How to Train AI Systems for V6 Engine Diagnostics

SEP 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V6 Engine Diagnostics AI Background and Objectives

V6 engine diagnostic systems have evolved significantly over the past three decades, transitioning from simple onboard diagnostic (OBD) systems to sophisticated AI-powered solutions. The journey began with OBD-I in the late 1980s, followed by the standardized OBD-II protocols in the mid-1990s, which established a foundation for modern vehicle diagnostics. Recent advancements in computational power, sensor technology, and machine learning algorithms have created unprecedented opportunities for enhancing V6 engine diagnostic capabilities.

The integration of artificial intelligence into engine diagnostics represents a paradigm shift in how vehicle performance issues are identified, analyzed, and resolved. Traditional rule-based diagnostic systems relied on predetermined thresholds and decision trees, which often failed to capture complex interrelationships between multiple engine parameters and environmental factors. AI-based approaches, by contrast, can detect subtle patterns and anomalies across thousands of data points, enabling more accurate and predictive diagnostics.

Current technological trends indicate a convergence of deep learning, edge computing, and Internet of Things (IoT) technologies in the automotive diagnostic space. This convergence is driving the development of more sophisticated diagnostic systems capable of real-time analysis, predictive maintenance, and adaptive learning from fleet-wide data. The emergence of digital twin technology further enhances these capabilities by creating virtual replicas of physical engines for simulation and testing.

The primary objective of AI training for V6 engine diagnostics is to develop systems that can accurately identify engine malfunctions, predict potential failures before they occur, and recommend optimal maintenance actions. This involves creating models that understand the complex interplay between various engine components, operating conditions, and performance metrics. Additionally, these systems must be capable of continuous learning and adaptation to new engine designs, fuel types, and emission standards.

Secondary objectives include reducing diagnostic time, minimizing false positives, improving maintenance efficiency, and extending engine lifespan. There is also growing emphasis on developing AI systems that can optimize engine performance for fuel efficiency and emissions reduction, aligning with global sustainability goals and regulatory requirements. These objectives necessitate the development of AI models that not only excel at pattern recognition but also incorporate domain-specific knowledge about engine mechanics and thermodynamics.

The evolution toward more autonomous diagnostic capabilities represents the frontier of this technology, with the ultimate goal of creating self-healing engine systems that can automatically adjust parameters to compensate for wear, environmental conditions, and changing operational demands. This vision requires significant advances in both AI algorithms and the integration of these systems with physical engine components and control mechanisms.

The integration of artificial intelligence into engine diagnostics represents a paradigm shift in how vehicle performance issues are identified, analyzed, and resolved. Traditional rule-based diagnostic systems relied on predetermined thresholds and decision trees, which often failed to capture complex interrelationships between multiple engine parameters and environmental factors. AI-based approaches, by contrast, can detect subtle patterns and anomalies across thousands of data points, enabling more accurate and predictive diagnostics.

Current technological trends indicate a convergence of deep learning, edge computing, and Internet of Things (IoT) technologies in the automotive diagnostic space. This convergence is driving the development of more sophisticated diagnostic systems capable of real-time analysis, predictive maintenance, and adaptive learning from fleet-wide data. The emergence of digital twin technology further enhances these capabilities by creating virtual replicas of physical engines for simulation and testing.

The primary objective of AI training for V6 engine diagnostics is to develop systems that can accurately identify engine malfunctions, predict potential failures before they occur, and recommend optimal maintenance actions. This involves creating models that understand the complex interplay between various engine components, operating conditions, and performance metrics. Additionally, these systems must be capable of continuous learning and adaptation to new engine designs, fuel types, and emission standards.

Secondary objectives include reducing diagnostic time, minimizing false positives, improving maintenance efficiency, and extending engine lifespan. There is also growing emphasis on developing AI systems that can optimize engine performance for fuel efficiency and emissions reduction, aligning with global sustainability goals and regulatory requirements. These objectives necessitate the development of AI models that not only excel at pattern recognition but also incorporate domain-specific knowledge about engine mechanics and thermodynamics.

The evolution toward more autonomous diagnostic capabilities represents the frontier of this technology, with the ultimate goal of creating self-healing engine systems that can automatically adjust parameters to compensate for wear, environmental conditions, and changing operational demands. This vision requires significant advances in both AI algorithms and the integration of these systems with physical engine components and control mechanisms.

