V12 Engine's Influence on Modern Supercar Dynamics

AUG 5, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V12 Engine Evolution

The V12 engine has undergone significant evolution since its inception, playing a crucial role in shaping the dynamics of modern supercars. Initially developed in the early 20th century, the V12 configuration gained prominence in high-performance automobiles due to its inherent balance and smooth power delivery.

In the 1960s and 1970s, V12 engines became synonymous with luxury and performance, finding their way into iconic vehicles like the Ferrari 365 GTB/4 Daytona and the Lamborghini Miura. These engines typically displaced 3 to 5 liters and produced around 300-350 horsepower, setting new standards for power and refinement in road-going vehicles.

The 1980s and 1990s saw a shift towards increased efficiency and power density. Manufacturers like BMW and Mercedes-Benz introduced advanced V12 designs featuring four-valve-per-cylinder heads, variable valve timing, and sophisticated engine management systems. These innovations allowed V12 engines to produce more power while meeting increasingly stringent emissions regulations.

The turn of the millennium marked a new era for V12 engines in supercars. Aston Martin's 5.9-liter V12, introduced in the DB7 Vantage, showcased the potential for large-displacement naturally aspirated engines. Meanwhile, Ferrari's F140 engine family, debuting in the Enzo, demonstrated the benefits of a high-revving V12 design, capable of producing over 600 horsepower without forced induction.

In recent years, the focus has shifted towards hybridization and electrification. The LaFerrari's V12 hybrid powertrain, producing a combined 950 horsepower, exemplifies this trend. Similarly, Lamborghini's Sián FKP 37 integrates a V12 engine with a 48V electric motor, showcasing how traditional V12 architecture can be adapted to meet future performance and efficiency demands.

Throughout its evolution, the V12 engine has consistently influenced supercar dynamics. Its inherent smoothness and linear power delivery have allowed for precise throttle control and predictable handling characteristics. The engine's low-end torque and high-revving nature provide a wide powerband, enabling supercars to deliver explosive acceleration across a broad range of speeds.

The weight distribution afforded by the V12's layout has also played a crucial role in supercar dynamics. Typically mounted in a front-mid or mid-engine configuration, V12 engines contribute to balanced weight distribution, enhancing cornering stability and overall handling prowess.

As we look to the future, the V12 engine continues to evolve. While facing challenges from stricter emissions regulations and the rise of electric powertrains, manufacturers are exploring innovative solutions to preserve the V12's unique character and performance attributes in the modern supercar landscape.

In the 1960s and 1970s, V12 engines became synonymous with luxury and performance, finding their way into iconic vehicles like the Ferrari 365 GTB/4 Daytona and the Lamborghini Miura. These engines typically displaced 3 to 5 liters and produced around 300-350 horsepower, setting new standards for power and refinement in road-going vehicles.

The 1980s and 1990s saw a shift towards increased efficiency and power density. Manufacturers like BMW and Mercedes-Benz introduced advanced V12 designs featuring four-valve-per-cylinder heads, variable valve timing, and sophisticated engine management systems. These innovations allowed V12 engines to produce more power while meeting increasingly stringent emissions regulations.

The turn of the millennium marked a new era for V12 engines in supercars. Aston Martin's 5.9-liter V12, introduced in the DB7 Vantage, showcased the potential for large-displacement naturally aspirated engines. Meanwhile, Ferrari's F140 engine family, debuting in the Enzo, demonstrated the benefits of a high-revving V12 design, capable of producing over 600 horsepower without forced induction.

In recent years, the focus has shifted towards hybridization and electrification. The LaFerrari's V12 hybrid powertrain, producing a combined 950 horsepower, exemplifies this trend. Similarly, Lamborghini's Sián FKP 37 integrates a V12 engine with a 48V electric motor, showcasing how traditional V12 architecture can be adapted to meet future performance and efficiency demands.

Throughout its evolution, the V12 engine has consistently influenced supercar dynamics. Its inherent smoothness and linear power delivery have allowed for precise throttle control and predictable handling characteristics. The engine's low-end torque and high-revving nature provide a wide powerband, enabling supercars to deliver explosive acceleration across a broad range of speeds.

The weight distribution afforded by the V12's layout has also played a crucial role in supercar dynamics. Typically mounted in a front-mid or mid-engine configuration, V12 engines contribute to balanced weight distribution, enhancing cornering stability and overall handling prowess.

As we look to the future, the V12 engine continues to evolve. While facing challenges from stricter emissions regulations and the rise of electric powertrains, manufacturers are exploring innovative solutions to preserve the V12's unique character and performance attributes in the modern supercar landscape.

Supercar Market Analysis

The supercar market has experienced significant growth and transformation in recent years, driven by technological advancements, changing consumer preferences, and global economic factors. The demand for high-performance vehicles continues to rise, particularly in emerging markets such as China and the Middle East, where a growing affluent class seeks luxury and exclusivity.

