The Role of Antifreeze in Building Envelope Protection

JUL 2, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Antifreeze in Construction: Background and Objectives

Antifreeze has played a crucial role in the construction industry for decades, particularly in regions experiencing harsh winter conditions. The primary objective of using antifreeze in building envelope protection is to prevent water-based materials from freezing and expanding, which can cause significant structural damage. This technology has evolved from simple salt-based solutions to more sophisticated chemical compounds designed to maintain the integrity of construction materials in sub-zero temperatures.

The development of antifreeze for construction applications can be traced back to the early 20th century when the rapid expansion of infrastructure in colder climates necessitated innovative solutions. Initially, the focus was on preventing concrete from freezing during the curing process, which led to the introduction of calcium chloride as an antifreeze admixture. As construction techniques advanced and building envelopes became more complex, the demand for more specialized antifreeze solutions grew.

In recent years, the construction industry has witnessed a shift towards more environmentally friendly and efficient antifreeze technologies. This trend is driven by increasing awareness of the ecological impact of traditional antifreeze chemicals and stricter regulations on construction materials. The current technological landscape includes a wide range of antifreeze solutions, from organic compounds to nano-engineered additives, each designed to address specific challenges in building envelope protection.

The primary goals of modern antifreeze technology in construction include enhancing the durability of building materials, extending the construction season in cold climates, and improving the overall energy efficiency of structures. Researchers and industry professionals are continuously working to develop antifreeze solutions that not only prevent freezing but also contribute to the long-term performance of building envelopes by resisting moisture penetration and thermal bridging.

As we look towards the future, the objectives for antifreeze in construction are becoming increasingly ambitious. There is a growing focus on creating multi-functional antifreeze materials that can simultaneously address multiple aspects of building envelope protection, such as thermal insulation, moisture control, and fire resistance. Additionally, there is a push towards developing smart antifreeze systems that can adapt to changing environmental conditions, potentially revolutionizing how we approach cold weather construction and building maintenance.

The ongoing technological evolution in this field is closely tied to broader trends in sustainable construction and smart building technologies. As such, the future of antifreeze in building envelope protection is likely to involve integration with advanced monitoring systems, renewable energy technologies, and innovative building materials. This holistic approach aims to create more resilient, energy-efficient, and environmentally friendly structures capable of withstanding extreme weather conditions while minimizing their ecological footprint.

The development of antifreeze for construction applications can be traced back to the early 20th century when the rapid expansion of infrastructure in colder climates necessitated innovative solutions. Initially, the focus was on preventing concrete from freezing during the curing process, which led to the introduction of calcium chloride as an antifreeze admixture. As construction techniques advanced and building envelopes became more complex, the demand for more specialized antifreeze solutions grew.

In recent years, the construction industry has witnessed a shift towards more environmentally friendly and efficient antifreeze technologies. This trend is driven by increasing awareness of the ecological impact of traditional antifreeze chemicals and stricter regulations on construction materials. The current technological landscape includes a wide range of antifreeze solutions, from organic compounds to nano-engineered additives, each designed to address specific challenges in building envelope protection.

The primary goals of modern antifreeze technology in construction include enhancing the durability of building materials, extending the construction season in cold climates, and improving the overall energy efficiency of structures. Researchers and industry professionals are continuously working to develop antifreeze solutions that not only prevent freezing but also contribute to the long-term performance of building envelopes by resisting moisture penetration and thermal bridging.

As we look towards the future, the objectives for antifreeze in construction are becoming increasingly ambitious. There is a growing focus on creating multi-functional antifreeze materials that can simultaneously address multiple aspects of building envelope protection, such as thermal insulation, moisture control, and fire resistance. Additionally, there is a push towards developing smart antifreeze systems that can adapt to changing environmental conditions, potentially revolutionizing how we approach cold weather construction and building maintenance.

