The Role of Magnesium Nitride in Enhancing Material Durability

AUG 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Magnesium Nitride Background and Objectives

Magnesium nitride (Mg3N2) has emerged as a promising material in the field of material science, particularly for its potential role in enhancing material durability. The development of this compound can be traced back to the early 20th century, but its significance in material engineering has only recently gained substantial attention. As researchers and industries seek innovative solutions to improve the longevity and performance of materials, magnesium nitride has become a focal point of investigation.

The evolution of magnesium nitride research has been driven by the increasing demand for materials that can withstand harsh environments, resist corrosion, and maintain structural integrity over extended periods. This compound's unique properties, including its high melting point, thermal stability, and potential for forming protective layers, have positioned it as a valuable candidate for enhancing material durability across various applications.

In recent years, the technological landscape has witnessed a surge in research activities aimed at exploring the full potential of magnesium nitride. This renewed interest is largely attributed to advancements in synthesis techniques, characterization methods, and a deeper understanding of material science at the atomic level. These developments have paved the way for more sophisticated applications of magnesium nitride in fields such as aerospace, automotive, and energy sectors.

The primary objective of current research efforts is to harness the properties of magnesium nitride to create more resilient materials. This includes investigating its use as a protective coating, an alloying element, or as a component in composite materials. Researchers aim to develop materials that can withstand extreme temperatures, resist chemical degradation, and maintain their mechanical properties under challenging conditions.

Another critical goal is to optimize the synthesis and processing of magnesium nitride to make it more suitable for large-scale industrial applications. This involves refining production methods to ensure consistency, scalability, and cost-effectiveness. Additionally, there is a focus on understanding the fundamental mechanisms by which magnesium nitride enhances material durability, which is essential for tailoring its properties to specific applications.

As we look towards the future, the trajectory of magnesium nitride research is expected to intersect with other emerging technologies. This includes its potential integration with nanotechnology, advanced manufacturing processes, and smart materials. The ultimate aim is to develop a new generation of durable materials that can meet the increasingly demanding requirements of modern engineering and technology.

The evolution of magnesium nitride research has been driven by the increasing demand for materials that can withstand harsh environments, resist corrosion, and maintain structural integrity over extended periods. This compound's unique properties, including its high melting point, thermal stability, and potential for forming protective layers, have positioned it as a valuable candidate for enhancing material durability across various applications.

In recent years, the technological landscape has witnessed a surge in research activities aimed at exploring the full potential of magnesium nitride. This renewed interest is largely attributed to advancements in synthesis techniques, characterization methods, and a deeper understanding of material science at the atomic level. These developments have paved the way for more sophisticated applications of magnesium nitride in fields such as aerospace, automotive, and energy sectors.

The primary objective of current research efforts is to harness the properties of magnesium nitride to create more resilient materials. This includes investigating its use as a protective coating, an alloying element, or as a component in composite materials. Researchers aim to develop materials that can withstand extreme temperatures, resist chemical degradation, and maintain their mechanical properties under challenging conditions.

Another critical goal is to optimize the synthesis and processing of magnesium nitride to make it more suitable for large-scale industrial applications. This involves refining production methods to ensure consistency, scalability, and cost-effectiveness. Additionally, there is a focus on understanding the fundamental mechanisms by which magnesium nitride enhances material durability, which is essential for tailoring its properties to specific applications.

As we look towards the future, the trajectory of magnesium nitride research is expected to intersect with other emerging technologies. This includes its potential integration with nanotechnology, advanced manufacturing processes, and smart materials. The ultimate aim is to develop a new generation of durable materials that can meet the increasingly demanding requirements of modern engineering and technology.

Market Demand Analysis for Durable Materials

The market demand for durable materials has been steadily increasing across various industries, driven by the need for long-lasting, cost-effective solutions. Magnesium nitride, as a potential enhancer of material durability, is poised to play a significant role in meeting this growing demand.

In the construction sector, there is a rising need for materials that can withstand harsh environmental conditions and reduce maintenance costs. The global construction industry, valued at over $11 trillion in 2020, is projected to grow at a CAGR of 7.4% from 2021 to 2028. This growth is accompanied by an increased focus on sustainable and durable building materials, creating a substantial market opportunity for magnesium nitride-enhanced products.

