V6 Engine Exhaust Gas Recirculation: System Evaluation

SEP 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V6 EGR Technology Background and Objectives

Exhaust Gas Recirculation (EGR) technology has evolved significantly since its introduction in the 1970s as a response to increasingly stringent emissions regulations. Initially implemented as a simple system to reduce nitrogen oxide (NOx) emissions, EGR has transformed into a sophisticated technology crucial for modern internal combustion engines. For V6 engines specifically, EGR systems have undergone substantial refinement to balance performance demands with environmental compliance.

The fundamental principle of EGR involves recirculating a portion of exhaust gases back into the engine's combustion chambers, thereby reducing peak combustion temperatures and consequently decreasing NOx formation. In V6 engines, this process presents unique challenges due to their specific firing order, cylinder arrangement, and thermal management requirements.

Historical development of V6 EGR systems shows a clear progression from low-pressure systems in early applications to the current high-pressure and dual-loop configurations. The transition from mechanical to electronic control systems marked a significant advancement, enabling more precise management of recirculation rates based on real-time engine operating conditions.

Recent technological advancements have introduced cooled EGR systems, which further enhance NOx reduction capabilities while minimizing the negative impact on engine performance. For V6 engines, these cooled systems have become particularly important as they help maintain the power density expected from this engine configuration while meeting emissions targets.

The primary objective of this technical evaluation is to comprehensively assess the current state of EGR technology specifically for V6 engine applications. This includes examining system efficiency, durability, integration challenges, and performance impacts across various operating conditions. Additionally, the evaluation aims to identify potential optimization opportunities that could enhance both emissions control and engine performance.

Secondary objectives include quantifying the trade-offs between emissions reduction and fuel economy, analyzing the integration challenges with other emission control technologies, and exploring the adaptability of current V6 EGR systems to future regulatory requirements. This evaluation will also consider how V6 EGR systems compare to those implemented in other engine configurations, identifying unique advantages or limitations.

The technological trajectory suggests that future V6 EGR systems will likely incorporate more advanced control algorithms, improved cooling efficiency, and potentially variable geometry components to optimize performance across the entire engine operating range. Understanding the current technological baseline is essential for projecting these development paths and identifying critical innovation opportunities.

The fundamental principle of EGR involves recirculating a portion of exhaust gases back into the engine's combustion chambers, thereby reducing peak combustion temperatures and consequently decreasing NOx formation. In V6 engines, this process presents unique challenges due to their specific firing order, cylinder arrangement, and thermal management requirements.

Historical development of V6 EGR systems shows a clear progression from low-pressure systems in early applications to the current high-pressure and dual-loop configurations. The transition from mechanical to electronic control systems marked a significant advancement, enabling more precise management of recirculation rates based on real-time engine operating conditions.

Recent technological advancements have introduced cooled EGR systems, which further enhance NOx reduction capabilities while minimizing the negative impact on engine performance. For V6 engines, these cooled systems have become particularly important as they help maintain the power density expected from this engine configuration while meeting emissions targets.

The primary objective of this technical evaluation is to comprehensively assess the current state of EGR technology specifically for V6 engine applications. This includes examining system efficiency, durability, integration challenges, and performance impacts across various operating conditions. Additionally, the evaluation aims to identify potential optimization opportunities that could enhance both emissions control and engine performance.

Secondary objectives include quantifying the trade-offs between emissions reduction and fuel economy, analyzing the integration challenges with other emission control technologies, and exploring the adaptability of current V6 EGR systems to future regulatory requirements. This evaluation will also consider how V6 EGR systems compare to those implemented in other engine configurations, identifying unique advantages or limitations.

The technological trajectory suggests that future V6 EGR systems will likely incorporate more advanced control algorithms, improved cooling efficiency, and potentially variable geometry components to optimize performance across the entire engine operating range. Understanding the current technological baseline is essential for projecting these development paths and identifying critical innovation opportunities.