The ongoing technological evolution in this field is closely tied to broader trends in sustainable construction and smart building technologies. As such, the future of antifreeze in building envelope protection is likely to involve integration with advanced monitoring systems, renewable energy technologies, and innovative building materials. This holistic approach aims to create more resilient, energy-efficient, and environmentally friendly structures capable of withstanding extreme weather conditions while minimizing their ecological footprint.

Market Analysis for Antifreeze Building Solutions

The market for antifreeze building solutions has been experiencing significant growth in recent years, driven by increasing awareness of the damaging effects of freeze-thaw cycles on building envelopes and the need for more resilient construction methods in cold climates. The global market for antifreeze admixtures in concrete and other building materials is estimated to reach several billion dollars by 2025, with a compound annual growth rate exceeding 5%.

The demand for antifreeze building solutions is particularly strong in regions with harsh winter conditions, such as North America, Northern Europe, and parts of Asia. In these areas, the construction industry is increasingly adopting antifreeze technologies to extend the building season and improve the durability of structures. The residential sector represents a substantial portion of this market, as homeowners seek to protect their investments from frost damage and reduce maintenance costs.

Commercial and industrial construction projects are also driving market growth, with a focus on critical infrastructure that must remain operational in extreme cold. This includes facilities such as airports, bridges, and power plants, where the use of antifreeze solutions in concrete and other building materials is essential for maintaining structural integrity and safety.

The market is segmented by product type, including antifreeze admixtures for concrete, antifreeze coatings for building exteriors, and specialized insulation materials. Concrete admixtures currently dominate the market share, but innovative coatings and insulation solutions are gaining traction due to their ease of application in both new construction and retrofitting projects.

Key market trends include the development of eco-friendly antifreeze solutions to meet growing environmental concerns and stricter regulations. Manufacturers are investing in research and development to create biodegradable and non-toxic alternatives to traditional antifreeze chemicals. Additionally, there is a rising demand for smart building envelope systems that integrate antifreeze technologies with sensors and automated climate control systems.

The construction industry's shift towards sustainable and energy-efficient buildings is also influencing the antifreeze solutions market. Products that can contribute to improved thermal performance and reduced energy consumption are seeing increased adoption, particularly in green building projects and LEED-certified structures.

Geographically, North America and Europe are the largest markets for antifreeze building solutions, but rapid urbanization and infrastructure development in emerging economies are creating new opportunities in Asia-Pacific and Latin America. These regions are expected to show the highest growth rates in the coming years as they invest in cold-resistant construction techniques to improve building longevity and reduce maintenance costs.

The demand for antifreeze building solutions is particularly strong in regions with harsh winter conditions, such as North America, Northern Europe, and parts of Asia. In these areas, the construction industry is increasingly adopting antifreeze technologies to extend the building season and improve the durability of structures. The residential sector represents a substantial portion of this market, as homeowners seek to protect their investments from frost damage and reduce maintenance costs.

Commercial and industrial construction projects are also driving market growth, with a focus on critical infrastructure that must remain operational in extreme cold. This includes facilities such as airports, bridges, and power plants, where the use of antifreeze solutions in concrete and other building materials is essential for maintaining structural integrity and safety.

The market is segmented by product type, including antifreeze admixtures for concrete, antifreeze coatings for building exteriors, and specialized insulation materials. Concrete admixtures currently dominate the market share, but innovative coatings and insulation solutions are gaining traction due to their ease of application in both new construction and retrofitting projects.

Key market trends include the development of eco-friendly antifreeze solutions to meet growing environmental concerns and stricter regulations. Manufacturers are investing in research and development to create biodegradable and non-toxic alternatives to traditional antifreeze chemicals. Additionally, there is a rising demand for smart building envelope systems that integrate antifreeze technologies with sensors and automated climate control systems.

The construction industry's shift towards sustainable and energy-efficient buildings is also influencing the antifreeze solutions market. Products that can contribute to improved thermal performance and reduced energy consumption are seeing increased adoption, particularly in green building projects and LEED-certified structures.

Geographically, North America and Europe are the largest markets for antifreeze building solutions, but rapid urbanization and infrastructure development in emerging economies are creating new opportunities in Asia-Pacific and Latin America. These regions are expected to show the highest growth rates in the coming years as they invest in cold-resistant construction techniques to improve building longevity and reduce maintenance costs.