Market analysis indicates that the global supercar market was valued at approximately $13.8 billion in 2020 and is projected to reach $22.2 billion by 2026, growing at a CAGR of 8.3% during the forecast period. This growth is attributed to factors such as increasing disposable income, technological innovations, and a growing passion for high-performance vehicles among enthusiasts.

The V12 engine, a hallmark of modern supercars, plays a crucial role in shaping market dynamics. Despite the industry's shift towards electrification and downsizing, V12-powered supercars continue to command a premium position in the market. These vehicles appeal to a niche segment of buyers who prioritize performance, prestige, and the unique driving experience offered by large-displacement engines.

Key players in the V12 supercar market include established brands like Ferrari, Lamborghini, and Aston Martin, as well as boutique manufacturers such as Pagani and Koenigsegg. These companies have successfully positioned their V12-powered models as flagship offerings, commanding higher profit margins and fostering brand loyalty among enthusiasts.

However, the supercar market faces challenges, including stringent emissions regulations and the global push towards sustainability. This has led to a gradual shift in market dynamics, with manufacturers investing heavily in hybrid and electric powertrains. The integration of V12 engines with electric motors in hybrid configurations represents a transitional phase, allowing manufacturers to maintain the allure of V12 power while improving efficiency and meeting regulatory requirements.

Consumer preferences in the supercar segment are evolving, with an increasing emphasis on technology, connectivity, and customization. While performance remains a primary selling point, buyers are also seeking advanced driver assistance systems, infotainment features, and personalization options. This trend has prompted manufacturers to invest in digital technologies and innovative materials, further driving up the cost and exclusivity of V12-powered supercars.

The COVID-19 pandemic has had a mixed impact on the supercar market. While initial disruptions in production and sales were observed, the luxury segment has shown resilience, with some manufacturers reporting strong order books and increased interest from high-net-worth individuals seeking alternative investment opportunities.

Market analysis indicates that the global supercar market was valued at approximately $13.8 billion in 2020 and is projected to reach $22.2 billion by 2026, growing at a CAGR of 8.3% during the forecast period. This growth is attributed to factors such as increasing disposable income, technological innovations, and a growing passion for high-performance vehicles among enthusiasts.

The V12 engine, a hallmark of modern supercars, plays a crucial role in shaping market dynamics. Despite the industry's shift towards electrification and downsizing, V12-powered supercars continue to command a premium position in the market. These vehicles appeal to a niche segment of buyers who prioritize performance, prestige, and the unique driving experience offered by large-displacement engines.

Key players in the V12 supercar market include established brands like Ferrari, Lamborghini, and Aston Martin, as well as boutique manufacturers such as Pagani and Koenigsegg. These companies have successfully positioned their V12-powered models as flagship offerings, commanding higher profit margins and fostering brand loyalty among enthusiasts.

However, the supercar market faces challenges, including stringent emissions regulations and the global push towards sustainability. This has led to a gradual shift in market dynamics, with manufacturers investing heavily in hybrid and electric powertrains. The integration of V12 engines with electric motors in hybrid configurations represents a transitional phase, allowing manufacturers to maintain the allure of V12 power while improving efficiency and meeting regulatory requirements.

Consumer preferences in the supercar segment are evolving, with an increasing emphasis on technology, connectivity, and customization. While performance remains a primary selling point, buyers are also seeking advanced driver assistance systems, infotainment features, and personalization options. This trend has prompted manufacturers to invest in digital technologies and innovative materials, further driving up the cost and exclusivity of V12-powered supercars.

The COVID-19 pandemic has had a mixed impact on the supercar market. While initial disruptions in production and sales were observed, the luxury segment has shown resilience, with some manufacturers reporting strong order books and increased interest from high-net-worth individuals seeking alternative investment opportunities.

V12 Tech Challenges

The V12 engine, a hallmark of high-performance supercars, presents several significant technical challenges that engineers must overcome to maintain its relevance in modern automotive design. One of the primary issues is the engine's substantial weight, which can negatively impact the vehicle's overall balance and handling characteristics. This weight distribution challenge requires innovative solutions in chassis design and material selection to ensure optimal performance.

Another major hurdle is the V12's fuel efficiency, or lack thereof. In an era of increasing environmental consciousness and stringent emissions regulations, the V12's typically high fuel consumption poses a significant obstacle. Engineers must develop advanced fuel management systems and explore hybrid technologies to improve efficiency without compromising the engine's legendary power output.

Heat management is a critical concern for V12 engines, given their high cylinder count and power density. The complex cooling systems required to maintain optimal operating temperatures add further weight and complexity to the vehicle design. This challenge necessitates the development of more efficient cooling technologies and thermal management strategies.

The V12's physical size presents packaging difficulties, particularly in modern supercars where aerodynamics play a crucial role. Designers must find creative ways to integrate the large engine while maintaining sleek body lines and efficient airflow. This often requires compromises in other areas of the vehicle's design, such as interior space or luggage capacity.

