V12 Engine Contribution to Supercar Performance Metrics

AUG 5, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V12 Engine Evolution

The V12 engine has been a cornerstone of supercar performance since its inception, evolving significantly over the decades. Initially developed in the early 20th century, V12 engines gained prominence in high-performance vehicles due to their smooth power delivery and impressive output capabilities.

In the 1960s and 1970s, V12 engines became synonymous with luxury and performance, featuring in iconic supercars like the Lamborghini Miura and Ferrari 365 GTB/4 Daytona. These early V12s were typically naturally aspirated, with displacements ranging from 3.0 to 5.0 liters, producing around 300-350 horsepower.

The 1980s and 1990s saw a significant leap in V12 technology. Advancements in materials science and engine management systems allowed for higher revving engines with increased power outputs. The Ferrari F50, introduced in 1995, showcased a 4.7-liter V12 derived from Formula 1 technology, producing 513 horsepower and revving to 8,500 RPM.

The turn of the millennium brought further refinements to V12 engines. Manufacturers like Aston Martin, Ferrari, and Lamborghini continued to push the boundaries of naturally aspirated V12 performance. The Ferrari Enzo, launched in 2002, featured a 6.0-liter V12 producing 651 horsepower, setting new standards for supercar performance.

In recent years, the focus has shifted towards efficiency and emissions reduction without compromising performance. This has led to the integration of technologies such as direct fuel injection, variable valve timing, and in some cases, hybridization. The Ferrari LaFerrari, introduced in 2013, combined a 6.3-liter V12 with an electric motor, resulting in a total output of 949 horsepower.

The latest evolution of V12 engines has seen a push towards even higher power outputs and increased efficiency. Manufacturers are employing advanced materials like carbon fiber for engine components, sophisticated engine management systems, and aerodynamic integration to maximize performance. The Aston Martin Valkyrie, for instance, features a naturally aspirated 6.5-liter V12 developed with Cosworth, producing over 1,000 horsepower without turbocharging or hybridization.

As environmental regulations tighten, the future of V12 engines in supercars faces challenges. However, manufacturers are exploring innovative solutions, including advanced hybrid systems and synthetic fuels, to ensure the continued relevance of these iconic powerplants in the realm of high-performance vehicles.

In the 1960s and 1970s, V12 engines became synonymous with luxury and performance, featuring in iconic supercars like the Lamborghini Miura and Ferrari 365 GTB/4 Daytona. These early V12s were typically naturally aspirated, with displacements ranging from 3.0 to 5.0 liters, producing around 300-350 horsepower.

The 1980s and 1990s saw a significant leap in V12 technology. Advancements in materials science and engine management systems allowed for higher revving engines with increased power outputs. The Ferrari F50, introduced in 1995, showcased a 4.7-liter V12 derived from Formula 1 technology, producing 513 horsepower and revving to 8,500 RPM.

The turn of the millennium brought further refinements to V12 engines. Manufacturers like Aston Martin, Ferrari, and Lamborghini continued to push the boundaries of naturally aspirated V12 performance. The Ferrari Enzo, launched in 2002, featured a 6.0-liter V12 producing 651 horsepower, setting new standards for supercar performance.

In recent years, the focus has shifted towards efficiency and emissions reduction without compromising performance. This has led to the integration of technologies such as direct fuel injection, variable valve timing, and in some cases, hybridization. The Ferrari LaFerrari, introduced in 2013, combined a 6.3-liter V12 with an electric motor, resulting in a total output of 949 horsepower.

The latest evolution of V12 engines has seen a push towards even higher power outputs and increased efficiency. Manufacturers are employing advanced materials like carbon fiber for engine components, sophisticated engine management systems, and aerodynamic integration to maximize performance. The Aston Martin Valkyrie, for instance, features a naturally aspirated 6.5-liter V12 developed with Cosworth, producing over 1,000 horsepower without turbocharging or hybridization.

As environmental regulations tighten, the future of V12 engines in supercars faces challenges. However, manufacturers are exploring innovative solutions, including advanced hybrid systems and synthetic fuels, to ensure the continued relevance of these iconic powerplants in the realm of high-performance vehicles.

Supercar Market Trends

The supercar market has experienced significant growth and transformation in recent years, driven by technological advancements, changing consumer preferences, and evolving regulatory landscapes. The global supercar market size was valued at approximately $13.8 billion in 2020 and is projected to reach $20.5 billion by 2027, growing at a CAGR of 5.8% during the forecast period.

