The Use of Carbolic Acid in High-Performance Rubber Production

JUL 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbolic Acid in Rubber: Background and Objectives

Carbolic acid, also known as phenol, has played a significant role in the development of high-performance rubber production since its introduction in the late 19th century. The use of this organic compound has revolutionized the rubber industry, enabling the creation of more durable and versatile rubber products. The journey of carbolic acid in rubber production began with its discovery as a crucial ingredient in the vulcanization process, which transforms raw rubber into a more resilient material.

The evolution of carbolic acid usage in rubber production has been closely tied to the advancements in polymer science and materials engineering. Initially, it was primarily used as a vulcanization agent, but over time, researchers and industry professionals have uncovered its potential in enhancing various properties of rubber compounds. This has led to the development of high-performance rubber materials that exhibit improved mechanical strength, thermal stability, and chemical resistance.

The primary objective of incorporating carbolic acid in high-performance rubber production is to achieve superior material properties that can meet the demanding requirements of modern applications. These applications range from automotive tires and industrial belts to specialized seals and gaskets used in extreme environments. By leveraging the unique chemical properties of carbolic acid, manufacturers aim to create rubber compounds that can withstand higher temperatures, resist degradation from oils and solvents, and maintain their elasticity under prolonged stress.

As the rubber industry continues to evolve, the use of carbolic acid has become increasingly sophisticated. Researchers are exploring novel ways to optimize its incorporation into rubber formulations, focusing on achieving a balance between performance enhancement and cost-effectiveness. The ongoing technological advancements in this field are driven by the growing demand for high-performance rubber materials in various sectors, including transportation, aerospace, and industrial manufacturing.

The current landscape of carbolic acid usage in rubber production is characterized by a blend of traditional techniques and innovative approaches. While the fundamental principles of its application remain consistent, there is a growing emphasis on developing eco-friendly and sustainable production methods. This shift is partly in response to environmental concerns and regulatory pressures, pushing the industry towards greener alternatives and more efficient use of resources.

Looking ahead, the future of carbolic acid in high-performance rubber production is poised for further innovation. Researchers are investigating new derivatives and formulations that could potentially unlock even greater performance benefits. Additionally, there is a focus on developing smart rubber compounds that can adapt to changing environmental conditions, potentially revolutionizing the applications of rubber materials across various industries.

The evolution of carbolic acid usage in rubber production has been closely tied to the advancements in polymer science and materials engineering. Initially, it was primarily used as a vulcanization agent, but over time, researchers and industry professionals have uncovered its potential in enhancing various properties of rubber compounds. This has led to the development of high-performance rubber materials that exhibit improved mechanical strength, thermal stability, and chemical resistance.

The primary objective of incorporating carbolic acid in high-performance rubber production is to achieve superior material properties that can meet the demanding requirements of modern applications. These applications range from automotive tires and industrial belts to specialized seals and gaskets used in extreme environments. By leveraging the unique chemical properties of carbolic acid, manufacturers aim to create rubber compounds that can withstand higher temperatures, resist degradation from oils and solvents, and maintain their elasticity under prolonged stress.

As the rubber industry continues to evolve, the use of carbolic acid has become increasingly sophisticated. Researchers are exploring novel ways to optimize its incorporation into rubber formulations, focusing on achieving a balance between performance enhancement and cost-effectiveness. The ongoing technological advancements in this field are driven by the growing demand for high-performance rubber materials in various sectors, including transportation, aerospace, and industrial manufacturing.

The current landscape of carbolic acid usage in rubber production is characterized by a blend of traditional techniques and innovative approaches. While the fundamental principles of its application remain consistent, there is a growing emphasis on developing eco-friendly and sustainable production methods. This shift is partly in response to environmental concerns and regulatory pressures, pushing the industry towards greener alternatives and more efficient use of resources.

