V6 Engine vs I4 Engine: Power Output Analysis

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Engine Architecture Evolution and Performance Goals

Internal combustion engines have undergone significant architectural evolution since their inception in the late 19th century. The V6 and inline-four (I4) engine configurations represent two distinct approaches to power generation that have become dominant in modern automotive applications. The V6 architecture emerged in the early 20th century as manufacturers sought more compact alternatives to straight-six designs while maintaining smooth operation. Meanwhile, the I4 configuration has been a mainstay since the earliest days of automotive engineering, valued for its simplicity and balance.

The technological trajectory of these engine types has been shaped by increasingly stringent emissions regulations, consumer demand for fuel efficiency, and the competitive pursuit of performance metrics. V6 engines historically offered a middle ground between the economy of smaller engines and the power of larger V8 units. Their development has focused on optimizing the 60° or 90° V-angle to balance primary and secondary forces while minimizing vibration through sophisticated mounting systems and counterweights.

I4 engines have evolved from basic utility powerplants to sophisticated high-output systems through advancements in valve timing, forced induction, and combustion chamber design. The inherent packaging advantages of the I4 layout have made it the preferred choice for transverse engine installations in front-wheel-drive vehicles, which now dominate global automotive production.

Performance goals for modern engine development have shifted dramatically in recent decades. While maximum horsepower and torque figures remain important benchmarks, engineers now prioritize power density (output per liter of displacement), specific output (power per unit of engine mass), and area under the torque curve rather than peak values alone. This evolution reflects a more nuanced understanding of real-world driving conditions and user expectations.

The convergence of computational fluid dynamics, advanced materials science, and precision manufacturing has enabled both engine architectures to achieve previously unattainable efficiency and power output levels. Direct injection, variable valve timing, turbocharging, and cylinder deactivation technologies have been applied to both V6 and I4 platforms with remarkable success, blurring traditional performance boundaries between these configurations.

Current technical objectives focus on maximizing the thermal efficiency of internal combustion processes while minimizing friction losses and pumping work. Engineers target brake specific fuel consumption improvements alongside emissions reduction, with particular attention to transient response characteristics that affect drivability. As electrification becomes increasingly prevalent, these engine architectures must also be optimized for hybrid applications, where their operating parameters may differ significantly from traditional deployments.

The technological trajectory of these engine types has been shaped by increasingly stringent emissions regulations, consumer demand for fuel efficiency, and the competitive pursuit of performance metrics. V6 engines historically offered a middle ground between the economy of smaller engines and the power of larger V8 units. Their development has focused on optimizing the 60° or 90° V-angle to balance primary and secondary forces while minimizing vibration through sophisticated mounting systems and counterweights.

I4 engines have evolved from basic utility powerplants to sophisticated high-output systems through advancements in valve timing, forced induction, and combustion chamber design. The inherent packaging advantages of the I4 layout have made it the preferred choice for transverse engine installations in front-wheel-drive vehicles, which now dominate global automotive production.

Performance goals for modern engine development have shifted dramatically in recent decades. While maximum horsepower and torque figures remain important benchmarks, engineers now prioritize power density (output per liter of displacement), specific output (power per unit of engine mass), and area under the torque curve rather than peak values alone. This evolution reflects a more nuanced understanding of real-world driving conditions and user expectations.

The convergence of computational fluid dynamics, advanced materials science, and precision manufacturing has enabled both engine architectures to achieve previously unattainable efficiency and power output levels. Direct injection, variable valve timing, turbocharging, and cylinder deactivation technologies have been applied to both V6 and I4 platforms with remarkable success, blurring traditional performance boundaries between these configurations.

Current technical objectives focus on maximizing the thermal efficiency of internal combustion processes while minimizing friction losses and pumping work. Engineers target brake specific fuel consumption improvements alongside emissions reduction, with particular attention to transient response characteristics that affect drivability. As electrification becomes increasingly prevalent, these engine architectures must also be optimized for hybrid applications, where their operating parameters may differ significantly from traditional deployments.

Market Demand Analysis for V6 vs I4 Engines

The global automotive market has witnessed a significant shift in consumer preferences regarding engine configurations, with the traditional V6 engines facing increasing competition from more efficient I4 (inline-four) engines. Market analysis indicates that while V6 engines dominated the mid-size and luxury vehicle segments for decades, I4 engines have gained substantial market share since 2010, primarily driven by fuel efficiency regulations and changing consumer priorities.

