V6 Engine Air Management: Optimization Strategies

SEP 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V6 Engine Air Management Evolution and Objectives

The evolution of air management systems in V6 engines represents a critical aspect of internal combustion engine development over the past several decades. Initially designed with basic intake and exhaust configurations, V6 engines have undergone significant transformations to meet increasingly stringent emissions regulations while simultaneously improving performance and fuel efficiency.

In the 1980s and early 1990s, V6 engines typically employed simple throttle body injection systems with limited airflow control capabilities. The primary focus during this period was on basic power delivery rather than optimization of the air-fuel mixture. As emissions standards tightened in the mid-1990s, manufacturers began implementing multi-port fuel injection systems, which offered improved air-fuel distribution but still lacked precise control over airflow dynamics.

The early 2000s marked a significant turning point with the introduction of variable valve timing (VVT) systems, allowing engines to adjust intake and exhaust valve operation based on engine load and speed. This technology represented the first major step toward dynamic air management in V6 engines, enabling better combustion efficiency across various operating conditions.

Further advancements emerged with the development of variable intake manifold systems, which could alter the length and configuration of intake runners to optimize airflow characteristics at different engine speeds. These systems typically employed flaps or valves that would redirect incoming air through either longer paths (for low-end torque) or shorter paths (for high-end power).

The current technological frontier in V6 air management includes direct injection, turbocharging, and advanced electronic throttle control systems. Modern V6 engines often incorporate multiple strategies simultaneously, creating complex but highly efficient air management ecosystems. Cylinder deactivation technology has also emerged as a key component, allowing engines to operate on fewer cylinders during light-load conditions, thereby reducing fuel consumption.

The primary objectives of contemporary V6 air management optimization include maximizing volumetric efficiency, minimizing pumping losses, ensuring optimal air-fuel mixture formation, and enabling precise combustion control across all operating conditions. Engineers are particularly focused on strategies that can deliver both high specific output and reduced emissions, a challenging balance that requires sophisticated air management solutions.

Looking forward, the integration of artificial intelligence and machine learning algorithms into engine management systems represents the next evolutionary step, potentially enabling real-time optimization of airflow parameters based on driving conditions, environmental factors, and predictive analytics.

In the 1980s and early 1990s, V6 engines typically employed simple throttle body injection systems with limited airflow control capabilities. The primary focus during this period was on basic power delivery rather than optimization of the air-fuel mixture. As emissions standards tightened in the mid-1990s, manufacturers began implementing multi-port fuel injection systems, which offered improved air-fuel distribution but still lacked precise control over airflow dynamics.

The early 2000s marked a significant turning point with the introduction of variable valve timing (VVT) systems, allowing engines to adjust intake and exhaust valve operation based on engine load and speed. This technology represented the first major step toward dynamic air management in V6 engines, enabling better combustion efficiency across various operating conditions.

Further advancements emerged with the development of variable intake manifold systems, which could alter the length and configuration of intake runners to optimize airflow characteristics at different engine speeds. These systems typically employed flaps or valves that would redirect incoming air through either longer paths (for low-end torque) or shorter paths (for high-end power).

The current technological frontier in V6 air management includes direct injection, turbocharging, and advanced electronic throttle control systems. Modern V6 engines often incorporate multiple strategies simultaneously, creating complex but highly efficient air management ecosystems. Cylinder deactivation technology has also emerged as a key component, allowing engines to operate on fewer cylinders during light-load conditions, thereby reducing fuel consumption.

The primary objectives of contemporary V6 air management optimization include maximizing volumetric efficiency, minimizing pumping losses, ensuring optimal air-fuel mixture formation, and enabling precise combustion control across all operating conditions. Engineers are particularly focused on strategies that can deliver both high specific output and reduced emissions, a challenging balance that requires sophisticated air management solutions.

Looking forward, the integration of artificial intelligence and machine learning algorithms into engine management systems represents the next evolutionary step, potentially enabling real-time optimization of airflow parameters based on driving conditions, environmental factors, and predictive analytics.