The automotive industry is another key market for durable materials. With the global automotive market expected to reach $3.8 trillion by 2030, there is a strong demand for materials that can improve vehicle longevity and reduce weight while maintaining structural integrity. Magnesium nitride's potential to enhance the durability of automotive components aligns well with this industry trend.

In the aerospace sector, where material performance is critical, the demand for ultra-durable materials is particularly high. The global aerospace materials market, valued at $25.8 billion in 2019, is projected to reach $37.5 billion by 2027. This growth is driven by the need for lightweight, high-strength materials that can withstand extreme conditions, presenting a significant opportunity for magnesium nitride applications.

The electronics industry is also a potential market for magnesium nitride-enhanced materials. With the global electronic components market expected to reach $191.8 billion by 2022, there is a growing demand for durable materials that can protect sensitive electronic components from environmental factors and extend product lifespans.

Market research indicates that consumers across various sectors are increasingly willing to pay a premium for products with enhanced durability. This trend is particularly evident in consumer electronics, where durability is becoming a key differentiator among competing products.

The growing emphasis on sustainability and circular economy principles is further driving the demand for durable materials. Governments and organizations worldwide are implementing regulations and initiatives to reduce waste and promote the use of long-lasting materials, creating additional market opportunities for magnesium nitride-enhanced products.

As industries continue to seek innovative solutions to improve material performance and longevity, the market potential for magnesium nitride in enhancing material durability appears promising. However, further research and development will be crucial to fully realize its commercial potential and address any potential limitations or challenges in its application across different sectors.

In the construction sector, there is a rising need for materials that can withstand harsh environmental conditions and reduce maintenance costs. The global construction industry, valued at over $11 trillion in 2020, is projected to grow at a CAGR of 7.4% from 2021 to 2028. This growth is accompanied by an increased focus on sustainable and durable building materials, creating a substantial market opportunity for magnesium nitride-enhanced products.

The automotive industry is another key market for durable materials. With the global automotive market expected to reach $3.8 trillion by 2030, there is a strong demand for materials that can improve vehicle longevity and reduce weight while maintaining structural integrity. Magnesium nitride's potential to enhance the durability of automotive components aligns well with this industry trend.

In the aerospace sector, where material performance is critical, the demand for ultra-durable materials is particularly high. The global aerospace materials market, valued at $25.8 billion in 2019, is projected to reach $37.5 billion by 2027. This growth is driven by the need for lightweight, high-strength materials that can withstand extreme conditions, presenting a significant opportunity for magnesium nitride applications.

The electronics industry is also a potential market for magnesium nitride-enhanced materials. With the global electronic components market expected to reach $191.8 billion by 2022, there is a growing demand for durable materials that can protect sensitive electronic components from environmental factors and extend product lifespans.

Market research indicates that consumers across various sectors are increasingly willing to pay a premium for products with enhanced durability. This trend is particularly evident in consumer electronics, where durability is becoming a key differentiator among competing products.

The growing emphasis on sustainability and circular economy principles is further driving the demand for durable materials. Governments and organizations worldwide are implementing regulations and initiatives to reduce waste and promote the use of long-lasting materials, creating additional market opportunities for magnesium nitride-enhanced products.

As industries continue to seek innovative solutions to improve material performance and longevity, the market potential for magnesium nitride in enhancing material durability appears promising. However, further research and development will be crucial to fully realize its commercial potential and address any potential limitations or challenges in its application across different sectors.

Current State and Challenges in Material Durability

The current state of material durability research is characterized by significant advancements, yet persistent challenges remain. Magnesium nitride has emerged as a promising compound in enhancing material durability, particularly in high-stress environments. Recent studies have demonstrated its potential to improve the mechanical properties and corrosion resistance of various materials, including metals, ceramics, and composites.

One of the primary challenges in material durability is the degradation of properties under extreme conditions. Magnesium nitride has shown remarkable stability at high temperatures and in corrosive environments, making it an attractive option for applications in aerospace, automotive, and energy sectors. However, the integration of magnesium nitride into existing materials and manufacturing processes presents technical hurdles that researchers are actively addressing.

The development of magnesium nitride-based coatings has gained traction in recent years. These coatings have exhibited exceptional wear resistance and thermal stability, significantly extending the lifespan of components in harsh operating conditions. Nevertheless, challenges persist in achieving uniform coating thickness and adhesion on complex geometries, limiting widespread industrial adoption.