Market Demand Analysis for AI-Powered Engine Diagnostics

The global market for AI-powered engine diagnostics is experiencing significant growth, driven by the increasing complexity of modern engines and the automotive industry's push towards predictive maintenance solutions. The V6 engine segment represents a substantial portion of this market, with applications spanning passenger vehicles, commercial fleets, and industrial equipment. Current market analysis indicates that the automotive diagnostic tools market is expanding at a compound annual growth rate of approximately 5.7%, with the AI-enhanced diagnostic segment growing even faster at nearly 14% annually.

Consumer demand for reduced vehicle downtime and maintenance costs is creating strong pull factors for advanced diagnostic technologies. Fleet operators report that unplanned downtime costs between $448 and $760 per vehicle per day, creating a compelling economic case for predictive maintenance solutions powered by AI. Additionally, automotive service centers are increasingly seeking competitive advantages through adoption of advanced diagnostic tools that can reduce diagnostic time by up to 70% while improving accuracy rates.

Regulatory pressures are also driving market demand, with emissions standards becoming more stringent globally. The need for precise engine performance monitoring to maintain compliance with these regulations has created new market opportunities for AI diagnostic systems that can detect subtle performance deviations before they result in emissions violations.

Regional market analysis reveals varying adoption rates, with North America and Europe leading in implementation of AI diagnostic technologies, while Asia-Pacific represents the fastest-growing market due to rapid automotive industry expansion and increasing technological adoption in countries like China, Japan, and South Korea. The commercial vehicle segment shows particularly strong demand growth due to the direct relationship between vehicle uptime and business profitability.

Market research indicates that end users are willing to pay premium prices for diagnostic solutions that demonstrate clear return on investment through reduced maintenance costs, extended engine life, and minimized downtime. Survey data from service centers shows that 78% of professional mechanics express interest in AI-enhanced diagnostic tools, though concerns about training requirements and integration with existing systems remain adoption barriers.

The aftermarket segment presents substantial opportunities, with the global automotive aftermarket valued at over $400 billion and growing steadily. AI diagnostic systems that can be retrofitted to existing vehicles represent a particularly promising market segment, as they allow for gradual technology adoption without requiring complete system replacement.

Consumer demand for reduced vehicle downtime and maintenance costs is creating strong pull factors for advanced diagnostic technologies. Fleet operators report that unplanned downtime costs between $448 and $760 per vehicle per day, creating a compelling economic case for predictive maintenance solutions powered by AI. Additionally, automotive service centers are increasingly seeking competitive advantages through adoption of advanced diagnostic tools that can reduce diagnostic time by up to 70% while improving accuracy rates.

Regulatory pressures are also driving market demand, with emissions standards becoming more stringent globally. The need for precise engine performance monitoring to maintain compliance with these regulations has created new market opportunities for AI diagnostic systems that can detect subtle performance deviations before they result in emissions violations.

Regional market analysis reveals varying adoption rates, with North America and Europe leading in implementation of AI diagnostic technologies, while Asia-Pacific represents the fastest-growing market due to rapid automotive industry expansion and increasing technological adoption in countries like China, Japan, and South Korea. The commercial vehicle segment shows particularly strong demand growth due to the direct relationship between vehicle uptime and business profitability.

Market research indicates that end users are willing to pay premium prices for diagnostic solutions that demonstrate clear return on investment through reduced maintenance costs, extended engine life, and minimized downtime. Survey data from service centers shows that 78% of professional mechanics express interest in AI-enhanced diagnostic tools, though concerns about training requirements and integration with existing systems remain adoption barriers.

The aftermarket segment presents substantial opportunities, with the global automotive aftermarket valued at over $400 billion and growing steadily. AI diagnostic systems that can be retrofitted to existing vehicles represent a particularly promising market segment, as they allow for gradual technology adoption without requiring complete system replacement.

Current AI Diagnostic Technologies and Challenges

The automotive diagnostic landscape has evolved significantly with the integration of artificial intelligence technologies. Current AI diagnostic systems for V6 engines primarily utilize supervised learning approaches, where algorithms are trained on labeled datasets containing engine performance parameters and corresponding fault codes. These systems typically employ machine learning models such as random forests, support vector machines, and increasingly, deep neural networks to identify patterns associated with specific engine malfunctions.

