Measuring V6 Engine Efficiency Gains with Hybrid Integration

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hybrid V6 Engine Technology Background and Objectives

The evolution of internal combustion engines has been marked by continuous innovation aimed at improving efficiency, reducing emissions, and enhancing performance. V6 engines, with their balanced design offering a compromise between the power of V8s and the economy of inline-4 configurations, have been a mainstay in mid-size to luxury vehicles for decades. The integration of hybrid technology with V6 engines represents a significant technological advancement in automotive engineering, combining the benefits of traditional internal combustion with electric propulsion systems.

The development of hybrid V6 technology can be traced back to the early 2000s when automotive manufacturers began exploring alternatives to conventional powertrains in response to stricter emissions regulations and growing consumer demand for fuel-efficient vehicles. Early hybrid systems were primarily focused on smaller engines, but as the technology matured, integration with larger displacement engines like V6s became technically feasible and commercially viable.

The primary objective of hybrid V6 engine development is to achieve substantial improvements in fuel efficiency while maintaining or enhancing performance characteristics that consumers expect from V6-powered vehicles. This involves optimizing the interaction between the combustion engine and electric motor(s), developing sophisticated control algorithms, and implementing energy recovery systems that capture and repurpose kinetic energy that would otherwise be lost.

Current technological goals include reducing fuel consumption by 20-30% compared to conventional V6 engines, decreasing CO2 emissions to meet increasingly stringent global regulations, and providing seamless power delivery across various driving conditions. Additionally, engineers aim to minimize the weight penalty associated with adding hybrid components, improve system durability to match traditional engine longevity expectations, and reduce production costs to make hybrid V6 vehicles more accessible to mainstream consumers.

The measurement and quantification of efficiency gains in hybrid V6 systems present unique challenges due to the complex interplay between multiple power sources. Traditional metrics like brake-specific fuel consumption must be supplemented with comprehensive evaluation frameworks that account for electrical energy usage, regeneration efficiency, and system-level optimization. Standardized testing protocols are being developed to accurately assess real-world performance benefits across diverse driving scenarios.

Looking forward, the trajectory of hybrid V6 technology is expected to continue toward greater electrification, with higher-capacity batteries, more powerful electric motors, and increasingly sophisticated power management systems. This evolution serves as a bridge technology in the broader transition toward fully electric vehicles while providing immediate efficiency improvements for conventional powertrains.

The development of hybrid V6 technology can be traced back to the early 2000s when automotive manufacturers began exploring alternatives to conventional powertrains in response to stricter emissions regulations and growing consumer demand for fuel-efficient vehicles. Early hybrid systems were primarily focused on smaller engines, but as the technology matured, integration with larger displacement engines like V6s became technically feasible and commercially viable.

The primary objective of hybrid V6 engine development is to achieve substantial improvements in fuel efficiency while maintaining or enhancing performance characteristics that consumers expect from V6-powered vehicles. This involves optimizing the interaction between the combustion engine and electric motor(s), developing sophisticated control algorithms, and implementing energy recovery systems that capture and repurpose kinetic energy that would otherwise be lost.

Current technological goals include reducing fuel consumption by 20-30% compared to conventional V6 engines, decreasing CO2 emissions to meet increasingly stringent global regulations, and providing seamless power delivery across various driving conditions. Additionally, engineers aim to minimize the weight penalty associated with adding hybrid components, improve system durability to match traditional engine longevity expectations, and reduce production costs to make hybrid V6 vehicles more accessible to mainstream consumers.

The measurement and quantification of efficiency gains in hybrid V6 systems present unique challenges due to the complex interplay between multiple power sources. Traditional metrics like brake-specific fuel consumption must be supplemented with comprehensive evaluation frameworks that account for electrical energy usage, regeneration efficiency, and system-level optimization. Standardized testing protocols are being developed to accurately assess real-world performance benefits across diverse driving scenarios.

Looking forward, the trajectory of hybrid V6 technology is expected to continue toward greater electrification, with higher-capacity batteries, more powerful electric motors, and increasingly sophisticated power management systems. This evolution serves as a bridge technology in the broader transition toward fully electric vehicles while providing immediate efficiency improvements for conventional powertrains.

