Trends and Projections for the QLED Industry

JUN 20, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

QLED Technology Evolution

QLED technology has undergone significant evolution since its inception, marking several key milestones in display technology. The journey began with the development of quantum dots (QDs) in the 1980s, primarily focused on their unique optical properties. However, it wasn't until the early 2000s that researchers started exploring their potential in display applications.

The first major breakthrough came in 2013 when the first QLED TV was introduced to the market. This initial iteration utilized quantum dots in a photo-emissive layer, enhancing color performance but still relying on LCD backlighting. The technology quickly gained traction due to its superior color gamut and brightness compared to traditional LED-LCD displays.

From 2015 to 2018, QLED technology saw rapid advancements in quantum dot efficiency and stability. Manufacturers focused on improving the quantum yield of dots and developing more robust encapsulation methods to prevent degradation. This period also saw the introduction of cadmium-free quantum dots, addressing environmental concerns and regulatory requirements.

The next significant leap occurred around 2019 with the development of quantum dot color conversion (QDCC) technology. This approach used quantum dots to convert blue light from LEDs into pure red and green, resulting in even more precise color control and energy efficiency. QDCC marked a transition towards true quantum dot-based light emission, rather than mere enhancement of existing LCD technology.

2020 to 2022 witnessed the emergence of hybrid quantum dot-OLED displays, combining the strengths of both technologies. This innovation aimed to leverage the perfect blacks of OLED with the vibrant colors and brightness of quantum dots, pushing the boundaries of display performance.

Most recently, from 2022 onwards, research has intensified on electroluminescent quantum dot (EL-QLED) technology. This represents the holy grail of QLED development – displays where quantum dots themselves emit light when electrically excited, eliminating the need for separate backlighting or OLED elements. While still in the research phase, EL-QLED promises unparalleled efficiency, color accuracy, and potentially lower production costs.

Looking ahead, the QLED technology roadmap is focused on several key areas. These include further improvements in quantum dot efficiency and stability, development of blue light-emitting quantum dots for full-color EL-QLED displays, and exploration of novel quantum dot materials and structures. Additionally, researchers are investigating quantum dot integration with flexible and transparent substrates, paving the way for next-generation display form factors.

The first major breakthrough came in 2013 when the first QLED TV was introduced to the market. This initial iteration utilized quantum dots in a photo-emissive layer, enhancing color performance but still relying on LCD backlighting. The technology quickly gained traction due to its superior color gamut and brightness compared to traditional LED-LCD displays.

From 2015 to 2018, QLED technology saw rapid advancements in quantum dot efficiency and stability. Manufacturers focused on improving the quantum yield of dots and developing more robust encapsulation methods to prevent degradation. This period also saw the introduction of cadmium-free quantum dots, addressing environmental concerns and regulatory requirements.

The next significant leap occurred around 2019 with the development of quantum dot color conversion (QDCC) technology. This approach used quantum dots to convert blue light from LEDs into pure red and green, resulting in even more precise color control and energy efficiency. QDCC marked a transition towards true quantum dot-based light emission, rather than mere enhancement of existing LCD technology.

2020 to 2022 witnessed the emergence of hybrid quantum dot-OLED displays, combining the strengths of both technologies. This innovation aimed to leverage the perfect blacks of OLED with the vibrant colors and brightness of quantum dots, pushing the boundaries of display performance.

Most recently, from 2022 onwards, research has intensified on electroluminescent quantum dot (EL-QLED) technology. This represents the holy grail of QLED development – displays where quantum dots themselves emit light when electrically excited, eliminating the need for separate backlighting or OLED elements. While still in the research phase, EL-QLED promises unparalleled efficiency, color accuracy, and potentially lower production costs.

Looking ahead, the QLED technology roadmap is focused on several key areas. These include further improvements in quantum dot efficiency and stability, development of blue light-emitting quantum dots for full-color EL-QLED displays, and exploration of novel quantum dot materials and structures. Additionally, researchers are investigating quantum dot integration with flexible and transparent substrates, paving the way for next-generation display form factors.

QLED Market Dynamics

The QLED (Quantum Dot Light Emitting Diode) industry has experienced significant growth and transformation in recent years, driven by advancements in display technology and increasing consumer demand for high-quality visual experiences. The market dynamics of QLED technology are characterized by rapid innovation, fierce competition, and evolving consumer preferences.

