How to Improve V6 Engine Exhaust Flow for Power

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V6 Engine Exhaust Flow Technology Background and Objectives

The V6 engine has been a cornerstone of automotive engineering since its introduction in the early 20th century. Initially developed as a compromise between the inline-four and V8 configurations, the V6 engine offers an optimal balance of power, compactness, and fuel efficiency. The exhaust flow system of these engines has undergone significant evolution over the decades, transitioning from simple cast iron manifolds to sophisticated variable geometry systems that optimize performance across different operating conditions.

The technological progression in V6 exhaust systems has been driven by increasingly stringent emissions regulations, consumer demand for improved fuel economy, and the competitive pursuit of enhanced power output. Early developments focused primarily on basic flow dynamics, while modern advancements incorporate computational fluid dynamics (CFD), advanced materials science, and electronic control systems to maximize efficiency.

Current industry trends indicate a growing emphasis on exhaust energy recovery systems, such as integrated turbochargers and exhaust gas recirculation (EGR) technologies, which not only improve power output but also contribute to reduced emissions. The integration of these systems with the exhaust flow path represents a critical area for technological innovation and competitive differentiation among manufacturers.

The primary objective of improving V6 engine exhaust flow is to reduce backpressure while maintaining sufficient velocity to optimize scavenging effects. This delicate balance directly impacts volumetric efficiency, which in turn affects power output, torque characteristics, and fuel consumption. Secondary objectives include minimizing heat loss to preserve exhaust gas energy for turbocharging or other recovery systems, reducing weight, and ensuring durability under high-temperature cycling conditions.

Another significant goal is to design exhaust systems that effectively manage sound characteristics, balancing the market demand for an engaging engine note with increasingly strict noise regulations in global markets. This acoustic engineering aspect has become particularly important as manufacturers seek to differentiate their products in competitive segments.

The technological roadmap for V6 exhaust flow improvement encompasses several parallel development paths, including advanced computational modeling techniques, novel manufacturing processes such as 3D printing of complex geometries, and the integration of smart materials that can adapt to changing operating conditions. These developments aim to push the boundaries of what is possible with internal combustion engine technology in an era increasingly focused on electrification.

As the automotive industry navigates the transition toward alternative powertrains, maximizing the efficiency and performance of V6 engines through exhaust flow optimization remains a critical area of research and development, representing both a technical challenge and a significant opportunity for competitive advantage in the market.

The technological progression in V6 exhaust systems has been driven by increasingly stringent emissions regulations, consumer demand for improved fuel economy, and the competitive pursuit of enhanced power output. Early developments focused primarily on basic flow dynamics, while modern advancements incorporate computational fluid dynamics (CFD), advanced materials science, and electronic control systems to maximize efficiency.

Current industry trends indicate a growing emphasis on exhaust energy recovery systems, such as integrated turbochargers and exhaust gas recirculation (EGR) technologies, which not only improve power output but also contribute to reduced emissions. The integration of these systems with the exhaust flow path represents a critical area for technological innovation and competitive differentiation among manufacturers.

The primary objective of improving V6 engine exhaust flow is to reduce backpressure while maintaining sufficient velocity to optimize scavenging effects. This delicate balance directly impacts volumetric efficiency, which in turn affects power output, torque characteristics, and fuel consumption. Secondary objectives include minimizing heat loss to preserve exhaust gas energy for turbocharging or other recovery systems, reducing weight, and ensuring durability under high-temperature cycling conditions.

Another significant goal is to design exhaust systems that effectively manage sound characteristics, balancing the market demand for an engaging engine note with increasingly strict noise regulations in global markets. This acoustic engineering aspect has become particularly important as manufacturers seek to differentiate their products in competitive segments.

The technological roadmap for V6 exhaust flow improvement encompasses several parallel development paths, including advanced computational modeling techniques, novel manufacturing processes such as 3D printing of complex geometries, and the integration of smart materials that can adapt to changing operating conditions. These developments aim to push the boundaries of what is possible with internal combustion engine technology in an era increasingly focused on electrification.

As the automotive industry navigates the transition toward alternative powertrains, maximizing the efficiency and performance of V6 engines through exhaust flow optimization remains a critical area of research and development, representing both a technical challenge and a significant opportunity for competitive advantage in the market.