Market Demand Analysis for EGR Systems

The global market for Exhaust Gas Recirculation (EGR) systems has experienced significant growth driven by increasingly stringent emission regulations worldwide. The automotive industry faces mounting pressure to reduce nitrogen oxide (NOx) emissions, particularly in diesel engines, where EGR technology has proven highly effective. Current market valuations place the global EGR system market at approximately 12 billion USD in 2023, with projections indicating a compound annual growth rate of 7.8% through 2030.

V6 engine applications represent a substantial segment within this market, as these powerplants are widely deployed in mid-size to large passenger vehicles, light trucks, and some commercial applications. The demand for EGR systems specifically designed for V6 engines is particularly strong in North America and Europe, where V6 engines maintain significant market share despite the trend toward downsizing.

Regional analysis reveals varying demand patterns. North American markets show robust demand for EGR systems in V6 engines due to their prevalence in popular vehicle categories such as SUVs and pickup trucks. European markets demonstrate growing demand driven by Euro 7 emission standards, which will impose even stricter NOx limits. The Asia-Pacific region, particularly China and India, represents the fastest-growing market segment as these countries implement more rigorous emission standards modeled after European regulations.

Customer requirements for V6 EGR systems have evolved significantly. Vehicle manufacturers increasingly demand systems that not only meet regulatory requirements but also maintain or improve fuel efficiency and engine performance. This has led to the development of more sophisticated EGR solutions incorporating advanced cooling technologies, precise electronic control, and integration with other emission control systems.

Market segmentation analysis indicates distinct requirements across different vehicle categories. Passenger vehicles prioritize compact design and seamless integration with existing engine architecture, while commercial applications emphasize durability and service intervals. Performance vehicles require EGR systems that minimize any negative impact on engine responsiveness and power output.

The aftermarket segment for V6 EGR systems also shows promising growth potential, driven by the aging vehicle fleet and increasing awareness of emission-related maintenance. This segment is expected to grow at 5.3% annually through 2028, creating opportunities for both OEM and third-party suppliers.

Industry forecasts suggest that technological advancements in EGR systems will continue to drive market growth, with particular emphasis on low-pressure EGR systems, which offer improved efficiency and compatibility with modern turbocharged V6 engines. The integration of EGR with other emission control technologies, such as selective catalytic reduction (SCR) systems, represents another significant market trend that will shape demand patterns in the coming years.

V6 engine applications represent a substantial segment within this market, as these powerplants are widely deployed in mid-size to large passenger vehicles, light trucks, and some commercial applications. The demand for EGR systems specifically designed for V6 engines is particularly strong in North America and Europe, where V6 engines maintain significant market share despite the trend toward downsizing.

Regional analysis reveals varying demand patterns. North American markets show robust demand for EGR systems in V6 engines due to their prevalence in popular vehicle categories such as SUVs and pickup trucks. European markets demonstrate growing demand driven by Euro 7 emission standards, which will impose even stricter NOx limits. The Asia-Pacific region, particularly China and India, represents the fastest-growing market segment as these countries implement more rigorous emission standards modeled after European regulations.

Customer requirements for V6 EGR systems have evolved significantly. Vehicle manufacturers increasingly demand systems that not only meet regulatory requirements but also maintain or improve fuel efficiency and engine performance. This has led to the development of more sophisticated EGR solutions incorporating advanced cooling technologies, precise electronic control, and integration with other emission control systems.

Market segmentation analysis indicates distinct requirements across different vehicle categories. Passenger vehicles prioritize compact design and seamless integration with existing engine architecture, while commercial applications emphasize durability and service intervals. Performance vehicles require EGR systems that minimize any negative impact on engine responsiveness and power output.

The aftermarket segment for V6 EGR systems also shows promising growth potential, driven by the aging vehicle fleet and increasing awareness of emission-related maintenance. This segment is expected to grow at 5.3% annually through 2028, creating opportunities for both OEM and third-party suppliers.

Industry forecasts suggest that technological advancements in EGR systems will continue to drive market growth, with particular emphasis on low-pressure EGR systems, which offer improved efficiency and compatibility with modern turbocharged V6 engines. The integration of EGR with other emission control technologies, such as selective catalytic reduction (SCR) systems, represents another significant market trend that will shape demand patterns in the coming years.

