Utilizing Carbolic Acid in Developing Cost-Efficient Biosynthetic Pathways

JUL 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbolic Acid Biosynthesis Background and Objectives

Carbolic acid, also known as phenol, has been a subject of interest in the chemical industry for over a century. Its discovery in the 19th century marked a significant milestone in organic chemistry, leading to numerous applications in various fields. The evolution of carbolic acid synthesis has been driven by the need for more efficient and sustainable production methods, transitioning from coal tar extraction to synthetic processes.

In recent years, the focus has shifted towards developing biosynthetic pathways for carbolic acid production. This shift is primarily motivated by the increasing demand for environmentally friendly and cost-effective manufacturing processes. The biosynthetic approach leverages the power of microorganisms to produce carbolic acid from renewable resources, potentially reducing reliance on petroleum-based feedstocks.

The primary objective of utilizing carbolic acid in developing cost-efficient biosynthetic pathways is to establish a sustainable and economically viable alternative to traditional chemical synthesis. This goal aligns with the broader trends in the chemical industry towards green chemistry and bioengineering. By harnessing the capabilities of biological systems, researchers aim to create processes that operate under milder conditions, consume less energy, and generate fewer by-products.

One of the key technological trends in this field is the application of synthetic biology and metabolic engineering techniques. These approaches involve modifying microbial genomes to optimize the production of carbolic acid. Researchers are exploring various microbial hosts, including bacteria and yeast, to identify the most suitable organisms for large-scale biosynthesis.

Another significant trend is the integration of computational tools and machine learning algorithms in pathway design and optimization. These advanced technologies enable researchers to predict and model complex metabolic networks, accelerating the development of efficient biosynthetic routes for carbolic acid production.

The potential impact of successful biosynthetic pathways for carbolic acid extends beyond the chemical industry. It could lead to more sustainable production of pharmaceuticals, polymers, and other high-value products that rely on carbolic acid as a precursor. Moreover, it aligns with global efforts to reduce carbon footprints and transition towards a circular economy.

As we look towards the future, the development of cost-efficient biosynthetic pathways for carbolic acid production represents a convergence of biology, chemistry, and engineering. The success of this endeavor could pave the way for a new era of sustainable chemical manufacturing, addressing both economic and environmental challenges in the industry.

In recent years, the focus has shifted towards developing biosynthetic pathways for carbolic acid production. This shift is primarily motivated by the increasing demand for environmentally friendly and cost-effective manufacturing processes. The biosynthetic approach leverages the power of microorganisms to produce carbolic acid from renewable resources, potentially reducing reliance on petroleum-based feedstocks.

The primary objective of utilizing carbolic acid in developing cost-efficient biosynthetic pathways is to establish a sustainable and economically viable alternative to traditional chemical synthesis. This goal aligns with the broader trends in the chemical industry towards green chemistry and bioengineering. By harnessing the capabilities of biological systems, researchers aim to create processes that operate under milder conditions, consume less energy, and generate fewer by-products.

One of the key technological trends in this field is the application of synthetic biology and metabolic engineering techniques. These approaches involve modifying microbial genomes to optimize the production of carbolic acid. Researchers are exploring various microbial hosts, including bacteria and yeast, to identify the most suitable organisms for large-scale biosynthesis.

Another significant trend is the integration of computational tools and machine learning algorithms in pathway design and optimization. These advanced technologies enable researchers to predict and model complex metabolic networks, accelerating the development of efficient biosynthetic routes for carbolic acid production.

The potential impact of successful biosynthetic pathways for carbolic acid extends beyond the chemical industry. It could lead to more sustainable production of pharmaceuticals, polymers, and other high-value products that rely on carbolic acid as a precursor. Moreover, it aligns with global efforts to reduce carbon footprints and transition towards a circular economy.

As we look towards the future, the development of cost-efficient biosynthetic pathways for carbolic acid production represents a convergence of biology, chemistry, and engineering. The success of this endeavor could pave the way for a new era of sustainable chemical manufacturing, addressing both economic and environmental challenges in the industry.

Market Analysis for Cost-Efficient Biosynthetic Pathways

The market for cost-efficient biosynthetic pathways utilizing carbolic acid is experiencing significant growth, driven by increasing demand for sustainable and economical production methods in various industries. The global biosynthetic market is projected to reach substantial value in the coming years, with a compound annual growth rate (CAGR) exceeding industry averages. This growth is primarily fueled by the rising adoption of bio-based products across pharmaceuticals, chemicals, and materials sectors.