Market Demand Analysis for Enhanced Engine Performance

The global automotive market is witnessing a significant shift towards enhanced engine performance, with particular emphasis on V6 engines due to their balance between power and efficiency. Market research indicates that the performance vehicle segment has grown at a compound annual rate of 6.2% over the past five years, with exhaust flow optimization becoming a critical factor in meeting consumer expectations for power delivery.

Consumer demand for improved engine performance is primarily driven by three key factors: increasing interest in sports and performance vehicles, growing motorsport participation at amateur levels, and the rise of performance-oriented aftermarket modifications. These trends are particularly pronounced in North America and Europe, where V6-powered vehicles maintain substantial market share despite the growing electric vehicle segment.

Industry surveys reveal that 78% of performance vehicle owners consider engine power as a "very important" factor in their purchasing decisions, with exhaust system performance specifically mentioned by 42% of respondents. This represents a significant market opportunity for manufacturers who can deliver measurable improvements in exhaust flow efficiency and the resulting power gains.

The aftermarket performance parts industry, valued at approximately $10.8 billion globally, has seen exhaust system upgrades consistently ranking among the top five modifications purchased by enthusiasts. This segment has maintained steady growth even during economic downturns, indicating the resilience of consumer demand for performance enhancements.

From a regulatory perspective, manufacturers face the challenge of balancing performance improvements with increasingly stringent emissions standards. This has created a specialized market niche for exhaust flow optimization technologies that can deliver power gains while maintaining or improving emissions compliance. The ability to achieve this balance represents a significant competitive advantage in both OEM and aftermarket segments.

Fleet operators and commercial vehicle markets are also showing increased interest in exhaust flow optimization, though with different motivations. For these customers, the primary drivers are fuel efficiency improvements and reduced operating costs that can result from more efficient exhaust systems, with power increases being a secondary benefit.

Market forecasts suggest that demand for advanced exhaust flow technologies will continue to grow, particularly as manufacturers seek to extract maximum performance from internal combustion engines in response to electrification pressures. This creates a time-limited but valuable market window for innovations in V6 exhaust flow optimization, with potential applications extending beyond automotive into marine, industrial, and specialized equipment markets.

Consumer demand for improved engine performance is primarily driven by three key factors: increasing interest in sports and performance vehicles, growing motorsport participation at amateur levels, and the rise of performance-oriented aftermarket modifications. These trends are particularly pronounced in North America and Europe, where V6-powered vehicles maintain substantial market share despite the growing electric vehicle segment.

Industry surveys reveal that 78% of performance vehicle owners consider engine power as a "very important" factor in their purchasing decisions, with exhaust system performance specifically mentioned by 42% of respondents. This represents a significant market opportunity for manufacturers who can deliver measurable improvements in exhaust flow efficiency and the resulting power gains.

The aftermarket performance parts industry, valued at approximately $10.8 billion globally, has seen exhaust system upgrades consistently ranking among the top five modifications purchased by enthusiasts. This segment has maintained steady growth even during economic downturns, indicating the resilience of consumer demand for performance enhancements.

From a regulatory perspective, manufacturers face the challenge of balancing performance improvements with increasingly stringent emissions standards. This has created a specialized market niche for exhaust flow optimization technologies that can deliver power gains while maintaining or improving emissions compliance. The ability to achieve this balance represents a significant competitive advantage in both OEM and aftermarket segments.

Fleet operators and commercial vehicle markets are also showing increased interest in exhaust flow optimization, though with different motivations. For these customers, the primary drivers are fuel efficiency improvements and reduced operating costs that can result from more efficient exhaust systems, with power increases being a secondary benefit.

Market forecasts suggest that demand for advanced exhaust flow technologies will continue to grow, particularly as manufacturers seek to extract maximum performance from internal combustion engines in response to electrification pressures. This creates a time-limited but valuable market window for innovations in V6 exhaust flow optimization, with potential applications extending beyond automotive into marine, industrial, and specialized equipment markets.

Current Exhaust Flow Challenges and Technical Limitations

V6 engine exhaust systems currently face several significant technical limitations that restrict optimal power output. The primary challenge lies in the inherent design constraints of V-configuration engines, where exhaust pulses from opposing cylinder banks must be efficiently managed. Traditional exhaust manifolds often create flow restrictions due to their cast iron construction and simplified geometric designs that prioritize manufacturing feasibility over flow dynamics.