Current Challenges in Building Envelope Protection

Building envelope protection faces several significant challenges in the current landscape of construction and architectural design. One of the primary issues is the increasing frequency and severity of extreme weather events due to climate change. These events, including intense freeze-thaw cycles, heavy precipitation, and rapid temperature fluctuations, put unprecedented stress on building envelopes, leading to accelerated deterioration and potential structural damage.

The complexity of modern building designs also presents a challenge for effective envelope protection. As architects push the boundaries of form and function, incorporating diverse materials and intricate geometries, traditional protection methods often fall short. This complexity demands more sophisticated and adaptable solutions that can seamlessly integrate with various architectural styles while maintaining optimal performance.

Energy efficiency requirements and sustainability goals have become increasingly stringent, placing additional demands on building envelope systems. The need to balance thermal insulation, moisture management, and air tightness while reducing the overall environmental impact of construction materials and processes presents a multifaceted challenge for engineers and designers.

The durability and longevity of building envelope protection systems are also under scrutiny. With the rising costs of maintenance and renovation, there is a growing demand for solutions that can withstand the test of time and reduce the frequency of repairs or replacements. This challenge is particularly acute in harsh environments where materials are subjected to extreme conditions over extended periods.

Another significant challenge lies in the retrofitting of existing structures. Many older buildings were constructed without modern envelope protection systems, and upgrading them to meet current standards can be technically complex and financially burdensome. Developing cost-effective and minimally invasive retrofit solutions remains a critical area of focus in the industry.

The integration of smart technologies and sensors into building envelopes presents both opportunities and challenges. While these technologies offer the potential for real-time monitoring and adaptive responses to environmental conditions, they also introduce new complexities in terms of installation, maintenance, and data management.

Lastly, the variability in regional climate conditions and building codes across different geographical areas complicates the development of universally applicable envelope protection solutions. This diversity necessitates a more nuanced and localized approach to building envelope design and protection, challenging manufacturers and designers to create versatile systems that can be easily adapted to specific regional requirements.

The complexity of modern building designs also presents a challenge for effective envelope protection. As architects push the boundaries of form and function, incorporating diverse materials and intricate geometries, traditional protection methods often fall short. This complexity demands more sophisticated and adaptable solutions that can seamlessly integrate with various architectural styles while maintaining optimal performance.

Energy efficiency requirements and sustainability goals have become increasingly stringent, placing additional demands on building envelope systems. The need to balance thermal insulation, moisture management, and air tightness while reducing the overall environmental impact of construction materials and processes presents a multifaceted challenge for engineers and designers.

The durability and longevity of building envelope protection systems are also under scrutiny. With the rising costs of maintenance and renovation, there is a growing demand for solutions that can withstand the test of time and reduce the frequency of repairs or replacements. This challenge is particularly acute in harsh environments where materials are subjected to extreme conditions over extended periods.

Another significant challenge lies in the retrofitting of existing structures. Many older buildings were constructed without modern envelope protection systems, and upgrading them to meet current standards can be technically complex and financially burdensome. Developing cost-effective and minimally invasive retrofit solutions remains a critical area of focus in the industry.

The integration of smart technologies and sensors into building envelopes presents both opportunities and challenges. While these technologies offer the potential for real-time monitoring and adaptive responses to environmental conditions, they also introduce new complexities in terms of installation, maintenance, and data management.

Lastly, the variability in regional climate conditions and building codes across different geographical areas complicates the development of universally applicable envelope protection solutions. This diversity necessitates a more nuanced and localized approach to building envelope design and protection, challenging manufacturers and designers to create versatile systems that can be easily adapted to specific regional requirements.