Current EGR Technology Status and Challenges

Exhaust Gas Recirculation (EGR) technology has evolved significantly over the past decades, becoming a critical component in modern V6 engine emission control systems. Currently, EGR systems are broadly categorized into high-pressure (HP) and low-pressure (LP) configurations, each with distinct operational characteristics and implementation challenges. HP-EGR systems recirculate exhaust gases before the turbocharger, while LP-EGR systems extract gases after the particulate filter, offering different benefits in terms of NOx reduction and thermal management.

The global automotive industry has achieved notable advancements in EGR technology, with European manufacturers generally leading in diesel EGR implementation, while North American and Asian manufacturers have made significant strides in gasoline EGR applications. Current state-of-the-art systems incorporate electronic control units that precisely regulate EGR valve operation based on comprehensive sensor data, including mass airflow, intake manifold pressure, and exhaust gas temperature.

Despite these advancements, several technical challenges persist in V6 EGR system optimization. Fouling and deposit formation remain significant issues, particularly in HP-EGR systems where carbon deposits can accumulate on valves and coolers, reducing system efficiency and requiring maintenance interventions. This challenge is especially pronounced in direct-injection V6 engines where incomplete combustion products can accelerate deposit formation.

Thermal management presents another substantial challenge, as EGR systems must balance the cooling requirements necessary for NOx reduction against the potential for condensation formation at lower temperatures, which can lead to corrosion and system degradation. Modern V6 engines with variable valve timing and multiple operating modes further complicate this balance, requiring sophisticated control algorithms.

Control precision and response time limitations constitute a third major challenge area. Current EGR systems struggle to maintain optimal recirculation rates during transient operating conditions, such as rapid acceleration or load changes common in real-world driving scenarios. The integration of EGR with other emission control technologies, including selective catalytic reduction (SCR) and particulate filters, introduces additional complexity in system optimization.

Durability concerns also persist, particularly in high-temperature applications where thermal cycling can lead to premature component failure. Materials science advancements have improved heat resistance, but cost-effective solutions for mass production remain elusive for some high-stress components.

Regulatory pressures continue to drive EGR technology development, with increasingly stringent emission standards worldwide requiring higher EGR rates and more precise control. The transition toward real driving emissions (RDE) testing protocols has exposed limitations in current systems' ability to maintain optimal performance across the full spectrum of operating conditions, highlighting the need for further innovation in adaptive control strategies and system integration.

The global automotive industry has achieved notable advancements in EGR technology, with European manufacturers generally leading in diesel EGR implementation, while North American and Asian manufacturers have made significant strides in gasoline EGR applications. Current state-of-the-art systems incorporate electronic control units that precisely regulate EGR valve operation based on comprehensive sensor data, including mass airflow, intake manifold pressure, and exhaust gas temperature.

Despite these advancements, several technical challenges persist in V6 EGR system optimization. Fouling and deposit formation remain significant issues, particularly in HP-EGR systems where carbon deposits can accumulate on valves and coolers, reducing system efficiency and requiring maintenance interventions. This challenge is especially pronounced in direct-injection V6 engines where incomplete combustion products can accelerate deposit formation.

Thermal management presents another substantial challenge, as EGR systems must balance the cooling requirements necessary for NOx reduction against the potential for condensation formation at lower temperatures, which can lead to corrosion and system degradation. Modern V6 engines with variable valve timing and multiple operating modes further complicate this balance, requiring sophisticated control algorithms.

Control precision and response time limitations constitute a third major challenge area. Current EGR systems struggle to maintain optimal recirculation rates during transient operating conditions, such as rapid acceleration or load changes common in real-world driving scenarios. The integration of EGR with other emission control technologies, including selective catalytic reduction (SCR) and particulate filters, introduces additional complexity in system optimization.

Durability concerns also persist, particularly in high-temperature applications where thermal cycling can lead to premature component failure. Materials science advancements have improved heat resistance, but cost-effective solutions for mass production remain elusive for some high-stress components.

