. As governments worldwide implement stricter emissions standards and fuel efficiency requirements, manufacturers of high-performance vehicles face increasing pressure to adapt their powertrains, including the iconic V12 engine.

The European Union's Euro 6 emissions standards, implemented in 2014 and further tightened in subsequent years, have posed considerable challenges for V12 engine manufacturers. These regulations set strict limits on nitrogen oxides (NOx), carbon monoxide (CO), and particulate matter emissions. Consequently, automakers have been forced to invest heavily in advanced emission control technologies, such as selective catalytic reduction (SCR) systems and gasoline particulate filters (GPF), to ensure compliance.

In the United States, the Corporate Average Fuel Economy (CAFE) standards have also impacted V12 engine development. These regulations require automakers to achieve specific fleet-wide fuel economy targets, which has led to a shift towards smaller, more efficient engines across vehicle lineups. This trend has put pressure on manufacturers to justify the continued production of large-displacement V12 engines, which typically have higher fuel consumption rates.

China, a crucial market for luxury and high-performance vehicles, has implemented its own stringent emissions regulations. The China 6 standards, phased in from 2019, are among the most stringent globally, further challenging V12 engine manufacturers to meet these requirements while maintaining performance characteristics.

The impact of these regulations has led to several notable developments in V12 engine technology. Manufacturers have increasingly turned to forced induction, particularly twin-turbocharging, to maintain power output while reducing engine displacement and improving efficiency. Advanced materials and manufacturing techniques have been employed to reduce engine weight and friction, further enhancing efficiency.

Hybridization has emerged as a key strategy for V12 engine preservation. By integrating electric motors and battery systems, manufacturers can offset the V12's fuel consumption during low-load conditions and provide additional power when needed. This approach allows automakers to meet emissions targets while retaining the prestige and performance associated with V12 engines.

Despite these advancements, some manufacturers have begun phasing out V12 engines in favor of smaller, more efficient powertrains. This trend is particularly evident in markets with the most stringent regulations, where the cost of compliance for V12 engines may outweigh the perceived benefits.

Looking ahead, the future of V12 engines will likely be shaped by the continued evolution of environmental regulations. As governments push for increased electrification and zero-emission vehicles, the long-term viability of V12 engines remains uncertain. Manufacturers may need to explore more radical solutions, such as synthetic fuels or complete powertrain electrification, to preserve the essence of V12 performance within an increasingly restrictive regulatory landscape.

The European Union's Euro 6 emissions standards, implemented in 2014 and further tightened in subsequent years, have posed considerable challenges for V12 engine manufacturers. These regulations set strict limits on nitrogen oxides (NOx), carbon monoxide (CO), and particulate matter emissions. Consequently, automakers have been forced to invest heavily in advanced emission control technologies, such as selective catalytic reduction (SCR) systems and gasoline particulate filters (GPF), to ensure compliance.

In the United States, the Corporate Average Fuel Economy (CAFE) standards have also impacted V12 engine development. These regulations require automakers to achieve specific fleet-wide fuel economy targets, which has led to a shift towards smaller, more efficient engines across vehicle lineups. This trend has put pressure on manufacturers to justify the continued production of large-displacement V12 engines, which typically have higher fuel consumption rates.

China, a crucial market for luxury and high-performance vehicles, has implemented its own stringent emissions regulations. The China 6 standards, phased in from 2019, are among the most stringent globally, further challenging V12 engine manufacturers to meet these requirements while maintaining performance characteristics.

The impact of these regulations has led to several notable developments in V12 engine technology. Manufacturers have increasingly turned to forced induction, particularly twin-turbocharging, to maintain power output while reducing engine displacement and improving efficiency. Advanced materials and manufacturing techniques have been employed to reduce engine weight and friction, further enhancing efficiency.

Hybridization has emerged as a key strategy for V12 engine preservation. By integrating electric motors and battery systems, manufacturers can offset the V12's fuel consumption during low-load conditions and provide additional power when needed. This approach allows automakers to meet emissions targets while retaining the prestige and performance associated with V12 engines.

Despite these advancements, some manufacturers have begun phasing out V12 engines in favor of smaller, more efficient powertrains. This trend is particularly evident in markets with the most stringent regulations, where the cost of compliance for V12 engines may outweigh the perceived benefits.