Existing Antifreeze Solutions for Building Envelopes

01 Antifreeze compositions for various applications

Antifreeze compositions are developed for use in different applications, including automotive cooling systems, industrial processes, and heat transfer systems. These compositions typically contain glycols, such as ethylene glycol or propylene glycol, along with additives to enhance performance and protect against corrosion. The formulations are designed to lower the freezing point of water and raise its boiling point, providing protection in extreme temperatures.- Antifreeze compositions for cooling systems: Antifreeze compositions are developed for use in cooling systems, particularly in vehicles. These compositions typically include glycols, corrosion inhibitors, and other additives to prevent freezing and protect engine components. The formulations are designed to maintain their effectiveness over a wide range of temperatures and operating conditions.

- Antifreeze protection for fire suppression systems: Specialized antifreeze solutions are formulated for use in fire suppression systems to prevent freezing in cold environments. These solutions are designed to maintain their fire-extinguishing properties while resisting freezing, ensuring the system remains operational in low temperatures. The compositions often include glycols, water, and specific additives to meet fire safety standards.

- Antifreeze protection for biological samples: Antifreeze solutions are developed for preserving biological samples at low temperatures. These formulations are designed to prevent ice crystal formation and maintain cellular integrity during freezing and thawing processes. The compositions often include cryoprotectants and other additives that protect cells and tissues from freeze damage.

- Environmental-friendly antifreeze formulations: Research focuses on developing eco-friendly antifreeze solutions that reduce environmental impact. These formulations often use biodegradable components and aim to minimize toxicity while maintaining effective freeze protection. The compositions may include plant-based glycols, natural corrosion inhibitors, and other sustainable ingredients.

- Antifreeze protection for industrial processes: Specialized antifreeze solutions are formulated for various industrial applications, such as in manufacturing, oil and gas, and chemical processing. These compositions are designed to prevent freezing in pipes, equipment, and storage tanks while considering specific operational requirements. The formulations often include additives for corrosion protection and heat transfer efficiency.

02 Environmentally friendly antifreeze solutions

Research focuses on developing eco-friendly antifreeze solutions to reduce environmental impact. These formulations often use biodegradable materials, such as plant-based glycols or organic compounds, as alternatives to traditional petroleum-based antifreeze. The goal is to maintain effective freeze protection while minimizing toxicity and improving sustainability.Expand Specific Solutions03 Antifreeze protection for specific industries

Specialized antifreeze solutions are developed for specific industries with unique requirements. This includes formulations for aerospace, marine applications, food processing, and medical equipment. These tailored solutions address industry-specific challenges such as extreme temperature ranges, compatibility with sensitive materials, or compliance with regulatory standards.Expand Specific Solutions04 Antifreeze systems and devices

Various systems and devices are designed to provide antifreeze protection in different contexts. These may include automated antifreeze circulation systems, heat exchangers with antifreeze capabilities, or specialized equipment for applying antifreeze solutions. Such innovations aim to improve efficiency, reduce maintenance requirements, and ensure consistent protection against freezing.Expand Specific Solutions05 Antifreeze additives and performance enhancers

Research focuses on developing additives and performance enhancers for antifreeze solutions. These may include corrosion inhibitors, anti-scaling agents, or compounds that improve heat transfer properties. The goal is to enhance the overall effectiveness of antifreeze formulations, extend their lifespan, and provide additional benefits such as equipment protection or improved thermal efficiency.Expand Specific Solutions

Key Players in Antifreeze and Building Materials Industry

The antifreeze market for building envelope protection is in a growth phase, driven by increasing awareness of energy efficiency and sustainability in construction. The global market size is expanding, with projections indicating significant growth in the coming years. Technologically, the field is evolving rapidly, with companies like Rolls-Royce, AGC Flat Glass North America, and Vector Foiltec leading innovations. These firms are developing advanced antifreeze solutions that offer improved thermal performance and durability for building envelopes. Research institutions such as Arizona State University and Massachusetts Institute of Technology are contributing to technological advancements, pushing the boundaries of antifreeze applications in construction. The competitive landscape is diverse, with both established players and emerging startups vying for market share through product differentiation and technological superiority.

AGC Flat Glass North America, Inc.