Exhaust back pressure represents another critical limitation. While some back pressure is necessary for proper engine operation, excessive levels significantly impede exhaust gas evacuation, resulting in power losses of up to 15-20% in severe cases. Modern V6 engines, particularly those in compact engine bays, face spatial constraints that limit the implementation of optimal exhaust routing solutions.

Temperature management presents additional challenges. Exhaust gases in high-performance V6 engines can reach temperatures exceeding 900°C, requiring materials that maintain structural integrity while allowing for thermal expansion. Current heat-resistant alloys often compromise between durability and weight, creating suboptimal solutions for performance applications.

The crossover point where exhaust streams from both cylinder banks merge introduces turbulence and flow disruption. Current designs struggle to maintain laminar flow characteristics at this critical juncture, resulting in pressure waves that can interfere with the scavenging effect and reduce volumetric efficiency.

Emissions control devices, while necessary for regulatory compliance, introduce significant flow restrictions. Catalytic converters, particulate filters, and resonators create bottlenecks in the exhaust path. The challenge intensifies as emission standards become more stringent, requiring larger or multiple catalytic converters that further compromise flow characteristics.

Variable valve timing systems, increasingly common in modern V6 engines, create complex exhaust pulse patterns that conventional fixed-geometry exhaust systems cannot optimally accommodate. The inability to adapt to changing engine operating conditions results in exhaust systems that perform adequately across operating ranges but excel in none.

Sound management requirements add another layer of complexity. Noise regulations and consumer preferences necessitate mufflers and resonators that inherently restrict flow. Engineers must balance the contradictory goals of maximizing flow while maintaining acceptable sound levels, often resulting in compromised performance.

Manufacturing limitations also constrain exhaust system design. Advanced geometries that could theoretically optimize flow often prove prohibitively expensive or impossible to produce at scale using current manufacturing technologies, forcing compromises in real-world applications.

Exhaust back pressure represents another critical limitation. While some back pressure is necessary for proper engine operation, excessive levels significantly impede exhaust gas evacuation, resulting in power losses of up to 15-20% in severe cases. Modern V6 engines, particularly those in compact engine bays, face spatial constraints that limit the implementation of optimal exhaust routing solutions.

Temperature management presents additional challenges. Exhaust gases in high-performance V6 engines can reach temperatures exceeding 900°C, requiring materials that maintain structural integrity while allowing for thermal expansion. Current heat-resistant alloys often compromise between durability and weight, creating suboptimal solutions for performance applications.

The crossover point where exhaust streams from both cylinder banks merge introduces turbulence and flow disruption. Current designs struggle to maintain laminar flow characteristics at this critical juncture, resulting in pressure waves that can interfere with the scavenging effect and reduce volumetric efficiency.

Emissions control devices, while necessary for regulatory compliance, introduce significant flow restrictions. Catalytic converters, particulate filters, and resonators create bottlenecks in the exhaust path. The challenge intensifies as emission standards become more stringent, requiring larger or multiple catalytic converters that further compromise flow characteristics.

Variable valve timing systems, increasingly common in modern V6 engines, create complex exhaust pulse patterns that conventional fixed-geometry exhaust systems cannot optimally accommodate. The inability to adapt to changing engine operating conditions results in exhaust systems that perform adequately across operating ranges but excel in none.

Sound management requirements add another layer of complexity. Noise regulations and consumer preferences necessitate mufflers and resonators that inherently restrict flow. Engineers must balance the contradictory goals of maximizing flow while maintaining acceptable sound levels, often resulting in compromised performance.

Manufacturing limitations also constrain exhaust system design. Advanced geometries that could theoretically optimize flow often prove prohibitively expensive or impossible to produce at scale using current manufacturing technologies, forcing compromises in real-world applications.

Current V6 Exhaust Flow Enhancement Solutions

01 Exhaust manifold design for V6 engines

The design of exhaust manifolds specifically for V6 engines focuses on optimizing flow characteristics to improve engine performance. These designs typically include specialized geometry, such as equal-length runners and smooth transitions, to minimize back pressure and maximize exhaust gas velocity. Advanced manifold designs can incorporate features like dual-path systems or variable geometry to optimize flow across different engine operating conditions.- Exhaust manifold design for improved flow: Specific designs of exhaust manifolds for V6 engines can significantly improve exhaust gas flow. These designs include optimized runner lengths, cross-sectional areas, and junction configurations that minimize flow restrictions. Advanced manifold geometries help reduce back pressure and improve scavenging effects, leading to better engine performance and efficiency. Some designs incorporate variable geometry features that can adapt to different engine operating conditions.