Regulatory pressures continue to drive EGR technology development, with increasingly stringent emission standards worldwide requiring higher EGR rates and more precise control. The transition toward real driving emissions (RDE) testing protocols has exposed limitations in current systems' ability to maintain optimal performance across the full spectrum of operating conditions, highlighting the need for further innovation in adaptive control strategies and system integration.

Current V6 EGR System Solutions

01 EGR system performance monitoring and evaluation methods

Various methods and systems for monitoring and evaluating the performance of EGR systems have been developed. These include sensors and diagnostic tools that can measure parameters such as EGR flow rates, temperature, and pressure to assess system efficiency. Performance evaluation techniques help identify issues like clogging, leakage, or valve malfunctions that could affect emissions control and engine performance.- EGR system performance monitoring and evaluation methods: Various methods and systems for monitoring and evaluating the performance of EGR systems have been developed. These include sensors and diagnostic tools that can measure parameters such as EGR flow rates, temperature, and pressure to assess system efficiency. Performance evaluation techniques help identify issues like clogging, leakage, or component failures that might affect the EGR system's ability to reduce emissions effectively.

- EGR flow control and optimization techniques: Advanced control strategies for optimizing EGR flow based on engine operating conditions have been developed. These techniques include electronic control units that adjust EGR valve positions to maintain optimal recirculation rates under varying load conditions. Some systems incorporate feedback mechanisms to continuously adjust EGR flow for maximum emission reduction while minimizing impact on engine performance and fuel efficiency.

- EGR cooling system evaluation and enhancement: Evaluation methods for EGR cooling systems assess heat exchange efficiency and fouling resistance. These techniques analyze cooler performance under various operating conditions to ensure optimal temperature reduction of recirculated exhaust gases. Enhanced cooling designs incorporate features to prevent condensation issues and deposit formation while maintaining effective heat transfer capabilities for improved emission control and engine performance.

- Integration of EGR systems with emission control technologies: Evaluation of how EGR systems interact with other emission control technologies such as selective catalytic reduction (SCR) and diesel particulate filters (DPF) is critical for overall emission reduction. These assessment methods examine the combined effect of multiple emission control systems working together and optimize their integration for maximum pollutant reduction while maintaining engine performance and durability.

- Durability and reliability testing of EGR components: Methods for evaluating the long-term durability and reliability of EGR system components under various operating conditions have been developed. These testing protocols assess component resistance to thermal cycling, corrosion, and deposit formation. Accelerated aging tests help predict service life and maintenance intervals for critical EGR components such as valves, coolers, and sensors to ensure consistent emission control performance throughout the engine's operational life.

02 EGR valve control and optimization strategies

Advanced control strategies for EGR valves focus on optimizing the recirculation rate based on engine operating conditions. These strategies involve electronic control units that adjust valve positions in response to parameters like engine load, speed, and temperature. Optimization algorithms aim to balance emissions reduction with fuel efficiency and engine performance, ensuring the EGR system operates effectively across various driving conditions.Expand Specific Solutions03 EGR cooling system design and efficiency

EGR cooling systems are designed to reduce the temperature of recirculated exhaust gases before they re-enter the combustion chamber. Efficient cooling designs incorporate heat exchangers that can withstand high temperatures and corrosive exhaust components. Evaluation of cooling efficiency focuses on heat transfer rates, pressure drop across the cooler, and resistance to fouling, which are critical for maintaining optimal NOx reduction and engine performance.Expand Specific Solutions04 EGR system integration with emission control technologies

Integration of EGR systems with other emission control technologies such as selective catalytic reduction (SCR), diesel particulate filters (DPF), and oxidation catalysts creates comprehensive emission management solutions. Evaluation methods assess how these integrated systems work together to meet stringent emission standards while maintaining engine performance. The focus is on optimizing the interaction between different emission control components to achieve the best overall results.Expand Specific Solutions05 EGR flow measurement and diagnostic techniques

Accurate measurement of EGR flow is essential for system evaluation and control. Various diagnostic techniques have been developed, including differential pressure sensors, mass flow meters, and model-based estimation methods. These techniques help in detecting faults such as flow restrictions, leaks, or sensor malfunctions. Advanced diagnostic algorithms can identify issues before they lead to system failure or emissions non-compliance, enabling predictive maintenance and ensuring optimal EGR operation.Expand Specific Solutions