Market Demand Analysis for Efficient V6 Engines

The global market for V6 engines has experienced significant transformation in recent years, driven by stringent emission regulations, increasing fuel costs, and growing consumer demand for environmentally friendly vehicles without sacrificing performance. Market research indicates that the V6 engine segment maintains a substantial presence in mid-size to luxury vehicles, SUVs, and light trucks, with an estimated global market value of $27.5 billion in 2023.

Consumer preferences have shifted notably toward engines that deliver optimal performance while maintaining fuel efficiency. A recent industry survey revealed that 68% of consumers consider fuel economy as a "very important" factor when purchasing vehicles with V6 engines, compared to 52% five years ago. This shift has created a robust demand for advanced air management systems that can enhance combustion efficiency.

Regional analysis shows varying market dynamics. North American consumers continue to favor V6 engines in pickup trucks and SUVs, with particular emphasis on towing capacity and acceleration. European markets demonstrate stronger preference for V6 diesel variants with sophisticated air management systems that comply with Euro 7 standards. Meanwhile, the Asia-Pacific region represents the fastest-growing market segment, with 7.3% annual growth in premium V6-equipped vehicles.

The commercial vehicle sector presents another significant market opportunity. Fleet operators increasingly prioritize total cost of ownership, where improved air management systems directly translate to fuel savings. Industry data suggests that a 5% improvement in air management efficiency can result in approximately 3-4% reduction in fleet operating costs over a vehicle's lifetime.

Automotive manufacturers are responding to these market demands by investing heavily in air management optimization technologies. The aftermarket segment for V6 engine air management components has also expanded, reaching $3.8 billion globally, with performance air intake systems and turbocharger upgrades leading the category.

Market forecasts project continued growth in demand for efficient V6 engines, particularly in hybrid powertrains where optimized air management becomes even more critical for balancing performance with efficiency. The premium vehicle segment, where V6 engines remain a popular option, is expected to grow at 4.2% annually through 2028, creating sustained demand for advanced air management solutions.

Competition from alternative powertrain technologies, particularly electric vehicles, presents both a challenge and opportunity for V6 engine development. Manufacturers are leveraging advanced air management strategies as a key differentiator to extend the market viability of internal combustion engines in an increasingly electrified automotive landscape.

Consumer preferences have shifted notably toward engines that deliver optimal performance while maintaining fuel efficiency. A recent industry survey revealed that 68% of consumers consider fuel economy as a "very important" factor when purchasing vehicles with V6 engines, compared to 52% five years ago. This shift has created a robust demand for advanced air management systems that can enhance combustion efficiency.

Regional analysis shows varying market dynamics. North American consumers continue to favor V6 engines in pickup trucks and SUVs, with particular emphasis on towing capacity and acceleration. European markets demonstrate stronger preference for V6 diesel variants with sophisticated air management systems that comply with Euro 7 standards. Meanwhile, the Asia-Pacific region represents the fastest-growing market segment, with 7.3% annual growth in premium V6-equipped vehicles.

The commercial vehicle sector presents another significant market opportunity. Fleet operators increasingly prioritize total cost of ownership, where improved air management systems directly translate to fuel savings. Industry data suggests that a 5% improvement in air management efficiency can result in approximately 3-4% reduction in fleet operating costs over a vehicle's lifetime.

Automotive manufacturers are responding to these market demands by investing heavily in air management optimization technologies. The aftermarket segment for V6 engine air management components has also expanded, reaching $3.8 billion globally, with performance air intake systems and turbocharger upgrades leading the category.

Market forecasts project continued growth in demand for efficient V6 engines, particularly in hybrid powertrains where optimized air management becomes even more critical for balancing performance with efficiency. The premium vehicle segment, where V6 engines remain a popular option, is expected to grow at 4.2% annually through 2028, creating sustained demand for advanced air management solutions.

Competition from alternative powertrain technologies, particularly electric vehicles, presents both a challenge and opportunity for V6 engine development. Manufacturers are leveraging advanced air management strategies as a key differentiator to extend the market viability of internal combustion engines in an increasingly electrified automotive landscape.