Looking ahead, the future of V12 engines will likely be shaped by the continued evolution of environmental regulations. As governments push for increased electrification and zero-emission vehicles, the long-term viability of V12 engines remains uncertain. Manufacturers may need to explore more radical solutions, such as synthetic fuels or complete powertrain electrification, to preserve the essence of V12 performance within an increasingly restrictive regulatory landscape.

V12 Engine Market Segmentation

The V12 engine market segmentation reflects the diverse consumer demands that have shaped the development and application of this high-performance powerplant. Traditionally associated with luxury and sports cars, V12 engines have found their niche in various automotive sectors, each catering to specific consumer preferences and requirements.

In the luxury car segment, V12 engines are synonymous with prestige and refinement. Brands like Rolls-Royce, Bentley, and Mercedes-Maybach have consistently offered V12 options to discerning customers who prioritize smooth power delivery and effortless acceleration. These consumers value the exclusivity and status associated with a V12-powered vehicle, often willing to pay a premium for the experience.

The high-performance sports car market represents another significant segment for V12 engines. Manufacturers such as Ferrari, Lamborghini, and Aston Martin have long relied on V12 powerplants to deliver exhilarating performance and emotive sound. Enthusiasts in this segment demand not only raw power but also the unique character and heritage that V12 engines embody.

Interestingly, the V12 engine has also found applications in the ultra-luxury SUV market. Vehicles like the Bentley Bentayga and Rolls-Royce Cullinan offer V12 options, catering to consumers who desire the combination of high-performance, luxury, and practicality. This emerging segment demonstrates the adaptability of V12 technology to evolving market trends.

In the realm of limited-edition hypercars, V12 engines continue to play a crucial role. Brands like Pagani and Koenigsegg utilize bespoke V12 designs to create some of the most exclusive and powerful vehicles in the world. These products target a small but influential group of collectors and enthusiasts who seek the pinnacle of automotive engineering.

The commercial vehicle sector, particularly in heavy-duty trucks and buses, represents a niche but important market for V12 engines. In this segment, the focus is on durability, reliability, and sustained power output rather than outright performance or luxury. Consumers in this market value the V12's ability to deliver consistent power over long periods and under demanding conditions.

As environmental concerns grow, a new segment is emerging for V12 engines in the form of hybrid and electric-assisted powertrains. This adaptation allows manufacturers to meet stricter emissions standards while preserving the unique characteristics of the V12 engine. Consumers in this segment seek to balance performance with environmental responsibility, indicating a potential future direction for V12 technology.

In the luxury car segment, V12 engines are synonymous with prestige and refinement. Brands like Rolls-Royce, Bentley, and Mercedes-Maybach have consistently offered V12 options to discerning customers who prioritize smooth power delivery and effortless acceleration. These consumers value the exclusivity and status associated with a V12-powered vehicle, often willing to pay a premium for the experience.

The high-performance sports car market represents another significant segment for V12 engines. Manufacturers such as Ferrari, Lamborghini, and Aston Martin have long relied on V12 powerplants to deliver exhilarating performance and emotive sound. Enthusiasts in this segment demand not only raw power but also the unique character and heritage that V12 engines embody.

Interestingly, the V12 engine has also found applications in the ultra-luxury SUV market. Vehicles like the Bentley Bentayga and Rolls-Royce Cullinan offer V12 options, catering to consumers who desire the combination of high-performance, luxury, and practicality. This emerging segment demonstrates the adaptability of V12 technology to evolving market trends.

In the realm of limited-edition hypercars, V12 engines continue to play a crucial role. Brands like Pagani and Koenigsegg utilize bespoke V12 designs to create some of the most exclusive and powerful vehicles in the world. These products target a small but influential group of collectors and enthusiasts who seek the pinnacle of automotive engineering.

The commercial vehicle sector, particularly in heavy-duty trucks and buses, represents a niche but important market for V12 engines. In this segment, the focus is on durability, reliability, and sustained power output rather than outright performance or luxury. Consumers in this market value the V12's ability to deliver consistent power over long periods and under demanding conditions.

As environmental concerns grow, a new segment is emerging for V12 engines in the form of hybrid and electric-assisted powertrains. This adaptation allows manufacturers to meet stricter emissions standards while preserving the unique characteristics of the V12 engine. Consumers in this segment seek to balance performance with environmental responsibility, indicating a potential future direction for V12 technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!