Vibration and noise control are additional technical challenges associated with V12 engines. While the V12 configuration inherently provides good balance, the high number of moving parts can still generate significant vibrations. Engineers must employ advanced materials and isolation techniques to ensure a smooth, refined driving experience befitting a luxury supercar.

The complexity of the V12 engine also presents maintenance and reliability challenges. With more components than smaller engines, there are more potential points of failure. This complexity translates to higher production costs and more frequent, expensive maintenance schedules, which can be a deterrent for both manufacturers and consumers.

Lastly, the development of high-performance electric powertrains poses an existential challenge to the V12 engine. As electric vehicles continue to improve in performance and range, engineers must find ways to justify the continued use of V12 engines in supercars, perhaps by focusing on their unique character and emotional appeal while addressing their technical shortcomings.

Another major hurdle is the V12's fuel efficiency, or lack thereof. In an era of increasing environmental consciousness and stringent emissions regulations, the V12's typically high fuel consumption poses a significant obstacle. Engineers must develop advanced fuel management systems and explore hybrid technologies to improve efficiency without compromising the engine's legendary power output.

Heat management is a critical concern for V12 engines, given their high cylinder count and power density. The complex cooling systems required to maintain optimal operating temperatures add further weight and complexity to the vehicle design. This challenge necessitates the development of more efficient cooling technologies and thermal management strategies.

The V12's physical size presents packaging difficulties, particularly in modern supercars where aerodynamics play a crucial role. Designers must find creative ways to integrate the large engine while maintaining sleek body lines and efficient airflow. This often requires compromises in other areas of the vehicle's design, such as interior space or luggage capacity.

Vibration and noise control are additional technical challenges associated with V12 engines. While the V12 configuration inherently provides good balance, the high number of moving parts can still generate significant vibrations. Engineers must employ advanced materials and isolation techniques to ensure a smooth, refined driving experience befitting a luxury supercar.

The complexity of the V12 engine also presents maintenance and reliability challenges. With more components than smaller engines, there are more potential points of failure. This complexity translates to higher production costs and more frequent, expensive maintenance schedules, which can be a deterrent for both manufacturers and consumers.

Lastly, the development of high-performance electric powertrains poses an existential challenge to the V12 engine. As electric vehicles continue to improve in performance and range, engineers must find ways to justify the continued use of V12 engines in supercars, perhaps by focusing on their unique character and emotional appeal while addressing their technical shortcomings.

Current V12 Solutions

01 Engine control and optimization

V12 engine dynamics can be improved through advanced control systems and optimization techniques. This includes methods for managing fuel injection, ignition timing, and valve timing to enhance performance, efficiency, and emissions control. Adaptive control algorithms and real-time monitoring systems can be employed to optimize engine operation under various conditions.- Engine control and optimization: V12 engine dynamics can be improved through advanced control systems and optimization techniques. This includes methods for managing fuel injection, ignition timing, and valve timing to enhance performance, efficiency, and emissions control. Adaptive control algorithms and real-time monitoring systems can be employed to optimize engine operation under various conditions.

- Vibration and noise reduction: Reducing vibration and noise is crucial for V12 engine dynamics. This can be achieved through innovative design of engine mounts, balancing mechanisms, and acoustic treatments. Advanced materials and damping technologies can be incorporated to minimize unwanted vibrations and enhance overall engine smoothness.

- Turbocharging and supercharging systems: Forced induction systems, such as turbochargers and superchargers, play a significant role in enhancing V12 engine dynamics. These systems can increase power output, improve throttle response, and optimize fuel efficiency. Advanced designs may include variable geometry turbochargers or electric compressors for better performance across the engine's operating range.

- Cylinder deactivation and variable displacement: Implementing cylinder deactivation or variable displacement technologies can significantly improve V12 engine dynamics, especially in terms of fuel efficiency. These systems allow the engine to operate on fewer cylinders during low-load conditions, reducing fuel consumption while maintaining the ability to deliver full power when needed.

- Advanced materials and manufacturing techniques: The use of advanced materials and manufacturing techniques can enhance V12 engine dynamics by reducing weight, improving thermal efficiency, and increasing durability. This may include the application of lightweight alloys, composite materials, or advanced coatings. Precision manufacturing methods, such as 3D printing or advanced machining techniques, can also contribute to improved engine performance and reliability.