Consumer demand patterns show regional variations, with North American markets still maintaining a stronger preference for V6 engines in SUVs and trucks, while European and Asian markets have more readily embraced I4 configurations across various vehicle segments. According to industry reports, the global market share for I4 engines has increased from approximately 60% in 2010 to over 75% in 2023, while V6 engines have declined from 25% to about 15% during the same period.

Economic factors play a crucial role in this market shift. The average manufacturing cost difference between comparable V6 and I4 engines ranges between $1,200-2,500 per unit, translating to significant pricing differentials for end consumers. Additionally, the operational cost advantage of I4 engines, delivering 15-30% better fuel economy on average, has become increasingly important to consumers amid rising fuel prices and environmental concerns.

Market segmentation analysis reveals that luxury and performance vehicle segments still maintain stronger demand for V6 engines, with consumers willing to pay premium prices for the perceived benefits in smoothness and power delivery. However, advancements in I4 engine technology, particularly turbocharging and direct injection, have narrowed the performance gap considerably, allowing manufacturers to target previously V6-dominated segments.

Future market projections suggest continued growth for advanced I4 engines, with the global market value for turbocharged I4 engines expected to reach $43 billion by 2028, growing at a CAGR of 6.8%. Meanwhile, V6 engines are increasingly being positioned as premium options in manufacturer lineups, with their market primarily sustained by performance vehicles, larger SUVs, and luxury applications where their inherent characteristics remain valued.

Consumer survey data indicates that while power output remains important to buyers, factors such as fuel efficiency, environmental impact, and total cost of ownership have gained prominence in purchase decisions. This shift has prompted manufacturers to invest heavily in I4 engine development, with over 80% of new passenger vehicle platforms designed to accommodate advanced four-cylinder powertrains as their primary or exclusive engine option.

Consumer demand patterns show regional variations, with North American markets still maintaining a stronger preference for V6 engines in SUVs and trucks, while European and Asian markets have more readily embraced I4 configurations across various vehicle segments. According to industry reports, the global market share for I4 engines has increased from approximately 60% in 2010 to over 75% in 2023, while V6 engines have declined from 25% to about 15% during the same period.

Economic factors play a crucial role in this market shift. The average manufacturing cost difference between comparable V6 and I4 engines ranges between $1,200-2,500 per unit, translating to significant pricing differentials for end consumers. Additionally, the operational cost advantage of I4 engines, delivering 15-30% better fuel economy on average, has become increasingly important to consumers amid rising fuel prices and environmental concerns.

Market segmentation analysis reveals that luxury and performance vehicle segments still maintain stronger demand for V6 engines, with consumers willing to pay premium prices for the perceived benefits in smoothness and power delivery. However, advancements in I4 engine technology, particularly turbocharging and direct injection, have narrowed the performance gap considerably, allowing manufacturers to target previously V6-dominated segments.

Future market projections suggest continued growth for advanced I4 engines, with the global market value for turbocharged I4 engines expected to reach $43 billion by 2028, growing at a CAGR of 6.8%. Meanwhile, V6 engines are increasingly being positioned as premium options in manufacturer lineups, with their market primarily sustained by performance vehicles, larger SUVs, and luxury applications where their inherent characteristics remain valued.

Consumer survey data indicates that while power output remains important to buyers, factors such as fuel efficiency, environmental impact, and total cost of ownership have gained prominence in purchase decisions. This shift has prompted manufacturers to invest heavily in I4 engine development, with over 80% of new passenger vehicle platforms designed to accommodate advanced four-cylinder powertrains as their primary or exclusive engine option.

Technical Comparison and Engineering Challenges

The V6 and I4 engines represent two fundamentally different approaches to internal combustion engine design, each with distinct characteristics affecting power output. V6 engines typically feature six cylinders arranged in a V-configuration, while I4 (inline-four) engines have four cylinders aligned in a straight line. This architectural difference creates inherent disparities in performance capabilities and engineering considerations.

From a power generation perspective, V6 engines generally produce higher horsepower and torque figures compared to I4 engines of similar displacement. This advantage stems from the V6's additional cylinders, which allow for more fuel-air mixture combustion per engine cycle. Empirical data indicates that modern V6 engines commonly deliver 250-350 horsepower, while comparable I4 engines typically generate 150-250 horsepower, representing a significant performance differential.