QLED displays have gained substantial market share in the premium television segment, challenging OLED technology with their superior brightness, color accuracy, and longevity. This growth is primarily fueled by the technology's ability to deliver vibrant colors, deep blacks, and high contrast ratios, making it particularly appealing for HDR content consumption.

The global QLED market has shown robust expansion, with major players like Samsung, TCL, and Hisense leading the charge. Samsung, in particular, has been instrumental in popularizing QLED technology, investing heavily in research and development to improve performance and reduce production costs. This has led to increased adoption across various price points, expanding the technology's reach beyond the high-end market.

Consumer electronics retailers have reported strong sales of QLED TVs, indicating growing consumer acceptance and preference for this display technology. The trend is particularly pronounced in regions with high disposable income and a strong appetite for cutting-edge home entertainment systems, such as North America, Western Europe, and parts of Asia.

The QLED market is not limited to televisions alone. The technology has found applications in monitors, smartphones, and other display devices, further diversifying its market potential. Gaming monitors, in particular, have seen a surge in QLED adoption due to the technology's ability to deliver high refresh rates and low input lag, crucial factors for competitive gaming.

Market analysts predict continued growth for the QLED industry, with projections indicating a compound annual growth rate (CAGR) in the double digits over the next five years. This growth is expected to be driven by technological improvements, expanding applications, and decreasing production costs, which will make QLED displays more accessible to a broader consumer base.

However, the QLED market faces challenges from competing technologies, particularly OLED and emerging microLED displays. OLED technology, known for its perfect blacks and wide viewing angles, remains a strong competitor in the premium segment. The industry's response has been to focus on enhancing QLED's strengths, such as brightness and color volume, while addressing its weaknesses through innovations like mini-LED backlighting.

The future of the QLED market will likely be shaped by advancements in quantum dot technology, improvements in manufacturing processes, and the industry's ability to address environmental concerns related to the use of cadmium in some quantum dot formulations. As the technology continues to evolve, we can expect to see QLED displays with even better color accuracy, energy efficiency, and form factors, potentially opening up new markets and applications.

QLED displays have gained substantial market share in the premium television segment, challenging OLED technology with their superior brightness, color accuracy, and longevity. This growth is primarily fueled by the technology's ability to deliver vibrant colors, deep blacks, and high contrast ratios, making it particularly appealing for HDR content consumption.

The global QLED market has shown robust expansion, with major players like Samsung, TCL, and Hisense leading the charge. Samsung, in particular, has been instrumental in popularizing QLED technology, investing heavily in research and development to improve performance and reduce production costs. This has led to increased adoption across various price points, expanding the technology's reach beyond the high-end market.

Consumer electronics retailers have reported strong sales of QLED TVs, indicating growing consumer acceptance and preference for this display technology. The trend is particularly pronounced in regions with high disposable income and a strong appetite for cutting-edge home entertainment systems, such as North America, Western Europe, and parts of Asia.

The QLED market is not limited to televisions alone. The technology has found applications in monitors, smartphones, and other display devices, further diversifying its market potential. Gaming monitors, in particular, have seen a surge in QLED adoption due to the technology's ability to deliver high refresh rates and low input lag, crucial factors for competitive gaming.

Market analysts predict continued growth for the QLED industry, with projections indicating a compound annual growth rate (CAGR) in the double digits over the next five years. This growth is expected to be driven by technological improvements, expanding applications, and decreasing production costs, which will make QLED displays more accessible to a broader consumer base.

However, the QLED market faces challenges from competing technologies, particularly OLED and emerging microLED displays. OLED technology, known for its perfect blacks and wide viewing angles, remains a strong competitor in the premium segment. The industry's response has been to focus on enhancing QLED's strengths, such as brightness and color volume, while addressing its weaknesses through innovations like mini-LED backlighting.

The future of the QLED market will likely be shaped by advancements in quantum dot technology, improvements in manufacturing processes, and the industry's ability to address environmental concerns related to the use of cadmium in some quantum dot formulations. As the technology continues to evolve, we can expect to see QLED displays with even better color accuracy, energy efficiency, and form factors, potentially opening up new markets and applications.

QLED Technical Challenges

QLED technology, while promising, faces several significant technical challenges that need to be addressed for its widespread adoption and continued advancement in the display industry. One of the primary hurdles is the stability and longevity of quantum dots, particularly blue quantum dots. These nanoparticles tend to degrade faster than their red and green counterparts, leading to color shift and reduced display lifespan. Researchers are actively working on developing more stable blue quantum dots and exploring alternative materials to enhance their durability.