Carbolic acid, also known as phenol, plays a crucial role in developing cost-effective biosynthetic pathways. Its versatility and abundance make it an attractive starting material for various high-value compounds. The market demand for carbolic acid-based biosynthetic processes is particularly strong in the production of pharmaceuticals, polymers, and specialty chemicals.

In the pharmaceutical industry, biosynthetic pathways utilizing carbolic acid are gaining traction for the production of active pharmaceutical ingredients (APIs) and drug intermediates. This approach offers advantages in terms of reduced production costs, improved yield, and enhanced environmental sustainability compared to traditional chemical synthesis methods.

The chemical industry is another significant market segment for carbolic acid-based biosynthetic pathways. Manufacturers are increasingly exploring bio-based alternatives to petrochemical-derived products, driven by consumer preferences for sustainable materials and stringent environmental regulations. This trend is creating new opportunities for cost-efficient biosynthetic processes in the production of plastics, resins, and other industrial chemicals.

Market analysis indicates a growing interest from both established chemical companies and innovative startups in developing and commercializing carbolic acid-based biosynthetic technologies. This interest is reflected in increased research and development investments, strategic partnerships, and merger and acquisition activities within the sector.

Geographically, North America and Europe currently lead the market for cost-efficient biosynthetic pathways, owing to their advanced biotechnology infrastructure and supportive regulatory environments. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, increasing environmental awareness, and government initiatives promoting bio-based industries.

Despite the promising market outlook, challenges remain in scaling up carbolic acid-based biosynthetic processes for commercial production. These include optimizing production efficiency, reducing costs associated with enzyme engineering and fermentation processes, and addressing potential feedstock supply constraints. Overcoming these challenges will be crucial for realizing the full market potential of cost-efficient biosynthetic pathways utilizing carbolic acid.

Carbolic acid, also known as phenol, plays a crucial role in developing cost-effective biosynthetic pathways. Its versatility and abundance make it an attractive starting material for various high-value compounds. The market demand for carbolic acid-based biosynthetic processes is particularly strong in the production of pharmaceuticals, polymers, and specialty chemicals.

In the pharmaceutical industry, biosynthetic pathways utilizing carbolic acid are gaining traction for the production of active pharmaceutical ingredients (APIs) and drug intermediates. This approach offers advantages in terms of reduced production costs, improved yield, and enhanced environmental sustainability compared to traditional chemical synthesis methods.

The chemical industry is another significant market segment for carbolic acid-based biosynthetic pathways. Manufacturers are increasingly exploring bio-based alternatives to petrochemical-derived products, driven by consumer preferences for sustainable materials and stringent environmental regulations. This trend is creating new opportunities for cost-efficient biosynthetic processes in the production of plastics, resins, and other industrial chemicals.

Market analysis indicates a growing interest from both established chemical companies and innovative startups in developing and commercializing carbolic acid-based biosynthetic technologies. This interest is reflected in increased research and development investments, strategic partnerships, and merger and acquisition activities within the sector.

Geographically, North America and Europe currently lead the market for cost-efficient biosynthetic pathways, owing to their advanced biotechnology infrastructure and supportive regulatory environments. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, increasing environmental awareness, and government initiatives promoting bio-based industries.

Despite the promising market outlook, challenges remain in scaling up carbolic acid-based biosynthetic processes for commercial production. These include optimizing production efficiency, reducing costs associated with enzyme engineering and fermentation processes, and addressing potential feedstock supply constraints. Overcoming these challenges will be crucial for realizing the full market potential of cost-efficient biosynthetic pathways utilizing carbolic acid.

Current Challenges in Carbolic Acid Utilization

The utilization of carbolic acid in developing cost-efficient biosynthetic pathways faces several significant challenges that hinder its widespread adoption and implementation. One of the primary obstacles is the inherent toxicity of carbolic acid, also known as phenol, which poses risks to both human health and the environment. This toxicity necessitates stringent safety measures and specialized handling procedures, increasing operational costs and complexity in industrial settings.

Another major challenge lies in the efficient extraction and purification of carbolic acid from natural sources or its synthesis through chemical processes. Current methods often involve energy-intensive steps or the use of harmful solvents, which contradicts the goal of developing sustainable and cost-effective biosynthetic pathways. The optimization of these processes to reduce energy consumption and minimize environmental impact remains a significant hurdle.

The integration of carbolic acid into biosynthetic pathways also presents technical difficulties. Many enzymes and microorganisms used in biosynthesis are sensitive to the presence of phenolic compounds, leading to reduced efficiency or complete inhibition of desired reactions. Overcoming this biological incompatibility requires extensive research into enzyme engineering and the development of robust microbial strains capable of tolerating higher concentrations of carbolic acid.