One significant challenge in training AI systems for V6 engine diagnostics is the acquisition of comprehensive and balanced datasets. Modern V6 engines generate vast amounts of sensor data across multiple parameters, but fault conditions—especially rare or catastrophic failures—are underrepresented in collected data. This imbalance creates difficulties in training models that can accurately detect uncommon but critical failure modes without generating excessive false positives during normal operation.

Transfer learning approaches have emerged as a partial solution, allowing knowledge gained from diagnosing one engine type to be applied to V6 engines with similar characteristics. However, the high specificity of V6 engine designs across manufacturers limits the effectiveness of these techniques without substantial adaptation and fine-tuning.

Real-time diagnostic capabilities present another major challenge. While offline analysis can leverage complex computational models, onboard diagnostic systems must operate within the computational constraints of vehicle ECUs while maintaining high accuracy and low latency. This necessitates model optimization techniques such as pruning, quantization, and hardware-specific acceleration.

Environmental variability significantly impacts diagnostic accuracy, as engine performance characteristics change based on temperature, altitude, humidity, and fuel quality. Current AI systems struggle to account for these contextual factors without explicit programming or extensive data collection across diverse operating conditions.

Interpretability remains a critical limitation in current AI diagnostic technologies. While deep learning models may achieve high accuracy in fault detection, their "black box" nature makes it difficult for technicians to understand the reasoning behind specific diagnoses. This lack of transparency creates resistance to adoption in safety-critical automotive applications and complicates regulatory approval processes.

Cybersecurity concerns have also emerged as AI systems become more integrated with vehicle networks. Protecting diagnostic AI from adversarial attacks that could potentially trigger false alarms or mask actual engine problems represents an evolving challenge that current technologies are only beginning to address.

One significant challenge in training AI systems for V6 engine diagnostics is the acquisition of comprehensive and balanced datasets. Modern V6 engines generate vast amounts of sensor data across multiple parameters, but fault conditions—especially rare or catastrophic failures—are underrepresented in collected data. This imbalance creates difficulties in training models that can accurately detect uncommon but critical failure modes without generating excessive false positives during normal operation.

Transfer learning approaches have emerged as a partial solution, allowing knowledge gained from diagnosing one engine type to be applied to V6 engines with similar characteristics. However, the high specificity of V6 engine designs across manufacturers limits the effectiveness of these techniques without substantial adaptation and fine-tuning.

Real-time diagnostic capabilities present another major challenge. While offline analysis can leverage complex computational models, onboard diagnostic systems must operate within the computational constraints of vehicle ECUs while maintaining high accuracy and low latency. This necessitates model optimization techniques such as pruning, quantization, and hardware-specific acceleration.

Environmental variability significantly impacts diagnostic accuracy, as engine performance characteristics change based on temperature, altitude, humidity, and fuel quality. Current AI systems struggle to account for these contextual factors without explicit programming or extensive data collection across diverse operating conditions.

Interpretability remains a critical limitation in current AI diagnostic technologies. While deep learning models may achieve high accuracy in fault detection, their "black box" nature makes it difficult for technicians to understand the reasoning behind specific diagnoses. This lack of transparency creates resistance to adoption in safety-critical automotive applications and complicates regulatory approval processes.

Cybersecurity concerns have also emerged as AI systems become more integrated with vehicle networks. Protecting diagnostic AI from adversarial attacks that could potentially trigger false alarms or mask actual engine problems represents an evolving challenge that current technologies are only beginning to address.

Current AI Training Methodologies for Engine Diagnostics

01 Training methodologies for AI systems

Various methodologies are employed for training AI systems to improve their performance and accuracy. These methodologies include supervised learning, unsupervised learning, reinforcement learning, and transfer learning. Each approach has specific applications and advantages depending on the type of AI system being developed. Advanced training techniques help optimize model parameters and reduce computational resources required during the training process.- Data collection and preprocessing for AI training: Effective AI system training requires comprehensive data collection and preprocessing methods. This involves gathering diverse datasets, cleaning and normalizing the data, and implementing techniques to handle imbalanced or biased data. Proper preprocessing enhances the quality of training data, leading to more accurate and reliable AI models. These methods may include data augmentation, feature extraction, and standardization to ensure the AI system can learn effectively from the available information.