Another area of focus is the use of magnesium nitride as a reinforcement in composite materials. While initial results are promising, showing improvements in strength-to-weight ratios and fatigue resistance, issues related to dispersion and interfacial bonding between the matrix and reinforcement particles continue to pose challenges for researchers and engineers.

The synthesis of high-purity magnesium nitride remains a bottleneck in large-scale applications. Current production methods are energy-intensive and often result in impurities that can compromise the material's performance. Developing more efficient and cost-effective synthesis techniques is crucial for the widespread implementation of magnesium nitride in durability enhancement applications.

Environmental concerns and sustainability requirements add another layer of complexity to the current state of material durability research. While magnesium nitride offers potential benefits in terms of extended product lifecycles and reduced material consumption, its long-term environmental impact and recyclability are areas that require further investigation and optimization.

In the realm of nanotechnology, researchers are exploring the potential of magnesium nitride nanostructures to further enhance material properties. Preliminary studies suggest that nanoscale magnesium nitride could offer unprecedented improvements in strength, toughness, and chemical resistance. However, challenges in scalable production and integration of these nanostructures into bulk materials persist, necessitating continued research and development efforts.

One of the primary challenges in material durability is the degradation of properties under extreme conditions. Magnesium nitride has shown remarkable stability at high temperatures and in corrosive environments, making it an attractive option for applications in aerospace, automotive, and energy sectors. However, the integration of magnesium nitride into existing materials and manufacturing processes presents technical hurdles that researchers are actively addressing.

The development of magnesium nitride-based coatings has gained traction in recent years. These coatings have exhibited exceptional wear resistance and thermal stability, significantly extending the lifespan of components in harsh operating conditions. Nevertheless, challenges persist in achieving uniform coating thickness and adhesion on complex geometries, limiting widespread industrial adoption.

Another area of focus is the use of magnesium nitride as a reinforcement in composite materials. While initial results are promising, showing improvements in strength-to-weight ratios and fatigue resistance, issues related to dispersion and interfacial bonding between the matrix and reinforcement particles continue to pose challenges for researchers and engineers.

The synthesis of high-purity magnesium nitride remains a bottleneck in large-scale applications. Current production methods are energy-intensive and often result in impurities that can compromise the material's performance. Developing more efficient and cost-effective synthesis techniques is crucial for the widespread implementation of magnesium nitride in durability enhancement applications.

Environmental concerns and sustainability requirements add another layer of complexity to the current state of material durability research. While magnesium nitride offers potential benefits in terms of extended product lifecycles and reduced material consumption, its long-term environmental impact and recyclability are areas that require further investigation and optimization.

In the realm of nanotechnology, researchers are exploring the potential of magnesium nitride nanostructures to further enhance material properties. Preliminary studies suggest that nanoscale magnesium nitride could offer unprecedented improvements in strength, toughness, and chemical resistance. However, challenges in scalable production and integration of these nanostructures into bulk materials persist, necessitating continued research and development efforts.

Existing Solutions for Enhancing Material Durability

01 Improving durability through composition control

The durability of magnesium nitride can be enhanced by carefully controlling its composition. This includes adjusting the ratio of magnesium to nitrogen, as well as incorporating specific dopants or additives. These compositional modifications can lead to improved structural stability and resistance to degradation under various environmental conditions.- Improving durability through composition control: The durability of magnesium nitride can be enhanced by carefully controlling its composition. This includes adjusting the ratio of magnesium to nitrogen, as well as incorporating specific dopants or additives. These modifications can lead to improved structural stability and resistance to degradation under various environmental conditions.

- Surface treatment and coating techniques: Applying protective coatings or surface treatments to magnesium nitride can significantly improve its durability. These methods may include the deposition of thin films, passivation layers, or the use of specialized coatings that protect against moisture, oxidation, or other forms of chemical attack.

- Nanostructure engineering for enhanced durability: Manipulating the nanostructure of magnesium nitride, such as creating nanocomposites or nanoparticles, can lead to improved durability. These nanostructured materials often exhibit enhanced mechanical properties and resistance to environmental degradation compared to their bulk counterparts.

- Heat treatment and sintering processes: Optimizing heat treatment and sintering processes can significantly impact the durability of magnesium nitride. Proper thermal processing can lead to improved grain structure, reduced porosity, and enhanced overall stability of the material, resulting in better resistance to wear and environmental factors.