Technical Solution: AGC Flat Glass North America has developed advanced low-emissivity (low-E) glass coatings that contribute to building envelope protection by managing heat transfer and reducing condensation, which is crucial in preventing freeze-thaw damage. Their Comfort Select™ series incorporates multiple layers of silver and other metals deposited on the glass surface using magnetron sputtering technology[7]. This creates a transparent, insulating barrier that reflects infrared heat while allowing visible light to pass through. The company has also introduced self-cleaning glass coatings that use photocatalytic and hydrophilic properties to break down organic dirt and spread water evenly across the surface, reducing the potential for ice formation[9]. Furthermore, AGC has developed vacuum insulated glazing (VIG) units that provide superior thermal insulation, helping to maintain consistent interior temperatures and reduce the risk of condensation and subsequent freezing on interior surfaces.

Strengths: Excellent thermal performance, reduced condensation risk, and improved energy efficiency. Weaknesses: Higher initial cost compared to standard glazing, and potential for seal failure in extreme conditions.

Construction Research & Technology GmbH

Technical Solution: Construction Research & Technology GmbH, a subsidiary of BASF, has developed MasterLife AMA series, a range of antifreeze admixtures for concrete that significantly improve its resistance to freeze-thaw cycles in building envelopes. These admixtures work by lowering the freezing point of water within the concrete pores and reducing the amount of freezable water[11]. The technology incorporates a combination of air-entraining agents and pore-blocking compounds that create a network of finely dispersed air voids while also reducing capillary water absorption. Additionally, the company has introduced MasterSeal waterproofing membranes that maintain flexibility at low temperatures, providing continuous protection against water ingress and frost damage[13]. Their latest innovation includes self-healing concrete admixtures that can automatically repair micro-cracks, further enhancing the durability of concrete structures in freeze-prone environments.

Strengths: Comprehensive freeze-thaw protection, improved concrete workability in cold weather, and enhanced long-term durability. Weaknesses: May require careful dosage control to avoid negative impacts on other concrete properties, and potential for increased air content affecting strength.

Innovative Antifreeze Compounds for Construction

Patent

Innovation

- Incorporation of antifreeze agents into building envelope materials to enhance freeze-thaw resistance and durability.

- Development of smart antifreeze systems that can adjust concentration based on real-time temperature monitoring.

- Integration of antifreeze properties with other protective features like waterproofing and fire resistance in a single solution.

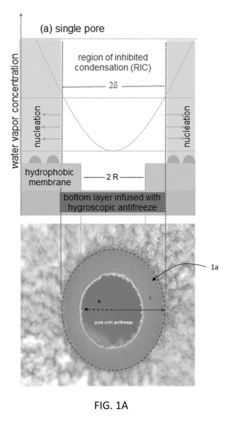

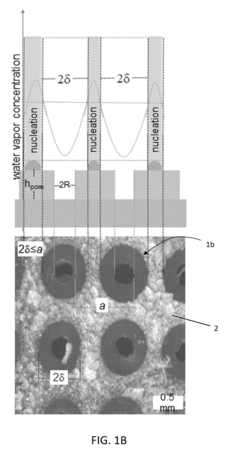

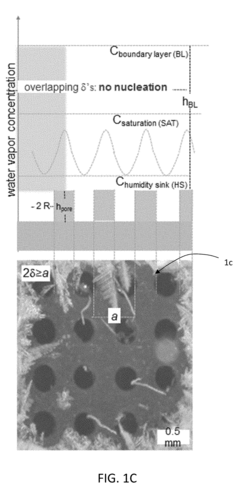

Nanoporous materials, method of manufacture and methods of use

PatentActiveUS20180215927A1

Innovation

- A bi-layer coating system comprising a hydrophilic or superhydrophilic first layer infused with antifreeze material and a permeable, omniphobic second layer with defined pores, which allows antifreeze migration and creates a localized humidity sink to inhibit frost formation, reducing the need for extensive antifreeze use and enhancing durability.