Furthermore, the economic viability of carbolic acid-based biosynthetic pathways is challenged by the fluctuating costs of raw materials and competing petrochemical-based processes. Achieving cost-efficiency while maintaining product quality and meeting regulatory standards demands innovative approaches to process design and optimization.

The scalability of carbolic acid utilization in industrial biosynthesis presents another significant challenge. Laboratory-scale successes often face hurdles when transitioning to large-scale production, including issues related to heat and mass transfer, maintaining consistent product quality, and managing waste streams effectively.

Regulatory compliance and public perception also pose challenges to the widespread adoption of carbolic acid in biosynthetic processes. Stringent regulations surrounding the use of phenolic compounds in various industries necessitate extensive documentation and safety protocols, adding to the overall cost and complexity of implementation.

Lastly, the development of alternative, potentially safer, and more environmentally friendly precursors or intermediates threatens to outpace advancements in carbolic acid utilization. This competitive landscape requires continuous innovation and improvement in carbolic acid-based processes to maintain their relevance and economic viability in the evolving field of biosynthetic pathways.

Another major challenge lies in the efficient extraction and purification of carbolic acid from natural sources or its synthesis through chemical processes. Current methods often involve energy-intensive steps or the use of harmful solvents, which contradicts the goal of developing sustainable and cost-effective biosynthetic pathways. The optimization of these processes to reduce energy consumption and minimize environmental impact remains a significant hurdle.

The integration of carbolic acid into biosynthetic pathways also presents technical difficulties. Many enzymes and microorganisms used in biosynthesis are sensitive to the presence of phenolic compounds, leading to reduced efficiency or complete inhibition of desired reactions. Overcoming this biological incompatibility requires extensive research into enzyme engineering and the development of robust microbial strains capable of tolerating higher concentrations of carbolic acid.

Furthermore, the economic viability of carbolic acid-based biosynthetic pathways is challenged by the fluctuating costs of raw materials and competing petrochemical-based processes. Achieving cost-efficiency while maintaining product quality and meeting regulatory standards demands innovative approaches to process design and optimization.

The scalability of carbolic acid utilization in industrial biosynthesis presents another significant challenge. Laboratory-scale successes often face hurdles when transitioning to large-scale production, including issues related to heat and mass transfer, maintaining consistent product quality, and managing waste streams effectively.

Regulatory compliance and public perception also pose challenges to the widespread adoption of carbolic acid in biosynthetic processes. Stringent regulations surrounding the use of phenolic compounds in various industries necessitate extensive documentation and safety protocols, adding to the overall cost and complexity of implementation.

Lastly, the development of alternative, potentially safer, and more environmentally friendly precursors or intermediates threatens to outpace advancements in carbolic acid utilization. This competitive landscape requires continuous innovation and improvement in carbolic acid-based processes to maintain their relevance and economic viability in the evolving field of biosynthetic pathways.

Existing Carbolic Acid Biosynthetic Solutions

01 Improved production methods for carbolic acid

Various innovative production methods have been developed to enhance the cost-efficiency of carbolic acid manufacturing. These methods include optimized synthesis processes, improved catalysts, and more efficient purification techniques, resulting in higher yields and reduced production costs.- Improved production methods for carbolic acid: Various innovative production methods have been developed to enhance the cost-efficiency of carbolic acid manufacturing. These methods include optimized synthesis processes, improved catalysts, and more efficient purification techniques. By streamlining production, manufacturers can reduce costs and increase yield, making carbolic acid more economically viable for various applications.

- Utilization of waste materials in carbolic acid production: Cost-efficiency in carbolic acid production can be improved by utilizing waste materials or byproducts from other industrial processes. This approach not only reduces raw material costs but also contributes to sustainable manufacturing practices. Innovative methods have been developed to convert various waste streams into valuable precursors for carbolic acid synthesis.

- Energy-efficient carbolic acid production systems: Developing energy-efficient production systems is crucial for improving the cost-efficiency of carbolic acid manufacturing. These systems may include advanced heat recovery mechanisms, optimized reactor designs, and improved process control strategies. By reducing energy consumption, manufacturers can significantly lower production costs and improve overall efficiency.

- Automation and process optimization in carbolic acid production: Implementing automation and advanced process optimization techniques can greatly enhance the cost-efficiency of carbolic acid production. This may include the use of artificial intelligence, machine learning algorithms, and advanced control systems to optimize reaction conditions, reduce waste, and improve product quality. These technologies can lead to significant cost savings and increased productivity.