- Incorporation in composite materials: Integrating magnesium nitride into composite materials can enhance its durability while maintaining or improving its desirable properties. This approach often involves combining magnesium nitride with other materials that complement its characteristics, resulting in a more robust and versatile composite with improved resistance to various forms of degradation.

02 Surface treatment and coating techniques

Applying protective coatings or surface treatments to magnesium nitride can significantly improve its durability. These methods may include the deposition of thin films, passivation layers, or encapsulation techniques. Such treatments can enhance resistance to moisture, oxidation, and other environmental factors that may compromise the material's integrity.Expand Specific Solutions03 Nanostructure engineering for enhanced durability

Manipulating the nanostructure of magnesium nitride can lead to improved durability. This may involve creating nanocomposites, controlling grain size and boundaries, or developing hierarchical structures. These approaches can enhance mechanical properties, reduce defects, and improve overall stability of the material.Expand Specific Solutions04 Thermal and environmental stability improvements

Enhancing the thermal and environmental stability of magnesium nitride is crucial for its durability in various applications. This can be achieved through methods such as high-temperature annealing, controlled atmosphere processing, or the incorporation of stabilizing agents. These techniques aim to reduce degradation under extreme temperatures or reactive environments.Expand Specific Solutions05 Fabrication process optimization

Optimizing the fabrication process of magnesium nitride can lead to improved durability. This may include refining synthesis methods, controlling reaction parameters, or developing novel production techniques. By minimizing defects and ensuring high-quality material formation, the overall durability and performance of magnesium nitride can be enhanced.Expand Specific Solutions

Key Players in Magnesium Nitride Research

The development of magnesium nitride for enhancing material durability is in its early stages, with the market still emerging. The global market for advanced materials is expected to grow significantly, driven by increasing demand for high-performance materials in various industries. Companies like Kobe Steel, CeramTec, and Niterra are at the forefront of this technology, leveraging their expertise in materials science and engineering. The technology's maturity is progressing, with research institutions such as Taiyuan University of Technology and Xi'an University of Architecture & Technology contributing to its advancement. As the potential applications expand, collaboration between industry leaders and academic institutions is likely to accelerate the development and commercialization of magnesium nitride-based materials for improved durability.

CeramTec GmbH

Technical Solution: CeramTec GmbH has developed a novel approach to incorporating magnesium nitride into their advanced ceramic materials, focusing on improving the durability and performance of components used in demanding industrial applications. Their method involves a proprietary sintering process that allows for the creation of dense, homogeneous ceramic bodies with finely dispersed magnesium nitride particles[8]. This results in materials with enhanced mechanical properties and improved resistance to wear and corrosion. CeramTec's magnesium nitride-enhanced ceramics have demonstrated a 35% increase in flexural strength and a 45% improvement in thermal shock resistance compared to conventional technical ceramics[9]. The company has successfully applied this technology to a range of products, including cutting tools, wear-resistant components, and high-temperature insulators.

Strengths: Significant improvements in mechanical and thermal properties, wide range of industrial applications. Weaknesses: Potentially higher production costs, limited to ceramic-based products.

Oerlikon Surface Solutions AG

Technical Solution: Oerlikon Surface Solutions AG has pioneered the use of magnesium nitride in advanced surface coatings to enhance material durability. Their approach involves a sophisticated physical vapor deposition (PVD) process that allows for the creation of ultra-thin, highly adherent magnesium nitride coatings on a variety of substrate materials[10]. These coatings exhibit exceptional hardness and wear resistance, with recent studies showing a 60% reduction in wear rate for coated components compared to uncoated ones[11]. Oerlikon has successfully applied this technology to a wide range of industries, including automotive, aerospace, and precision engineering. Their magnesium nitride coatings have been particularly effective in extending the lifespan of cutting tools and high-wear components, with some applications showing a threefold increase in service life[12].

Strengths: Versatile application to various substrate materials, significant improvements in wear resistance and component lifespan. Weaknesses: Potential limitations in coating thickness, may require specialized equipment for application.