Major EGR System Manufacturers and Suppliers

The V6 Engine Exhaust Gas Recirculation (EGR) system market is in a mature growth phase, with established technologies being refined for increasingly stringent emissions regulations. The global market size is estimated at approximately $3.5 billion, driven by environmental compliance requirements across automotive and industrial sectors. Leading players include traditional automotive manufacturers like Ford, GM, Toyota, and Hyundai, alongside specialized powertrain technology companies such as Cummins and Honeywell. Technical innovation focuses on integration with advanced engine management systems, with Ford Global Technologies, Cummins, and Caterpillar demonstrating the highest technology readiness levels through extensive patent portfolios and commercial implementations. Chinese manufacturers like United Automotive Electronic Systems and Weichai Power are rapidly advancing their capabilities, challenging established Western and Japanese competitors.

Cummins, Inc.

Technical Solution: Cummins has developed a sophisticated Single Module™ aftertreatment system for V6 engines that integrates EGR functionality with selective catalytic reduction (SCR). Their approach utilizes a high-efficiency EGR cooler design with advanced metallurgy that resists corrosion from acidic condensates formed during the cooling process. The system employs variable-geometry turbocharging to precisely control exhaust backpressure, facilitating optimal EGR flow across diverse operating conditions. Cummins' proprietary XPI fuel system works in concert with the EGR system, allowing for multiple injection events per cycle to manage combustion temperatures and reduce NOx formation at source. Their EGR system incorporates venturi flow measurement technology that provides real-time feedback to the engine control module, enabling dynamic adjustments to EGR rates based on actual flow rather than estimated values. The system also features an innovative bypass mechanism that protects the cooler during cold starts and prevents fouling during low-load operation.

Strengths: Exceptional durability with documented field testing showing over 500,000 miles without significant performance degradation; superior NOx reduction efficiency of up to 95% when combined with SCR. Weaknesses: Higher initial system cost compared to simpler EGR implementations; requires more sophisticated diagnostic capabilities for maintenance personnel.

GM Global Technology Operations LLC

Technical Solution: General Motors has developed an advanced EGR system for their V6 engines featuring a multi-stage cooling architecture. Their system employs a primary high-temperature cooler followed by a secondary low-temperature cooler, allowing for optimal thermal management across varying engine loads. GM's implementation includes an innovative EGR distribution system that ensures uniform delivery of recirculated exhaust gases to all cylinders, addressing the common issue of cylinder-to-cylinder variation in EGR concentration. The system incorporates electrically actuated EGR valves with position feedback sensors that provide millisecond-level response times for precise flow control. GM's V6 EGR technology is integrated with their Dynamic Skip Fire (DSF) cylinder deactivation system, allowing for coordinated control strategies that optimize both technologies simultaneously. Their EGR coolers utilize a proprietary fin design that enhances heat transfer efficiency while minimizing flow restriction, achieving approximately 30% improvement in cooling capacity compared to conventional designs.

Strengths: Excellent integration with cylinder deactivation technology providing cumulative efficiency benefits; superior cylinder-to-cylinder EGR distribution reducing combustion variation. Weaknesses: Complex control strategy requires extensive calibration effort; potential reliability concerns with electrical actuators in high-temperature exhaust environments.

Key EGR Patents and Technical Innovations

Engine exhaust gas recirculation system

PatentInactiveEP0485089A3

Innovation

- An engine exhaust gas recirculation system that feeds exhaust gas into the cylinder in a laminar form alongside the air/fuel mixture, using timing mechanisms such as camshafts and recirculation control valves to ensure uniform distribution and optimal recirculation flow based on engine roughness detection, thereby preventing combustion deterioration and reducing fuel consumption and NOx emissions.

Exhaust gas recirculation system

PatentInactiveUS20070039322A1

Innovation

- An air-cooled EGR system with a venturi unit that uses exhaust flow to draw cooling air through an EGR cooler, eliminating the need for pressurized air and mass flow sensors, and includes a temperature-controlled valve to regulate airflow and prevent condensation by maintaining a temperature difference for efficient heat transfer.