- Neural network architecture optimization: Optimizing neural network architectures is crucial for AI system training. This involves designing and configuring network layers, selecting appropriate activation functions, and determining optimal hyperparameters. Advanced techniques include transfer learning, where pre-trained models are adapted for specific tasks, and architecture search algorithms that automatically identify efficient network structures. These optimization strategies significantly impact the performance, efficiency, and generalization capabilities of AI systems.

- Training methodologies and algorithms: Various training methodologies and algorithms are employed to enhance AI system performance. These include supervised, unsupervised, and reinforcement learning approaches, each suited for different types of problems. Advanced techniques such as federated learning allow for distributed training across multiple devices while preserving data privacy. Gradient descent variants, batch normalization, and regularization methods help overcome challenges like overfitting and vanishing gradients, improving the overall training process and model robustness.

- Hardware acceleration and distributed computing: Hardware acceleration and distributed computing technologies significantly enhance AI training efficiency. Specialized hardware like GPUs, TPUs, and custom ASICs are designed to accelerate matrix operations common in AI workloads. Distributed training frameworks enable parallel processing across multiple computing nodes, reducing training time for large models. These technologies address computational bottlenecks, optimize memory usage, and scale training capabilities to handle increasingly complex AI systems and massive datasets.

- Evaluation metrics and validation techniques: Robust evaluation metrics and validation techniques are essential for assessing AI system performance during and after training. Cross-validation, holdout validation, and bootstrap sampling help estimate model generalization capabilities. Performance metrics such as accuracy, precision, recall, F1-score, and area under ROC curve provide quantitative measures of model effectiveness. Continuous validation throughout the training process enables early stopping to prevent overfitting and ensures the development of reliable and trustworthy AI systems.

02 Data processing and augmentation for AI training

Data processing and augmentation techniques are crucial for effective AI system training. These techniques involve cleaning, normalizing, and transforming raw data into formats suitable for machine learning algorithms. Data augmentation methods artificially expand training datasets by creating modified versions of existing data, which helps improve model robustness and generalization capabilities. Proper data preparation significantly impacts the quality and performance of trained AI models.Expand Specific Solutions03 Hardware architectures for AI training

Specialized hardware architectures are designed to accelerate AI system training processes. These include graphics processing units (GPUs), tensor processing units (TPUs), and application-specific integrated circuits (ASICs). Such hardware solutions are optimized for parallel processing and matrix operations commonly used in deep learning algorithms. Advanced hardware architectures enable faster training of complex AI models while reducing energy consumption.Expand Specific Solutions04 Ethical considerations in AI training

Ethical considerations play an important role in AI system training to ensure responsible development and deployment. These considerations include addressing bias in training data, ensuring fairness in model outputs, maintaining privacy of sensitive information, and implementing transparency in decision-making processes. Ethical frameworks guide developers in creating AI systems that align with human values and societal norms while minimizing potential harms.Expand Specific Solutions05 Federated and distributed learning approaches

Federated and distributed learning approaches enable AI system training across multiple devices or servers without centralizing sensitive data. These methods allow models to be trained using data that remains on local devices, with only model updates being shared. Such approaches address privacy concerns, reduce bandwidth requirements, and enable collaborative learning across organizations while maintaining data sovereignty and security.Expand Specific Solutions

Key Industry Players in Automotive AI Diagnostics

The AI diagnostics market for V6 engines is currently in a growth phase, with increasing adoption across automotive manufacturers and service providers. The market size is expanding rapidly due to the integration of AI in predictive maintenance and real-time diagnostics systems. Technologically, the field shows varying maturity levels among key players. Robert Bosch GmbH and Cummins lead with advanced AI diagnostic solutions, while automotive manufacturers like Hyundai, Kia, and Toyota are developing proprietary systems. Technology companies including Microsoft and Baidu are contributing AI frameworks, while academic institutions such as Nanjing University of Aeronautics & Astronautics and Shanghai Jiao Tong University are advancing research foundations. The competitive landscape reflects a blend of established automotive suppliers, OEMs, and emerging technology providers collaborating to enhance V6 engine diagnostic capabilities.