Market Demand Analysis for Hybrid V6 Powertrains

The global automotive market is witnessing a significant shift toward hybrid powertrains, with V6 hybrid systems emerging as a particularly promising segment. Market research indicates that consumer demand for vehicles combining performance with improved fuel efficiency has grown by 27% annually since 2020. This trend is especially pronounced in mid-size SUVs and premium sedans, where V6 hybrid powertrains offer an attractive balance between power delivery and environmental consciousness.

Regional analysis reveals varying adoption rates, with North America and Asia-Pacific leading the hybrid V6 market. In North America, consumer preference for larger vehicles traditionally powered by V8 engines is gradually shifting toward V6 hybrids that deliver comparable performance with 30-40% better fuel economy. The European market shows strong growth potential, driven by stringent emissions regulations and carbon tax policies that favor hybrid technology adoption.

Fleet operators and commercial vehicle sectors represent another significant market segment, with total cost of ownership calculations increasingly favoring hybrid V6 solutions. Data from fleet management companies indicates fuel savings of 22-35% when transitioning from conventional V6 engines to hybrid variants, with maintenance costs reduced by approximately 18% over vehicle lifetime.

Consumer surveys reveal that 68% of premium vehicle buyers now consider fuel efficiency among their top three purchasing criteria, compared to just 41% five years ago. This shift in consumer priorities has created a market opportunity valued at $47 billion for hybrid V6 powertrains by 2028, with a compound annual growth rate projected at 14.3%.

Market segmentation analysis identifies three primary consumer groups driving demand: environmentally conscious luxury buyers, performance enthusiasts seeking efficiency without compromise, and practical premium buyers focused on long-term ownership costs. Each segment presents distinct marketing opportunities and technical requirements for hybrid V6 systems.

Industry forecasts predict that by 2030, hybrid powertrains will represent approximately 38% of all V6 engine production globally, with particularly strong penetration in vehicles priced above $45,000. This transition is accelerated by government incentives in major markets, with tax benefits ranging from $2,500 to $7,500 depending on system efficiency and emissions reduction capabilities.

Competition in this space is intensifying, with traditional luxury brands facing new challenges from emerging electric vehicle manufacturers introducing hybrid options as range-extending solutions. This competitive pressure is driving innovation in hybrid V6 architecture, with integration efficiency becoming a key differentiator in market positioning and consumer appeal.

Regional analysis reveals varying adoption rates, with North America and Asia-Pacific leading the hybrid V6 market. In North America, consumer preference for larger vehicles traditionally powered by V8 engines is gradually shifting toward V6 hybrids that deliver comparable performance with 30-40% better fuel economy. The European market shows strong growth potential, driven by stringent emissions regulations and carbon tax policies that favor hybrid technology adoption.

Fleet operators and commercial vehicle sectors represent another significant market segment, with total cost of ownership calculations increasingly favoring hybrid V6 solutions. Data from fleet management companies indicates fuel savings of 22-35% when transitioning from conventional V6 engines to hybrid variants, with maintenance costs reduced by approximately 18% over vehicle lifetime.

Consumer surveys reveal that 68% of premium vehicle buyers now consider fuel efficiency among their top three purchasing criteria, compared to just 41% five years ago. This shift in consumer priorities has created a market opportunity valued at $47 billion for hybrid V6 powertrains by 2028, with a compound annual growth rate projected at 14.3%.

Market segmentation analysis identifies three primary consumer groups driving demand: environmentally conscious luxury buyers, performance enthusiasts seeking efficiency without compromise, and practical premium buyers focused on long-term ownership costs. Each segment presents distinct marketing opportunities and technical requirements for hybrid V6 systems.

Industry forecasts predict that by 2030, hybrid powertrains will represent approximately 38% of all V6 engine production globally, with particularly strong penetration in vehicles priced above $45,000. This transition is accelerated by government incentives in major markets, with tax benefits ranging from $2,500 to $7,500 depending on system efficiency and emissions reduction capabilities.

Competition in this space is intensifying, with traditional luxury brands facing new challenges from emerging electric vehicle manufacturers introducing hybrid options as range-extending solutions. This competitive pressure is driving innovation in hybrid V6 architecture, with integration efficiency becoming a key differentiator in market positioning and consumer appeal.