02 Vibration and noise reduction

Reducing vibration and noise is crucial for V12 engine dynamics. This can be achieved through innovative design of engine mounts, balancing mechanisms, and acoustic treatments. Advanced materials and damping technologies can be utilized to minimize unwanted vibrations and enhance overall engine smoothness.Expand Specific Solutions03 Turbocharging and supercharging systems

Forced induction systems, such as turbochargers and superchargers, can significantly enhance V12 engine dynamics. These systems increase air intake, allowing for improved power output and efficiency. Advanced designs may incorporate variable geometry turbines, electric compressors, or multi-stage boosting to optimize performance across the engine's operating range.Expand Specific Solutions04 Cylinder deactivation and variable displacement

Implementing cylinder deactivation or variable displacement technologies can improve fuel efficiency and reduce emissions in V12 engines. These systems allow the engine to operate on fewer cylinders during low-load conditions, while maintaining full power capability when needed. Advanced control strategies ensure smooth transitions between operating modes.Expand Specific Solutions05 Thermal management and cooling systems

Effective thermal management is essential for optimizing V12 engine dynamics. This includes advanced cooling systems, heat recovery mechanisms, and intelligent temperature control strategies. Improved thermal efficiency can lead to better overall engine performance, reduced emissions, and increased durability.Expand Specific Solutions

Key V12 Manufacturers

The V12 engine's influence on modern supercar dynamics represents a mature technology in a niche market segment. The supercar industry, while relatively small in scale, continues to evolve with advancements in engine design and performance. Companies like Ferrari, Lamborghini, and Aston Martin have long been at the forefront of V12 engine development, pushing the boundaries of power and efficiency. However, with increasing focus on electrification and environmental concerns, traditional V12 engines are facing challenges. Manufacturers such as BMW and Mercedes-Benz are exploring hybrid V12 systems to maintain performance while improving fuel economy, indicating a transition phase in this high-end automotive sector.

Toyota Motor Corp.

