How to Develop V6 Engine Cycle Models for Efficiency

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V6 Engine Development History and Efficiency Goals

The V6 engine configuration has evolved significantly since its inception in the early 20th century. Initially developed as a compact alternative to inline-six and V8 engines, the V6 gained prominence in the 1950s when introduced in production vehicles by companies like Lancia and Ferrari. The 60-degree V6 design emerged as a popular configuration due to its natural balance characteristics, though 90-degree variants were also developed to share production tooling with V8 engines.

The 1970s oil crisis marked a pivotal turning point in V6 engine development, shifting focus from pure performance to fuel efficiency. This period saw manufacturers like Ford, General Motors, and Nissan investing heavily in V6 technology as a compromise between the economy of four-cylinder engines and the power of V8s. The 1980s and 1990s witnessed significant advancements in fuel injection systems, valve timing, and engine management electronics, all contributing to improved efficiency.

By the early 2000s, direct injection technology began appearing in production V6 engines, offering substantial improvements in both power output and fuel economy. Variable valve timing and lift systems became increasingly sophisticated, allowing engines to optimize performance across wider operating ranges. The introduction of turbocharging and supercharging to smaller displacement V6 engines enabled "downsizing" strategies, where smaller forced-induction engines could replace larger naturally aspirated ones while delivering comparable power with better efficiency.

Current efficiency goals for V6 engine development are primarily driven by stringent global emissions regulations and consumer demand for fuel economy. Manufacturers aim to achieve thermal efficiencies exceeding 40%, compared to the 25-30% typical of earlier generations. Reduction of friction losses through advanced materials and coatings represents another key objective, with potential efficiency gains of 2-3% through optimized bearing designs and low-friction piston rings.

Cycle modeling for V6 engines now focuses on optimizing combustion processes through precise control of air-fuel mixtures, ignition timing, and exhaust gas recirculation. Advanced computational fluid dynamics (CFD) simulations enable engineers to model complex in-cylinder phenomena with unprecedented accuracy. The integration of real-time adaptive control systems allows modern V6 engines to continuously optimize their operating parameters based on driving conditions and performance demands.

Looking forward, V6 engine development aims to incorporate technologies like homogeneous charge compression ignition (HCCI), variable compression ratios, and advanced thermal management systems. These innovations, coupled with increasingly sophisticated cycle modeling techniques, are expected to push the efficiency boundaries of internal combustion engines while meeting ever-tightening emissions standards.

The 1970s oil crisis marked a pivotal turning point in V6 engine development, shifting focus from pure performance to fuel efficiency. This period saw manufacturers like Ford, General Motors, and Nissan investing heavily in V6 technology as a compromise between the economy of four-cylinder engines and the power of V8s. The 1980s and 1990s witnessed significant advancements in fuel injection systems, valve timing, and engine management electronics, all contributing to improved efficiency.

By the early 2000s, direct injection technology began appearing in production V6 engines, offering substantial improvements in both power output and fuel economy. Variable valve timing and lift systems became increasingly sophisticated, allowing engines to optimize performance across wider operating ranges. The introduction of turbocharging and supercharging to smaller displacement V6 engines enabled "downsizing" strategies, where smaller forced-induction engines could replace larger naturally aspirated ones while delivering comparable power with better efficiency.

Current efficiency goals for V6 engine development are primarily driven by stringent global emissions regulations and consumer demand for fuel economy. Manufacturers aim to achieve thermal efficiencies exceeding 40%, compared to the 25-30% typical of earlier generations. Reduction of friction losses through advanced materials and coatings represents another key objective, with potential efficiency gains of 2-3% through optimized bearing designs and low-friction piston rings.

Cycle modeling for V6 engines now focuses on optimizing combustion processes through precise control of air-fuel mixtures, ignition timing, and exhaust gas recirculation. Advanced computational fluid dynamics (CFD) simulations enable engineers to model complex in-cylinder phenomena with unprecedented accuracy. The integration of real-time adaptive control systems allows modern V6 engines to continuously optimize their operating parameters based on driving conditions and performance demands.

Looking forward, V6 engine development aims to incorporate technologies like homogeneous charge compression ignition (HCCI), variable compression ratios, and advanced thermal management systems. These innovations, coupled with increasingly sophisticated cycle modeling techniques, are expected to push the efficiency boundaries of internal combustion engines while meeting ever-tightening emissions standards.

Market Demand Analysis for High-Efficiency V6 Engines

The global automotive industry is witnessing a significant shift towards higher efficiency engines, with V6 engines maintaining a strong position in the market due to their balance of power, efficiency, and cost. Market analysis indicates that the demand for high-efficiency V6 engines is primarily driven by stringent emission regulations across major automotive markets, including the European Union's Euro 7 standards, the United States' Corporate Average Fuel Economy (CAFE) standards, and China's increasingly strict emissions policies.