Environmental Impact of Antifreeze in Construction

The use of antifreeze in construction, particularly for building envelope protection, raises significant environmental concerns that warrant careful consideration. Antifreeze compounds, typically composed of ethylene glycol or propylene glycol, can have detrimental effects on ecosystems if released into the environment. When these substances leach from building materials or are improperly disposed of, they can contaminate soil and water sources.

One of the primary environmental risks associated with antifreeze in construction is its potential to pollute groundwater. As antifreeze chemicals seep into the soil, they can eventually reach aquifers, compromising the quality of drinking water sources. This contamination poses threats to both human health and aquatic ecosystems. Ethylene glycol, in particular, is known to be toxic to animals and can cause severe ecological damage if it enters waterways.

Furthermore, the production and disposal of antifreeze compounds contribute to the overall carbon footprint of construction projects. The manufacturing process of these chemicals involves energy-intensive procedures and the use of petrochemical resources, which can lead to increased greenhouse gas emissions. Additionally, the improper disposal of antifreeze-containing materials at the end of a building's lifecycle can result in further environmental degradation.

The persistence of antifreeze compounds in the environment is another significant concern. While some modern formulations are designed to be more biodegradable, many traditional antifreeze products can remain in ecosystems for extended periods, potentially accumulating in food chains and causing long-term ecological impacts. This persistence underscores the importance of responsible use and disposal practices in the construction industry.

To mitigate these environmental risks, the construction sector is increasingly exploring alternative solutions and best practices. These include the development of more environmentally friendly antifreeze formulations, improved application techniques to minimize leaching, and enhanced recycling and disposal protocols. Some projects are also investigating natural or bio-based antifreeze alternatives that offer comparable performance with reduced environmental impact.

Regulatory bodies and environmental agencies are also taking steps to address the environmental concerns associated with antifreeze in construction. Stricter guidelines for the use, handling, and disposal of these materials are being implemented in many regions. These regulations aim to minimize the release of harmful substances into the environment and promote more sustainable construction practices.

One of the primary environmental risks associated with antifreeze in construction is its potential to pollute groundwater. As antifreeze chemicals seep into the soil, they can eventually reach aquifers, compromising the quality of drinking water sources. This contamination poses threats to both human health and aquatic ecosystems. Ethylene glycol, in particular, is known to be toxic to animals and can cause severe ecological damage if it enters waterways.

Furthermore, the production and disposal of antifreeze compounds contribute to the overall carbon footprint of construction projects. The manufacturing process of these chemicals involves energy-intensive procedures and the use of petrochemical resources, which can lead to increased greenhouse gas emissions. Additionally, the improper disposal of antifreeze-containing materials at the end of a building's lifecycle can result in further environmental degradation.

The persistence of antifreeze compounds in the environment is another significant concern. While some modern formulations are designed to be more biodegradable, many traditional antifreeze products can remain in ecosystems for extended periods, potentially accumulating in food chains and causing long-term ecological impacts. This persistence underscores the importance of responsible use and disposal practices in the construction industry.

To mitigate these environmental risks, the construction sector is increasingly exploring alternative solutions and best practices. These include the development of more environmentally friendly antifreeze formulations, improved application techniques to minimize leaching, and enhanced recycling and disposal protocols. Some projects are also investigating natural or bio-based antifreeze alternatives that offer comparable performance with reduced environmental impact.

Regulatory bodies and environmental agencies are also taking steps to address the environmental concerns associated with antifreeze in construction. Stricter guidelines for the use, handling, and disposal of these materials are being implemented in many regions. These regulations aim to minimize the release of harmful substances into the environment and promote more sustainable construction practices.

Cost-Benefit Analysis of Antifreeze Building Solutions

The cost-benefit analysis of antifreeze building solutions is a critical aspect of evaluating the role of antifreeze in building envelope protection. This analysis involves assessing the financial implications of implementing antifreeze measures against the potential benefits and savings they offer.