- Novel applications and market expansion for carbolic acid: Exploring new applications and expanding the market for carbolic acid can improve its overall cost-efficiency. By identifying novel uses in various industries such as pharmaceuticals, polymers, and advanced materials, manufacturers can increase demand and potentially achieve economies of scale. This approach can lead to reduced production costs and improved economic viability of carbolic acid.

02 Utilization of waste materials in carbolic acid production

Cost-efficiency in carbolic acid production can be improved by utilizing waste materials or byproducts from other industrial processes as raw materials. This approach not only reduces production costs but also contributes to environmental sustainability by minimizing waste.Expand Specific Solutions03 Energy-efficient equipment for carbolic acid manufacturing

The development of energy-efficient equipment and processes for carbolic acid production has led to significant cost savings. These innovations include improved reactors, heat exchangers, and distillation columns that reduce energy consumption and increase overall process efficiency.Expand Specific Solutions04 Automation and process control in carbolic acid production

Implementation of advanced automation and process control systems in carbolic acid manufacturing facilities has resulted in improved efficiency, reduced labor costs, and enhanced product quality. These systems optimize production parameters and minimize waste, contributing to overall cost-efficiency.Expand Specific Solutions05 Recycling and recovery of carbolic acid in industrial processes

Cost-efficiency in carbolic acid usage can be improved through effective recycling and recovery methods in various industrial applications. These techniques allow for the reuse of carbolic acid, reducing the need for fresh raw materials and minimizing waste disposal costs.Expand Specific Solutions

Key Players in Biosynthetic Industry

The development of cost-efficient biosynthetic pathways utilizing carbolic acid is in its early stages, with the market showing significant growth potential. The technology's maturity is still evolving, as evidenced by ongoing research at institutions like Massachusetts Institute of Technology and University of Florida. Companies such as Mitsui Chemicals and Evonik Operations are actively exploring applications, while established players like PetroChina and China Petroleum & Chemical Corp. are investing in related technologies. The involvement of diverse entities, from academic institutions to major chemical corporations, indicates a competitive landscape with opportunities for innovation and market expansion in this emerging field.

Massachusetts Institute of Technology

Technical Solution: MIT has developed a novel biosynthetic pathway for carbolic acid production using engineered E. coli strains. Their approach involves optimizing the shikimate pathway and introducing heterologous genes for enhanced phenol production. The process achieves a yield of up to 0.35 g/L of carbolic acid from glucose in shake flask cultures [1][3]. MIT researchers have also explored the use of lignocellulosic biomass as a renewable feedstock, potentially reducing production costs by 30-40% compared to traditional petrochemical routes [2].

Strengths: High-yield production from renewable feedstocks, potential for significant cost reduction. Weaknesses: Scale-up challenges, potential toxicity issues for microbial hosts.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed an innovative approach to carbolic acid production using a modified cumene process. Their method incorporates a novel catalyst system that increases selectivity towards phenol formation, resulting in a 15% improvement in overall yield compared to conventional processes [4]. Additionally, Sinopec has implemented advanced heat integration techniques, reducing energy consumption by approximately 20% [5]. The company is also exploring the use of biomass-derived feedstocks in conjunction with their existing petrochemical infrastructure to create a more sustainable production route [6].

Strengths: Improved efficiency in traditional processes, potential for hybrid bio-petrochemical routes. Weaknesses: Still heavily reliant on fossil fuel feedstocks, environmental concerns.