One of the key trends shaping the supercar market is the increasing demand for high-performance vehicles with advanced technologies. Consumers are seeking not only raw power and speed but also cutting-edge features such as advanced driver assistance systems, connectivity, and customization options. This has led to a surge in research and development investments by supercar manufacturers to incorporate innovative technologies into their vehicles.

The shift towards electrification has also begun to impact the supercar market. While traditional internal combustion engines, particularly V12 engines, continue to dominate the segment, there is a growing interest in hybrid and fully electric supercars. Several established manufacturers and new entrants are developing electric supercars that promise to deliver exceptional performance while addressing environmental concerns.

Geographical trends in the supercar market show a diversification of demand. While traditional markets such as North America and Europe remain strong, there is significant growth in emerging markets, particularly in Asia-Pacific. China, in particular, has become a crucial market for supercar manufacturers, with sales in the country growing at double-digit rates in recent years.

Customization and personalization have become increasingly important in the supercar market. Manufacturers are offering extensive customization options, allowing buyers to tailor their vehicles to their specific preferences. This trend has led to the development of bespoke programs and limited-edition models, which not only cater to individual tastes but also drive up average transaction prices.

The COVID-19 pandemic initially caused disruptions in the supercar market, with production halts and supply chain issues. However, the market has shown resilience, with demand rebounding strongly in late 2020 and 2021. This recovery has been attributed to increased disposable income among high-net-worth individuals and a renewed focus on luxury purchases as travel restrictions limited other spending options.

Looking ahead, the supercar market is expected to continue evolving, with a focus on balancing performance with sustainability. Manufacturers are investing in lightweight materials, aerodynamic designs, and advanced powertrain technologies to meet stringent emissions regulations while maintaining the high-performance characteristics that define the supercar segment. The role of V12 engines in this evolving landscape remains a topic of intense interest and debate within the industry.

One of the key trends shaping the supercar market is the increasing demand for high-performance vehicles with advanced technologies. Consumers are seeking not only raw power and speed but also cutting-edge features such as advanced driver assistance systems, connectivity, and customization options. This has led to a surge in research and development investments by supercar manufacturers to incorporate innovative technologies into their vehicles.

The shift towards electrification has also begun to impact the supercar market. While traditional internal combustion engines, particularly V12 engines, continue to dominate the segment, there is a growing interest in hybrid and fully electric supercars. Several established manufacturers and new entrants are developing electric supercars that promise to deliver exceptional performance while addressing environmental concerns.

Geographical trends in the supercar market show a diversification of demand. While traditional markets such as North America and Europe remain strong, there is significant growth in emerging markets, particularly in Asia-Pacific. China, in particular, has become a crucial market for supercar manufacturers, with sales in the country growing at double-digit rates in recent years.

Customization and personalization have become increasingly important in the supercar market. Manufacturers are offering extensive customization options, allowing buyers to tailor their vehicles to their specific preferences. This trend has led to the development of bespoke programs and limited-edition models, which not only cater to individual tastes but also drive up average transaction prices.

The COVID-19 pandemic initially caused disruptions in the supercar market, with production halts and supply chain issues. However, the market has shown resilience, with demand rebounding strongly in late 2020 and 2021. This recovery has been attributed to increased disposable income among high-net-worth individuals and a renewed focus on luxury purchases as travel restrictions limited other spending options.

Looking ahead, the supercar market is expected to continue evolving, with a focus on balancing performance with sustainability. Manufacturers are investing in lightweight materials, aerodynamic designs, and advanced powertrain technologies to meet stringent emissions regulations while maintaining the high-performance characteristics that define the supercar segment. The role of V12 engines in this evolving landscape remains a topic of intense interest and debate within the industry.

V12 Tech Challenges

The V12 engine, a hallmark of supercar performance, faces several significant technical challenges in the modern automotive landscape. One of the primary issues is the increasing pressure to meet stringent emissions regulations. As environmental concerns grow, manufacturers must find innovative ways to reduce the carbon footprint of these powerful engines without compromising their performance characteristics.

Another major challenge lies in the realm of fuel efficiency. V12 engines are notorious for their high fuel consumption, which is at odds with the global push for more economical vehicles. Engineers must develop advanced technologies to improve fuel economy while maintaining the power output that supercar enthusiasts expect.