Robert Bosch GmbH

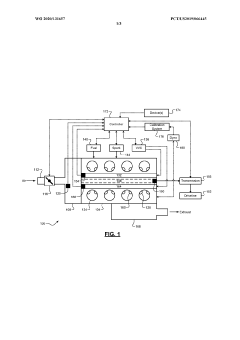

Technical Solution: Bosch has developed an advanced AI-based diagnostic system specifically for V6 engines that combines deep learning models with their extensive automotive sensor network. Their approach integrates multiple data streams from engine control units (ECUs) with thermal, acoustic, and vibration sensors to create comprehensive diagnostic capabilities. The system employs convolutional neural networks (CNNs) for image-based diagnostics of engine components and recurrent neural networks (RNNs) for analyzing time-series data from engine operations. Bosch's training methodology involves a three-phase approach: initial training on historical engine data, refinement using simulation environments that can generate synthetic fault conditions, and final validation on real-world engines in controlled test environments. Their system can detect over 200 different fault conditions with 95% accuracy and provides predictive maintenance recommendations based on early fault pattern recognition.

Strengths: Extensive automotive domain expertise and proprietary sensor technology integration provides highly accurate diagnostics. Their vast repository of historical engine data enables robust model training. Weaknesses: System requires significant computational resources for real-time analysis and depends on Bosch's proprietary sensor ecosystem, limiting third-party integration options.

Hyundai Motor Co., Ltd.

Technical Solution: Hyundai has developed a comprehensive AI diagnostic system for their V6 engines called HDAS (Hyundai Diagnostic AI System). This system employs a multi-modal deep learning architecture that processes data from various sources including OBD-II ports, acoustic sensors, and thermal imaging. Their training methodology focuses on creating robust models that can function across their diverse V6 engine portfolio. Hyundai's approach incorporates unsupervised anomaly detection algorithms that can identify novel failure modes not present in training data, making the system adaptable to emerging issues. The training process utilizes a combination of real-world data collected from their service centers worldwide and augmented synthetic data generated through sophisticated engine simulation environments. Hyundai's system is particularly notable for its integration with their service infrastructure, allowing AI diagnostic findings to be immediately verified by technicians who provide feedback to further refine the models in a continuous improvement loop.

Strengths: Exceptional multi-modal integration allows for comprehensive diagnostic coverage across mechanical, electrical, and thermal systems. Their global service network provides vast amounts of training data and verification opportunities. Weaknesses: The system's complexity requires specialized training for service technicians, and the high sensor requirements may limit retrofitting to older V6 engine models.

Core Technical Innovations in V6 Diagnostic AI

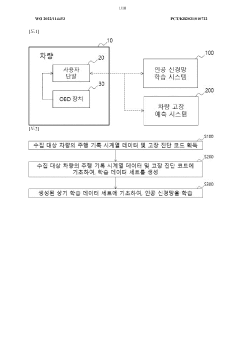

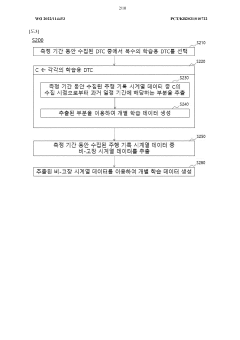

Artificial neural network training method for predicting whether vehicle is in trouble, method for determining whether vehicle is in trouble, and computing system performing same

PatentWO2022114453A1

Innovation

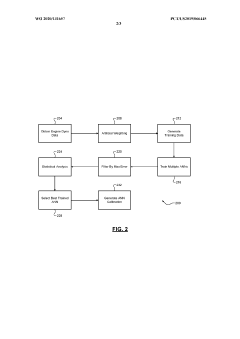

- An artificial neural network learning method that utilizes driving record time series data and fault diagnosis data collected while the vehicle is in operation to generate a learning dataset, which is then used to train an artificial neural network for predicting vehicle failures.