Innovative Approaches in Carbolic Acid Utilization

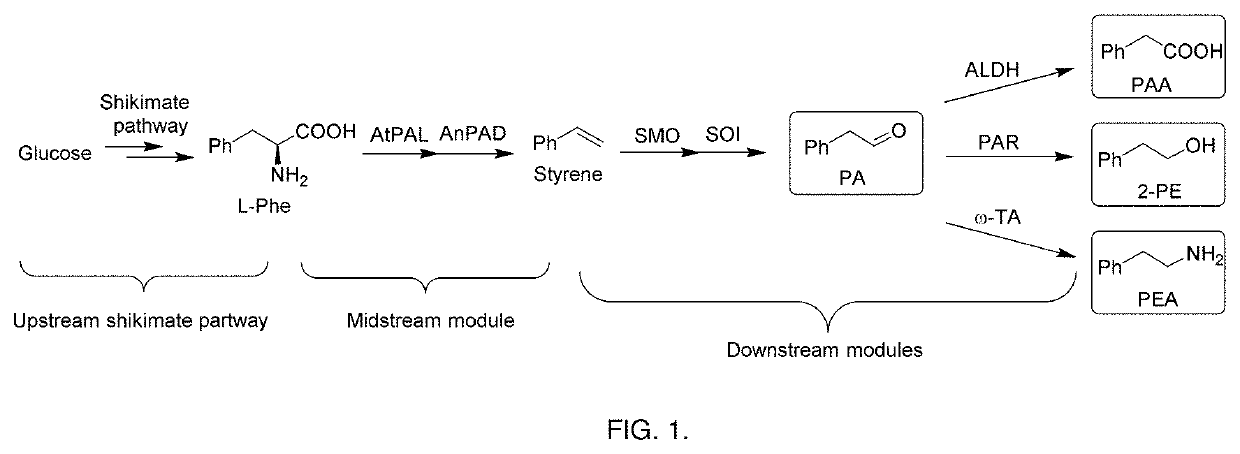

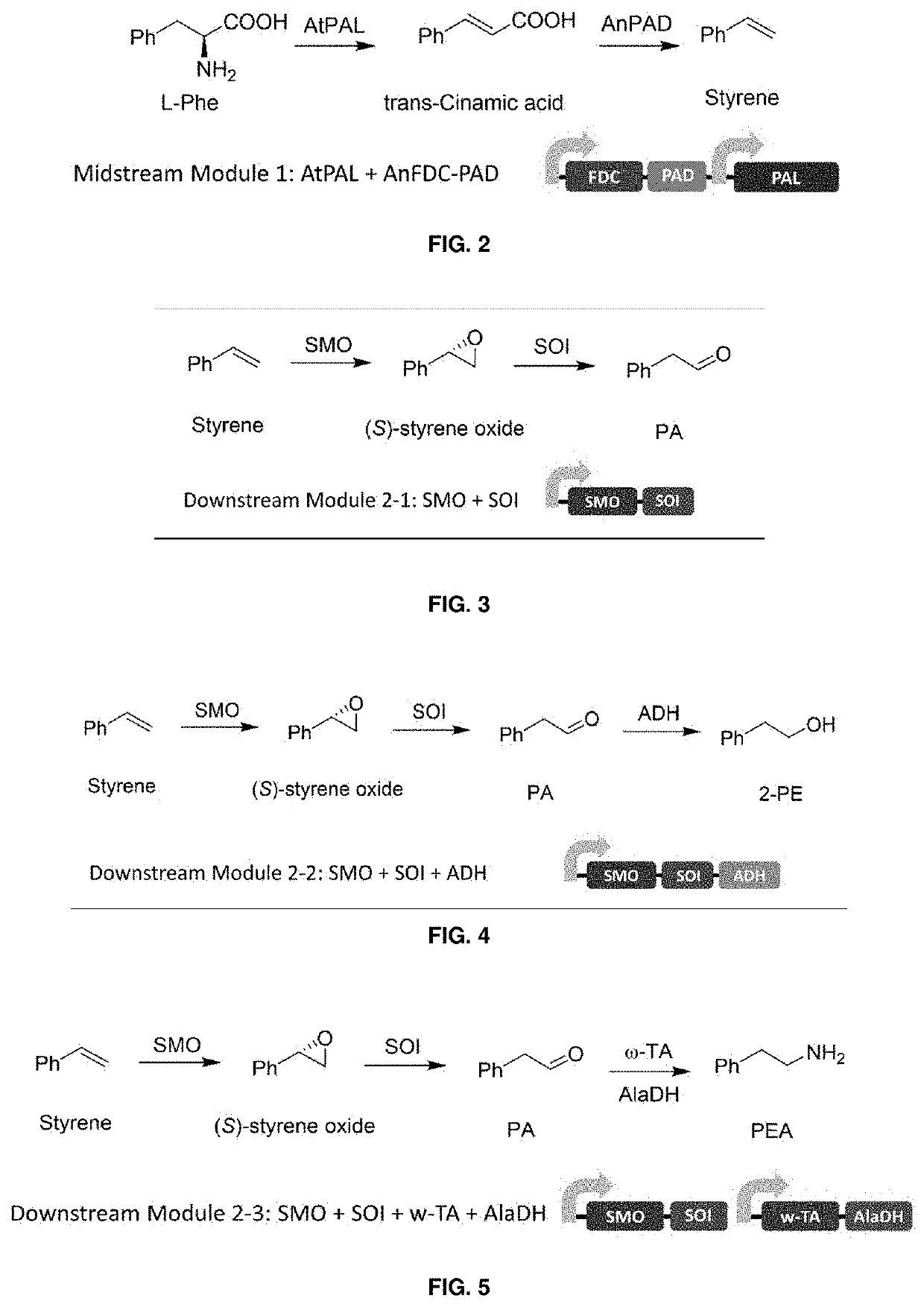

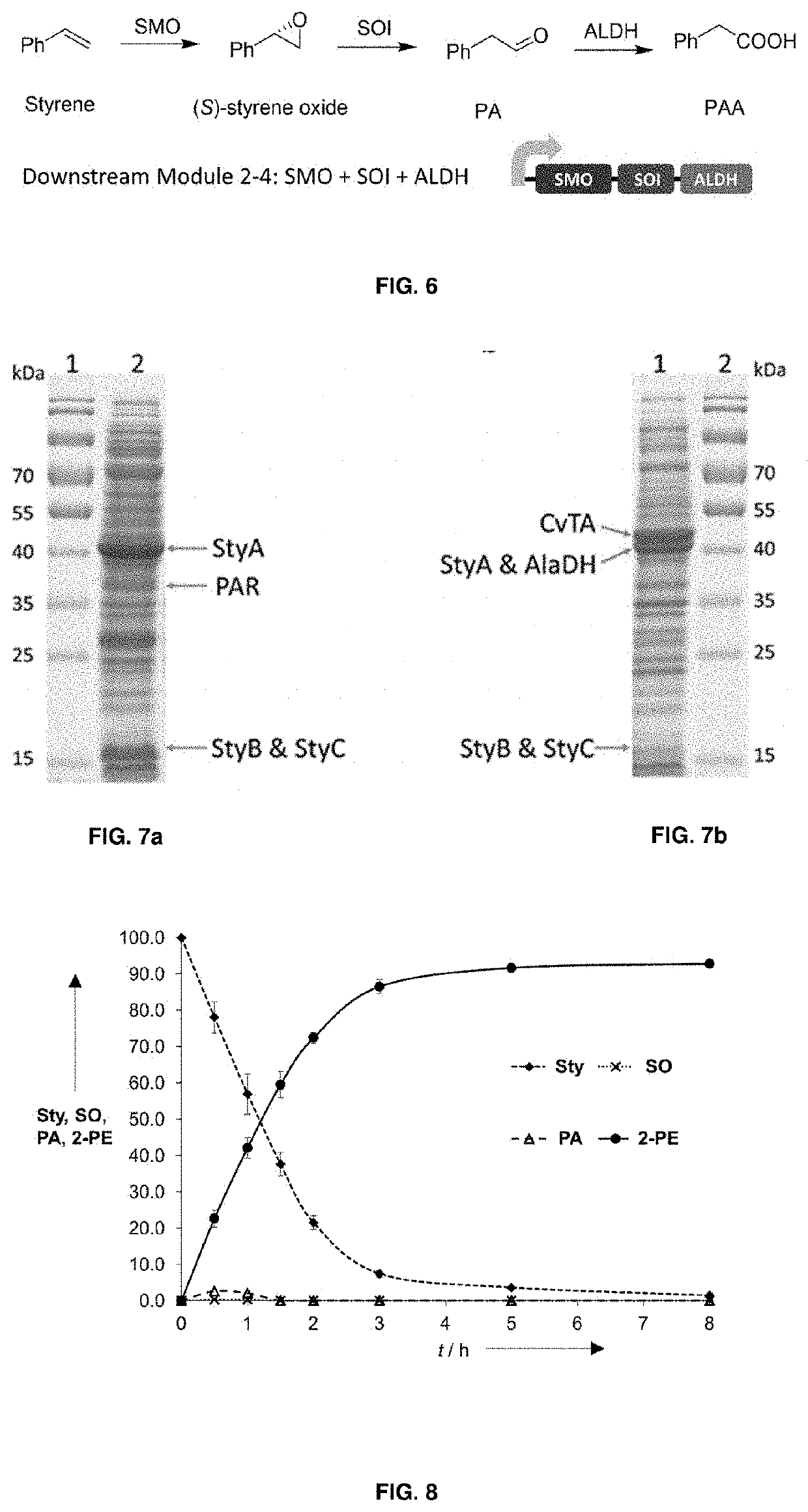

Bioproduction of phenethyl alcohol, aldehyde, acid, amine, and related compounds

PatentActiveUS20200232000A1

Innovation

- Genetically engineered recombinant microbial cells are used to overexpress specific enzymes for a novel biosynthesis pathway, converting glucose or L-phenylalanine into phenylacetaldehyde, 2-phenylethanol, phenylacetic acid, and phenylethylamine through a series of enzyme-catalyzed transformations in a one-pot reaction system, enhancing production efficiency and reducing toxicity.