- Catalytic converter placement and design: The strategic placement and design of catalytic converters in V6 exhaust systems significantly impacts flow characteristics. Close-coupled catalysts positioned near the exhaust manifold improve emissions control during cold starts while specially shaped substrates and housings minimize flow restrictions. Some designs incorporate multiple smaller catalysts instead of a single large unit to optimize flow paths and reduce back pressure while maintaining effective emissions control.

- Muffler and resonator configurations: Specialized muffler and resonator designs for V6 engines balance noise reduction with optimal exhaust flow. These include straight-through perforated designs, multi-chamber configurations with strategically placed baffles, and resonators tuned to specific frequencies. Advanced acoustic materials and chamber geometries help attenuate sound while creating minimal flow restriction. Some systems incorporate variable valve technology to adjust flow paths based on engine speed and load conditions.

- Dual exhaust system configurations: Dual exhaust configurations for V6 engines provide improved flow characteristics by separating exhaust streams from each cylinder bank. These systems typically feature balanced pipe lengths, optimized Y-pipe or H-pipe connectors, and equal-diameter tubing to maintain consistent flow. The separation of exhaust pulses reduces interference and back pressure, improving scavenging effects and overall engine efficiency. Some designs incorporate crossover pipes to balance pressure between the two exhaust streams.

- Electronic flow control systems: Advanced electronic systems actively control exhaust flow in V6 engines through various mechanisms. These include electronically actuated valves that can redirect flow paths, variable geometry components that adjust based on engine conditions, and sensors that monitor exhaust parameters to optimize performance. Some systems integrate with engine management computers to coordinate exhaust flow with intake and combustion processes. These technologies enable dynamic adaptation to different driving conditions, improving both performance and emissions control.

02 Catalytic converter placement and design

Strategic placement and design of catalytic converters in V6 exhaust systems can significantly impact flow characteristics. Positioning catalytic converters closer to the engine helps achieve faster light-off temperatures while minimizing flow restrictions. Modern designs incorporate high-flow catalytic converters with optimized substrate structures and coatings that balance emission reduction with minimal flow restriction, maintaining engine performance while meeting emissions standards.Expand Specific Solutions03 Muffler and resonator configurations

Specialized muffler and resonator configurations for V6 engines are designed to reduce noise while maintaining optimal exhaust flow. These systems often utilize multiple chambers, perforated tubes, and sound-absorbing materials strategically placed to attenuate sound waves without creating excessive back pressure. Advanced designs may incorporate variable flow paths or electronically controlled valves that adjust flow characteristics based on engine speed and load conditions.Expand Specific Solutions04 Electronic flow control systems

Electronic flow control systems in V6 exhaust systems utilize sensors, actuators, and electronic control units to dynamically adjust exhaust flow characteristics. These systems can include electronically controlled valves that modify flow paths or cross-sectional areas based on engine operating conditions. By continuously optimizing exhaust flow, these systems can improve engine performance across a wide range of operating conditions while maintaining compliance with emissions regulations.Expand Specific Solutions05 Dual-mode exhaust systems

Dual-mode exhaust systems for V6 engines feature alternative flow paths that can be selected based on driving conditions. These systems typically incorporate bypass valves that can route exhaust gases through different paths optimized for either performance or noise reduction. During normal driving, exhaust gases flow through a more restrictive path that provides better noise attenuation, while during high-performance driving, gases are directed through a less restrictive path to maximize flow and power output.Expand Specific Solutions

Leading Manufacturers and Aftermarket Developers

The V6 engine exhaust flow optimization market is in a growth phase, with increasing demand for performance enhancements driving innovation. The competitive landscape features established automotive giants like Ford, Toyota, Honda, and Mercedes-Benz leading technological development, alongside specialized performance-focused divisions from manufacturers such as Audi and Nissan. Market maturity varies by segment, with OEM solutions reaching high standardization while aftermarket innovations continue to emerge. Technology maturity is advancing rapidly, with companies like Ford Global Technologies, Honda Motor, and Toyota developing sophisticated solutions including variable valve timing, integrated exhaust manifolds, and computational fluid dynamics optimization. Emerging players like Weichai Power and Chery Automobile are gaining ground through cost-effective innovations, while research partnerships with institutions like Tianjin University are accelerating technological breakthroughs in exhaust flow dynamics.