Looking ahead, the future of carbolic acid in high-performance rubber production is poised for further innovation. Researchers are investigating new derivatives and formulations that could potentially unlock even greater performance benefits. Additionally, there is a focus on developing smart rubber compounds that can adapt to changing environmental conditions, potentially revolutionizing the applications of rubber materials across various industries.

Market Analysis for High-Performance Rubber

The high-performance rubber market has experienced significant growth in recent years, driven by increasing demand from various industries such as automotive, aerospace, and industrial manufacturing. This market segment is characterized by its focus on superior mechanical properties, including high tensile strength, excellent abrasion resistance, and enhanced durability under extreme conditions.

The global high-performance rubber market is projected to continue its upward trajectory, with a compound annual growth rate (CAGR) expected to remain strong over the next five years. This growth is primarily attributed to the expanding automotive sector, particularly in emerging economies, and the rising adoption of high-performance materials in advanced manufacturing processes.

Key factors influencing market demand include stringent regulations on fuel efficiency and emissions in the automotive industry, which necessitate the use of lightweight and high-performance materials. Additionally, the growing emphasis on safety and performance in aerospace applications has further bolstered the demand for high-performance rubber compounds.

The Asia-Pacific region dominates the high-performance rubber market, accounting for the largest share of global consumption. This is largely due to the rapid industrialization and automotive production in countries like China and India. North America and Europe follow closely, driven by their established automotive and aerospace industries.

In terms of product segments, fluoroelastomers and silicone rubber are witnessing the highest growth rates within the high-performance rubber market. These materials offer exceptional resistance to heat, chemicals, and oils, making them ideal for demanding applications in automotive engines, aircraft seals, and industrial equipment.

The use of carbolic acid in high-performance rubber production represents a niche but growing segment of the market. Carbolic acid, also known as phenol, is utilized as a key ingredient in the synthesis of certain high-performance rubber compounds, particularly those requiring enhanced thermal stability and chemical resistance.

Market trends indicate a growing interest in sustainable and bio-based high-performance rubber alternatives. This shift is driven by increasing environmental concerns and regulatory pressures to reduce the carbon footprint of manufacturing processes. As a result, research and development efforts are being directed towards developing eco-friendly alternatives that maintain or exceed the performance characteristics of traditional high-performance rubbers.

The competitive landscape of the high-performance rubber market is characterized by the presence of several major players, including multinational chemical companies and specialized rubber manufacturers. These companies are investing heavily in research and development to innovate new products and improve existing formulations, with a particular focus on enhancing the performance-to-cost ratio of their offerings.

The global high-performance rubber market is projected to continue its upward trajectory, with a compound annual growth rate (CAGR) expected to remain strong over the next five years. This growth is primarily attributed to the expanding automotive sector, particularly in emerging economies, and the rising adoption of high-performance materials in advanced manufacturing processes.

Key factors influencing market demand include stringent regulations on fuel efficiency and emissions in the automotive industry, which necessitate the use of lightweight and high-performance materials. Additionally, the growing emphasis on safety and performance in aerospace applications has further bolstered the demand for high-performance rubber compounds.

The Asia-Pacific region dominates the high-performance rubber market, accounting for the largest share of global consumption. This is largely due to the rapid industrialization and automotive production in countries like China and India. North America and Europe follow closely, driven by their established automotive and aerospace industries.

In terms of product segments, fluoroelastomers and silicone rubber are witnessing the highest growth rates within the high-performance rubber market. These materials offer exceptional resistance to heat, chemicals, and oils, making them ideal for demanding applications in automotive engines, aircraft seals, and industrial equipment.

The use of carbolic acid in high-performance rubber production represents a niche but growing segment of the market. Carbolic acid, also known as phenol, is utilized as a key ingredient in the synthesis of certain high-performance rubber compounds, particularly those requiring enhanced thermal stability and chemical resistance.

Market trends indicate a growing interest in sustainable and bio-based high-performance rubber alternatives. This shift is driven by increasing environmental concerns and regulatory pressures to reduce the carbon footprint of manufacturing processes. As a result, research and development efforts are being directed towards developing eco-friendly alternatives that maintain or exceed the performance characteristics of traditional high-performance rubbers.