Consumer preferences are also evolving, with a growing segment of buyers seeking vehicles that offer both performance and fuel economy. This dual demand creates a substantial market opportunity for optimized V6 engines, particularly in mid-size to large sedans, SUVs, and light trucks. According to industry forecasts, the global market for V6 engines is expected to grow at a compound annual growth rate of 3.2% through 2028, with high-efficiency variants capturing an increasing share.

The premium automotive segment represents a particularly strong market for advanced V6 engines, where customers are willing to pay for technologies that deliver improved efficiency without compromising performance. Luxury vehicle manufacturers are increasingly positioning efficient V6 engines as alternatives to larger V8 configurations, emphasizing comparable performance with reduced fuel consumption and emissions.

Commercial vehicle applications present another significant market opportunity. Fleet operators are increasingly focused on total cost of ownership, where fuel efficiency plays a crucial role. High-efficiency V6 engines that can deliver diesel-like economy with lower acquisition and maintenance costs are gaining traction in this segment.

Regional market analysis reveals varying demands. North American consumers continue to prioritize power alongside efficiency, while European markets show stronger preference for downsized engines with advanced efficiency technologies. Emerging markets, particularly in Asia-Pacific, demonstrate growing demand for V6 engines in premium vehicles as disposable incomes rise.

The hybridization trend is also reshaping market demands for V6 engines. Mild hybrid, full hybrid, and plug-in hybrid systems paired with V6 engines are seeing increased adoption, creating demand for engine cycle models specifically optimized for hybrid operation. This integration requires specialized development approaches to maximize efficiency across various operating conditions.

Market research indicates that automotive manufacturers are willing to invest substantially in advanced engine development technologies, including sophisticated cycle modeling tools, if they can demonstrate clear efficiency improvements of at least 8-10% over previous generation engines while maintaining or improving performance characteristics.

Consumer preferences are also evolving, with a growing segment of buyers seeking vehicles that offer both performance and fuel economy. This dual demand creates a substantial market opportunity for optimized V6 engines, particularly in mid-size to large sedans, SUVs, and light trucks. According to industry forecasts, the global market for V6 engines is expected to grow at a compound annual growth rate of 3.2% through 2028, with high-efficiency variants capturing an increasing share.

The premium automotive segment represents a particularly strong market for advanced V6 engines, where customers are willing to pay for technologies that deliver improved efficiency without compromising performance. Luxury vehicle manufacturers are increasingly positioning efficient V6 engines as alternatives to larger V8 configurations, emphasizing comparable performance with reduced fuel consumption and emissions.

Commercial vehicle applications present another significant market opportunity. Fleet operators are increasingly focused on total cost of ownership, where fuel efficiency plays a crucial role. High-efficiency V6 engines that can deliver diesel-like economy with lower acquisition and maintenance costs are gaining traction in this segment.

Regional market analysis reveals varying demands. North American consumers continue to prioritize power alongside efficiency, while European markets show stronger preference for downsized engines with advanced efficiency technologies. Emerging markets, particularly in Asia-Pacific, demonstrate growing demand for V6 engines in premium vehicles as disposable incomes rise.

The hybridization trend is also reshaping market demands for V6 engines. Mild hybrid, full hybrid, and plug-in hybrid systems paired with V6 engines are seeing increased adoption, creating demand for engine cycle models specifically optimized for hybrid operation. This integration requires specialized development approaches to maximize efficiency across various operating conditions.

Market research indicates that automotive manufacturers are willing to invest substantially in advanced engine development technologies, including sophisticated cycle modeling tools, if they can demonstrate clear efficiency improvements of at least 8-10% over previous generation engines while maintaining or improving performance characteristics.

Current V6 Engine Cycle Modeling Challenges

Despite significant advancements in V6 engine cycle modeling, several persistent challenges continue to impede the development of highly accurate and efficient models. One of the primary obstacles is the complexity of combustion dynamics within V6 engines, which involves intricate chemical reactions, heat transfer mechanisms, and fluid dynamics that are difficult to capture in simplified models. Current modeling approaches often struggle to accurately represent the transient behaviors during different operating conditions, particularly during cold starts, rapid acceleration, and varying load scenarios.

The computational intensity of high-fidelity models presents another significant challenge. Comprehensive models that account for detailed combustion chemistry, turbulence, and thermal dynamics require substantial computational resources, making them impractical for real-time applications or integration into broader vehicle system models. This creates a fundamental trade-off between model accuracy and computational efficiency that engineers must constantly navigate.

Calibration and validation of V6 engine cycle models remain problematic due to the difficulty in obtaining comprehensive experimental data across all operating conditions. The cost and complexity of instrumentation required to capture detailed in-cylinder measurements limit the availability of validation data, particularly for advanced combustion modes and alternative fuel operations.