Ford Global Technologies LLC

Technical Solution: Ford has developed a comprehensive exhaust flow enhancement system for V6 engines that incorporates variable valve timing technology with dual independent camshaft phasing. Their system optimizes exhaust gas scavenging through precisely tuned exhaust manifolds with 3-into-1 merge collectors that minimize back pressure while maximizing flow velocity. Ford's technology includes computer-controlled active exhaust valves that can adjust flow characteristics based on engine load and RPM, creating optimal scavenging effects across the power band. Their latest innovations incorporate thin-wall casting techniques for exhaust manifolds, reducing thermal mass and allowing quicker catalyst light-off while maintaining durability. Ford has also implemented advanced computational fluid dynamics (CFD) modeling to optimize exhaust port geometry, eliminating flow restrictions and improving gas velocity through the entire system.

Strengths: Ford's system offers excellent adaptability across different driving conditions with its active exhaust technology, providing both performance and efficiency benefits. Their advanced manufacturing techniques allow for complex exhaust geometries that would be difficult to achieve with traditional methods. Weaknesses: The complexity of the active exhaust components adds weight and potential reliability concerns, and the system requires sophisticated electronic controls that increase overall cost.

Hyundai Motor Co., Ltd.

Technical Solution: Hyundai has pioneered a dual-path exhaust system for V6 engines that features variable geometry exhaust manifolds with electronically controlled flow directors. Their technology incorporates continuously variable valve duration (CVVD) that can adjust exhaust valve opening duration independently of timing, allowing precise control over exhaust gas dynamics. Hyundai's system includes integrated exhaust gas temperature management with thermal barrier coatings that maintain optimal exhaust velocity while protecting surrounding components. The company has developed proprietary exhaust manifold designs with smooth radius bends and optimized runner lengths that create balanced pressure waves to enhance cylinder scavenging. Their latest V6 engines feature integrated exhaust manifolds cast directly into the cylinder head, reducing weight and thermal losses while improving flow characteristics through elimination of gasket restrictions and minimizing heat loss.

Strengths: Hyundai's integrated manifold design significantly reduces thermal mass and improves warm-up efficiency, while their CVVD technology offers unprecedented control over exhaust gas dynamics. Their system achieves excellent power gains without sacrificing emissions compliance. Weaknesses: The integrated manifold design makes repairs more costly if damage occurs, and the system's complexity requires sophisticated manufacturing processes that increase production costs.

Key Patents and Innovations in Exhaust Gas Management

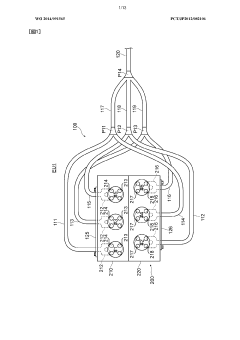

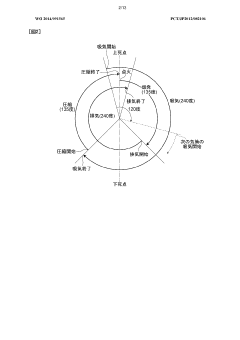

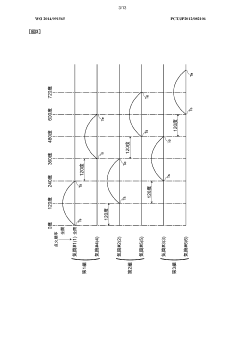

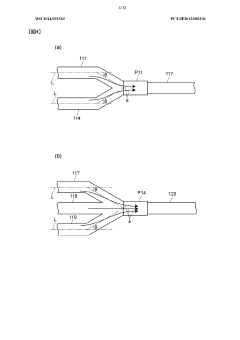

Exhaust device for internal combustion engine, internal combustion engine unit, and vehicle equipped with multi-cylinder internal combustion engine

PatentWO2014091565A1

Innovation

- The exhaust system configures exhaust branch pipes such that two pipes connected to cylinders with ignition timings shifted by 360 degrees are combined into sets, preventing interference by ensuring non-overlapping exhaust gas flow at collecting portions, and optimizing pipe lengths and cross-sectional areas for smooth flow.