Another critical challenge lies in the manufacturing process of QLED displays. The precise deposition of quantum dots onto the substrate requires highly controlled environments and advanced techniques. Achieving uniform distribution and preventing aggregation of quantum dots across large display areas remains a complex task. This challenge becomes even more pronounced as manufacturers aim to scale up production for larger screen sizes and higher resolutions.

Color purity and color gamut expansion present ongoing challenges for QLED technology. While QLEDs offer superior color performance compared to many existing display technologies, there is still room for improvement in achieving even wider color gamuts and more accurate color reproduction. This involves fine-tuning the emission spectra of quantum dots and optimizing the overall display architecture to minimize light leakage and color crosstalk.

Energy efficiency is another area where QLED technology faces challenges. Although QLEDs are generally more energy-efficient than traditional LCD displays, there is a continuous push to reduce power consumption further, especially for mobile devices and large-format displays. This involves improving the quantum yield of quantum dots, enhancing light extraction efficiency, and optimizing the backlight and color filter designs.

The environmental impact and potential toxicity of quantum dot materials pose both technical and regulatory challenges. Many quantum dots contain heavy metals like cadmium, which raises concerns about their long-term environmental effects and disposal. Developing cadmium-free quantum dots with comparable performance characteristics is an active area of research, as is the exploration of more environmentally friendly synthesis methods and materials.

Lastly, cost-effective production remains a significant hurdle for widespread QLED adoption. The synthesis of high-quality quantum dots and the integration of these materials into display manufacturing processes can be expensive. Reducing production costs while maintaining or improving display quality is crucial for QLED technology to compete effectively with other display technologies in various market segments.

Another critical challenge lies in the manufacturing process of QLED displays. The precise deposition of quantum dots onto the substrate requires highly controlled environments and advanced techniques. Achieving uniform distribution and preventing aggregation of quantum dots across large display areas remains a complex task. This challenge becomes even more pronounced as manufacturers aim to scale up production for larger screen sizes and higher resolutions.

Color purity and color gamut expansion present ongoing challenges for QLED technology. While QLEDs offer superior color performance compared to many existing display technologies, there is still room for improvement in achieving even wider color gamuts and more accurate color reproduction. This involves fine-tuning the emission spectra of quantum dots and optimizing the overall display architecture to minimize light leakage and color crosstalk.

Energy efficiency is another area where QLED technology faces challenges. Although QLEDs are generally more energy-efficient than traditional LCD displays, there is a continuous push to reduce power consumption further, especially for mobile devices and large-format displays. This involves improving the quantum yield of quantum dots, enhancing light extraction efficiency, and optimizing the backlight and color filter designs.

The environmental impact and potential toxicity of quantum dot materials pose both technical and regulatory challenges. Many quantum dots contain heavy metals like cadmium, which raises concerns about their long-term environmental effects and disposal. Developing cadmium-free quantum dots with comparable performance characteristics is an active area of research, as is the exploration of more environmentally friendly synthesis methods and materials.

Lastly, cost-effective production remains a significant hurdle for widespread QLED adoption. The synthesis of high-quality quantum dots and the integration of these materials into display manufacturing processes can be expensive. Reducing production costs while maintaining or improving display quality is crucial for QLED technology to compete effectively with other display technologies in various market segments.

Current QLED Solutions

01 Quantum dot structure and composition

QLED technology utilizes quantum dots, which are semiconductor nanocrystals. The structure and composition of these quantum dots are crucial for the performance of QLEDs. Various materials and fabrication methods are employed to optimize the quantum dot properties, such as emission wavelength, efficiency, and stability.- Quantum dot structure and composition: QLED technology utilizes quantum dots, which are semiconductor nanocrystals. The structure and composition of these quantum dots are crucial for the performance of QLEDs. Various materials and fabrication methods are employed to optimize the quantum dot properties, such as emission wavelength, efficiency, and stability.

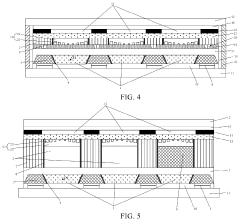

- QLED device architecture: The design and architecture of QLED devices play a significant role in their performance. This includes the arrangement of layers, such as the electron transport layer, hole transport layer, and emissive layer containing quantum dots. Innovations in device structure aim to improve efficiency, color purity, and longevity of QLED displays.

- Quantum dot synthesis and processing: The synthesis and processing of quantum dots are critical for QLED manufacturing. This includes methods for producing quantum dots with specific sizes and compositions, as well as techniques for incorporating them into device layers. Innovations in this area focus on improving quantum dot uniformity, stability, and integration into display manufacturing processes.