Weight reduction presents a further hurdle for V12 engines. The sheer size and complexity of these powerplants contribute significantly to a vehicle's overall mass, which can negatively impact handling and acceleration. Designers are tasked with finding ways to lighten the engine without sacrificing durability or performance.

Heat management is a critical concern for V12 engines, particularly in high-performance applications. The intense heat generated by these engines can lead to reduced efficiency and potential reliability issues. Developing effective cooling systems that can cope with the extreme temperatures while minimizing weight and space requirements is a constant challenge.

The complexity of V12 engines also poses difficulties in terms of manufacturing and maintenance. With a higher number of components compared to smaller engines, production costs are elevated, and servicing becomes more intricate and time-consuming. This complexity can impact both the initial cost of the vehicle and long-term ownership expenses.

Packaging constraints present another significant challenge. Fitting a large V12 engine into a sleek supercar design while maintaining optimal weight distribution and aerodynamics requires ingenious engineering solutions. This often involves compromises in other areas of the vehicle's design.

Lastly, the advent of electric and hybrid powertrains has put pressure on V12 technology to justify its continued existence. As alternative propulsion systems become more powerful and efficient, V12 engines must evolve to offer unique advantages that cannot be replicated by electric motors or smaller, turbocharged engines.

Addressing these challenges requires a multifaceted approach, combining advanced materials science, cutting-edge thermal management techniques, and innovative engine design. The future of V12 engines in supercars will depend on the industry's ability to overcome these hurdles while preserving the character and performance that make these powerplants so iconic.

Another major challenge lies in the realm of fuel efficiency. V12 engines are notorious for their high fuel consumption, which is at odds with the global push for more economical vehicles. Engineers must develop advanced technologies to improve fuel economy while maintaining the power output that supercar enthusiasts expect.

Weight reduction presents a further hurdle for V12 engines. The sheer size and complexity of these powerplants contribute significantly to a vehicle's overall mass, which can negatively impact handling and acceleration. Designers are tasked with finding ways to lighten the engine without sacrificing durability or performance.

Heat management is a critical concern for V12 engines, particularly in high-performance applications. The intense heat generated by these engines can lead to reduced efficiency and potential reliability issues. Developing effective cooling systems that can cope with the extreme temperatures while minimizing weight and space requirements is a constant challenge.

The complexity of V12 engines also poses difficulties in terms of manufacturing and maintenance. With a higher number of components compared to smaller engines, production costs are elevated, and servicing becomes more intricate and time-consuming. This complexity can impact both the initial cost of the vehicle and long-term ownership expenses.

Packaging constraints present another significant challenge. Fitting a large V12 engine into a sleek supercar design while maintaining optimal weight distribution and aerodynamics requires ingenious engineering solutions. This often involves compromises in other areas of the vehicle's design.

Lastly, the advent of electric and hybrid powertrains has put pressure on V12 technology to justify its continued existence. As alternative propulsion systems become more powerful and efficient, V12 engines must evolve to offer unique advantages that cannot be replicated by electric motors or smaller, turbocharged engines.

Addressing these challenges requires a multifaceted approach, combining advanced materials science, cutting-edge thermal management techniques, and innovative engine design. The future of V12 engines in supercars will depend on the industry's ability to overcome these hurdles while preserving the character and performance that make these powerplants so iconic.

Current V12 Designs

01 Engine performance monitoring and analysis

Systems and methods for monitoring and analyzing V12 engine performance metrics, including real-time data collection, processing, and visualization of various engine parameters to optimize performance and identify potential issues.- Engine performance monitoring and analysis: Systems and methods for monitoring and analyzing V12 engine performance metrics, including real-time data collection, processing, and visualization of various engine parameters to optimize performance and identify potential issues.

- Predictive maintenance and diagnostics: Advanced diagnostic techniques and predictive maintenance algorithms specifically designed for V12 engines, utilizing machine learning and data analytics to forecast potential failures and schedule maintenance activities proactively.

- Fuel efficiency optimization: Innovative approaches to improve fuel efficiency in V12 engines, including advanced fuel injection systems, combustion optimization techniques, and adaptive engine control strategies to maximize performance while minimizing fuel consumption.