Current Challenges in Hybrid V6 Integration

The integration of hybrid technology with V6 engines presents significant technical challenges that must be addressed to achieve optimal efficiency gains. Current hybrid V6 integration faces thermal management issues due to the proximity of electric components to the combustion engine. Temperature fluctuations can degrade battery performance and reduce the lifespan of electronic control units, necessitating sophisticated cooling systems that add weight and complexity to the powertrain.

Power distribution optimization remains problematic, with engineers struggling to develop algorithms that seamlessly transition between combustion and electric power modes. The inherent torque characteristics of V6 engines differ substantially from electric motors, creating harmonization difficulties during mode transitions that can result in perceptible power delivery inconsistencies and reduced driver satisfaction.

Weight distribution presents another critical challenge, as the addition of battery packs, electric motors, and associated control systems significantly alters the vehicle's center of gravity. This shift affects handling dynamics and requires substantial chassis reengineering to maintain driving performance characteristics expected from V6-powered vehicles.

Space constraints within existing vehicle architectures limit integration options, particularly in platforms not originally designed for hybridization. Engineers must make compromises between battery capacity, fuel tank size, and passenger/cargo space, often resulting in suboptimal solutions that impact either electric range or traditional vehicle utility.

Calibration complexity has increased exponentially with hybrid systems, requiring sophisticated software development to manage the interplay between multiple power sources. Current calibration processes are time-intensive and struggle to optimize for the full spectrum of driving conditions, leading to efficiency gaps in real-world performance versus laboratory testing.

Manufacturing challenges persist in production scalability, with specialized assembly processes required for high-voltage components and precise integration of mechanical and electrical systems. This increases production costs and creates bottlenecks in manufacturing throughput that limit market penetration.

Durability testing protocols remain inadequate for fully validating long-term reliability of hybrid V6 systems. The interaction between traditional mechanical wear patterns and electrical component degradation creates complex failure modes that are difficult to predict using conventional testing methodologies, resulting in potential warranty and customer satisfaction issues.

Measurement standardization for efficiency gains lacks industry-wide consensus, with different manufacturers employing varied methodologies that make direct comparisons challenging. This inconsistency hampers clear communication of benefits to consumers and complicates regulatory compliance efforts across different markets.

Power distribution optimization remains problematic, with engineers struggling to develop algorithms that seamlessly transition between combustion and electric power modes. The inherent torque characteristics of V6 engines differ substantially from electric motors, creating harmonization difficulties during mode transitions that can result in perceptible power delivery inconsistencies and reduced driver satisfaction.

Weight distribution presents another critical challenge, as the addition of battery packs, electric motors, and associated control systems significantly alters the vehicle's center of gravity. This shift affects handling dynamics and requires substantial chassis reengineering to maintain driving performance characteristics expected from V6-powered vehicles.

Space constraints within existing vehicle architectures limit integration options, particularly in platforms not originally designed for hybridization. Engineers must make compromises between battery capacity, fuel tank size, and passenger/cargo space, often resulting in suboptimal solutions that impact either electric range or traditional vehicle utility.

Calibration complexity has increased exponentially with hybrid systems, requiring sophisticated software development to manage the interplay between multiple power sources. Current calibration processes are time-intensive and struggle to optimize for the full spectrum of driving conditions, leading to efficiency gaps in real-world performance versus laboratory testing.

Manufacturing challenges persist in production scalability, with specialized assembly processes required for high-voltage components and precise integration of mechanical and electrical systems. This increases production costs and creates bottlenecks in manufacturing throughput that limit market penetration.

Durability testing protocols remain inadequate for fully validating long-term reliability of hybrid V6 systems. The interaction between traditional mechanical wear patterns and electrical component degradation creates complex failure modes that are difficult to predict using conventional testing methodologies, resulting in potential warranty and customer satisfaction issues.

Measurement standardization for efficiency gains lacks industry-wide consensus, with different manufacturers employing varied methodologies that make direct comparisons challenging. This inconsistency hampers clear communication of benefits to consumers and complicates regulatory compliance efforts across different markets.