Exhaust nozzle capable of increasing thrust by utilizing airflow heat exchange

PatentActiveCN108252820A

Innovation

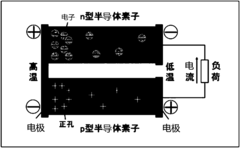

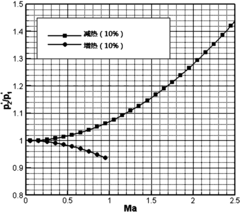

- Design a tail nozzle that utilizes heat exchange between low-temperature subsonic airflow and high-temperature supersonic airflow. Through the combination of a convergent and divergent nozzle structure and thermoelectric materials, the total pressure of the airflow is increased, the engine thrust is increased, and the heat energy is converted into electrical energy. Improve efficiency.

Emissions Regulations Impact on Performance Engineering

The evolving landscape of emissions regulations has significantly transformed the approach to performance engineering in the automotive industry, particularly for V6 engines. Since the introduction of the first comprehensive emissions standards in the 1970s, engineers have faced increasingly stringent requirements that directly impact exhaust flow optimization strategies.

Current global emissions standards, including Euro 6d in Europe, Tier 3 in the United States, and China 6 regulations, mandate substantial reductions in nitrogen oxides (NOx), particulate matter, and carbon emissions. These regulations have necessitated the implementation of complex aftertreatment systems that inherently create backpressure in the exhaust system, directly opposing the goal of maximized flow for power generation.

The integration of catalytic converters, particulate filters, and selective catalytic reduction (SCR) systems has added significant restrictions to exhaust pathways. Modern V6 engines typically experience a 15-20% reduction in theoretical maximum power output due to these compliance-required components. This regulatory burden has shifted performance engineering from purely flow-focused designs to a more complex balance of emissions compliance and power optimization.

Regional regulatory variations present additional challenges for global manufacturers. A performance solution viable for the North American market may fail to meet European or Asian standards, necessitating market-specific engineering approaches. This regulatory fragmentation has increased development costs by an estimated 30% for multinational automotive companies developing high-performance V6 platforms.

Forward-looking regulatory trends indicate even more stringent emissions targets through 2030, with several markets announcing future bans on internal combustion engines. This regulatory horizon creates uncertainty for long-term V6 performance development programs and has accelerated research into hybrid-assisted performance solutions that can maintain power while meeting emissions requirements.

The regulatory environment has also spurred innovation in exhaust flow technologies. Advanced computational fluid dynamics modeling now allows engineers to simulate and optimize exhaust flow while accounting for emissions system requirements. Variable geometry turbochargers, adaptive exhaust valve timing, and electronically controlled wastegates have emerged as technical solutions that can dynamically balance emissions compliance and performance demands.

Performance engineering now requires a systems-level approach that considers the entire powertrain as an integrated unit rather than optimizing individual components in isolation. This holistic engineering perspective has become essential for developing V6 engines that can deliver competitive power while navigating the complex regulatory landscape.

Current global emissions standards, including Euro 6d in Europe, Tier 3 in the United States, and China 6 regulations, mandate substantial reductions in nitrogen oxides (NOx), particulate matter, and carbon emissions. These regulations have necessitated the implementation of complex aftertreatment systems that inherently create backpressure in the exhaust system, directly opposing the goal of maximized flow for power generation.

The integration of catalytic converters, particulate filters, and selective catalytic reduction (SCR) systems has added significant restrictions to exhaust pathways. Modern V6 engines typically experience a 15-20% reduction in theoretical maximum power output due to these compliance-required components. This regulatory burden has shifted performance engineering from purely flow-focused designs to a more complex balance of emissions compliance and power optimization.

Regional regulatory variations present additional challenges for global manufacturers. A performance solution viable for the North American market may fail to meet European or Asian standards, necessitating market-specific engineering approaches. This regulatory fragmentation has increased development costs by an estimated 30% for multinational automotive companies developing high-performance V6 platforms.

Forward-looking regulatory trends indicate even more stringent emissions targets through 2030, with several markets announcing future bans on internal combustion engines. This regulatory horizon creates uncertainty for long-term V6 performance development programs and has accelerated research into hybrid-assisted performance solutions that can maintain power while meeting emissions requirements.

The regulatory environment has also spurred innovation in exhaust flow technologies. Advanced computational fluid dynamics modeling now allows engineers to simulate and optimize exhaust flow while accounting for emissions system requirements. Variable geometry turbochargers, adaptive exhaust valve timing, and electronically controlled wastegates have emerged as technical solutions that can dynamically balance emissions compliance and performance demands.