- Emissions control and environmental performance: Technologies and methods for reducing emissions and improving the environmental performance of V12 engines, including advanced catalytic converters, exhaust gas recirculation systems, and intelligent engine management to meet stringent emission standards.

- Performance benchmarking and testing: Comprehensive benchmarking and testing methodologies specifically tailored for V12 engines, including standardized performance metrics, dynamometer testing protocols, and comparative analysis techniques to evaluate and improve engine performance across various operating conditions.

02 Predictive maintenance for V12 engines

Techniques for predicting maintenance needs and potential failures in V12 engines based on performance metrics, historical data, and machine learning algorithms, enabling proactive maintenance scheduling and reducing downtime.Expand Specific Solutions03 Performance optimization and tuning

Methods for optimizing V12 engine performance through advanced tuning techniques, including adaptive algorithms that adjust engine parameters based on real-time performance metrics and environmental conditions.Expand Specific Solutions04 Comparative analysis of V12 engine metrics

Systems for comparing performance metrics across different V12 engine models or configurations, enabling benchmarking and identification of best practices for engine design and operation.Expand Specific Solutions05 Integration of V12 engine metrics with vehicle systems

Approaches for integrating V12 engine performance metrics with other vehicle systems, such as transmission, fuel management, and driver assistance systems, to enhance overall vehicle performance and efficiency.Expand Specific Solutions

Key V12 Manufacturers

The V12 engine's contribution to supercar performance metrics is characterized by a mature yet evolving competitive landscape. The market, while niche, remains significant due to the prestige and performance associated with V12 engines. Technologically, it's in a late maturity stage, with companies like GM Global Technology Operations, Toyota, Ford, and Honda continuously refining the design. Luxury brands such as Ferrari and Lamborghini, though not listed, are key players. The focus is shifting towards hybridization and electrification, with companies like Nissan and Toyota leading in this transition, potentially reshaping the future of high-performance engines in supercars.

GM Global Technology Operations LLC

Technical Solution: GM's approach to V12 engine contribution in supercar performance focuses on advanced materials and precision engineering. They utilize lightweight alloys and carbon fiber components to reduce engine weight while maintaining structural integrity. GM's V12 engines feature direct fuel injection and variable valve timing, optimizing fuel efficiency and power output. The company has developed a proprietary combustion chamber design that enhances fuel atomization and combustion efficiency, resulting in improved power-to-weight ratios[1]. GM's V12 engines also incorporate advanced thermal management systems, allowing for sustained high-performance operation while minimizing wear and tear[3].

Strengths: Lightweight design, advanced materials, and efficient combustion technology. Weaknesses: Higher production costs and complexity compared to smaller engines.

Toyota Motor Corp.

Technical Solution: Toyota's V12 engine technology for supercars emphasizes a balance between performance and reliability. Their approach involves a dual-overhead-camshaft design with four valves per cylinder, maximizing airflow and combustion efficiency. Toyota incorporates variable valve timing and lift (VVT-iE) technology, allowing for optimal performance across a wide range of engine speeds[2]. The company has also developed a high-pressure direct injection system that improves fuel atomization and combustion efficiency. Toyota's V12 engines feature a dry-sump lubrication system, ensuring consistent oil pressure during high-G cornering and acceleration[4]. Additionally, they utilize advanced engine management systems with adaptive learning capabilities to fine-tune performance in real-time.

Strengths: Excellent reliability, advanced valve control, and adaptive performance. Weaknesses: Slightly lower peak power output compared to some competitors.

V12 Performance Patents

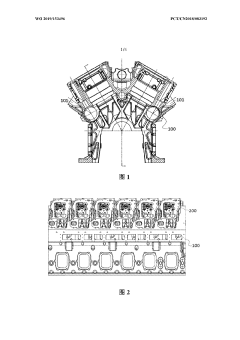

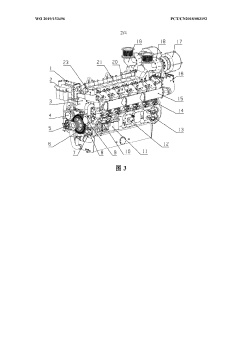

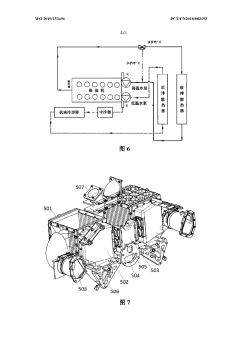

V-type 12-cylinder diesel engine

PatentWO2019153496A1

Innovation

- It adopts a V-shaped 12-cylinder diesel engine design, including a V-shaped cylinder block, 12 single cylinder heads, an electronically controlled single pump diesel supply system, an air intake system and a high and low temperature water separate cooling system to achieve double-sided oil supply, supercharged cooling and Classified cooling to improve the power and performance of diesel engines.