Current Air Management Technologies and Challenges

Air management in V6 engines represents a critical aspect of modern internal combustion engine design, with significant implications for performance, efficiency, and emissions. Current technologies employ a sophisticated blend of mechanical and electronic systems to optimize airflow throughout the engine's operation cycle. Variable Valve Timing (VVT) systems have evolved from simple dual-stage mechanisms to continuously variable implementations that precisely adjust valve timing based on engine load and speed conditions.

Intake manifold design has progressed substantially, with modern systems featuring variable geometry that can alter runner length and plenum volume to optimize volumetric efficiency across different RPM ranges. These systems typically employ electronically controlled flaps or valves that redirect airflow paths based on real-time engine parameters, allowing for optimized torque curves throughout the operating range.

Turbocharging and supercharging technologies have become increasingly sophisticated, with twin-scroll turbochargers, variable geometry turbines, and electric compressors gaining prominence in V6 applications. These forced induction systems are now commonly integrated with advanced electronic wastegate controls and intercooling solutions that minimize lag while maximizing boost pressure and thermal efficiency.

Despite these advancements, significant challenges persist in V6 air management. Balancing the competing demands of emissions compliance, fuel efficiency, and performance remains difficult, particularly as regulatory standards become increasingly stringent. Engineers face complex trade-offs when optimizing for low-end torque versus high-end power, often requiring compromises in overall engine performance characteristics.

Thermal management presents another substantial challenge, as higher compression ratios and forced induction systems generate increased heat loads that must be effectively managed to prevent detonation and ensure component longevity. This has led to the development of integrated cooling systems that specifically target intake charge temperatures.

Calibration complexity has grown exponentially with the introduction of multiple variable systems working in concert. Modern engine control units must process inputs from dozens of sensors to make real-time adjustments to numerous air management parameters, creating significant challenges in algorithm development and validation testing.

Manufacturing tolerances and production consistency represent ongoing challenges, particularly for components like variable valve timing actuators and variable geometry turbochargers that require precise operation under extreme conditions. Even minor variations in component specifications can lead to noticeable performance differences between otherwise identical engines.

Intake manifold design has progressed substantially, with modern systems featuring variable geometry that can alter runner length and plenum volume to optimize volumetric efficiency across different RPM ranges. These systems typically employ electronically controlled flaps or valves that redirect airflow paths based on real-time engine parameters, allowing for optimized torque curves throughout the operating range.

Turbocharging and supercharging technologies have become increasingly sophisticated, with twin-scroll turbochargers, variable geometry turbines, and electric compressors gaining prominence in V6 applications. These forced induction systems are now commonly integrated with advanced electronic wastegate controls and intercooling solutions that minimize lag while maximizing boost pressure and thermal efficiency.

Despite these advancements, significant challenges persist in V6 air management. Balancing the competing demands of emissions compliance, fuel efficiency, and performance remains difficult, particularly as regulatory standards become increasingly stringent. Engineers face complex trade-offs when optimizing for low-end torque versus high-end power, often requiring compromises in overall engine performance characteristics.

Thermal management presents another substantial challenge, as higher compression ratios and forced induction systems generate increased heat loads that must be effectively managed to prevent detonation and ensure component longevity. This has led to the development of integrated cooling systems that specifically target intake charge temperatures.

Calibration complexity has grown exponentially with the introduction of multiple variable systems working in concert. Modern engine control units must process inputs from dozens of sensors to make real-time adjustments to numerous air management parameters, creating significant challenges in algorithm development and validation testing.

Manufacturing tolerances and production consistency represent ongoing challenges, particularly for components like variable valve timing actuators and variable geometry turbochargers that require precise operation under extreme conditions. Even minor variations in component specifications can lead to noticeable performance differences between otherwise identical engines.

Current Optimization Solutions for V6 Air Management

01 Intake manifold design optimization

Optimizing the design of intake manifolds for V6 engines can significantly improve air management. This includes modifications to the geometry, length, and cross-sectional area of intake runners to enhance airflow dynamics. Advanced manifold designs can reduce pressure drops, improve volumetric efficiency, and ensure balanced air distribution to all cylinders, resulting in better combustion efficiency and engine performance.- Intake and exhaust system optimization: Optimization of intake and exhaust systems in V6 engines to improve air flow dynamics and combustion efficiency. This includes redesigned intake manifolds, advanced valve timing mechanisms, and exhaust gas recirculation systems that help balance air-fuel ratios. These modifications reduce flow resistance, improve volumetric efficiency, and enhance overall engine performance while reducing emissions.