Emissions Regulations Impact on EGR Systems

Emissions regulations worldwide have undergone significant evolution over the past two decades, directly influencing the development and implementation of Exhaust Gas Recirculation (EGR) systems in V6 engines. The progressive tightening of these regulations has been a primary driver for technological advancements in EGR systems, pushing manufacturers to develop increasingly sophisticated solutions.

The European Union's Euro standards have been particularly influential, with Euro 6d imposing stringent NOx limits of 80 mg/km for diesel vehicles and 60 mg/km for gasoline vehicles. Similarly, the United States EPA Tier 3 standards and California's LEVIII regulations have established challenging emissions targets that directly impact EGR system design requirements. These regulations have shifted from laboratory-based testing to Real Driving Emissions (RDE) tests, requiring EGR systems to perform effectively across a broader range of operating conditions.

China's implementation of China 6 standards, equivalent to Euro 6 in many aspects, has expanded the global market for advanced EGR technologies. This regulatory convergence across major automotive markets has created a unified pressure for manufacturers to optimize EGR performance in V6 engines, particularly for luxury and performance vehicle segments where these engines are common.

The regulatory focus on reducing NOx emissions specifically has elevated the importance of EGR systems, as they represent one of the most cost-effective in-engine solutions for NOx reduction. This has led to the development of dual-loop EGR systems in V6 engines, combining high-pressure and low-pressure recirculation paths to optimize emissions reduction across different engine operating conditions.

Cold-start emissions requirements have further complicated EGR system design, as traditional EGR systems are typically less effective during engine warm-up phases. This has prompted the development of fast warm-up strategies and electrically heated catalysts that work in conjunction with EGR systems to meet emissions targets during all operating phases.

Looking forward, upcoming regulations such as Euro 7 and EPA post-2026 standards are expected to further reduce permissible emission levels, potentially requiring EGR systems with even higher recirculation rates and more precise control strategies. This regulatory trajectory suggests that EGR systems will remain a critical component in emissions control strategies for V6 engines, with increasing integration with other emissions technologies such as selective catalytic reduction (SCR) and gasoline particulate filters (GPF).

The European Union's Euro standards have been particularly influential, with Euro 6d imposing stringent NOx limits of 80 mg/km for diesel vehicles and 60 mg/km for gasoline vehicles. Similarly, the United States EPA Tier 3 standards and California's LEVIII regulations have established challenging emissions targets that directly impact EGR system design requirements. These regulations have shifted from laboratory-based testing to Real Driving Emissions (RDE) tests, requiring EGR systems to perform effectively across a broader range of operating conditions.

China's implementation of China 6 standards, equivalent to Euro 6 in many aspects, has expanded the global market for advanced EGR technologies. This regulatory convergence across major automotive markets has created a unified pressure for manufacturers to optimize EGR performance in V6 engines, particularly for luxury and performance vehicle segments where these engines are common.

The regulatory focus on reducing NOx emissions specifically has elevated the importance of EGR systems, as they represent one of the most cost-effective in-engine solutions for NOx reduction. This has led to the development of dual-loop EGR systems in V6 engines, combining high-pressure and low-pressure recirculation paths to optimize emissions reduction across different engine operating conditions.

Cold-start emissions requirements have further complicated EGR system design, as traditional EGR systems are typically less effective during engine warm-up phases. This has prompted the development of fast warm-up strategies and electrically heated catalysts that work in conjunction with EGR systems to meet emissions targets during all operating phases.

Looking forward, upcoming regulations such as Euro 7 and EPA post-2026 standards are expected to further reduce permissible emission levels, potentially requiring EGR systems with even higher recirculation rates and more precise control strategies. This regulatory trajectory suggests that EGR systems will remain a critical component in emissions control strategies for V6 engines, with increasing integration with other emissions technologies such as selective catalytic reduction (SCR) and gasoline particulate filters (GPF).