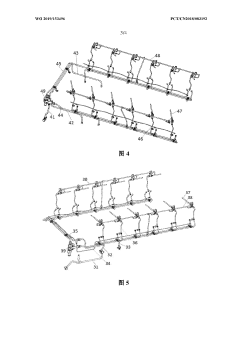

Casting technique of V12-type engine cylinder block

PatentInactiveCN103273007A

Innovation

- Using the improved lost foam casting and vibrating-side pouring dense strengthening casting method, through making foam molds, vibration modeling, vacuum casting and cooling cleaning, combined with small density ceramsite sand and special resin sand, using a vibration table for one-dimensional vibration Pouring ensures that the molding sand is enriched and gas is discharged, and improves the density and surface quality of the casting.

Emissions Regulations

Emissions regulations have become a critical factor in the development and production of V12 engines for supercars. As environmental concerns grow and governments worldwide implement stricter emissions standards, supercar manufacturers face significant challenges in maintaining the performance characteristics of their V12 powerplants while meeting these regulations.

The European Union's Euro 6d emissions standards, implemented in 2021, have set stringent limits on nitrogen oxides (NOx) and particulate matter emissions. These regulations have forced supercar manufacturers to adopt advanced technologies such as selective catalytic reduction (SCR) systems and gasoline particulate filters (GPF) to reduce harmful emissions from V12 engines.

In the United States, the Corporate Average Fuel Economy (CAFE) standards and the Environmental Protection Agency's (EPA) emissions regulations have also impacted V12 engine development. Manufacturers must balance the power output and performance metrics of their engines with the need to meet increasingly strict fuel efficiency and emissions targets.

To address these challenges, supercar manufacturers have implemented various strategies. One approach is the integration of hybrid powertrains, combining V12 engines with electric motors to improve overall efficiency and reduce emissions. This allows manufacturers to maintain the desirable characteristics of V12 engines while meeting regulatory requirements.

Another strategy involves the use of advanced engine management systems and variable valve timing technologies. These innovations enable more precise control over fuel injection and combustion processes, optimizing engine performance while minimizing emissions across a wide range of operating conditions.

Lightweight materials and improved aerodynamics have also played a role in meeting emissions regulations. By reducing the overall weight of supercars and enhancing their aerodynamic efficiency, manufacturers can maintain performance metrics while reducing fuel consumption and emissions.

Despite these advancements, the future of V12 engines in supercars remains uncertain. Some manufacturers have announced plans to phase out V12 engines in favor of smaller, turbocharged engines or fully electric powertrains. However, others remain committed to preserving the V12 engine's legacy, investing in research and development to ensure compliance with future emissions regulations while maintaining the unique character and performance that enthusiasts expect from these iconic powerplants.

The European Union's Euro 6d emissions standards, implemented in 2021, have set stringent limits on nitrogen oxides (NOx) and particulate matter emissions. These regulations have forced supercar manufacturers to adopt advanced technologies such as selective catalytic reduction (SCR) systems and gasoline particulate filters (GPF) to reduce harmful emissions from V12 engines.

In the United States, the Corporate Average Fuel Economy (CAFE) standards and the Environmental Protection Agency's (EPA) emissions regulations have also impacted V12 engine development. Manufacturers must balance the power output and performance metrics of their engines with the need to meet increasingly strict fuel efficiency and emissions targets.

To address these challenges, supercar manufacturers have implemented various strategies. One approach is the integration of hybrid powertrains, combining V12 engines with electric motors to improve overall efficiency and reduce emissions. This allows manufacturers to maintain the desirable characteristics of V12 engines while meeting regulatory requirements.

Another strategy involves the use of advanced engine management systems and variable valve timing technologies. These innovations enable more precise control over fuel injection and combustion processes, optimizing engine performance while minimizing emissions across a wide range of operating conditions.

Lightweight materials and improved aerodynamics have also played a role in meeting emissions regulations. By reducing the overall weight of supercars and enhancing their aerodynamic efficiency, manufacturers can maintain performance metrics while reducing fuel consumption and emissions.