- Turbocharging and supercharging solutions: Implementation of forced induction systems specifically designed for V6 engines to increase air density and volumetric efficiency. These systems include optimized turbocharger placement, variable geometry turbines, and integrated supercharger designs that address the unique layout challenges of V6 configurations. Advanced control systems manage boost pressure according to engine load and speed to maximize performance while maintaining reliability.

- Electronic air management control systems: Advanced electronic control systems that dynamically manage airflow in V6 engines based on real-time operating conditions. These systems incorporate sensors, actuators, and sophisticated algorithms to optimize air-fuel mixture, ignition timing, and valve operation. Machine learning and adaptive control strategies continuously refine air management parameters to improve efficiency across various driving conditions.

- Innovative air filter and intake duct designs: Novel air filtration systems and intake duct geometries specifically engineered for V6 engine configurations. These designs focus on reducing pressure drop, minimizing turbulence, and ensuring uniform air distribution to all cylinders. Advanced materials and computational fluid dynamics optimization create intake paths that maximize airflow while effectively filtering contaminants and reducing intake noise.

- Thermal management integration with air systems: Integrated approaches that combine thermal management with air flow optimization in V6 engines. These systems coordinate cooling strategies with intake air temperature control to maintain optimal combustion conditions. Heat exchangers, charge air coolers, and strategic component placement work together to manage thermal loads while ensuring consistent air density and quality across all operating conditions.

02 Variable valve timing systems

Implementation of variable valve timing systems in V6 engines allows for dynamic control of air intake and exhaust processes. These systems can adjust valve timing based on engine load and speed, optimizing air-fuel mixture and combustion efficiency across different operating conditions. Advanced electronic control units manage the valve actuation to achieve optimal air management, resulting in improved power output, fuel economy, and reduced emissions.Expand Specific Solutions03 Turbocharging and supercharging solutions

Forced induction systems such as turbochargers and superchargers enhance air management in V6 engines by increasing the density of intake air. These systems compress incoming air, allowing more oxygen to enter the combustion chamber for improved fuel burning efficiency. Modern designs incorporate intercoolers, wastegates, and electronic boost control to optimize air delivery across the engine's operating range, resulting in significant performance improvements.Expand Specific Solutions04 Electronic air management control systems

Advanced electronic control systems optimize V6 engine air management through real-time monitoring and adjustment of multiple parameters. These systems utilize sensors to measure airflow, temperature, pressure, and oxygen content, allowing precise control of air-fuel ratios. Sophisticated algorithms in the engine control unit can adjust throttle position, valve timing, and boost pressure to maintain optimal air management under varying operating conditions and environmental factors.Expand Specific Solutions05 Innovative air filtration and flow path design

Enhanced air filtration systems and optimized flow path designs improve air quality and flow characteristics in V6 engines. This includes aerodynamically designed air boxes, high-flow air filters, and streamlined ducting to reduce turbulence and restriction. Some designs incorporate resonator chambers and acoustic tuning elements to manage pressure waves and optimize air delivery across different engine speeds, contributing to improved volumetric efficiency and performance.Expand Specific Solutions

Leading Manufacturers and Competitive Landscape

V6 Engine Air Management optimization is currently in a mature development phase, with a substantial market size driven by automotive and industrial applications. The competitive landscape is characterized by established automotive giants like GM, Ford, Mercedes-Benz, and Toyota focusing on efficiency improvements, while specialized engineering firms such as AVL List, Bosch, and Rolls-Royce provide advanced technical solutions. The technology has reached high maturity levels with companies like Caterpillar, Cummins, and Weichai Power implementing sophisticated air management systems for performance and emissions compliance. Recent innovations from Mazda, Yamaha, and Geely demonstrate ongoing refinement in thermal efficiency and emissions control, indicating continued evolution despite the technology's maturity.