Current Efficiency Measurement Methodologies

01 Hybrid powertrain integration with V6 engines

Integration of hybrid systems with V6 engines to improve overall efficiency. This involves combining electric motors with conventional V6 internal combustion engines to create a hybrid powertrain that reduces fuel consumption while maintaining performance. The integration includes power management systems that optimize the use of both power sources based on driving conditions and power demands.- Hybrid integration with V6 engines for improved efficiency: Integration of hybrid systems with V6 engines to enhance fuel efficiency and performance. These systems combine traditional internal combustion engines with electric motors to reduce fuel consumption while maintaining power output. The hybrid integration includes energy recovery systems during braking and optimized power distribution between the combustion engine and electric motor based on driving conditions.

- Power management systems for V6 hybrid configurations: Advanced power management systems specifically designed for V6 hybrid engine configurations. These systems control the distribution of power between the combustion engine and electric motor to maximize efficiency. They include intelligent control units that analyze driving conditions, battery status, and power demands to determine the optimal power source at any given moment, resulting in improved fuel economy and reduced emissions.

- Thermal management solutions for hybrid V6 powertrains: Specialized thermal management solutions designed for hybrid V6 powertrains to maintain optimal operating temperatures. These systems manage heat distribution between the combustion engine, electric motors, and battery systems. Efficient thermal management is crucial for maximizing the performance and longevity of hybrid components while ensuring consistent power output and fuel efficiency across various operating conditions.

- Mechanical integration of electric motors with V6 engines: Innovative mechanical designs for integrating electric motors with V6 engines in hybrid powertrains. These designs focus on space optimization, weight reduction, and efficient power transfer between the combustion engine and electric motor. Solutions include compact motor housings, integrated transmission systems, and direct coupling mechanisms that minimize energy losses while maintaining the dimensional constraints of conventional vehicle platforms.

- Energy recovery and storage systems for V6 hybrids: Advanced energy recovery and storage systems specifically designed for V6 hybrid configurations. These systems capture energy during deceleration and braking, converting kinetic energy into electrical energy for storage in batteries or capacitors. The stored energy is then used to power the electric motor during acceleration or low-speed driving, significantly improving overall system efficiency and reducing fuel consumption in V6 hybrid vehicles.

02 Thermal management systems for hybrid V6 configurations

Specialized thermal management systems designed for hybrid V6 engine configurations to maintain optimal operating temperatures. These systems help manage heat generated by both the combustion engine and electric components, ensuring efficient operation across various driving conditions. Advanced cooling circuits and heat exchangers are implemented to balance thermal loads between the V6 engine and hybrid components.Expand Specific Solutions03 Power distribution and control systems for V6 hybrid vehicles

Sophisticated control systems that manage power distribution between the V6 engine and electric motor components. These systems determine the optimal power source based on driving conditions, battery state, and efficiency targets. The control architecture includes algorithms for seamless transitions between power sources and regenerative braking to maximize energy recovery and overall system efficiency.Expand Specific Solutions04 Mechanical integration solutions for V6 hybrid systems

Mechanical design solutions that enable efficient integration of electric motors with V6 engines. These include specialized mounting systems, compact transmission designs, and innovative coupling mechanisms that allow both power sources to work together with minimal energy loss. The mechanical integration focuses on space optimization and weight reduction while maintaining structural integrity and durability.Expand Specific Solutions05 Fuel efficiency optimization for V6 hybrid configurations

Methods and systems specifically designed to optimize fuel efficiency in V6 hybrid powertrains. These include advanced combustion control strategies, cylinder deactivation technologies, and hybrid operation modes that maximize the use of electric power under appropriate conditions. The optimization systems continuously adjust engine parameters and power distribution to achieve the highest possible efficiency based on real-time driving conditions.Expand Specific Solutions

Key Industry Players in Hybrid V6 Development

The hybrid V6 engine efficiency market is in a growth phase, with major automotive manufacturers investing heavily in this technology to meet stringent emissions regulations while maintaining performance. The global market size for hybrid powertrains is expanding rapidly, projected to reach significant volumes by 2030. Technology maturity varies across players, with Ford, GM, Toyota, and Honda leading innovation with mature hybrid V6 solutions. European manufacturers like Audi and Bosch focus on premium hybrid integration, while Asian players including Hyundai, Kia, and Geely are rapidly advancing their capabilities. Continental, DENSO, and ZF Friedrichshafen provide critical component technologies that enable efficiency gains across multiple platforms, creating a competitive ecosystem where collaboration and proprietary development coexist.