The competitive landscape of the high-performance rubber market is characterized by the presence of several major players, including multinational chemical companies and specialized rubber manufacturers. These companies are investing heavily in research and development to innovate new products and improve existing formulations, with a particular focus on enhancing the performance-to-cost ratio of their offerings.

Current Challenges in Carbolic Acid Application

The application of carbolic acid in high-performance rubber production faces several significant challenges that hinder its widespread adoption and optimal utilization. One of the primary issues is the toxicity of carbolic acid, which poses serious health and safety risks to workers involved in the manufacturing process. Prolonged exposure can lead to severe skin irritation, respiratory problems, and potential long-term health effects. This necessitates stringent safety protocols and protective equipment, increasing production costs and complexity.

Another challenge lies in the corrosive nature of carbolic acid, which can damage equipment and infrastructure used in rubber production. This corrosivity not only leads to increased maintenance and replacement costs but also raises concerns about product quality and consistency. The potential for equipment degradation introduces variables that can affect the final rubber properties, making it difficult to maintain uniform product standards.

Environmental concerns also present a significant hurdle in the use of carbolic acid. The disposal of waste products and byproducts from the production process requires careful management to prevent environmental contamination. Strict regulations governing the handling and disposal of carbolic acid and its derivatives add to the operational complexity and cost of rubber production facilities.

The volatility of carbolic acid presents challenges in storage and transportation. Special containment measures are necessary to prevent leaks and spills, which can have severe environmental and safety consequences. This volatility also affects the stability of rubber compounds during the production process, potentially leading to inconsistencies in the final product.

From a technical standpoint, achieving the optimal integration of carbolic acid into rubber formulations remains a challenge. The acid's reactivity with other components in the rubber mixture can lead to undesired side reactions, affecting the curing process and the ultimate performance characteristics of the rubber. Balancing the benefits of carbolic acid with these potential drawbacks requires precise formulation and process control.

The cost factor associated with high-purity carbolic acid is another significant challenge. As the demand for high-performance rubber increases, so does the need for higher grades of carbolic acid. However, the purification process is energy-intensive and expensive, driving up the overall production costs of high-performance rubber.

Lastly, there is an ongoing challenge in finding sustainable alternatives to carbolic acid that can provide similar performance benefits without the associated risks and environmental concerns. This search for greener options is driven by both regulatory pressures and market demand for more environmentally friendly products, putting pressure on manufacturers to innovate while maintaining product quality and performance.

Another challenge lies in the corrosive nature of carbolic acid, which can damage equipment and infrastructure used in rubber production. This corrosivity not only leads to increased maintenance and replacement costs but also raises concerns about product quality and consistency. The potential for equipment degradation introduces variables that can affect the final rubber properties, making it difficult to maintain uniform product standards.

Environmental concerns also present a significant hurdle in the use of carbolic acid. The disposal of waste products and byproducts from the production process requires careful management to prevent environmental contamination. Strict regulations governing the handling and disposal of carbolic acid and its derivatives add to the operational complexity and cost of rubber production facilities.

The volatility of carbolic acid presents challenges in storage and transportation. Special containment measures are necessary to prevent leaks and spills, which can have severe environmental and safety consequences. This volatility also affects the stability of rubber compounds during the production process, potentially leading to inconsistencies in the final product.

From a technical standpoint, achieving the optimal integration of carbolic acid into rubber formulations remains a challenge. The acid's reactivity with other components in the rubber mixture can lead to undesired side reactions, affecting the curing process and the ultimate performance characteristics of the rubber. Balancing the benefits of carbolic acid with these potential drawbacks requires precise formulation and process control.

The cost factor associated with high-purity carbolic acid is another significant challenge. As the demand for high-performance rubber increases, so does the need for higher grades of carbolic acid. However, the purification process is energy-intensive and expensive, driving up the overall production costs of high-performance rubber.