Initial costs associated with antifreeze building solutions can be substantial. These expenses include the purchase of specialized antifreeze materials, such as chemical additives for concrete or insulation materials with antifreeze properties. Additionally, there are installation costs, which may involve hiring skilled professionals familiar with antifreeze technologies. The design phase may also incur extra expenses due to the need for specialized engineering to incorporate antifreeze solutions effectively.

However, these upfront costs must be weighed against the long-term benefits. One of the primary advantages is the reduction in maintenance and repair costs. Buildings protected by antifreeze solutions are less likely to suffer from freeze-thaw damage, which can lead to cracks, spalling, and structural deterioration. This decreased vulnerability translates to lower repair expenses over the building's lifetime.

Energy efficiency is another significant benefit. Antifreeze solutions often contribute to better insulation, reducing heat loss during cold seasons. This improved thermal performance can lead to substantial energy savings, lowering heating costs and potentially cooling costs in warmer months. Over time, these energy savings can offset a significant portion of the initial investment.

The longevity of building materials is also enhanced by antifreeze protection. By preventing freeze-thaw cycles from damaging the building envelope, the lifespan of construction materials is extended. This durability translates to delayed replacement costs and less frequent renovations, contributing to long-term cost savings.

Insurance premiums may also be affected positively. Buildings with robust antifreeze protection are at lower risk of water damage from burst pipes or structural damage from freezing conditions. This reduced risk profile can lead to more favorable insurance terms and potentially lower premiums.

When conducting a cost-benefit analysis, it's crucial to consider the specific climate conditions of the building's location. In regions with severe winters, the benefits of antifreeze solutions are likely to be more pronounced, potentially justifying higher initial investments. Conversely, in milder climates, the cost-benefit ratio may be less favorable, requiring careful consideration of the necessity and scale of antifreeze measures.

The analysis should also factor in the expected lifespan of the building and the antifreeze solutions themselves. Some antifreeze measures may require periodic renewal or maintenance, which should be included in long-term cost projections. The potential for future climate changes and their impact on the building's freeze risk should also be considered in a comprehensive analysis.

Initial costs associated with antifreeze building solutions can be substantial. These expenses include the purchase of specialized antifreeze materials, such as chemical additives for concrete or insulation materials with antifreeze properties. Additionally, there are installation costs, which may involve hiring skilled professionals familiar with antifreeze technologies. The design phase may also incur extra expenses due to the need for specialized engineering to incorporate antifreeze solutions effectively.

However, these upfront costs must be weighed against the long-term benefits. One of the primary advantages is the reduction in maintenance and repair costs. Buildings protected by antifreeze solutions are less likely to suffer from freeze-thaw damage, which can lead to cracks, spalling, and structural deterioration. This decreased vulnerability translates to lower repair expenses over the building's lifetime.

Energy efficiency is another significant benefit. Antifreeze solutions often contribute to better insulation, reducing heat loss during cold seasons. This improved thermal performance can lead to substantial energy savings, lowering heating costs and potentially cooling costs in warmer months. Over time, these energy savings can offset a significant portion of the initial investment.

The longevity of building materials is also enhanced by antifreeze protection. By preventing freeze-thaw cycles from damaging the building envelope, the lifespan of construction materials is extended. This durability translates to delayed replacement costs and less frequent renovations, contributing to long-term cost savings.

Insurance premiums may also be affected positively. Buildings with robust antifreeze protection are at lower risk of water damage from burst pipes or structural damage from freezing conditions. This reduced risk profile can lead to more favorable insurance terms and potentially lower premiums.

When conducting a cost-benefit analysis, it's crucial to consider the specific climate conditions of the building's location. In regions with severe winters, the benefits of antifreeze solutions are likely to be more pronounced, potentially justifying higher initial investments. Conversely, in milder climates, the cost-benefit ratio may be less favorable, requiring careful consideration of the necessity and scale of antifreeze measures.

The analysis should also factor in the expected lifespan of the building and the antifreeze solutions themselves. Some antifreeze measures may require periodic renewal or maintenance, which should be included in long-term cost projections. The potential for future climate changes and their impact on the building's freeze risk should also be considered in a comprehensive analysis.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!