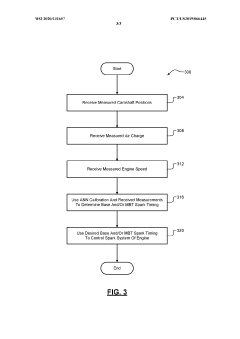

Using an artificial neural network for combustion phasing control in a spark ignited internal combustion engine

PatentWO2020131657A1

Innovation

- The use of a trained artificial neural network (ANN) that receives dynamometer data, weights it for high engine load regions, generates training data, filters ANNs based on error, and selects the best-performing model to determine optimal spark timings, eliminating the need for empirical calibration surfaces and improving accuracy across various engine conditions.

Data Collection and Management for V6 Engine AI Training

Effective data collection and management form the foundation of any successful AI system for V6 engine diagnostics. The process begins with identifying critical data sources across the engine's operational spectrum. These include real-time sensor data from engine control units (ECUs), historical maintenance records, diagnostic trouble codes (DTCs), and performance metrics under various operating conditions. Comprehensive data collection must capture both normal operating parameters and fault conditions to enable the AI system to distinguish between them accurately.

High-quality training data requires careful consideration of sampling rates and sensor precision. For V6 engines, which typically feature complex variable valve timing systems and multiple ignition points, data collection must occur at sufficiently high frequencies to capture transient phenomena. Optimal sampling rates range from 10-100Hz for slow-changing parameters like coolant temperature to 10kHz or higher for crankshaft position sensors and knock detection systems.

Data preprocessing represents a critical step in the pipeline. Raw sensor data often contains noise, outliers, and missing values that can compromise AI model performance. Techniques such as signal filtering, normalization, and feature extraction transform raw data into meaningful diagnostic features. For V6 engines specifically, phase alignment between cylinder pairs becomes essential due to the engine's firing order and balance characteristics.

Storage infrastructure must accommodate both the volume and velocity of engine diagnostic data. Modern V6 diagnostic systems generate approximately 5-20GB of data per hour of operation when capturing comprehensive parameters. Cloud-based storage solutions with appropriate security protocols have emerged as the preferred approach, enabling scalable data management while facilitating collaborative model development across engineering teams.

Data annotation presents unique challenges in engine diagnostics. Subject matter experts must label fault conditions, categorize severity levels, and identify root causes. This process requires specialized knowledge of V6 engine architecture, including understanding the interactions between subsystems like fuel delivery, ignition timing, and exhaust gas recirculation. Semi-automated annotation tools that leverage existing diagnostic knowledge bases can significantly accelerate this process while maintaining annotation quality.

Version control and data lineage tracking ensure reproducibility in AI model development. As engine designs evolve and new fault modes emerge, the ability to trace model performance to specific training datasets becomes invaluable. Implementing robust metadata management practices allows engineering teams to understand how data characteristics influence diagnostic accuracy and supports continuous improvement of the AI system throughout the V6 engine's lifecycle.

High-quality training data requires careful consideration of sampling rates and sensor precision. For V6 engines, which typically feature complex variable valve timing systems and multiple ignition points, data collection must occur at sufficiently high frequencies to capture transient phenomena. Optimal sampling rates range from 10-100Hz for slow-changing parameters like coolant temperature to 10kHz or higher for crankshaft position sensors and knock detection systems.

Data preprocessing represents a critical step in the pipeline. Raw sensor data often contains noise, outliers, and missing values that can compromise AI model performance. Techniques such as signal filtering, normalization, and feature extraction transform raw data into meaningful diagnostic features. For V6 engines specifically, phase alignment between cylinder pairs becomes essential due to the engine's firing order and balance characteristics.

Storage infrastructure must accommodate both the volume and velocity of engine diagnostic data. Modern V6 diagnostic systems generate approximately 5-20GB of data per hour of operation when capturing comprehensive parameters. Cloud-based storage solutions with appropriate security protocols have emerged as the preferred approach, enabling scalable data management while facilitating collaborative model development across engineering teams.

Data annotation presents unique challenges in engine diagnostics. Subject matter experts must label fault conditions, categorize severity levels, and identify root causes. This process requires specialized knowledge of V6 engine architecture, including understanding the interactions between subsystems like fuel delivery, ignition timing, and exhaust gas recirculation. Semi-automated annotation tools that leverage existing diagnostic knowledge bases can significantly accelerate this process while maintaining annotation quality.