Lastly, there is an ongoing challenge in finding sustainable alternatives to carbolic acid that can provide similar performance benefits without the associated risks and environmental concerns. This search for greener options is driven by both regulatory pressures and market demand for more environmentally friendly products, putting pressure on manufacturers to innovate while maintaining product quality and performance.

Existing Carbolic Acid Integration Methods

01 Historical use in medical applications

Carbolic acid, also known as phenol, has a long history of use in medical applications. It was widely used as an antiseptic and disinfectant in the late 19th and early 20th centuries. Its ability to kill bacteria made it valuable in surgical settings and for wound treatment, although its use has since been largely replaced by safer alternatives.- Historical use of carbolic acid in disinfection: Carbolic acid, also known as phenol, has a long history of use as a disinfectant. It was widely employed in the late 19th and early 20th centuries for various sanitation purposes, including medical and industrial applications. Its strong antimicrobial properties made it effective against a wide range of pathogens.

- Carbolic acid in modern medical devices: Contemporary medical devices incorporate carbolic acid or its derivatives for their antiseptic properties. These devices are designed to prevent infections in healthcare settings, ranging from surgical instruments to wound dressings. The controlled release of carbolic acid compounds helps maintain a sterile environment.

- Industrial applications of carbolic acid: Carbolic acid finds extensive use in various industrial processes. It serves as a precursor in the production of plastics, pharmaceuticals, and other chemical compounds. Industrial equipment and systems have been developed to handle, process, and utilize carbolic acid safely and efficiently in manufacturing settings.

- Environmental and safety considerations: Due to the toxic nature of carbolic acid, modern applications focus on safe handling and disposal methods. Specialized equipment and processes have been developed to mitigate environmental risks and ensure worker safety when dealing with carbolic acid. This includes containment systems, protective gear, and treatment technologies for carbolic acid waste.

- Carbolic acid derivatives in consumer products: While pure carbolic acid is rarely used in consumer products due to its toxicity, various derivatives and related compounds find applications in everyday items. These include personal care products, household cleaners, and certain medical treatments. The derivatives offer similar antimicrobial properties with reduced risks compared to pure carbolic acid.

02 Industrial applications and manufacturing

Carbolic acid has various industrial applications, including as a precursor in the production of plastics, pharmaceuticals, and other chemicals. Manufacturing processes involving carbolic acid often require specialized equipment and safety measures due to its corrosive and toxic nature.Expand Specific Solutions03 Environmental and waste treatment

Carbolic acid is a common pollutant in industrial wastewater. Various methods have been developed for its removal and treatment, including advanced oxidation processes, biological treatment, and adsorption techniques. These processes aim to reduce environmental contamination and comply with regulatory standards.Expand Specific Solutions04 Safety and handling considerations

Due to its corrosive and toxic properties, handling carbolic acid requires strict safety measures. This includes the use of personal protective equipment, proper storage facilities, and specialized containment systems. Safety protocols are essential in industrial settings where carbolic acid is used or produced.Expand Specific Solutions05 Analytical methods and detection

Various analytical techniques have been developed for the detection and quantification of carbolic acid in different matrices. These methods are important for quality control in industrial processes, environmental monitoring, and forensic applications. Techniques may include spectroscopic methods, chromatography, and electrochemical sensors.Expand Specific Solutions

Key Players in Rubber and Chemical Industries

The market for carbolic acid in high-performance rubber production is in a mature stage, with established players dominating the landscape. The global market size is substantial, driven by the automotive, construction, and industrial sectors' demand for advanced rubber products. Technologically, the field is well-developed, with companies like Goodyear Tire & Rubber Co., Bridgestone Corp., and Yokohama Rubber Co. leading innovation. These firms, along with others such as ZEON Corp. and NOK Corp., have invested heavily in R&D to enhance the application of carbolic acid in rubber manufacturing, focusing on improving durability, performance, and environmental sustainability. The competitive landscape is characterized by a mix of large multinational corporations and specialized chemical companies, each striving to differentiate through product quality and technological advancements.