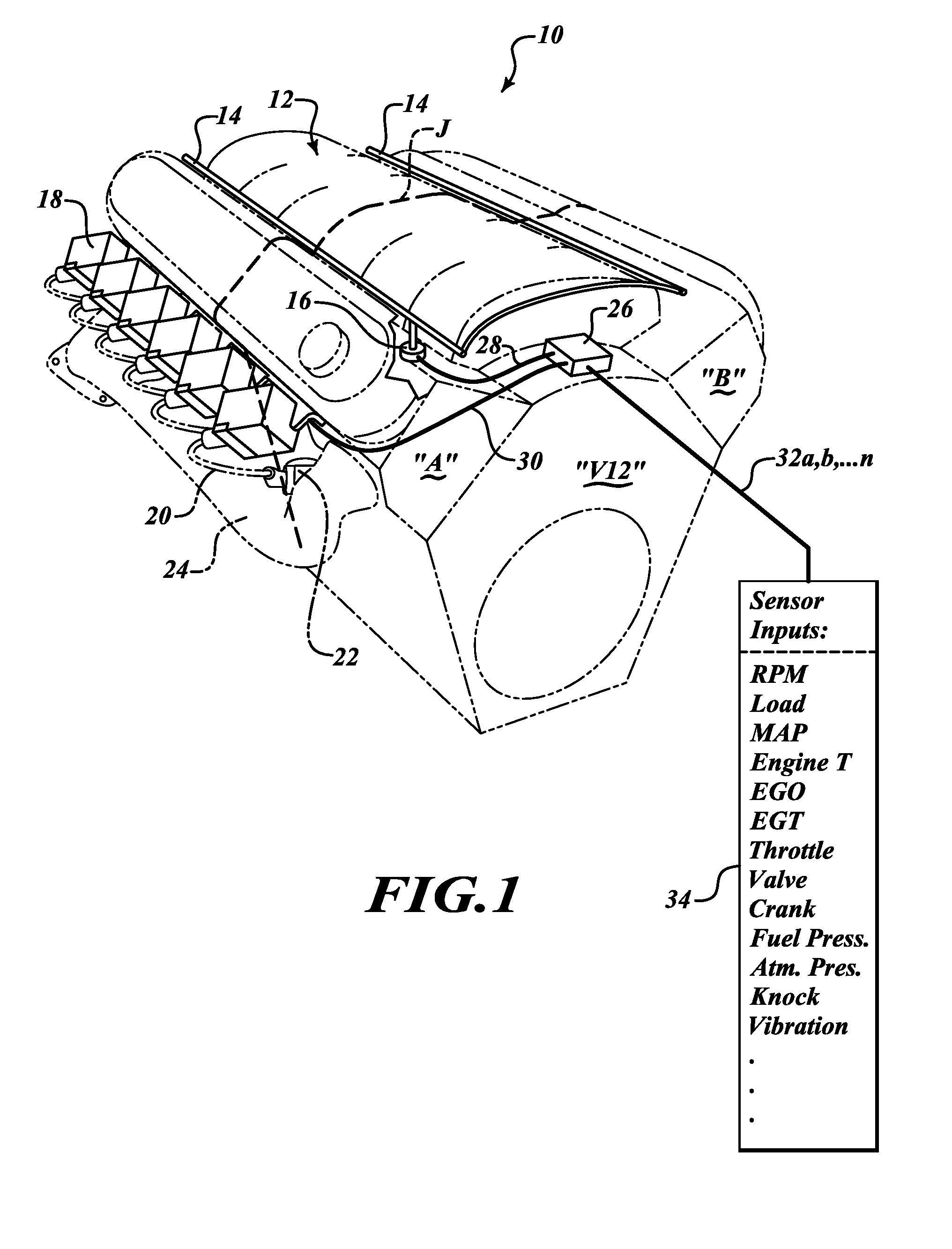

Technical Solution: Toyota has been at the forefront of V12 engine development for supercars, particularly with their Lexus LFA model. The company's 4.8-liter V12 engine, codenamed 1LR-GUE, was developed specifically for the LFA and produces 553 horsepower at 8,700 rpm[1]. This engine features a 72-degree bank angle, dry-sump lubrication, and titanium valves, allowing it to rev up to 9,000 rpm[2]. Toyota's approach focuses on lightweight design and high-revving capabilities, which significantly influence the car's dynamics by providing exceptional power-to-weight ratio and responsive acceleration[3].

Strengths: Exceptional power-to-weight ratio, high-revving capability, and advanced materials. Weaknesses: High production costs and limited applicability to mass-market vehicles.

Ford Global Technologies LLC

Technical Solution: Ford's contribution to V12 engines in modern supercars is primarily through their involvement with Aston Martin when the British marque was under Ford's ownership. The 5.9-liter V12 engine developed during this period continues to influence supercar dynamics today. This engine, known for its smooth power delivery and distinctive sound, produces up to 715 horsepower in its most recent iterations[4]. Ford's approach emphasizes a balance between performance and refinement, with the V12 engine providing linear power delivery and a wide torque band, which enhances drivability and overall vehicle dynamics[5].

Strengths: Smooth power delivery, wide torque band, and refined performance. Weaknesses: Relatively large displacement may lead to higher fuel consumption and emissions.

V12 Innovations

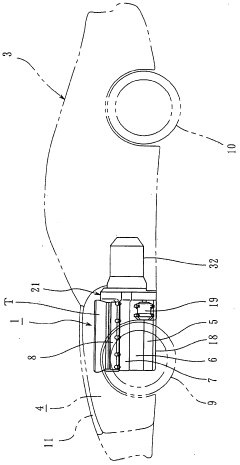

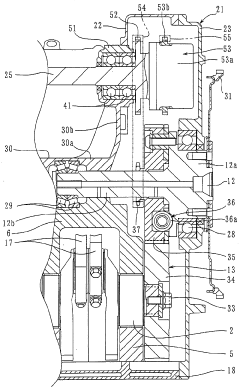

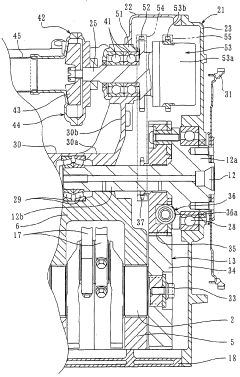

V-engine for vehicle

PatentWO2003074852A1

Innovation

- The V-type engine design incorporates auxiliary machines and transmission means on both sides of the crankshaft, with a dry sump lubrication system and strategically positioned output shafts and valve drive shafts to adjust the engine's center of gravity closer to the vehicle's center, allowing for improved power transmission and reduced height, while balancing weights for enhanced stability.