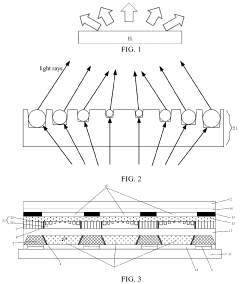

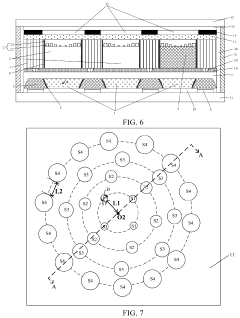

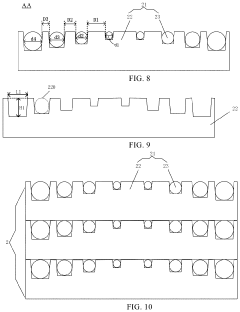

- Color conversion and light management: QLEDs utilize quantum dots for color conversion, allowing for improved color gamut and efficiency. Techniques for optimizing light management within the device, such as reducing light scattering and improving outcoupling, are essential for enhancing QLED performance. This includes the development of optical films and structures to maximize light extraction.

- QLED manufacturing and scaling: Scaling up QLED technology for mass production presents various challenges. Innovations in this area focus on developing manufacturing processes that are compatible with large-scale production, such as roll-to-roll printing or photolithography techniques. This includes methods for patterning quantum dot layers, improving yield, and reducing production costs.

02 QLED device architecture

The design and architecture of QLED devices play a significant role in their performance. This includes the arrangement of layers such as the electron transport layer, hole transport layer, and emissive layer. Innovations in device structure aim to improve efficiency, color purity, and longevity of QLED displays.Expand Specific Solutions03 Quantum dot synthesis and processing

The synthesis and processing of quantum dots are critical for QLED manufacturing. Various techniques are employed to produce quantum dots with desired properties, including size control, surface modification, and incorporation into host materials. These processes influence the optical and electrical characteristics of the resulting QLED devices.Expand Specific Solutions04 Color conversion and light management

QLEDs utilize quantum dots for color conversion and light management. This involves optimizing the interaction between blue LEDs and quantum dots to produce a wide color gamut. Techniques for enhancing light extraction and reducing energy loss are also explored to improve overall display efficiency.Expand Specific Solutions05 QLED manufacturing and integration

The manufacturing and integration of QLEDs into display panels present unique challenges. Innovations in this area focus on scalable production methods, patterning techniques, and integration with existing display technologies. Efforts are made to improve yield, reduce costs, and enhance the overall performance of QLED displays.Expand Specific Solutions

QLED Industry Leaders

The QLED industry is experiencing rapid growth and technological advancement, currently in a phase of expansion and innovation. The market size is projected to increase significantly, driven by rising demand for high-quality displays in various applications. Technological maturity varies among key players, with companies like BOE Technology Group, TCL China Star Optoelectronics, and Sharp Corp. leading in research and development. Universities such as Zhejiang University and The Hong Kong University of Science & Technology contribute to fundamental research, while companies like Huawei Technologies and Guangdong Juhua Printing Display Technology focus on practical applications. The competitive landscape is diverse, with both established electronics giants and specialized optoelectronics firms vying for market share and technological breakthroughs.

BOE Technology Group Co., Ltd.

Technical Solution: BOE has developed advanced QLED technology using quantum dot materials to enhance color gamut and brightness. Their approach involves depositing quantum dots directly onto LED chips, creating a more efficient and cost-effective manufacturing process. BOE's QLED displays feature improved color accuracy, wider viewing angles, and higher peak brightness compared to traditional LCD panels. The company has also invested in developing flexible QLED displays for curved and foldable devices, leveraging their expertise in flexible OLED technology.

Strengths: Advanced manufacturing capabilities, strong R&D in quantum dot materials, and integration with existing display technologies. Weaknesses: Potential challenges in scaling production and competition from OLED technology.

Shenzhen China Star Optoelectronics Semicon Display Tech Co.

Technical Solution: China Star Optoelectronics has developed a proprietary QLED technology that utilizes a unique quantum dot composition to achieve superior color performance. Their approach focuses on enhancing the stability and longevity of quantum dots, addressing one of the key challenges in QLED adoption. The company has also made significant progress in developing large-scale QLED panels for TV applications, with a focus on improving energy efficiency and reducing production costs. Their QLED displays offer HDR capabilities and a wide color gamut, making them particularly suitable for high-end consumer electronics.