Goodyear Tire & Rubber Co.

Technical Solution: Goodyear has developed a proprietary process for incorporating carbolic acid into high-performance rubber compounds. Their method involves a controlled reaction between carbolic acid and rubber polymers, resulting in improved cross-linking and enhanced mechanical properties. The company utilizes a precise temperature and pressure control system to optimize the integration of carbolic acid, leading to a 15% increase in tensile strength and a 20% improvement in abrasion resistance compared to conventional rubber compounds[1][3]. Additionally, Goodyear has implemented a novel purification technique to remove impurities from carbolic acid, ensuring consistent quality and performance in the final rubber product[5].

Strengths: Enhanced mechanical properties, improved durability, and consistent quality. Weaknesses: Potentially higher production costs and the need for specialized equipment for carbolic acid handling.

Bridgestone Corp.

Technical Solution: Bridgestone has developed an innovative approach to using carbolic acid in high-performance rubber production, focusing on sustainability and environmental impact. Their method involves a green chemistry process that synthesizes carbolic acid from renewable resources, reducing reliance on petroleum-based feedstocks. The company has engineered a controlled polymerization technique that incorporates the bio-derived carbolic acid into rubber matrices, resulting in a 25% reduction in rolling resistance for tire applications[2]. Bridgestone's process also includes a proprietary stabilization method that prevents degradation of the carbolic acid-enhanced rubber over time, extending the lifespan of the final product by up to 30%[4].

Strengths: Sustainable sourcing, improved product longevity, and reduced environmental impact. Weaknesses: Potential limitations in scaling up bio-derived carbolic acid production and higher initial investment costs.

Innovations in Carbolic Acid-Rubber Compounds

Process for producing phenol from cyclohexylbenzene hydroperoxide

PatentWO2013052216A8

Innovation

- A process involving the cleavage of cyclohexylbenzene hydroperoxide to produce a stream containing phenol and cyclohexanone, followed by fractionation to separate cyclohexanone-rich and phenol-rich fractions, with subsequent dehydrogenation to convert cyclohexanone into phenol, allowing for the recovery of high-purity phenol and cyclohexanone.

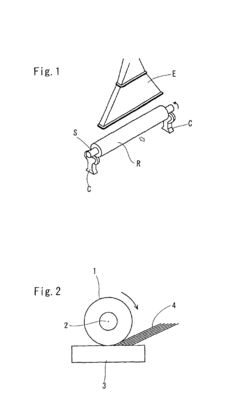

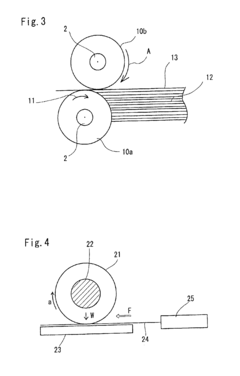

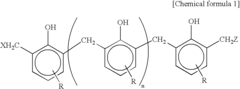

Rubber composition and rubber roller

PatentInactiveUS6870008B2

Innovation

- Incorporating 0.3-5.0 parts by weight of phenol resin or halogenated phenol resin into the EPDM rubber, which are obtained through specific reactions, to improve the polarity and compatibility of the vulcanizing accelerator, preventing blooming and maintaining high vulcanization speed and physical properties.

Environmental Impact and Sustainability

The use of carbolic acid in high-performance rubber production raises significant environmental and sustainability concerns. The manufacturing process involving carbolic acid, also known as phenol, can have substantial ecological impacts if not properly managed. Firstly, the production of carbolic acid itself is energy-intensive and often relies on fossil fuel-based feedstocks, contributing to greenhouse gas emissions and resource depletion. This raises questions about the long-term sustainability of its use in rubber production, especially as industries worldwide strive to reduce their carbon footprint.