GM Global Technology Operations LLC

Technical Solution: GM's V6 engine air management optimization focuses on their Dynamic Fuel Management (DFM) technology, which represents an advanced cylinder deactivation system. Unlike traditional systems that deactivate fixed cylinder sets, GM's DFM can deactivate any combination of cylinders in real-time based on driving conditions. This is achieved through sophisticated valvetrain components including deactivation lifters and solenoids that can disable intake and exhaust valve operation. The system is complemented by advanced intake manifold designs featuring variable runner lengths and integrated resonance chambers that optimize airflow across varying engine speeds. GM has also implemented dual-path intake systems that can switch between long and short intake runners to optimize torque delivery across the RPM range. Their latest V6 engines incorporate active thermal management systems that precisely control coolant flow to different engine regions, maintaining optimal combustion temperatures for improved air-fuel mixing and reduced emissions.

Strengths: Industry-leading cylinder deactivation technology allows for 17 different firing patterns, providing exceptional fuel economy without sacrificing performance. The system can transition between patterns seamlessly without driver awareness. Weaknesses: The complex valvetrain system adds cost and potential reliability concerns over the vehicle's lifetime, and the technology requires sophisticated electronic controls that increase development and manufacturing complexity.

Ford Global Technologies LLC

Technical Solution: Ford's approach to V6 engine air management optimization centers on their EcoBoost technology platform, which combines direct fuel injection, turbocharging, and variable valve timing. For air management specifically, Ford employs dual sequential turbocharging on their high-performance V6 engines, with electronically actuated wastegates that precisely control boost pressure across the engine's operating range. Their intake manifold design incorporates active charge motion control valves that create targeted air turbulence at low engine speeds to improve combustion efficiency. Ford has pioneered the integration of port and direct injection systems working in tandem, allowing for optimal fuel delivery based on operating conditions. The company's latest V6 engines feature integrated exhaust manifolds within the cylinder head, reducing warm-up times and enabling more precise control of exhaust gas temperatures for emissions control systems. Ford also utilizes advanced computational fluid dynamics (CFD) modeling to optimize intake port geometry, achieving an ideal balance between swirl and tumble motion of incoming air for improved combustion dynamics.

Strengths: The dual-injection strategy provides excellent low-end torque while maintaining efficiency at higher RPMs, and the integrated exhaust manifolds reduce overall engine weight while improving thermal efficiency. Weaknesses: The complex turbocharging systems require sophisticated control algorithms and can experience turbo lag under certain operating conditions, and the high-pressure components may have higher maintenance requirements over the vehicle's lifetime.

Key Patents and Innovations in Air Flow Technology

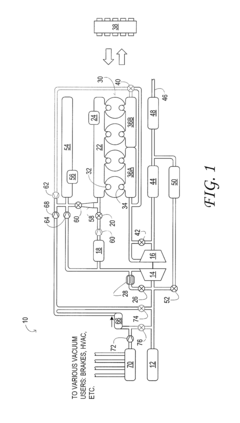

Stored compressed air management for improved engine performance

PatentInactiveUS8069665B2

Innovation

- A method that varies the relative amount of exhaust gas in stored compressed air in a boost tank based on engine conditions, allowing for the supply of appropriate air mixtures during open- and closed-throttle conditions, and uses a configurable air management system to store and discharge air effectively.

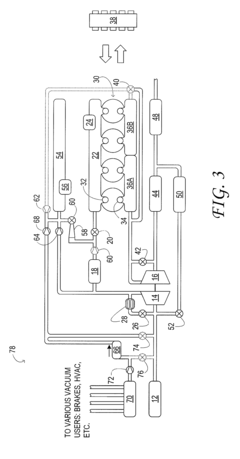

Method for controlling the compressed air supply of an internal combustion engine and a transmission

PatentWO2009103588A1

Innovation

- A method that controls the timing, duration, pressure, and volume of additional compressed air supplied to the engine's air intake tract based on driver demand, engine speed, load condition, and transmission ratio changes, using an electronic control unit to coordinate with the transmission and compressed air system, ensuring optimal torque delivery and fuel efficiency.