The engineering challenges between these configurations are multifaceted. V6 engines present greater complexity in terms of manufacturing precision, requiring more components and tighter tolerances. The V-configuration necessitates sophisticated balancing mechanisms to mitigate vibration issues inherent to the design. Additionally, the more complex valve train and dual cylinder banks increase production costs by approximately 30-40% compared to I4 counterparts.

I4 engines, while offering lower absolute power output, present advantages in efficiency and packaging. Their simpler design facilitates easier maintenance and typically delivers 10-15% better fuel economy under comparable driving conditions. However, I4 engines face challenges in smoothness of operation, particularly at higher RPMs where second-order vibrations become pronounced without proper balancing shafts.

Thermal management represents another significant engineering challenge. V6 engines generate more heat due to their higher power output and compact design, necessitating more sophisticated cooling systems. This often requires dual cooling circuits and more complex radiator designs, adding to system complexity and potential failure points.

Weight distribution also differs substantially between these configurations. V6 engines are typically 70-100 pounds heavier than comparable I4 engines, affecting vehicle dynamics and requiring additional chassis engineering to maintain optimal handling characteristics. The V6's more compact length, however, offers advantages in certain front-wheel-drive applications where engine bay space is limited.

Modern engineering solutions have narrowed the performance gap through technologies like turbocharging and direct injection. These advancements have enabled smaller I4 engines to achieve power outputs previously associated with naturally aspirated V6 engines, though often with different power delivery characteristics and NVH (Noise, Vibration, Harshness) profiles that require additional engineering mitigation strategies.

From a power generation perspective, V6 engines generally produce higher horsepower and torque figures compared to I4 engines of similar displacement. This advantage stems from the V6's additional cylinders, which allow for more fuel-air mixture combustion per engine cycle. Empirical data indicates that modern V6 engines commonly deliver 250-350 horsepower, while comparable I4 engines typically generate 150-250 horsepower, representing a significant performance differential.

The engineering challenges between these configurations are multifaceted. V6 engines present greater complexity in terms of manufacturing precision, requiring more components and tighter tolerances. The V-configuration necessitates sophisticated balancing mechanisms to mitigate vibration issues inherent to the design. Additionally, the more complex valve train and dual cylinder banks increase production costs by approximately 30-40% compared to I4 counterparts.

I4 engines, while offering lower absolute power output, present advantages in efficiency and packaging. Their simpler design facilitates easier maintenance and typically delivers 10-15% better fuel economy under comparable driving conditions. However, I4 engines face challenges in smoothness of operation, particularly at higher RPMs where second-order vibrations become pronounced without proper balancing shafts.

Thermal management represents another significant engineering challenge. V6 engines generate more heat due to their higher power output and compact design, necessitating more sophisticated cooling systems. This often requires dual cooling circuits and more complex radiator designs, adding to system complexity and potential failure points.

Weight distribution also differs substantially between these configurations. V6 engines are typically 70-100 pounds heavier than comparable I4 engines, affecting vehicle dynamics and requiring additional chassis engineering to maintain optimal handling characteristics. The V6's more compact length, however, offers advantages in certain front-wheel-drive applications where engine bay space is limited.

Modern engineering solutions have narrowed the performance gap through technologies like turbocharging and direct injection. These advancements have enabled smaller I4 engines to achieve power outputs previously associated with naturally aspirated V6 engines, though often with different power delivery characteristics and NVH (Noise, Vibration, Harshness) profiles that require additional engineering mitigation strategies.

Current Power Output Enhancement Solutions

01 Power output comparison between V6 and I4 engines

V6 engines generally produce more power than I4 engines due to their larger displacement and additional cylinders. The V6 configuration allows for smoother operation and higher torque output across a wider RPM range. This power difference makes V6 engines suitable for larger vehicles and applications requiring greater performance, while I4 engines are typically more fuel-efficient but provide less overall power output.- Power output comparison between V6 and I4 engines: V6 engines generally produce more power than I4 engines due to their larger displacement and additional cylinders. The V6 configuration allows for smoother operation and higher torque output across a wider RPM range. In contrast, I4 engines are more fuel-efficient but typically generate less power. The power difference between these engine types is significant in applications requiring high performance, though modern turbocharging technology has narrowed this gap in some cases.