EGR System Integration with Engine Management

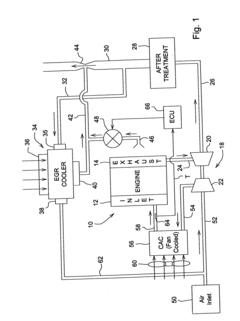

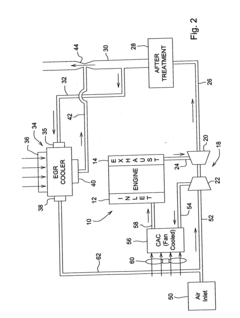

The integration of Exhaust Gas Recirculation (EGR) systems with engine management represents a critical aspect of modern V6 engine design. This integration requires sophisticated control algorithms that continuously monitor and adjust EGR flow rates based on real-time engine operating conditions. The Engine Control Unit (ECU) serves as the central nervous system, processing inputs from various sensors including mass airflow, intake manifold pressure, exhaust gas temperature, and oxygen sensors.

Advanced engine management systems employ model-based control strategies that predict optimal EGR rates for different driving conditions. These models account for factors such as engine load, speed, ambient temperature, and altitude to maintain the delicate balance between NOx reduction, fuel economy, and overall performance. The integration challenge lies in ensuring seamless communication between the EGR components and the broader engine management architecture.

Calibration processes for integrated EGR systems involve extensive mapping of engine operating points across the entire performance envelope. Engineers must develop robust control parameters that accommodate both steady-state and transient conditions, with particular attention to cold-start scenarios and rapid load changes where EGR management becomes especially challenging.

Modern V6 engines increasingly utilize dual-loop EGR systems, incorporating both high-pressure and low-pressure recirculation paths. This configuration demands more complex integration with engine management systems, requiring sophisticated switching logic to determine optimal EGR routing based on instantaneous operating conditions. The ECU must coordinate these multiple EGR paths while maintaining precise control over other engine subsystems.

Diagnostic capabilities represent another crucial aspect of EGR-engine management integration. On-board diagnostic (OBD) systems continuously monitor EGR performance, detecting faults such as valve sticking, cooler fouling, or sensor degradation. These diagnostics must be fully integrated with the vehicle's broader health monitoring systems to ensure regulatory compliance and optimal performance throughout the engine's service life.

The integration architecture typically employs a distributed control approach, with dedicated EGR control modules communicating with the main ECU via high-speed CAN networks. This modular design allows for more specialized control algorithms while maintaining overall system coordination. Software integration challenges include managing update cycles, ensuring backward compatibility, and implementing robust fail-safe modes that maintain acceptable engine operation even when EGR functionality is compromised.

Advanced engine management systems employ model-based control strategies that predict optimal EGR rates for different driving conditions. These models account for factors such as engine load, speed, ambient temperature, and altitude to maintain the delicate balance between NOx reduction, fuel economy, and overall performance. The integration challenge lies in ensuring seamless communication between the EGR components and the broader engine management architecture.

Calibration processes for integrated EGR systems involve extensive mapping of engine operating points across the entire performance envelope. Engineers must develop robust control parameters that accommodate both steady-state and transient conditions, with particular attention to cold-start scenarios and rapid load changes where EGR management becomes especially challenging.

Modern V6 engines increasingly utilize dual-loop EGR systems, incorporating both high-pressure and low-pressure recirculation paths. This configuration demands more complex integration with engine management systems, requiring sophisticated switching logic to determine optimal EGR routing based on instantaneous operating conditions. The ECU must coordinate these multiple EGR paths while maintaining precise control over other engine subsystems.

Diagnostic capabilities represent another crucial aspect of EGR-engine management integration. On-board diagnostic (OBD) systems continuously monitor EGR performance, detecting faults such as valve sticking, cooler fouling, or sensor degradation. These diagnostics must be fully integrated with the vehicle's broader health monitoring systems to ensure regulatory compliance and optimal performance throughout the engine's service life.

The integration architecture typically employs a distributed control approach, with dedicated EGR control modules communicating with the main ECU via high-speed CAN networks. This modular design allows for more specialized control algorithms while maintaining overall system coordination. Software integration challenges include managing update cycles, ensuring backward compatibility, and implementing robust fail-safe modes that maintain acceptable engine operation even when EGR functionality is compromised.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!