Emissions Regulations Impact on Air Management Design

Emissions regulations have become increasingly stringent worldwide, fundamentally reshaping air management system design in V6 engines. The European Union's Euro 7 standards, expected to be implemented by 2025, will require a 55% reduction in NOx emissions compared to Euro 6 levels, while the United States EPA's Tier 3 and California's LEVIII standards continue to push manufacturers toward near-zero emission targets. These regulatory frameworks have created a complex global compliance landscape that directly impacts engineering decisions in air management optimization.

The tightening regulations have catalyzed significant technological adaptations in V6 engine air management systems. Enhanced exhaust gas recirculation (EGR) systems have become essential components, with dual-loop configurations (both high and low pressure) increasingly common to meet NOx reduction requirements across various operating conditions. The integration of advanced sensors and real-time monitoring capabilities has also become necessary to ensure compliance with on-board diagnostic (OBD) requirements that mandate continuous emissions performance verification.

Thermal management has emerged as a critical focus area due to regulatory emphasis on cold-start emissions. Engineers must now design air management systems that rapidly reach optimal operating temperatures, often incorporating active thermal management strategies such as electrically heated catalysts and variable coolant flow control. These solutions directly address the fact that up to 80% of total emissions in standardized test cycles occur during the first 120 seconds of operation.

The regulatory push toward real-world driving emissions (RDE) testing has fundamentally altered the optimization approach for air management systems. Traditional laboratory-based optimization is no longer sufficient, as systems must now perform efficiently across a much wider range of operating conditions. This has led to the development of more sophisticated control algorithms that can adapt to varying ambient conditions, driving styles, and engine loads while maintaining emissions compliance.

Particulate matter regulations have also influenced air management design, particularly in direct injection V6 engines. Enhanced intake port designs that promote better air-fuel mixing, coupled with optimized combustion chamber geometries, have become essential strategies. Additionally, many manufacturers have implemented gasoline particulate filters (GPFs) as part of their air management strategy, requiring careful backpressure management to maintain engine performance while capturing ultrafine particles.

The global nature of emissions regulations has created additional complexity, as manufacturers must design air management systems capable of meeting different standards across various markets. This has led to modular approaches where core air management architectures can be adapted with market-specific calibrations and after-treatment components, balancing the need for manufacturing efficiency with regulatory compliance across diverse regions.

The tightening regulations have catalyzed significant technological adaptations in V6 engine air management systems. Enhanced exhaust gas recirculation (EGR) systems have become essential components, with dual-loop configurations (both high and low pressure) increasingly common to meet NOx reduction requirements across various operating conditions. The integration of advanced sensors and real-time monitoring capabilities has also become necessary to ensure compliance with on-board diagnostic (OBD) requirements that mandate continuous emissions performance verification.

Thermal management has emerged as a critical focus area due to regulatory emphasis on cold-start emissions. Engineers must now design air management systems that rapidly reach optimal operating temperatures, often incorporating active thermal management strategies such as electrically heated catalysts and variable coolant flow control. These solutions directly address the fact that up to 80% of total emissions in standardized test cycles occur during the first 120 seconds of operation.

The regulatory push toward real-world driving emissions (RDE) testing has fundamentally altered the optimization approach for air management systems. Traditional laboratory-based optimization is no longer sufficient, as systems must now perform efficiently across a much wider range of operating conditions. This has led to the development of more sophisticated control algorithms that can adapt to varying ambient conditions, driving styles, and engine loads while maintaining emissions compliance.

Particulate matter regulations have also influenced air management design, particularly in direct injection V6 engines. Enhanced intake port designs that promote better air-fuel mixing, coupled with optimized combustion chamber geometries, have become essential strategies. Additionally, many manufacturers have implemented gasoline particulate filters (GPFs) as part of their air management strategy, requiring careful backpressure management to maintain engine performance while capturing ultrafine particles.

The global nature of emissions regulations has created additional complexity, as manufacturers must design air management systems capable of meeting different standards across various markets. This has led to modular approaches where core air management architectures can be adapted with market-specific calibrations and after-treatment components, balancing the need for manufacturing efficiency with regulatory compliance across diverse regions.

Thermal Efficiency and Performance Trade-offs

The optimization of V6 engine air management systems presents a complex interplay between thermal efficiency and performance parameters. Engineers must navigate critical trade-offs that significantly impact overall engine operation and vehicle drivability.