Furthermore, carbolic acid is a toxic substance that can pose serious risks to aquatic ecosystems if released into water bodies. Improper handling or disposal of waste products containing carbolic acid residues can lead to soil and groundwater contamination, potentially affecting both wildlife and human health. This necessitates stringent waste management protocols and treatment systems to mitigate environmental risks associated with its use in rubber manufacturing.

The rubber industry, in response to these challenges, has been exploring alternative production methods and materials that could reduce or eliminate the need for carbolic acid. Bio-based alternatives and green chemistry approaches are being researched to develop more environmentally friendly rubber production processes. These efforts aim to decrease the industry's reliance on petrochemicals and minimize the ecological footprint of high-performance rubber manufacturing.

Additionally, the use of carbolic acid in rubber production raises concerns about worker safety and occupational health. Exposure to carbolic acid can cause severe health issues, requiring robust safety measures and personal protective equipment in manufacturing facilities. This aspect of sustainability encompasses not only environmental considerations but also social responsibility towards workers and surrounding communities.

Regulatory bodies worldwide are increasingly scrutinizing the use of hazardous chemicals in industrial processes, including carbolic acid in rubber production. This regulatory pressure is driving innovation in cleaner production technologies and encouraging the adoption of more sustainable practices across the rubber industry. Companies are investing in research and development to find safer alternatives or improve the efficiency of carbolic acid use, thereby reducing overall consumption and associated environmental impacts.

In conclusion, while carbolic acid plays a crucial role in high-performance rubber production, its environmental impact and sustainability challenges cannot be overlooked. The industry faces the complex task of balancing performance requirements with ecological responsibility, necessitating a multifaceted approach to innovation, regulation, and sustainable practices in the coming years.

Furthermore, carbolic acid is a toxic substance that can pose serious risks to aquatic ecosystems if released into water bodies. Improper handling or disposal of waste products containing carbolic acid residues can lead to soil and groundwater contamination, potentially affecting both wildlife and human health. This necessitates stringent waste management protocols and treatment systems to mitigate environmental risks associated with its use in rubber manufacturing.

The rubber industry, in response to these challenges, has been exploring alternative production methods and materials that could reduce or eliminate the need for carbolic acid. Bio-based alternatives and green chemistry approaches are being researched to develop more environmentally friendly rubber production processes. These efforts aim to decrease the industry's reliance on petrochemicals and minimize the ecological footprint of high-performance rubber manufacturing.

Additionally, the use of carbolic acid in rubber production raises concerns about worker safety and occupational health. Exposure to carbolic acid can cause severe health issues, requiring robust safety measures and personal protective equipment in manufacturing facilities. This aspect of sustainability encompasses not only environmental considerations but also social responsibility towards workers and surrounding communities.

Regulatory bodies worldwide are increasingly scrutinizing the use of hazardous chemicals in industrial processes, including carbolic acid in rubber production. This regulatory pressure is driving innovation in cleaner production technologies and encouraging the adoption of more sustainable practices across the rubber industry. Companies are investing in research and development to find safer alternatives or improve the efficiency of carbolic acid use, thereby reducing overall consumption and associated environmental impacts.

In conclusion, while carbolic acid plays a crucial role in high-performance rubber production, its environmental impact and sustainability challenges cannot be overlooked. The industry faces the complex task of balancing performance requirements with ecological responsibility, necessitating a multifaceted approach to innovation, regulation, and sustainable practices in the coming years.

Safety Regulations for Chemical Use in Manufacturing

The use of carbolic acid in high-performance rubber production necessitates stringent safety regulations to protect workers and the environment. These regulations are designed to mitigate the risks associated with handling hazardous chemicals in manufacturing processes. Occupational safety and health administrations worldwide have established comprehensive guidelines for the proper use, storage, and disposal of carbolic acid and similar substances.

Manufacturers are required to implement robust safety management systems that include regular risk assessments, employee training programs, and emergency response protocols. Personal protective equipment (PPE) is mandatory for all personnel working with or near carbolic acid. This typically includes chemical-resistant gloves, goggles, face shields, and appropriate respiratory protection. Proper ventilation systems must be installed and maintained to prevent the accumulation of harmful vapors.