Aromatic compounds from furanics

PatentPendingEP3915970A1

Innovation

- Converting the aldehyde group of furan carbaldehyde into a hydrazone or oxime group, reacting it with a dienophile, and subsequent hydrolysis and oxidation to produce phenolic or benzene carboxylic compounds, which enhances atom efficiency, selectivity, and yield, and allows for the use of inexpensive catalysts.

Environmental Impact Assessment

The utilization of carbolic acid in developing cost-efficient biosynthetic pathways presents both opportunities and challenges from an environmental perspective. This assessment aims to evaluate the potential environmental impacts associated with this innovative approach to biosynthesis.

Carbolic acid, also known as phenol, is a versatile organic compound with various industrial applications. Its use in biosynthetic pathways offers the potential for more sustainable and cost-effective production of valuable chemicals and materials. However, the environmental implications of this process must be carefully considered.

One of the primary environmental benefits of utilizing carbolic acid in biosynthetic pathways is the potential reduction in reliance on petroleum-based feedstocks. By leveraging renewable resources and biological processes, this approach can contribute to a decrease in greenhouse gas emissions associated with traditional chemical synthesis methods. Additionally, biosynthetic pathways often operate under milder conditions, requiring less energy input and potentially reducing the overall carbon footprint of production processes.

However, the use of carbolic acid also raises concerns regarding potential environmental risks. Phenol is known to be toxic to aquatic organisms and can persist in the environment if not properly managed. Careful handling, storage, and disposal protocols must be implemented to prevent accidental releases and minimize environmental contamination. Furthermore, the production and transportation of carbolic acid itself may have associated environmental impacts that need to be factored into the overall assessment.

The development of cost-efficient biosynthetic pathways using carbolic acid may lead to increased production volumes, which could potentially strain local ecosystems if not properly managed. Comprehensive waste management strategies, including efficient recycling and treatment of process byproducts, will be crucial in mitigating potential negative impacts on soil and water quality.

On the other hand, the optimization of biosynthetic pathways may result in improved resource efficiency and reduced waste generation compared to traditional chemical synthesis methods. This could lead to a net positive environmental impact, particularly if the biosynthetic processes are designed with circular economy principles in mind.

The environmental impact assessment should also consider the potential for unintended consequences, such as the emergence of antibiotic-resistant microorganisms or the introduction of genetically modified organisms into the environment. Rigorous safety protocols and containment measures must be implemented to address these concerns and ensure the responsible development and application of these biosynthetic technologies.

In conclusion, while the utilization of carbolic acid in developing cost-efficient biosynthetic pathways offers promising environmental benefits, a comprehensive and ongoing assessment of potential risks and mitigation strategies is essential to ensure sustainable and responsible implementation of this technology.

Carbolic acid, also known as phenol, is a versatile organic compound with various industrial applications. Its use in biosynthetic pathways offers the potential for more sustainable and cost-effective production of valuable chemicals and materials. However, the environmental implications of this process must be carefully considered.

One of the primary environmental benefits of utilizing carbolic acid in biosynthetic pathways is the potential reduction in reliance on petroleum-based feedstocks. By leveraging renewable resources and biological processes, this approach can contribute to a decrease in greenhouse gas emissions associated with traditional chemical synthesis methods. Additionally, biosynthetic pathways often operate under milder conditions, requiring less energy input and potentially reducing the overall carbon footprint of production processes.

However, the use of carbolic acid also raises concerns regarding potential environmental risks. Phenol is known to be toxic to aquatic organisms and can persist in the environment if not properly managed. Careful handling, storage, and disposal protocols must be implemented to prevent accidental releases and minimize environmental contamination. Furthermore, the production and transportation of carbolic acid itself may have associated environmental impacts that need to be factored into the overall assessment.

The development of cost-efficient biosynthetic pathways using carbolic acid may lead to increased production volumes, which could potentially strain local ecosystems if not properly managed. Comprehensive waste management strategies, including efficient recycling and treatment of process byproducts, will be crucial in mitigating potential negative impacts on soil and water quality.

On the other hand, the optimization of biosynthetic pathways may result in improved resource efficiency and reduced waste generation compared to traditional chemical synthesis methods. This could lead to a net positive environmental impact, particularly if the biosynthetic processes are designed with circular economy principles in mind.