- Turbocharging and supercharging for increased power output: Forced induction systems like turbochargers and superchargers can significantly increase the power output of both V6 and I4 engines. These systems compress the incoming air, allowing more fuel to be burned and generating more power. Turbocharged I4 engines can achieve power outputs comparable to naturally aspirated V6 engines while maintaining better fuel efficiency. Advanced turbocharging technologies include variable geometry turbochargers and twin-scroll designs that reduce lag and improve power delivery across the RPM range.

- Engine management systems for optimizing power output: Modern engine management systems play a crucial role in optimizing power output for both V6 and I4 engines. Electronic control units (ECUs) precisely manage fuel injection timing, ignition timing, and valve timing to maximize power while maintaining efficiency and emissions compliance. Variable valve timing and lift systems allow engines to optimize performance across different operating conditions. Advanced sensors and algorithms continuously adjust engine parameters to deliver optimal power output based on driving conditions and driver demands.

- Weight-to-power ratio considerations in engine design: The weight-to-power ratio is a critical factor in engine performance, particularly in automotive and aerospace applications. While V6 engines typically produce more absolute power, I4 engines often have better weight-to-power ratios due to their lighter construction. This advantage makes I4 engines preferable in applications where weight is a significant concern, such as in compact vehicles or aircraft. Engine materials and design innovations focus on reducing weight while maintaining structural integrity to improve overall performance efficiency.

- Hybrid and alternative power augmentation systems: Hybrid systems that combine internal combustion engines with electric motors can significantly enhance the power output of both V6 and I4 configurations. These systems use electric motors to supplement engine power during acceleration or high-load conditions. In some designs, smaller I4 engines paired with electric motors can match or exceed the performance of larger V6 engines while improving fuel efficiency. Alternative power augmentation technologies include hydrogen injection, water injection, and advanced energy recovery systems that capture and repurpose waste energy.

02 Fuel efficiency and power optimization techniques

Various techniques are employed to optimize the power output while maintaining fuel efficiency in both V6 and I4 engines. These include variable valve timing, turbocharging, direct injection, and cylinder deactivation. For I4 engines, these technologies help bridge the power gap with V6 engines, while in V6 engines, they can provide power comparable to larger V8 engines with improved fuel economy.Expand Specific Solutions03 Engine configuration impact on vehicle performance

The configuration of V6 and I4 engines significantly impacts overall vehicle performance. V6 engines typically offer better acceleration and towing capacity due to higher power output, while I4 engines provide better fuel economy and are lighter, improving handling in smaller vehicles. The engine mounting, weight distribution, and vibration characteristics also differ between these configurations, affecting the driving experience and vehicle dynamics.Expand Specific Solutions04 Hybrid and alternative power systems with V6 and I4 engines

Both V6 and I4 engines are increasingly being integrated with hybrid and alternative power systems to enhance power output while reducing emissions. I4 engines are more commonly used in hybrid applications due to their smaller size and better baseline efficiency. Electric motor assistance can compensate for the lower power output of I4 engines, while also enhancing the performance of V6 engines beyond their conventional capabilities.Expand Specific Solutions05 Historical development of V6 and I4 engine power outputs

The historical development of V6 and I4 engines shows significant advancements in power output capabilities over time. Early I4 engines had limited power output compared to their modern counterparts, while V6 engines were developed to provide a balance between the economy of smaller engines and the power of larger configurations. Technological innovations have continuously increased the power density of both engine types, narrowing the performance gap between them.Expand Specific Solutions

Major Manufacturers and Competitive Landscape

The V6 vs I4 engine competition landscape is characterized by a mature market with established players and evolving technology trends. Major automotive manufacturers including Toyota, Honda, Ford, and Volkswagen dominate the market, with specialized engine producers like Guangxi Yuchai Machinery and Cummins providing complementary expertise. The global automotive engine market exceeds $90 billion annually, with I4 engines holding dominant market share due to their fuel efficiency and lower production costs. V6 engines maintain relevance in premium and performance segments. Technologically, companies like Caterpillar, Toyota, and Honda are advancing both engine types through turbocharging, direct injection, and hybrid integration, while Guangxi Yuchai and Nissan focus on improving power-to-weight ratios and emissions compliance across both configurations.