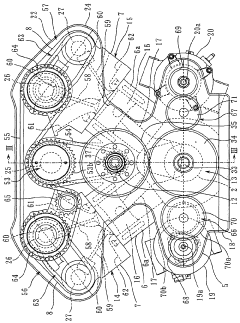

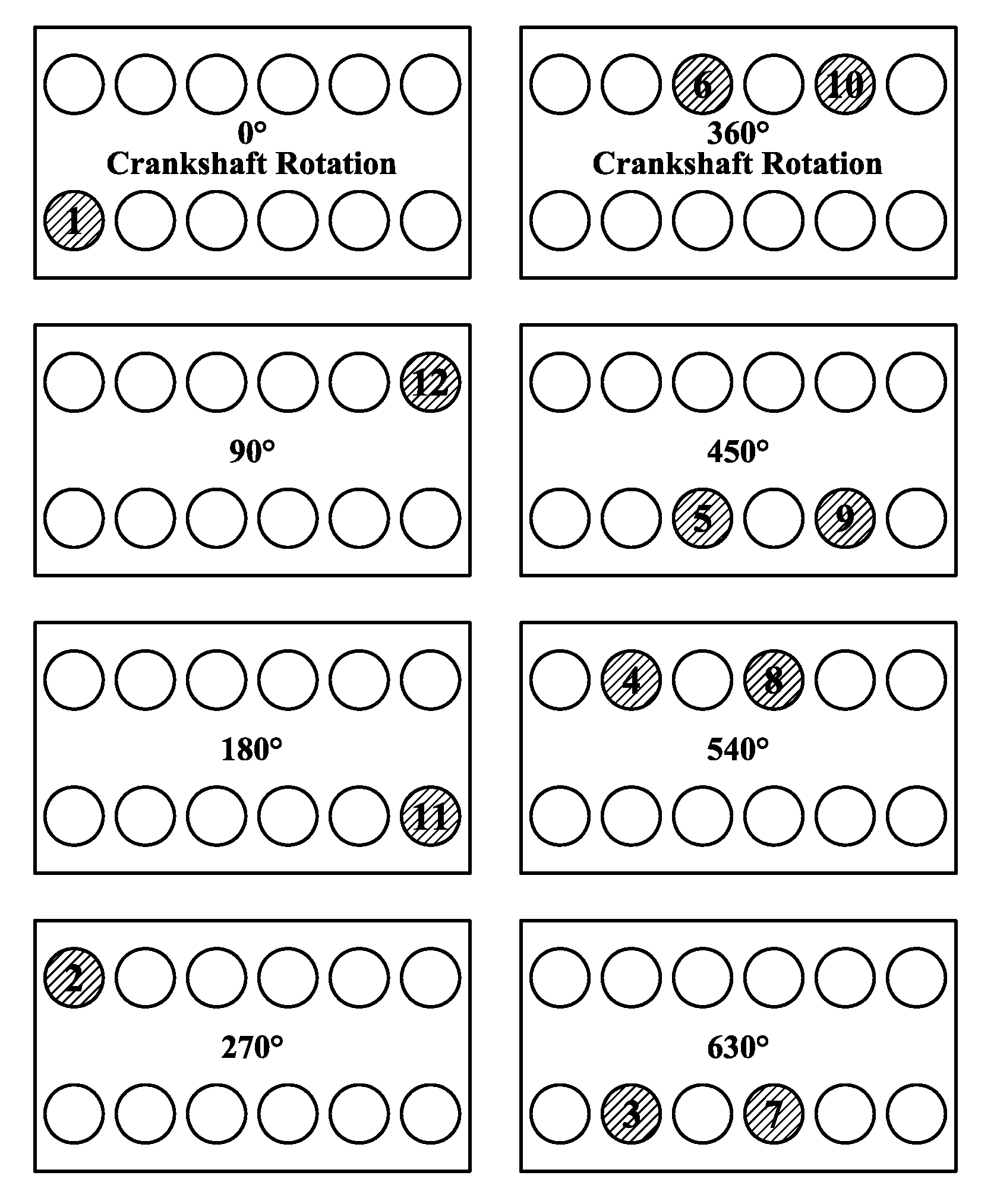

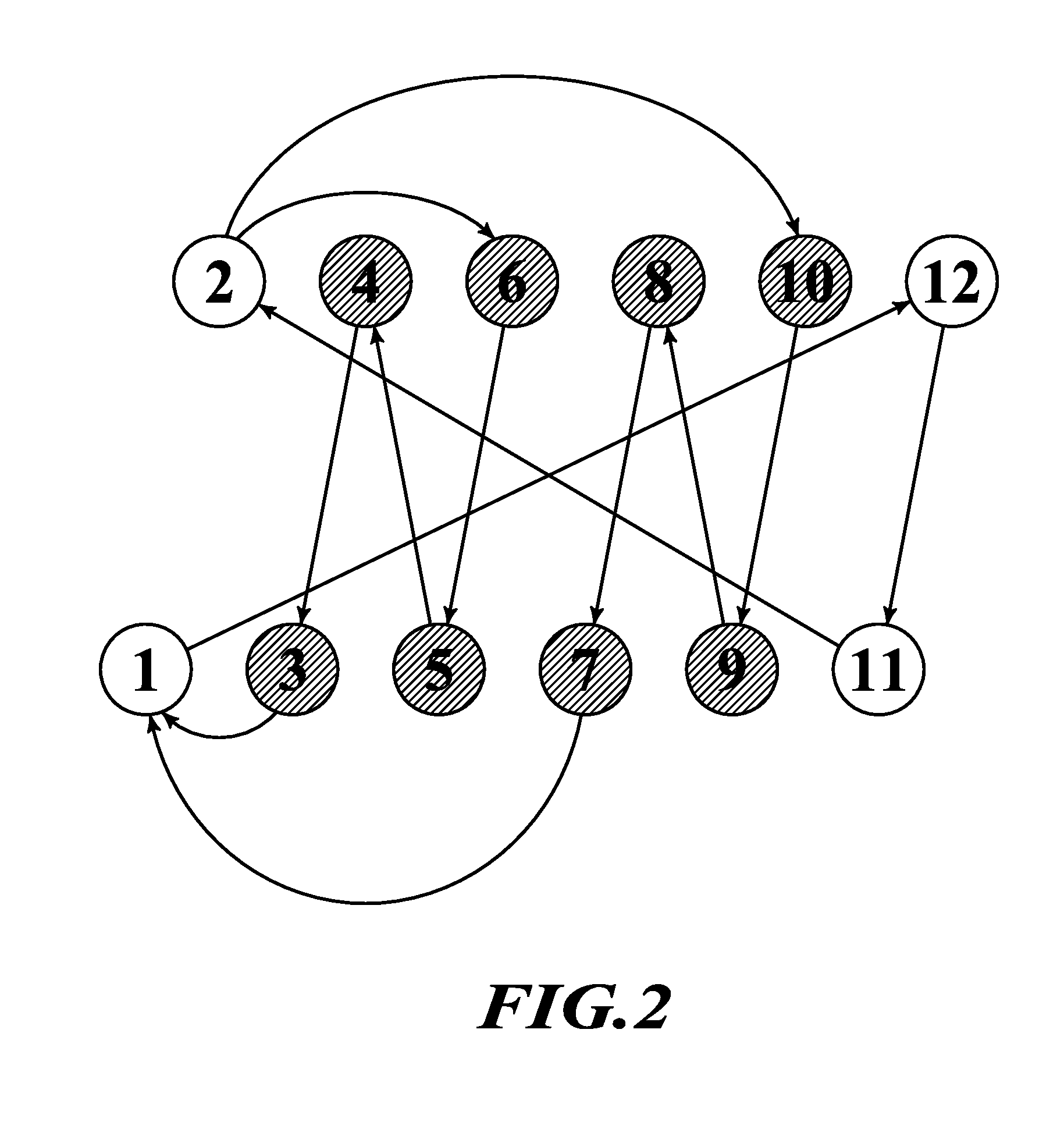

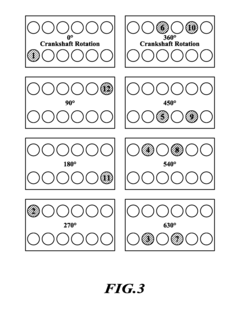

Even fire 90°V12 IC engines, fueling and firing sequence controllers, and methods of operation by PS/P technology and IFR compensation by fuel feed control

PatentInactiveUS7979193B2

Innovation

- Implementing a Progressive Single/Pair (PS/P) fueling and firing sequence controlled by a Powertrain Control Module (PCM) that allows all cylinders in a 90°V12 to operate in Even Fire mode, with Dynamic Fuel Balancing and IFR Compensation by selectively reducing fuel to specific cylinders during imbalance frequencies, effectively converting the engine's operation to a balanced V8 mode during peak vibrations.

Emissions Regulations

Emissions regulations have become a critical factor in shaping the development and future of V12 engines in modern supercars. As governments worldwide implement increasingly stringent emissions standards, automakers are facing significant challenges in maintaining the performance and allure of V12-powered vehicles while meeting these regulatory requirements.

The European Union's Euro 6 standards and the United States' EPA Tier 3 regulations have set ambitious targets for reducing carbon dioxide emissions and other pollutants. These regulations have forced supercar manufacturers to adopt innovative technologies to improve fuel efficiency and reduce emissions without compromising the power and performance that V12 engines are known for.

One of the primary strategies employed by manufacturers is the integration of hybrid powertrains. By combining electric motors with V12 engines, automakers can achieve lower emissions during city driving while still delivering the exhilarating performance expected from a supercar. This approach has been successfully implemented in vehicles like the Ferrari SF90 Stradale and the upcoming Lamborghini Sián.