Version control and data lineage tracking ensure reproducibility in AI model development. As engine designs evolve and new fault modes emerge, the ability to trace model performance to specific training datasets becomes invaluable. Implementing robust metadata management practices allows engineering teams to understand how data characteristics influence diagnostic accuracy and supports continuous improvement of the AI system throughout the V6 engine's lifecycle.

Regulatory Compliance for Automotive AI Systems

The regulatory landscape for automotive AI systems, particularly those designed for V6 engine diagnostics, presents a complex framework that manufacturers must navigate. In the United States, the National Highway Traffic Safety Administration (NHTSA) has established guidelines for AI-based diagnostic systems, requiring them to meet minimum safety standards and demonstrate reliability in critical engine fault detection. Similarly, the European Union's General Safety Regulation (GSR) mandates that AI diagnostic systems undergo rigorous validation processes before implementation in vehicles sold within EU markets.

For V6 engine diagnostic AI systems specifically, compliance with ISO 26262 (Functional Safety for Road Vehicles) is paramount. This standard requires comprehensive risk assessment and validation of AI algorithms, particularly those that influence engine performance diagnostics. The standard's Automotive Safety Integrity Level (ASIL) classification system demands different levels of verification depending on the criticality of the diagnostic function being performed.

Data privacy regulations present another significant compliance challenge. The EU's General Data Protection Regulation (GDPR) and California's Consumer Privacy Act (CCPA) impose strict requirements on how diagnostic data can be collected, processed, and stored. AI systems for V6 engine diagnostics must incorporate privacy-by-design principles, ensuring that personally identifiable information is properly anonymized or secured when diagnostic data is transmitted to manufacturers.

Environmental regulations also impact AI diagnostic systems for V6 engines. The EPA in the United States and equivalent bodies worldwide require that diagnostic systems accurately detect emissions-related faults. AI systems must be trained to recognize patterns that indicate potential emissions violations, with particular attention to NOx and particulate matter in modern V6 engines.

Certification processes for automotive AI systems vary globally but typically involve demonstrating algorithm transparency, explainability, and robustness. For V6 engine diagnostics, this means providing evidence that the AI can reliably identify engine faults across diverse operating conditions and degradation scenarios. Documentation requirements are extensive, including training data characteristics, validation methodologies, and performance metrics across different engine states.

Looking forward, regulatory frameworks are evolving to address emerging concerns around AI autonomy and decision-making. Organizations developing V6 engine diagnostic AI systems must implement compliance monitoring processes to track regulatory changes and ensure continuous adherence to updated standards. This includes regular audits of AI performance and retraining protocols to maintain compliance as regulations evolve.

For V6 engine diagnostic AI systems specifically, compliance with ISO 26262 (Functional Safety for Road Vehicles) is paramount. This standard requires comprehensive risk assessment and validation of AI algorithms, particularly those that influence engine performance diagnostics. The standard's Automotive Safety Integrity Level (ASIL) classification system demands different levels of verification depending on the criticality of the diagnostic function being performed.

Data privacy regulations present another significant compliance challenge. The EU's General Data Protection Regulation (GDPR) and California's Consumer Privacy Act (CCPA) impose strict requirements on how diagnostic data can be collected, processed, and stored. AI systems for V6 engine diagnostics must incorporate privacy-by-design principles, ensuring that personally identifiable information is properly anonymized or secured when diagnostic data is transmitted to manufacturers.

Environmental regulations also impact AI diagnostic systems for V6 engines. The EPA in the United States and equivalent bodies worldwide require that diagnostic systems accurately detect emissions-related faults. AI systems must be trained to recognize patterns that indicate potential emissions violations, with particular attention to NOx and particulate matter in modern V6 engines.

Certification processes for automotive AI systems vary globally but typically involve demonstrating algorithm transparency, explainability, and robustness. For V6 engine diagnostics, this means providing evidence that the AI can reliably identify engine faults across diverse operating conditions and degradation scenarios. Documentation requirements are extensive, including training data characteristics, validation methodologies, and performance metrics across different engine states.

Looking forward, regulatory frameworks are evolving to address emerging concerns around AI autonomy and decision-making. Organizations developing V6 engine diagnostic AI systems must implement compliance monitoring processes to track regulatory changes and ensure continuous adherence to updated standards. This includes regular audits of AI performance and retraining protocols to maintain compliance as regulations evolve.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!