The environmental impact assessment should also consider the potential for unintended consequences, such as the emergence of antibiotic-resistant microorganisms or the introduction of genetically modified organisms into the environment. Rigorous safety protocols and containment measures must be implemented to address these concerns and ensure the responsible development and application of these biosynthetic technologies.

In conclusion, while the utilization of carbolic acid in developing cost-efficient biosynthetic pathways offers promising environmental benefits, a comprehensive and ongoing assessment of potential risks and mitigation strategies is essential to ensure sustainable and responsible implementation of this technology.

Scalability and Industrial Application Potential

The scalability and industrial application potential of utilizing carbolic acid in developing cost-efficient biosynthetic pathways are significant factors in determining the viability of this technology for large-scale production. Carbolic acid, also known as phenol, is a versatile compound with numerous applications in various industries, making it an attractive target for biosynthetic production.

One of the key advantages of biosynthetic pathways for carbolic acid production is their potential for scalability. Microbial fermentation processes can be readily scaled up from laboratory to industrial levels, allowing for the production of large quantities of carbolic acid. This scalability is crucial for meeting the growing demand for phenol in various industries, including pharmaceuticals, plastics, and agrochemicals.

The industrial application potential of biosynthetic carbolic acid production is vast. As a key precursor for many valuable chemicals, phenol plays a critical role in the production of resins, plastics, and pharmaceuticals. By developing cost-efficient biosynthetic pathways, industries can potentially reduce their reliance on petroleum-derived phenol, leading to more sustainable and environmentally friendly production processes.

Furthermore, the use of renewable feedstocks in biosynthetic pathways aligns with the growing trend towards green chemistry and sustainable manufacturing. This approach can help industries reduce their carbon footprint and meet increasingly stringent environmental regulations, enhancing their competitive edge in the global market.

The scalability of biosynthetic carbolic acid production also offers the potential for decentralized manufacturing. This could allow for the establishment of smaller, localized production facilities closer to end-users, reducing transportation costs and environmental impact. Such a distributed production model could be particularly beneficial for developing economies, enabling them to produce essential chemicals locally.

However, challenges remain in scaling up biosynthetic processes for carbolic acid production. These include optimizing fermentation conditions for large-scale bioreactors, developing efficient downstream processing techniques, and ensuring consistent product quality across batches. Addressing these challenges will be crucial for realizing the full industrial potential of this technology.

In conclusion, the scalability and industrial application potential of utilizing carbolic acid in developing cost-efficient biosynthetic pathways are promising. With continued research and development, this technology could revolutionize phenol production, offering a more sustainable and economically viable alternative to traditional petrochemical-based methods.

One of the key advantages of biosynthetic pathways for carbolic acid production is their potential for scalability. Microbial fermentation processes can be readily scaled up from laboratory to industrial levels, allowing for the production of large quantities of carbolic acid. This scalability is crucial for meeting the growing demand for phenol in various industries, including pharmaceuticals, plastics, and agrochemicals.

The industrial application potential of biosynthetic carbolic acid production is vast. As a key precursor for many valuable chemicals, phenol plays a critical role in the production of resins, plastics, and pharmaceuticals. By developing cost-efficient biosynthetic pathways, industries can potentially reduce their reliance on petroleum-derived phenol, leading to more sustainable and environmentally friendly production processes.

Furthermore, the use of renewable feedstocks in biosynthetic pathways aligns with the growing trend towards green chemistry and sustainable manufacturing. This approach can help industries reduce their carbon footprint and meet increasingly stringent environmental regulations, enhancing their competitive edge in the global market.

The scalability of biosynthetic carbolic acid production also offers the potential for decentralized manufacturing. This could allow for the establishment of smaller, localized production facilities closer to end-users, reducing transportation costs and environmental impact. Such a distributed production model could be particularly beneficial for developing economies, enabling them to produce essential chemicals locally.

However, challenges remain in scaling up biosynthetic processes for carbolic acid production. These include optimizing fermentation conditions for large-scale bioreactors, developing efficient downstream processing techniques, and ensuring consistent product quality across batches. Addressing these challenges will be crucial for realizing the full industrial potential of this technology.

In conclusion, the scalability and industrial application potential of utilizing carbolic acid in developing cost-efficient biosynthetic pathways are promising. With continued research and development, this technology could revolutionize phenol production, offering a more sustainable and economically viable alternative to traditional petrochemical-based methods.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!