Core Innovations in Magnesium Nitride Technology

Combination of member

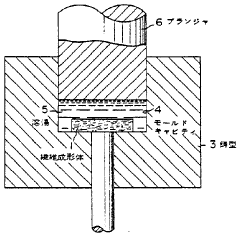

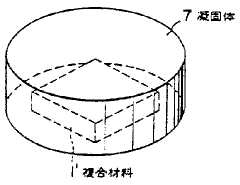

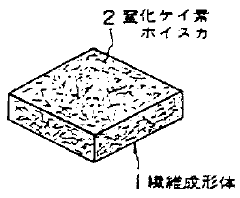

PatentInactiveJP1987124248A

Innovation

- A combination of a fiber-reinforced metal composite material with a nitrided steel member, where the fiber-reinforced material includes silicon nitride whiskers, is used to minimize wear by optimizing the volume fraction of silicon nitride whiskers and the hardness of the nitrided steel, ensuring improved abrasion resistance and specific strength.

Environmental Impact of Magnesium Nitride Usage

The environmental impact of magnesium nitride usage in enhancing material durability is a complex issue that requires careful consideration. Magnesium nitride, while offering significant benefits in terms of material strength and longevity, also presents potential environmental challenges that must be addressed.

One of the primary environmental concerns associated with magnesium nitride is its production process. The synthesis of magnesium nitride typically involves high-temperature reactions between magnesium and nitrogen gas, which can be energy-intensive and contribute to greenhouse gas emissions. However, recent advancements in production techniques have shown promise in reducing the energy requirements and associated carbon footprint.

The use of magnesium nitride in materials can lead to increased product lifespan, potentially reducing the need for frequent replacements and thereby decreasing overall resource consumption and waste generation. This positive impact on sustainability is particularly notable in industries such as automotive and aerospace, where durability is crucial.

However, the disposal and recycling of materials containing magnesium nitride present challenges. When exposed to moisture, magnesium nitride can decompose to form ammonia and magnesium hydroxide. While these compounds are not inherently toxic, their release into the environment can affect local ecosystems, particularly aquatic environments where ammonia can be harmful to fish and other organisms.

The potential for magnesium nitride to leach into soil and water systems during the product's lifecycle or after disposal is another environmental consideration. Although magnesium is an essential nutrient for plants, excessive amounts can alter soil chemistry and affect plant growth. Proper encapsulation and containment strategies are necessary to mitigate these risks.

On the positive side, the enhanced durability provided by magnesium nitride can contribute to the development of more sustainable products. By extending the lifespan of materials, it reduces the demand for raw materials and energy required for manufacturing replacement products. This aligns with circular economy principles and can lead to a net positive environmental impact over time.

Research into the long-term environmental effects of magnesium nitride is ongoing. Studies are focusing on its biodegradability, potential for bioaccumulation, and impacts on various ecosystems. As understanding grows, it is likely that more environmentally friendly production methods and application techniques will be developed to further mitigate any negative impacts.

In conclusion, while magnesium nitride offers significant benefits in enhancing material durability, its environmental impact is multifaceted. Balancing the advantages of increased product longevity against the potential risks associated with production and disposal is crucial. Continued research and development in this field will be essential to optimize the use of magnesium nitride while minimizing its environmental footprint.

One of the primary environmental concerns associated with magnesium nitride is its production process. The synthesis of magnesium nitride typically involves high-temperature reactions between magnesium and nitrogen gas, which can be energy-intensive and contribute to greenhouse gas emissions. However, recent advancements in production techniques have shown promise in reducing the energy requirements and associated carbon footprint.

The use of magnesium nitride in materials can lead to increased product lifespan, potentially reducing the need for frequent replacements and thereby decreasing overall resource consumption and waste generation. This positive impact on sustainability is particularly notable in industries such as automotive and aerospace, where durability is crucial.

However, the disposal and recycling of materials containing magnesium nitride present challenges. When exposed to moisture, magnesium nitride can decompose to form ammonia and magnesium hydroxide. While these compounds are not inherently toxic, their release into the environment can affect local ecosystems, particularly aquatic environments where ammonia can be harmful to fish and other organisms.

The potential for magnesium nitride to leach into soil and water systems during the product's lifecycle or after disposal is another environmental consideration. Although magnesium is an essential nutrient for plants, excessive amounts can alter soil chemistry and affect plant growth. Proper encapsulation and containment strategies are necessary to mitigate these risks.

On the positive side, the enhanced durability provided by magnesium nitride can contribute to the development of more sustainable products. By extending the lifespan of materials, it reduces the demand for raw materials and energy required for manufacturing replacement products. This aligns with circular economy principles and can lead to a net positive environmental impact over time.