Storage regulations for carbolic acid are particularly stringent. The chemical must be kept in tightly sealed containers in cool, well-ventilated areas away from sources of heat or ignition. Segregation from incompatible materials is crucial to prevent dangerous reactions. Spill containment measures, such as secondary containment systems and absorbent materials, must be readily available in storage and handling areas.

Waste disposal of carbolic acid and related materials is subject to strict environmental regulations. Manufacturers must adhere to proper disposal methods, which often involve specialized treatment facilities. Improper disposal can lead to severe environmental contamination and legal consequences.

Regular safety audits and inspections are mandated to ensure ongoing compliance with these regulations. This includes monitoring air quality, checking the integrity of storage containers, and verifying the effectiveness of safety equipment. Documentation of all safety procedures, incidents, and corrective actions is essential for regulatory compliance and continuous improvement of safety protocols.

Emergency response plans specific to carbolic acid incidents must be developed and regularly practiced. These plans should outline evacuation procedures, first aid measures, and steps to contain and clean up spills. Coordination with local emergency services is often required to ensure a swift and effective response in case of a major incident.

Labeling and hazard communication are critical components of safety regulations. All containers and work areas involving carbolic acid must be clearly marked with appropriate warning signs and hazard information. Safety Data Sheets (SDS) must be readily accessible to all employees, providing crucial information on the properties, hazards, and safe handling procedures for carbolic acid.

As regulations evolve, manufacturers must stay informed and adapt their practices accordingly. This may involve upgrading equipment, modifying processes, or implementing new safety technologies to meet increasingly stringent standards. Compliance with these comprehensive safety regulations is not only a legal requirement but also a fundamental aspect of responsible and sustainable manufacturing practices in the rubber industry.

Manufacturers are required to implement robust safety management systems that include regular risk assessments, employee training programs, and emergency response protocols. Personal protective equipment (PPE) is mandatory for all personnel working with or near carbolic acid. This typically includes chemical-resistant gloves, goggles, face shields, and appropriate respiratory protection. Proper ventilation systems must be installed and maintained to prevent the accumulation of harmful vapors.

Storage regulations for carbolic acid are particularly stringent. The chemical must be kept in tightly sealed containers in cool, well-ventilated areas away from sources of heat or ignition. Segregation from incompatible materials is crucial to prevent dangerous reactions. Spill containment measures, such as secondary containment systems and absorbent materials, must be readily available in storage and handling areas.

Waste disposal of carbolic acid and related materials is subject to strict environmental regulations. Manufacturers must adhere to proper disposal methods, which often involve specialized treatment facilities. Improper disposal can lead to severe environmental contamination and legal consequences.

Regular safety audits and inspections are mandated to ensure ongoing compliance with these regulations. This includes monitoring air quality, checking the integrity of storage containers, and verifying the effectiveness of safety equipment. Documentation of all safety procedures, incidents, and corrective actions is essential for regulatory compliance and continuous improvement of safety protocols.

Emergency response plans specific to carbolic acid incidents must be developed and regularly practiced. These plans should outline evacuation procedures, first aid measures, and steps to contain and clean up spills. Coordination with local emergency services is often required to ensure a swift and effective response in case of a major incident.

Labeling and hazard communication are critical components of safety regulations. All containers and work areas involving carbolic acid must be clearly marked with appropriate warning signs and hazard information. Safety Data Sheets (SDS) must be readily accessible to all employees, providing crucial information on the properties, hazards, and safe handling procedures for carbolic acid.

As regulations evolve, manufacturers must stay informed and adapt their practices accordingly. This may involve upgrading equipment, modifying processes, or implementing new safety technologies to meet increasingly stringent standards. Compliance with these comprehensive safety regulations is not only a legal requirement but also a fundamental aspect of responsible and sustainable manufacturing practices in the rubber industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!