Strengths: Innovative quantum dot composition, focus on stability and longevity, progress in large-scale panel production. Weaknesses: Potential limitations in small-scale display applications, competition from established OLED manufacturers.

QLED Core Innovations

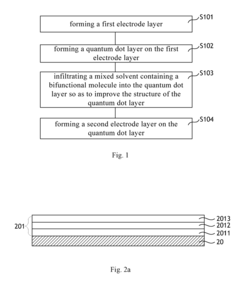

QLED device and manufacturing method thereof, QLED display panel and QLED display device

PatentActiveUS20180294414A1

Innovation

- A method involving the infiltration of a mixed solvent containing bifunctional molecules into the quantum dot layer to form bridges between loose quantum dots, improving the compactness and regularity of both the surface and internal structure, using a process that includes temperature adjustment, rotation, and annealing to enhance solubility and diffusion.

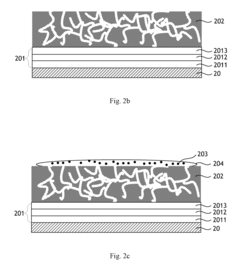

Display panel and producing method thereof, and display device

PatentPendingUS20240224736A1

Innovation

- A display panel design featuring light emitting units with scattering components, where scattering particles are arranged in a matrix with particle sizes and distances correlated to increase light output, and refractive indexes varying along the light exiting direction to converge light rays, combined with quantum-dot luminescent layers and color converting units for improved light emission.

QLED Supply Chain Analysis

The QLED supply chain is a complex network of manufacturers, suppliers, and distributors that work together to produce and deliver Quantum Dot Light Emitting Diode (QLED) displays to the market. This chain encompasses various stages, from raw material sourcing to final product assembly and distribution.

At the foundation of the QLED supply chain are the suppliers of quantum dots, the key component that gives QLED displays their superior color performance. Companies like Nanosys, Quantum Materials Corp, and Nanoco Group are major players in this segment, continuously innovating to improve quantum dot efficiency and stability.

The next crucial link in the chain involves panel manufacturers. These companies integrate quantum dots into display panels, a process that requires precision and advanced manufacturing capabilities. Key players in this segment include Samsung Display, BOE Technology, and AUO. These firms have invested heavily in QLED technology, driving advancements in panel production techniques.

Component suppliers form another vital part of the QLED ecosystem. These companies provide essential elements such as backlights, color filters, and driver ICs. Firms like LG Innotek, Corning, and Synaptics play significant roles in this segment, contributing to the overall performance and quality of QLED displays.

The assembly and integration stage of the supply chain involves ODMs (Original Design Manufacturers) and OEMs (Original Equipment Manufacturers). Companies like TCL, Hisense, and Vizio work closely with panel manufacturers to incorporate QLED panels into finished products, including televisions, monitors, and other display devices.

Distribution networks and retail channels complete the QLED supply chain. Major electronics retailers, e-commerce platforms, and brand-specific stores play crucial roles in bringing QLED products to consumers. The efficiency and reach of these distribution channels significantly impact market penetration and consumer adoption of QLED technology.

As the QLED industry continues to evolve, the supply chain is experiencing several trends and challenges. There's an increasing focus on vertical integration, with some major players like Samsung aiming to control multiple stages of the supply chain to ensure quality and reduce costs. Additionally, there's a growing emphasis on sustainable and eco-friendly practices throughout the supply chain, from raw material sourcing to product recycling.

The QLED supply chain is also facing challenges related to global semiconductor shortages and geopolitical tensions affecting international trade. These factors have led to increased efforts in supply chain diversification and localization of production in key markets.

At the foundation of the QLED supply chain are the suppliers of quantum dots, the key component that gives QLED displays their superior color performance. Companies like Nanosys, Quantum Materials Corp, and Nanoco Group are major players in this segment, continuously innovating to improve quantum dot efficiency and stability.

The next crucial link in the chain involves panel manufacturers. These companies integrate quantum dots into display panels, a process that requires precision and advanced manufacturing capabilities. Key players in this segment include Samsung Display, BOE Technology, and AUO. These firms have invested heavily in QLED technology, driving advancements in panel production techniques.

Component suppliers form another vital part of the QLED ecosystem. These companies provide essential elements such as backlights, color filters, and driver ICs. Firms like LG Innotek, Corning, and Synaptics play significant roles in this segment, contributing to the overall performance and quality of QLED displays.