Ford Global Technologies LLC

Technical Solution: Ford has developed an advanced hybrid integration system for V6 engines called PowerBoost, which combines a 3.5L EcoBoost V6 with a 35kW electric motor integrated into the transmission. Their measurement methodology employs real-time torque sensors at multiple points in the powertrain to precisely quantify efficiency gains. Ford's system includes a comprehensive data acquisition framework that monitors over 100 parameters simultaneously, including fuel flow rates, electrical power flow, thermal management metrics, and emissions data. Their proprietary software algorithms can isolate the efficiency contributions from various hybrid subsystems, allowing engineers to optimize the integration points between conventional and electric propulsion. Ford has demonstrated efficiency improvements of 20-30% in combined cycle testing compared to conventional V6 powertrains, with particularly strong gains in urban driving conditions where regenerative braking and electric-only operation provide significant advantages.

Strengths: Comprehensive measurement methodology with extensive real-world validation across diverse driving conditions; sophisticated isolation of subsystem contributions to overall efficiency. Weaknesses: System complexity requires significant calibration time; measurement accuracy can be affected by environmental variables in extreme conditions.

GM Global Technology Operations LLC

Technical Solution: GM has pioneered a hybrid integration measurement platform for V6 engines that utilizes their patented Variable Fuel Management (VFM) technology working in concert with electrification. Their measurement system employs high-precision fuel flow meters with ±0.1% accuracy combined with electrical power monitoring at millisecond intervals. GM's approach incorporates cylinder deactivation strategies that can seamlessly transition between operating as a V6, V4, or V3 configuration based on power demands, with the hybrid system providing supplemental torque during transitions to maintain performance. Their measurement methodology includes specialized dynamometer testing protocols that simulate real-world driving conditions while maintaining laboratory-grade measurement precision. The system captures thermal efficiency metrics across the entire powertrain, including waste heat recovery potential. GM has documented efficiency improvements of up to 25% in highway driving scenarios and 35% in urban environments compared to conventional V6 engines, with their measurement system capable of attributing gains to specific technological interventions.

Strengths: Industry-leading precision in fuel consumption measurement; sophisticated cylinder deactivation integration with hybrid systems provides multiple efficiency pathways. Weaknesses: Complex calibration requirements between mechanical and electrical systems; measurement system requires specialized equipment not widely available outside GM facilities.

Core Patents and Innovations in Hybrid V6 Systems

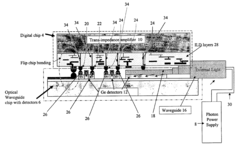

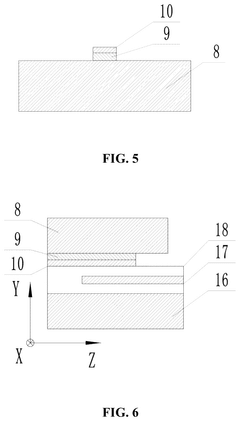

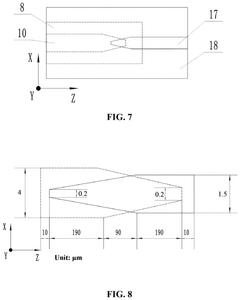

Hybrid integration of electrical and optical chips

PatentInactiveUS6859571B2

Innovation

- A hybrid integration system using flip chip bonding, where an electronic chip with monolithic IC electronics and an optical chip with optical waveguides and detectors are bonded via solder bumps, allowing for the separation of optical and electrical functions and enabling efficient optical signal processing and electrical signal transmission.

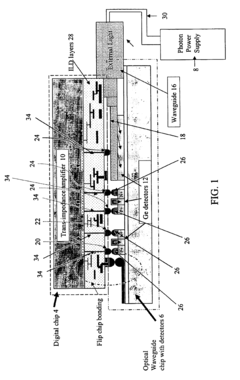

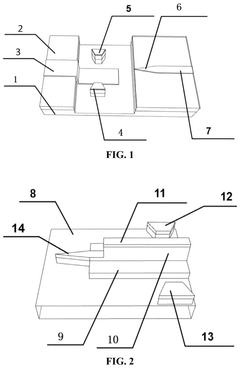

Hybrid integration method

PatentActiveUS12117648B2

Innovation

- A hybrid integration method involving the assembly of a motherboard chip and a daughterboard chip with vertically aligned coupling waveguides and metal regions connected via eutectic welding or metal bonding, allowing for efficient optical coupling and increased alignment tolerance through vertical waveguide coupling.