Thermal efficiency in V6 engines is fundamentally linked to combustion temperature management. Higher combustion temperatures generally yield better thermal efficiency but simultaneously increase NOx emissions and thermal stress on engine components. Modern V6 designs implement strategic cooling pathways around combustion chambers to maintain optimal thermal conditions without compromising structural integrity.

Air-fuel ratio management represents another crucial trade-off domain. While stoichiometric mixtures (approximately 14.7:1 for gasoline engines) optimize emissions control with three-way catalytic converters, slight deviations toward richer or leaner mixtures can enhance either performance or efficiency respectively. Advanced V6 engines employ dynamic air-fuel ratio control systems that adjust mixture composition based on operational demands.

Intake manifold design exemplifies the efficiency-performance balance. Long, narrow runners promote better cylinder filling at lower RPMs, enhancing torque and fuel efficiency during typical driving conditions. Conversely, shorter, wider passages facilitate higher airflow volumes at elevated engine speeds, maximizing peak power output. Variable geometry intake systems attempt to reconcile these competing objectives through adjustable runner configurations.

Valve timing strategies further illustrate this dichotomy. Early intake valve closing improves efficiency through reduced pumping losses but may restrict maximum airflow. Late exhaust valve opening enhances power by extending the expansion stroke but potentially increases exhaust gas temperatures. Variable valve timing and lift technologies enable dynamic optimization across the engine's operational envelope.

Turbocharging and supercharging systems introduce additional complexity to the efficiency-performance relationship. While forced induction increases power density and can improve efficiency through downsizing, it also creates thermal management challenges and potential lag in power delivery. Modern twin-scroll turbochargers and electric superchargers represent technological responses to these inherent trade-offs.

Exhaust gas recirculation (EGR) systems demonstrate how performance can be sacrificed for efficiency and emissions benefits. While EGR reduces combustion temperatures and NOx formation, excessive recirculation can diminish combustion stability and throttle response. Precise EGR calibration remains essential for balancing these competing priorities in contemporary V6 applications.

Thermal efficiency in V6 engines is fundamentally linked to combustion temperature management. Higher combustion temperatures generally yield better thermal efficiency but simultaneously increase NOx emissions and thermal stress on engine components. Modern V6 designs implement strategic cooling pathways around combustion chambers to maintain optimal thermal conditions without compromising structural integrity.

Air-fuel ratio management represents another crucial trade-off domain. While stoichiometric mixtures (approximately 14.7:1 for gasoline engines) optimize emissions control with three-way catalytic converters, slight deviations toward richer or leaner mixtures can enhance either performance or efficiency respectively. Advanced V6 engines employ dynamic air-fuel ratio control systems that adjust mixture composition based on operational demands.

Intake manifold design exemplifies the efficiency-performance balance. Long, narrow runners promote better cylinder filling at lower RPMs, enhancing torque and fuel efficiency during typical driving conditions. Conversely, shorter, wider passages facilitate higher airflow volumes at elevated engine speeds, maximizing peak power output. Variable geometry intake systems attempt to reconcile these competing objectives through adjustable runner configurations.

Valve timing strategies further illustrate this dichotomy. Early intake valve closing improves efficiency through reduced pumping losses but may restrict maximum airflow. Late exhaust valve opening enhances power by extending the expansion stroke but potentially increases exhaust gas temperatures. Variable valve timing and lift technologies enable dynamic optimization across the engine's operational envelope.

Turbocharging and supercharging systems introduce additional complexity to the efficiency-performance relationship. While forced induction increases power density and can improve efficiency through downsizing, it also creates thermal management challenges and potential lag in power delivery. Modern twin-scroll turbochargers and electric superchargers represent technological responses to these inherent trade-offs.

Exhaust gas recirculation (EGR) systems demonstrate how performance can be sacrificed for efficiency and emissions benefits. While EGR reduces combustion temperatures and NOx formation, excessive recirculation can diminish combustion stability and throttle response. Precise EGR calibration remains essential for balancing these competing priorities in contemporary V6 applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!