Research into the long-term environmental effects of magnesium nitride is ongoing. Studies are focusing on its biodegradability, potential for bioaccumulation, and impacts on various ecosystems. As understanding grows, it is likely that more environmentally friendly production methods and application techniques will be developed to further mitigate any negative impacts.

In conclusion, while magnesium nitride offers significant benefits in enhancing material durability, its environmental impact is multifaceted. Balancing the advantages of increased product longevity against the potential risks associated with production and disposal is crucial. Continued research and development in this field will be essential to optimize the use of magnesium nitride while minimizing its environmental footprint.

Scalability and Cost-Effectiveness Analysis

The scalability and cost-effectiveness of magnesium nitride in enhancing material durability are critical factors for its widespread adoption in industrial applications. As the demand for more durable materials continues to grow across various sectors, the ability to scale up production and maintain cost competitiveness becomes paramount.

In terms of scalability, magnesium nitride production has shown promising potential for large-scale manufacturing. The synthesis process, typically involving the direct nitridation of magnesium metal or the reaction of magnesium oxide with ammonia, can be adapted to industrial-scale reactors. However, challenges remain in maintaining consistent quality and purity levels during scale-up. Advanced process control systems and optimized reactor designs are being developed to address these issues, potentially enabling production volumes that meet commercial demands.

The cost-effectiveness of magnesium nitride as a durability enhancer is multifaceted. While the raw materials for production, primarily magnesium and nitrogen sources, are relatively abundant and affordable, the energy-intensive nature of the synthesis process can contribute significantly to overall costs. Recent advancements in energy-efficient production methods, such as microwave-assisted synthesis and plasma-enhanced chemical vapor deposition, show promise in reducing energy consumption and, consequently, production costs.

When considering the total cost of ownership for materials enhanced with magnesium nitride, the extended lifespan and improved performance characteristics often justify the initial investment. Industries such as aerospace, automotive, and construction stand to benefit from reduced maintenance and replacement costs over time. However, the economic viability varies depending on the specific application and the extent of durability improvement achieved.

Market analysis indicates that as production scales up and becomes more efficient, the price point for magnesium nitride-enhanced materials is expected to decrease, making them more competitive with traditional alternatives. This trend is further supported by increasing environmental regulations and sustainability initiatives, which favor materials with longer lifespans and reduced environmental impact.

To fully realize the scalability and cost-effectiveness of magnesium nitride in material enhancement, ongoing research focuses on optimizing production processes, exploring novel synthesis routes, and developing innovative applications that maximize the value proposition of enhanced durability. Collaborative efforts between academic institutions and industry partners are driving progress in these areas, with the potential to unlock new markets and applications for magnesium nitride-enhanced materials.

In terms of scalability, magnesium nitride production has shown promising potential for large-scale manufacturing. The synthesis process, typically involving the direct nitridation of magnesium metal or the reaction of magnesium oxide with ammonia, can be adapted to industrial-scale reactors. However, challenges remain in maintaining consistent quality and purity levels during scale-up. Advanced process control systems and optimized reactor designs are being developed to address these issues, potentially enabling production volumes that meet commercial demands.

The cost-effectiveness of magnesium nitride as a durability enhancer is multifaceted. While the raw materials for production, primarily magnesium and nitrogen sources, are relatively abundant and affordable, the energy-intensive nature of the synthesis process can contribute significantly to overall costs. Recent advancements in energy-efficient production methods, such as microwave-assisted synthesis and plasma-enhanced chemical vapor deposition, show promise in reducing energy consumption and, consequently, production costs.

When considering the total cost of ownership for materials enhanced with magnesium nitride, the extended lifespan and improved performance characteristics often justify the initial investment. Industries such as aerospace, automotive, and construction stand to benefit from reduced maintenance and replacement costs over time. However, the economic viability varies depending on the specific application and the extent of durability improvement achieved.

Market analysis indicates that as production scales up and becomes more efficient, the price point for magnesium nitride-enhanced materials is expected to decrease, making them more competitive with traditional alternatives. This trend is further supported by increasing environmental regulations and sustainability initiatives, which favor materials with longer lifespans and reduced environmental impact.

To fully realize the scalability and cost-effectiveness of magnesium nitride in material enhancement, ongoing research focuses on optimizing production processes, exploring novel synthesis routes, and developing innovative applications that maximize the value proposition of enhanced durability. Collaborative efforts between academic institutions and industry partners are driving progress in these areas, with the potential to unlock new markets and applications for magnesium nitride-enhanced materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!