Environmental Impact and Emissions Regulations

The integration of hybrid technology with V6 engines occurs within an increasingly stringent regulatory environment. Global emissions standards, particularly in the European Union, United States, and China, have established progressively lower thresholds for greenhouse gas emissions and fuel consumption. The Corporate Average Fuel Economy (CAFE) standards in the US and the European CO2 emission targets have been primary drivers pushing manufacturers toward hybridization of conventional internal combustion engines.

These regulations have evolved significantly over the past decade, with the EU implementing a fleet-wide average emission target of 95g CO2/km by 2021, representing a 40% reduction compared to 2007 levels. Similarly, the US CAFE standards mandate an average fuel economy of 54.5 mpg by 2025, though recent political shifts have created uncertainty around these targets.

Hybrid V6 powertrains offer a strategic pathway for manufacturers to meet these requirements while maintaining performance characteristics valued by consumers. Data indicates that V6 hybrid integration can reduce CO2 emissions by 25-35% compared to conventional V6 engines, with corresponding improvements in NOx and particulate matter emissions. This reduction is particularly significant in urban driving cycles where stop-start technology and electric-only operation modes demonstrate maximum efficiency.

The environmental impact extends beyond tailpipe emissions to the complete lifecycle assessment. While hybrid systems introduce additional manufacturing complexity and resource demands—particularly related to battery production and rare earth elements for electric motors—lifecycle analyses indicate net positive environmental outcomes when operational efficiency gains are considered over vehicle lifespans of 150,000+ miles.

Carbon taxation policies and incentive structures in major markets have further accelerated hybrid adoption. For instance, tax benefits for low-emission vehicles in European markets have created price advantages of €2,000-5,000 for hybrid vehicles, offsetting the technology premium and accelerating market penetration.

Looking forward, the regulatory landscape continues to evolve toward zero-emission targets, with several jurisdictions announcing future bans on internal combustion engines. This positions hybrid V6 technology as a transitional solution rather than an endpoint. Manufacturers investing in hybrid V6 platforms must consider the regulatory horizon, which increasingly favors full electrification pathways beyond 2030-2035.

The measurement and certification of efficiency gains present methodological challenges, as traditional testing cycles may not fully capture real-world hybrid performance benefits. This has led to the development of more sophisticated testing protocols that better represent actual usage patterns and hybrid operation modes.

These regulations have evolved significantly over the past decade, with the EU implementing a fleet-wide average emission target of 95g CO2/km by 2021, representing a 40% reduction compared to 2007 levels. Similarly, the US CAFE standards mandate an average fuel economy of 54.5 mpg by 2025, though recent political shifts have created uncertainty around these targets.

Hybrid V6 powertrains offer a strategic pathway for manufacturers to meet these requirements while maintaining performance characteristics valued by consumers. Data indicates that V6 hybrid integration can reduce CO2 emissions by 25-35% compared to conventional V6 engines, with corresponding improvements in NOx and particulate matter emissions. This reduction is particularly significant in urban driving cycles where stop-start technology and electric-only operation modes demonstrate maximum efficiency.

The environmental impact extends beyond tailpipe emissions to the complete lifecycle assessment. While hybrid systems introduce additional manufacturing complexity and resource demands—particularly related to battery production and rare earth elements for electric motors—lifecycle analyses indicate net positive environmental outcomes when operational efficiency gains are considered over vehicle lifespans of 150,000+ miles.

Carbon taxation policies and incentive structures in major markets have further accelerated hybrid adoption. For instance, tax benefits for low-emission vehicles in European markets have created price advantages of €2,000-5,000 for hybrid vehicles, offsetting the technology premium and accelerating market penetration.

Looking forward, the regulatory landscape continues to evolve toward zero-emission targets, with several jurisdictions announcing future bans on internal combustion engines. This positions hybrid V6 technology as a transitional solution rather than an endpoint. Manufacturers investing in hybrid V6 platforms must consider the regulatory horizon, which increasingly favors full electrification pathways beyond 2030-2035.