Despite these advancements, the future of V12 engines in supercars remains uncertain. Some manufacturers have announced plans to phase out V12 engines in favor of smaller, turbocharged engines or fully electric powertrains. However, others remain committed to preserving the V12 engine's legacy, investing in research and development to ensure compliance with future emissions regulations while maintaining the unique character and performance that enthusiasts expect from these iconic powerplants.

Lightweight Materials

Lightweight materials play a crucial role in enhancing the performance metrics of supercars equipped with V12 engines. The use of advanced materials such as carbon fiber, aluminum alloys, and titanium has revolutionized the automotive industry, particularly in the high-performance sector. These materials offer significant weight reduction while maintaining or even improving structural integrity, directly impacting the power-to-weight ratio of supercars.

Carbon fiber reinforced polymers (CFRP) have become increasingly prevalent in supercar construction. Their exceptional strength-to-weight ratio allows for substantial weight savings in body panels, chassis components, and aerodynamic elements. The reduced mass enables V12-powered supercars to achieve higher acceleration rates, improved handling characteristics, and enhanced fuel efficiency without compromising on power output.

Aluminum alloys, particularly those developed for aerospace applications, have found their way into supercar engine components and structural elements. These alloys offer excellent strength and stiffness while being significantly lighter than traditional steel counterparts. The use of aluminum in engine blocks, cylinder heads, and suspension components contributes to overall weight reduction, allowing V12 engines to deliver optimal performance with reduced inertial losses.

Titanium, known for its high strength-to-weight ratio and corrosion resistance, is utilized in critical components such as exhaust systems, connecting rods, and valve springs. The implementation of titanium parts in V12 engines helps reduce reciprocating mass, enabling higher engine speeds and improved throttle response. This translates to enhanced acceleration and top speed capabilities in supercars.

The integration of lightweight materials extends beyond the engine bay, influencing the entire vehicle design. Magnesium alloys, for instance, are employed in gearbox casings and wheels, further reducing unsprung weight and improving handling dynamics. Advanced composites are also used in driveshafts and suspension components, contributing to reduced rotational mass and enhanced performance characteristics.

The synergy between lightweight materials and V12 engines in supercars results in a virtuous cycle of performance improvements. The weight savings allow for more aggressive power outputs without compromising vehicle dynamics, while the reduced mass enables better utilization of the V12's power across various performance metrics. This combination ultimately leads to superior acceleration, higher top speeds, improved cornering abilities, and enhanced overall driving experience that defines the modern supercar.

Carbon fiber reinforced polymers (CFRP) have become increasingly prevalent in supercar construction. Their exceptional strength-to-weight ratio allows for substantial weight savings in body panels, chassis components, and aerodynamic elements. The reduced mass enables V12-powered supercars to achieve higher acceleration rates, improved handling characteristics, and enhanced fuel efficiency without compromising on power output.

Aluminum alloys, particularly those developed for aerospace applications, have found their way into supercar engine components and structural elements. These alloys offer excellent strength and stiffness while being significantly lighter than traditional steel counterparts. The use of aluminum in engine blocks, cylinder heads, and suspension components contributes to overall weight reduction, allowing V12 engines to deliver optimal performance with reduced inertial losses.

Titanium, known for its high strength-to-weight ratio and corrosion resistance, is utilized in critical components such as exhaust systems, connecting rods, and valve springs. The implementation of titanium parts in V12 engines helps reduce reciprocating mass, enabling higher engine speeds and improved throttle response. This translates to enhanced acceleration and top speed capabilities in supercars.

The integration of lightweight materials extends beyond the engine bay, influencing the entire vehicle design. Magnesium alloys, for instance, are employed in gearbox casings and wheels, further reducing unsprung weight and improving handling dynamics. Advanced composites are also used in driveshafts and suspension components, contributing to reduced rotational mass and enhanced performance characteristics.

The synergy between lightweight materials and V12 engines in supercars results in a virtuous cycle of performance improvements. The weight savings allow for more aggressive power outputs without compromising vehicle dynamics, while the reduced mass enables better utilization of the V12's power across various performance metrics. This combination ultimately leads to superior acceleration, higher top speeds, improved cornering abilities, and enhanced overall driving experience that defines the modern supercar.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!