Another technological advancement in response to emissions regulations is the implementation of cylinder deactivation systems. These systems allow V12 engines to operate on fewer cylinders during low-load conditions, significantly reducing fuel consumption and emissions without sacrificing the ability to unleash full power when needed.

Turbocharging and supercharging technologies have also been refined to improve efficiency while maintaining or even increasing power output. These forced induction systems allow for smaller displacement engines that can still deliver the performance expected from a V12, but with reduced emissions and improved fuel economy.

Advanced engine management systems and direct fuel injection technologies have further contributed to optimizing V12 engine performance while meeting emissions standards. These systems provide precise control over fuel delivery and combustion, resulting in cleaner and more efficient operation.

Despite these advancements, the long-term viability of V12 engines in supercars remains uncertain. Some manufacturers are exploring alternative powertrains, such as all-electric systems, to meet future emissions regulations. However, the unique character and emotional appeal of V12 engines continue to drive innovation in the supercar industry, as manufacturers strive to preserve this iconic powertrain while adapting to a changing regulatory landscape.

The European Union's Euro 6 standards and the United States' EPA Tier 3 regulations have set ambitious targets for reducing carbon dioxide emissions and other pollutants. These regulations have forced supercar manufacturers to adopt innovative technologies to improve fuel efficiency and reduce emissions without compromising the power and performance that V12 engines are known for.