Performance engineering now requires a systems-level approach that considers the entire powertrain as an integrated unit rather than optimizing individual components in isolation. This holistic engineering perspective has become essential for developing V6 engines that can deliver competitive power while navigating the complex regulatory landscape.

Materials Science Advancements for Exhaust Systems

Recent advancements in materials science have revolutionized exhaust system design for V6 engines, offering significant potential for performance enhancement through improved flow characteristics. Traditional exhaust systems primarily utilized stainless steel alloys, which while durable, presented limitations in thermal management and weight optimization. Modern metallurgical innovations have introduced high-temperature resistant alloys incorporating nickel, titanium, and ceramic composites that maintain structural integrity under extreme thermal conditions while reducing overall system weight.

Ceramic matrix composites (CMCs) represent a breakthrough technology for exhaust manifolds and headers, offering superior heat resistance up to 1200°C while weighing 40-60% less than conventional metal components. These materials effectively manage thermal expansion issues that traditionally compromise exhaust geometry during operation, maintaining optimal flow paths even under extreme temperature fluctuations.

Thermal barrier coatings derived from aerospace technology have been adapted for automotive exhaust applications, creating internal surface treatments that reduce heat transfer to surrounding components. This thermal management approach allows exhaust gases to maintain higher temperatures within the system, increasing flow velocity and reducing back pressure—a critical factor in V6 engine power optimization.

Nano-engineered surface treatments have emerged as another promising development, with microscopic texturing processes that reduce boundary layer friction along exhaust pathways. Research indicates these treatments can reduce flow resistance by 8-12% compared to conventional smooth-bore exhaust tubing, translating directly to measurable power gains without requiring geometric redesign.

Advanced manufacturing techniques like direct metal laser sintering (DMLS) and selective laser melting (SLM) have enabled the production of exhaust components with complex internal geometries previously impossible to manufacture. These techniques allow for optimized gas flow paths with precisely controlled expansion chambers and smooth transitions that minimize turbulence and flow separation.

Composite materials incorporating carbon fiber reinforced polymers (CFRP) with specialized high-temperature resins have begun appearing in production vehicles' exhaust systems, primarily in exterior components where temperatures permit their use. These materials offer exceptional strength-to-weight ratios and vibration damping properties that contribute to system stability under high-flow conditions.

The integration of shape memory alloys in specific exhaust components represents an emerging frontier, potentially enabling adaptive geometry that responds to temperature and flow conditions. Preliminary research suggests such systems could optimize exhaust flow characteristics across varying engine loads and RPM ranges, addressing a fundamental challenge in fixed-geometry exhaust design.

Ceramic matrix composites (CMCs) represent a breakthrough technology for exhaust manifolds and headers, offering superior heat resistance up to 1200°C while weighing 40-60% less than conventional metal components. These materials effectively manage thermal expansion issues that traditionally compromise exhaust geometry during operation, maintaining optimal flow paths even under extreme temperature fluctuations.

Thermal barrier coatings derived from aerospace technology have been adapted for automotive exhaust applications, creating internal surface treatments that reduce heat transfer to surrounding components. This thermal management approach allows exhaust gases to maintain higher temperatures within the system, increasing flow velocity and reducing back pressure—a critical factor in V6 engine power optimization.

Nano-engineered surface treatments have emerged as another promising development, with microscopic texturing processes that reduce boundary layer friction along exhaust pathways. Research indicates these treatments can reduce flow resistance by 8-12% compared to conventional smooth-bore exhaust tubing, translating directly to measurable power gains without requiring geometric redesign.

Advanced manufacturing techniques like direct metal laser sintering (DMLS) and selective laser melting (SLM) have enabled the production of exhaust components with complex internal geometries previously impossible to manufacture. These techniques allow for optimized gas flow paths with precisely controlled expansion chambers and smooth transitions that minimize turbulence and flow separation.

Composite materials incorporating carbon fiber reinforced polymers (CFRP) with specialized high-temperature resins have begun appearing in production vehicles' exhaust systems, primarily in exterior components where temperatures permit their use. These materials offer exceptional strength-to-weight ratios and vibration damping properties that contribute to system stability under high-flow conditions.

The integration of shape memory alloys in specific exhaust components represents an emerging frontier, potentially enabling adaptive geometry that responds to temperature and flow conditions. Preliminary research suggests such systems could optimize exhaust flow characteristics across varying engine loads and RPM ranges, addressing a fundamental challenge in fixed-geometry exhaust design.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!