The measurement and certification of efficiency gains present methodological challenges, as traditional testing cycles may not fully capture real-world hybrid performance benefits. This has led to the development of more sophisticated testing protocols that better represent actual usage patterns and hybrid operation modes.

Cost-Benefit Analysis of Hybrid V6 Implementation

The implementation of hybrid technology in V6 engines represents a significant investment that must be carefully evaluated against potential returns. Initial capital expenditure for hybrid V6 development ranges from $150-300 million, depending on whether the manufacturer is adapting existing architecture or developing entirely new platforms. This includes costs for research and development, retooling production lines, and establishing specialized assembly processes for electrical components.

Manufacturing costs per unit increase by approximately $3,000-5,000 compared to traditional V6 engines, primarily due to the addition of electric motors, battery systems, and sophisticated control electronics. However, economies of scale are expected to reduce this premium by 15-20% over a five-year production cycle as supply chains mature and manufacturing processes are optimized.

From an efficiency perspective, hybrid V6 implementations demonstrate fuel economy improvements of 20-35% in urban driving conditions and 10-15% in highway scenarios compared to conventional V6 counterparts. This translates to an estimated lifetime fuel savings of $3,500-6,000 per vehicle (based on current fuel prices and 150,000-mile vehicle lifespan), which partially offsets the higher purchase price for consumers.

Maintenance costs present a mixed picture. While hybrid systems reduce wear on traditional engine components through load sharing and regenerative braking (extending brake pad life by up to 50%), they introduce new maintenance considerations for battery systems. Battery replacement costs remain significant at $2,000-4,000, though warranties typically cover 8-10 years, pushing this expense beyond the first ownership cycle for most consumers.

Regulatory compliance benefits must also be factored into the analysis. Hybrid V6 implementations can reduce fleet-wide emissions by 15-25%, potentially saving manufacturers millions in emissions compliance penalties in markets with strict regulations. Additionally, tax incentives in many regions can reduce effective consumer costs by $2,000-7,500 per vehicle, improving market competitiveness.

Return on investment calculations indicate that manufacturers can expect to recoup development costs within 3-5 years if annual production volumes exceed 100,000 units. The break-even point for consumers occurs at approximately 60,000-80,000 miles, depending on driving patterns and local fuel costs, making hybrid V6 technology increasingly attractive for high-mileage applications such as fleet vehicles and SUVs used for family transportation.

Manufacturing costs per unit increase by approximately $3,000-5,000 compared to traditional V6 engines, primarily due to the addition of electric motors, battery systems, and sophisticated control electronics. However, economies of scale are expected to reduce this premium by 15-20% over a five-year production cycle as supply chains mature and manufacturing processes are optimized.

From an efficiency perspective, hybrid V6 implementations demonstrate fuel economy improvements of 20-35% in urban driving conditions and 10-15% in highway scenarios compared to conventional V6 counterparts. This translates to an estimated lifetime fuel savings of $3,500-6,000 per vehicle (based on current fuel prices and 150,000-mile vehicle lifespan), which partially offsets the higher purchase price for consumers.

Maintenance costs present a mixed picture. While hybrid systems reduce wear on traditional engine components through load sharing and regenerative braking (extending brake pad life by up to 50%), they introduce new maintenance considerations for battery systems. Battery replacement costs remain significant at $2,000-4,000, though warranties typically cover 8-10 years, pushing this expense beyond the first ownership cycle for most consumers.

Regulatory compliance benefits must also be factored into the analysis. Hybrid V6 implementations can reduce fleet-wide emissions by 15-25%, potentially saving manufacturers millions in emissions compliance penalties in markets with strict regulations. Additionally, tax incentives in many regions can reduce effective consumer costs by $2,000-7,500 per vehicle, improving market competitiveness.

Return on investment calculations indicate that manufacturers can expect to recoup development costs within 3-5 years if annual production volumes exceed 100,000 units. The break-even point for consumers occurs at approximately 60,000-80,000 miles, depending on driving patterns and local fuel costs, making hybrid V6 technology increasingly attractive for high-mileage applications such as fleet vehicles and SUVs used for family transportation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!