One of the primary strategies employed by manufacturers is the integration of hybrid powertrains. By combining electric motors with V12 engines, automakers can achieve lower emissions during city driving while still delivering the exhilarating performance expected from a supercar. This approach has been successfully implemented in vehicles like the Ferrari SF90 Stradale and the upcoming Lamborghini Sián.

Another technological advancement in response to emissions regulations is the implementation of cylinder deactivation systems. These systems allow V12 engines to operate on fewer cylinders during low-load conditions, significantly reducing fuel consumption and emissions without sacrificing the ability to unleash full power when needed.

Turbocharging and supercharging technologies have also been refined to improve efficiency while maintaining or even increasing power output. These forced induction systems allow for smaller displacement engines that can still deliver the performance expected from a V12, but with reduced emissions and improved fuel economy.

Advanced engine management systems and direct fuel injection technologies have further contributed to optimizing V12 engine performance while meeting emissions standards. These systems provide precise control over fuel delivery and combustion, resulting in cleaner and more efficient operation.

Despite these advancements, the long-term viability of V12 engines in supercars remains uncertain. Some manufacturers are exploring alternative powertrains, such as all-electric systems, to meet future emissions regulations. However, the unique character and emotional appeal of V12 engines continue to drive innovation in the supercar industry, as manufacturers strive to preserve this iconic powertrain while adapting to a changing regulatory landscape.

Hybrid V12 Technologies

The integration of hybrid technologies with V12 engines represents a significant advancement in modern supercar dynamics. This fusion combines the raw power and prestige of traditional V12 engines with the efficiency and environmental benefits of electric propulsion systems. Hybrid V12 technologies typically incorporate one or more electric motors alongside the conventional V12 internal combustion engine, creating a complex powertrain that offers enhanced performance and reduced emissions.

One of the primary advantages of hybrid V12 systems is the ability to provide instant torque from the electric motors, complementing the high-end power delivery of the V12 engine. This combination results in improved acceleration across the entire speed range, particularly at lower speeds where traditional V12 engines may lag. The electric motors can fill in the power gaps, providing a more linear and responsive acceleration curve.

Furthermore, hybrid V12 technologies often employ regenerative braking systems, which recover kinetic energy during deceleration and convert it into electrical energy. This energy is then stored in high-capacity batteries for later use, improving overall efficiency and extending the vehicle's range. The regenerative braking also contributes to enhanced brake performance and reduced wear on conventional brake components.

Advanced power management systems are crucial in hybrid V12 setups. These systems intelligently distribute power between the V12 engine and electric motors, optimizing performance and efficiency based on driving conditions and driver inputs. Some hybrid V12 supercars offer multiple driving modes, allowing drivers to prioritize all-electric operation for short distances, maximize performance, or balance power and efficiency.

The integration of electric components also allows for more precise torque vectoring, enhancing handling and cornering capabilities. By independently controlling the power delivery to each wheel, hybrid V12 systems can improve traction, stability, and overall dynamic performance, particularly in high-speed cornering scenarios.

While hybrid V12 technologies offer numerous benefits, they also present challenges. The additional weight of batteries and electric motors can impact the vehicle's overall weight distribution and handling characteristics. Engineers must carefully balance these factors to maintain the agility and responsiveness expected in high-performance supercars. Additionally, the complexity of hybrid systems requires sophisticated cooling solutions to manage heat generated by both the V12 engine and electric components.

One of the primary advantages of hybrid V12 systems is the ability to provide instant torque from the electric motors, complementing the high-end power delivery of the V12 engine. This combination results in improved acceleration across the entire speed range, particularly at lower speeds where traditional V12 engines may lag. The electric motors can fill in the power gaps, providing a more linear and responsive acceleration curve.

Furthermore, hybrid V12 technologies often employ regenerative braking systems, which recover kinetic energy during deceleration and convert it into electrical energy. This energy is then stored in high-capacity batteries for later use, improving overall efficiency and extending the vehicle's range. The regenerative braking also contributes to enhanced brake performance and reduced wear on conventional brake components.

Advanced power management systems are crucial in hybrid V12 setups. These systems intelligently distribute power between the V12 engine and electric motors, optimizing performance and efficiency based on driving conditions and driver inputs. Some hybrid V12 supercars offer multiple driving modes, allowing drivers to prioritize all-electric operation for short distances, maximize performance, or balance power and efficiency.

The integration of electric components also allows for more precise torque vectoring, enhancing handling and cornering capabilities. By independently controlling the power delivery to each wheel, hybrid V12 systems can improve traction, stability, and overall dynamic performance, particularly in high-speed cornering scenarios.

While hybrid V12 technologies offer numerous benefits, they also present challenges. The additional weight of batteries and electric motors can impact the vehicle's overall weight distribution and handling characteristics. Engineers must carefully balance these factors to maintain the agility and responsiveness expected in high-performance supercars. Additionally, the complexity of hybrid systems requires sophisticated cooling solutions to manage heat generated by both the V12 engine and electric components.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!