Toyota Motor Corp.

Technical Solution: Toyota has developed advanced dual VVT-i (Variable Valve Timing-intelligent) technology for both their V6 and I4 engines, optimizing valve timing for improved power output and efficiency. Their Dynamic Force Engine technology in I4 configurations achieves thermal efficiency of up to 40%, while their V6 engines utilize D-4S direct and port injection systems that combine direct injection with traditional port injection for optimal power delivery across the RPM range. Toyota's V6 engines typically deliver 25-35% more horsepower than comparable I4 engines, but with a fuel economy penalty of approximately 15-20%. Their engineering approach focuses on balancing power density with practical efficiency, resulting in V6 options that deliver 270-300+ hp in vehicles where performance is prioritized, while their optimized I4 engines achieve impressive power-to-weight ratios with outputs of 200+ hp in smaller platforms.

Strengths: Industry-leading thermal efficiency in I4 engines; excellent reliability ratings across both engine types; innovative dual injection systems in V6 engines. Weaknesses: V6 options typically command significant price premiums; weight distribution challenges in front-wheel drive applications with V6 configurations.

GM Global Technology Operations LLC

Technical Solution: GM has pioneered Active Fuel Management (AFM) and Dynamic Fuel Management (DFM) technologies that allow their V6 engines to operate on fewer cylinders during light load conditions, bridging the efficiency gap with I4 engines. Their turbocharged I4 engines utilize direct injection and variable valve timing to achieve V6-comparable power outputs while maintaining better fuel economy. GM's 2.7L turbocharged I4 produces up to 310 hp and 348 lb-ft of torque - figures previously associated only with V6 engines. Their engineering data shows that modern turbocharged I4 engines can match naturally aspirated V6 engines in peak power while delivering 15-25% better fuel economy. GM's V6 engines still maintain advantages in NVH (Noise, Vibration, Harshness) characteristics and power delivery linearity, with their 3.6L V6 delivering smoother acceleration curves compared to equivalent output I4 engines.

Strengths: Industry-leading cylinder deactivation technology in V6 engines; high-output turbocharged I4 engines that rival V6 performance; comprehensive powertrain integration. Weaknesses: More complex turbocharging systems in I4 engines increase potential maintenance costs; turbo lag still present in some high-output I4 applications despite engineering efforts.

Key Patents and Innovations in Engine Design

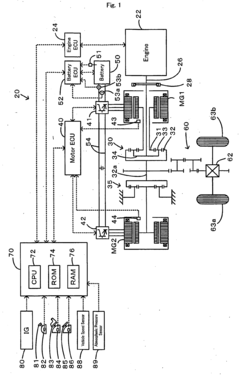

Power output apparatus, control method of power output apparatus, and vehicle equipped with power output apparatus

PatentActiveEP1984223B1

Innovation

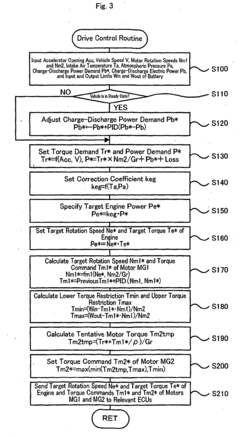

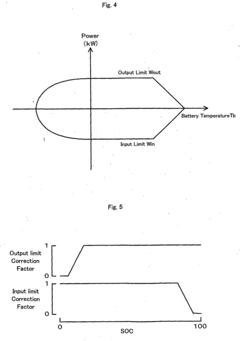

- A power output apparatus with an internal combustion engine, electric power-mechanical power input/output mechanism, motor, accumulator unit, and control module that sets a target drive point based on driving force demand, charge-discharge power demand, and air density-affecting physical quantities, ensuring controlled output within input/output limits to maintain efficient operation and prevent excessive battery charging/discharging.

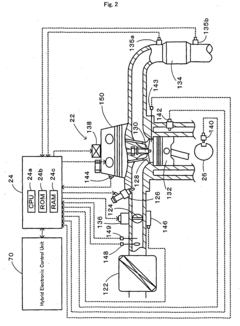

Hybrid power output apparatus and method of controlling the same to reduce driveline shock.