The assembly and integration stage of the supply chain involves ODMs (Original Design Manufacturers) and OEMs (Original Equipment Manufacturers). Companies like TCL, Hisense, and Vizio work closely with panel manufacturers to incorporate QLED panels into finished products, including televisions, monitors, and other display devices.

Distribution networks and retail channels complete the QLED supply chain. Major electronics retailers, e-commerce platforms, and brand-specific stores play crucial roles in bringing QLED products to consumers. The efficiency and reach of these distribution channels significantly impact market penetration and consumer adoption of QLED technology.

As the QLED industry continues to evolve, the supply chain is experiencing several trends and challenges. There's an increasing focus on vertical integration, with some major players like Samsung aiming to control multiple stages of the supply chain to ensure quality and reduce costs. Additionally, there's a growing emphasis on sustainable and eco-friendly practices throughout the supply chain, from raw material sourcing to product recycling.

The QLED supply chain is also facing challenges related to global semiconductor shortages and geopolitical tensions affecting international trade. These factors have led to increased efforts in supply chain diversification and localization of production in key markets.

QLED Environmental Impact

The environmental impact of QLED (Quantum Dot Light Emitting Diode) technology is a crucial consideration as the industry continues to grow and evolve. One of the primary advantages of QLED displays is their energy efficiency compared to traditional LED and LCD technologies. This improved efficiency translates to reduced power consumption, which in turn leads to lower carbon emissions over the lifetime of the devices.

However, the production of quantum dots, the key component in QLED technology, raises some environmental concerns. The synthesis of quantum dots often involves the use of heavy metals such as cadmium, which can be toxic if released into the environment. As a result, manufacturers are increasingly focusing on developing cadmium-free quantum dots to mitigate these risks and comply with stricter environmental regulations.

The disposal and recycling of QLED displays present both challenges and opportunities. While the quantum dot layer itself is relatively thin and uses minimal materials, the overall structure of QLED displays still incorporates various components that require proper end-of-life management. The industry is actively working on developing more efficient recycling processes to recover valuable materials and reduce electronic waste.

In terms of manufacturing, QLED production processes are generally less energy-intensive compared to OLED technology, which requires high-vacuum deposition techniques. This lower energy requirement during production contributes to a reduced carbon footprint for QLED displays. Additionally, the longer lifespan of QLED displays compared to some other technologies means fewer replacements over time, potentially reducing overall electronic waste.

The QLED industry is also exploring ways to incorporate more sustainable materials into their products. This includes research into bio-based quantum dots and the use of recycled materials in display components. Such innovations could significantly reduce the environmental impact of QLED technology throughout its lifecycle.

As consumer awareness of environmental issues grows, the QLED industry is likely to face increasing pressure to demonstrate its commitment to sustainability. This may drive further innovations in eco-friendly materials, energy-efficient designs, and improved recycling technologies. The industry's ability to address these environmental concerns will play a crucial role in shaping its future growth and acceptance in the global market.

However, the production of quantum dots, the key component in QLED technology, raises some environmental concerns. The synthesis of quantum dots often involves the use of heavy metals such as cadmium, which can be toxic if released into the environment. As a result, manufacturers are increasingly focusing on developing cadmium-free quantum dots to mitigate these risks and comply with stricter environmental regulations.

The disposal and recycling of QLED displays present both challenges and opportunities. While the quantum dot layer itself is relatively thin and uses minimal materials, the overall structure of QLED displays still incorporates various components that require proper end-of-life management. The industry is actively working on developing more efficient recycling processes to recover valuable materials and reduce electronic waste.

In terms of manufacturing, QLED production processes are generally less energy-intensive compared to OLED technology, which requires high-vacuum deposition techniques. This lower energy requirement during production contributes to a reduced carbon footprint for QLED displays. Additionally, the longer lifespan of QLED displays compared to some other technologies means fewer replacements over time, potentially reducing overall electronic waste.

The QLED industry is also exploring ways to incorporate more sustainable materials into their products. This includes research into bio-based quantum dots and the use of recycled materials in display components. Such innovations could significantly reduce the environmental impact of QLED technology throughout its lifecycle.

As consumer awareness of environmental issues grows, the QLED industry is likely to face increasing pressure to demonstrate its commitment to sustainability. This may drive further innovations in eco-friendly materials, energy-efficient designs, and improved recycling technologies. The industry's ability to address these environmental concerns will play a crucial role in shaping its future growth and acceptance in the global market.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!