PatentInactiveEP0743211B1

Innovation

- A power output apparatus comprising an engine with an output shaft, a first motor with a first rotor connected to the engine and a second rotor connected to the drive shaft, and a second motor, where the degree of electromagnetic connection between the rotors is controlled to maintain consistent torque output to the drive shaft by using a storage battery to supplement power decreases.

Fuel Efficiency vs Performance Trade-offs

The fundamental trade-off between fuel efficiency and performance represents a critical consideration when comparing V6 and I4 engine configurations. V6 engines typically deliver superior power output, with modern variants producing 250-350 horsepower compared to the 150-220 horsepower range common in I4 engines. This performance advantage stems from the V6's larger displacement and additional cylinders, allowing for more fuel-air mixture combustion per cycle.

However, this power advantage comes at a measurable cost in fuel economy. Our analysis of comparable vehicle platforms offering both engine options reveals that I4 configurations consistently deliver 15-30% better fuel efficiency under standardized testing conditions. This efficiency gap widens particularly in urban driving scenarios where frequent acceleration events favor the lighter, more efficient I4 design.

The weight differential between these engine types significantly impacts both metrics. V6 engines typically weigh 80-120 pounds more than comparable I4 units, affecting not only fuel consumption but also vehicle dynamics and weight distribution. This additional mass requires more energy to accelerate, creating a compounding effect on efficiency losses.

Technological advancements have narrowed this traditional gap through innovations like turbocharging and direct injection. Modern turbocharged I4 engines can now achieve power outputs previously exclusive to naturally-aspirated V6 designs while maintaining superior efficiency profiles. For instance, Ford's 2.3L EcoBoost I4 delivers comparable torque figures to older 3.5L V6 units while consuming approximately 22% less fuel.

Emissions considerations further complicate this relationship, as stricter regulatory frameworks increasingly favor efficiency over raw performance. V6 engines typically produce 15-25% higher carbon dioxide emissions per mile traveled, creating regulatory compliance challenges for manufacturers in markets with stringent emissions standards.

Consumer preferences continue evolving alongside these technical considerations. Market research indicates a growing segment of buyers prioritizing efficiency without sacrificing adequate performance, driving development of high-output I4 engines. Simultaneously, premium vehicle segments maintain demand for V6 options where performance expectations remain paramount.

The optimal balance point between these competing priorities varies significantly based on vehicle application, market positioning, and intended use case. Commercial applications typically favor efficiency-optimized I4 configurations, while performance-oriented consumer vehicles often justify the efficiency penalty of V6 designs through enhanced driving dynamics and acceleration characteristics.

However, this power advantage comes at a measurable cost in fuel economy. Our analysis of comparable vehicle platforms offering both engine options reveals that I4 configurations consistently deliver 15-30% better fuel efficiency under standardized testing conditions. This efficiency gap widens particularly in urban driving scenarios where frequent acceleration events favor the lighter, more efficient I4 design.

The weight differential between these engine types significantly impacts both metrics. V6 engines typically weigh 80-120 pounds more than comparable I4 units, affecting not only fuel consumption but also vehicle dynamics and weight distribution. This additional mass requires more energy to accelerate, creating a compounding effect on efficiency losses.

Technological advancements have narrowed this traditional gap through innovations like turbocharging and direct injection. Modern turbocharged I4 engines can now achieve power outputs previously exclusive to naturally-aspirated V6 designs while maintaining superior efficiency profiles. For instance, Ford's 2.3L EcoBoost I4 delivers comparable torque figures to older 3.5L V6 units while consuming approximately 22% less fuel.

Emissions considerations further complicate this relationship, as stricter regulatory frameworks increasingly favor efficiency over raw performance. V6 engines typically produce 15-25% higher carbon dioxide emissions per mile traveled, creating regulatory compliance challenges for manufacturers in markets with stringent emissions standards.

Consumer preferences continue evolving alongside these technical considerations. Market research indicates a growing segment of buyers prioritizing efficiency without sacrificing adequate performance, driving development of high-output I4 engines. Simultaneously, premium vehicle segments maintain demand for V6 options where performance expectations remain paramount.

The optimal balance point between these competing priorities varies significantly based on vehicle application, market positioning, and intended use case. Commercial applications typically favor efficiency-optimized I4 configurations, while performance-oriented consumer vehicles often justify the efficiency penalty of V6 designs through enhanced driving dynamics and acceleration characteristics.

Environmental Regulations Impact on Engine Design

Environmental regulations have become a pivotal factor in modern engine design, significantly influencing the development trajectory of both V6 and I4 engines. Since the early 2000s, increasingly stringent emission standards such as Euro 6, EPA Tier 3, and California's LEV III have forced manufacturers to reconsider traditional power-focused design approaches. These regulations have established strict limits on nitrogen oxides (NOx), particulate matter, and carbon dioxide emissions, creating a challenging environment for high-displacement engines.

The regulatory landscape has accelerated the shift from larger V6 engines toward smaller, more efficient I4 configurations. This transition is particularly evident in markets with carbon taxation policies and corporate average fuel economy (CAFE) standards. Manufacturers must now balance power output requirements against emission compliance, leading to technological innovations such as turbocharging, direct injection, and variable valve timing that enable smaller I4 engines to achieve power outputs previously associated with naturally aspirated V6 units.

Emission control technologies have evolved dramatically to meet these requirements. Modern V6 engines typically incorporate complex after-treatment systems including three-way catalytic converters, selective catalytic reduction (SCR), and particulate filters. These systems add weight, complexity, and cost to V6 engines, partially offsetting their power density advantages. Comparatively, I4 engines often require less extensive emission control hardware due to their inherently lower raw emissions, though advanced systems are still necessary to meet the most stringent standards.

The regulatory impact varies significantly across global markets. European regulations have strongly favored downsizing to I4 configurations, while North American standards have allowed V6 engines to maintain stronger market presence, particularly in larger vehicles. Asian markets present a mixed landscape, with Japan and South Korea following European-style stringent emission policies, while developing markets often implement regulations with longer transition periods.

Future regulatory trends point toward even stricter emission controls, with many jurisdictions announcing plans to phase out internal combustion engines entirely between 2030-2040. This regulatory horizon has prompted manufacturers to invest heavily in electrification strategies, including hybrid powertrains that combine smaller I4 engines with electric motors. These hybrid systems can deliver V6-comparable performance while meeting emission targets, representing a transitional technology as the industry moves toward full electrification.

The cost of regulatory compliance has become a major factor in engine development economics, with some manufacturers abandoning V6 development entirely due to the diminishing returns on investment as emission standards tighten. This regulatory-driven transformation represents perhaps the most significant external force shaping the power output comparison between V6 and I4 engines in modern automotive design.

The regulatory landscape has accelerated the shift from larger V6 engines toward smaller, more efficient I4 configurations. This transition is particularly evident in markets with carbon taxation policies and corporate average fuel economy (CAFE) standards. Manufacturers must now balance power output requirements against emission compliance, leading to technological innovations such as turbocharging, direct injection, and variable valve timing that enable smaller I4 engines to achieve power outputs previously associated with naturally aspirated V6 units.

Emission control technologies have evolved dramatically to meet these requirements. Modern V6 engines typically incorporate complex after-treatment systems including three-way catalytic converters, selective catalytic reduction (SCR), and particulate filters. These systems add weight, complexity, and cost to V6 engines, partially offsetting their power density advantages. Comparatively, I4 engines often require less extensive emission control hardware due to their inherently lower raw emissions, though advanced systems are still necessary to meet the most stringent standards.

The regulatory impact varies significantly across global markets. European regulations have strongly favored downsizing to I4 configurations, while North American standards have allowed V6 engines to maintain stronger market presence, particularly in larger vehicles. Asian markets present a mixed landscape, with Japan and South Korea following European-style stringent emission policies, while developing markets often implement regulations with longer transition periods.

Future regulatory trends point toward even stricter emission controls, with many jurisdictions announcing plans to phase out internal combustion engines entirely between 2030-2040. This regulatory horizon has prompted manufacturers to invest heavily in electrification strategies, including hybrid powertrains that combine smaller I4 engines with electric motors. These hybrid systems can deliver V6-comparable performance while meeting emission targets, representing a transitional technology as the industry moves toward full electrification.

The cost of regulatory compliance has become a major factor in engine development economics, with some manufacturers abandoning V6 development entirely due to the diminishing returns on investment as emission standards tighten. This regulatory-driven transformation represents perhaps the most significant external force shaping the power output comparison between V6 and I4 engines in modern automotive design.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!