Integration challenges exist between component-level models and system-level simulations. Current approaches often struggle to effectively bridge the gap between detailed component models (such as combustion chamber processes) and full engine system behavior, leading to discrepancies when scaling from component to system level predictions.

The increasing diversity of V6 engine configurations, including various valve timing strategies, turbocharging systems, and hybrid powertrains, further complicates the development of universally applicable modeling frameworks. Models developed for specific engine configurations often require substantial recalibration when applied to different designs.

Emissions prediction represents a particularly challenging aspect of current modeling efforts. Accurately predicting the formation of pollutants such as NOx, particulate matter, and unburned hydrocarbons requires extremely detailed chemistry models that are difficult to integrate into cycle-level simulations without significant computational penalties.

Finally, there is a growing need for models that can effectively represent the aging and degradation of engine components over time, as these factors significantly impact long-term efficiency. Current models typically assume ideal or static component characteristics, failing to capture the gradual performance deterioration that occurs throughout an engine's operational lifetime.

The computational intensity of high-fidelity models presents another significant challenge. Comprehensive models that account for detailed combustion chemistry, turbulence, and thermal dynamics require substantial computational resources, making them impractical for real-time applications or integration into broader vehicle system models. This creates a fundamental trade-off between model accuracy and computational efficiency that engineers must constantly navigate.

Calibration and validation of V6 engine cycle models remain problematic due to the difficulty in obtaining comprehensive experimental data across all operating conditions. The cost and complexity of instrumentation required to capture detailed in-cylinder measurements limit the availability of validation data, particularly for advanced combustion modes and alternative fuel operations.

Integration challenges exist between component-level models and system-level simulations. Current approaches often struggle to effectively bridge the gap between detailed component models (such as combustion chamber processes) and full engine system behavior, leading to discrepancies when scaling from component to system level predictions.

The increasing diversity of V6 engine configurations, including various valve timing strategies, turbocharging systems, and hybrid powertrains, further complicates the development of universally applicable modeling frameworks. Models developed for specific engine configurations often require substantial recalibration when applied to different designs.

Emissions prediction represents a particularly challenging aspect of current modeling efforts. Accurately predicting the formation of pollutants such as NOx, particulate matter, and unburned hydrocarbons requires extremely detailed chemistry models that are difficult to integrate into cycle-level simulations without significant computational penalties.

Finally, there is a growing need for models that can effectively represent the aging and degradation of engine components over time, as these factors significantly impact long-term efficiency. Current models typically assume ideal or static component characteristics, failing to capture the gradual performance deterioration that occurs throughout an engine's operational lifetime.

Current V6 Engine Cycle Modeling Approaches

01 Optimization of V6 engine combustion cycles

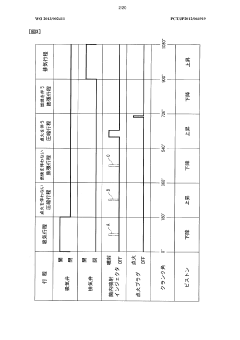

Various combustion cycle models have been developed to improve the efficiency of V6 engines. These models focus on optimizing the timing and sequence of combustion events to maximize power output while minimizing fuel consumption. Advanced cycle models incorporate variable valve timing, cylinder deactivation, and modified compression ratios to enhance thermal efficiency and reduce energy losses during the combustion process.- Optimization of V6 engine combustion cycles: Various combustion cycle models have been developed to improve the efficiency of V6 engines. These models focus on optimizing the timing and sequence of intake, compression, power, and exhaust strokes. By refining the combustion cycle, engineers can achieve better fuel combustion, reduced emissions, and increased power output. Advanced cycle models incorporate variable valve timing and lift mechanisms to adapt the engine operation to different load conditions.

- Thermal efficiency improvements in V6 engines: Enhancing the thermal efficiency of V6 engines involves reducing heat losses and improving heat recovery systems. This includes optimizing cooling systems, implementing thermal barrier coatings, and utilizing exhaust heat recovery technologies. By managing thermal energy more effectively, these innovations help convert more fuel energy into mechanical work, thereby increasing the overall efficiency of the engine cycle. Some approaches also incorporate advanced materials that can withstand higher operating temperatures.

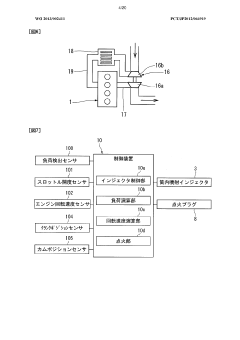

- Electronic control systems for V6 engine efficiency: Modern V6 engines utilize sophisticated electronic control systems to optimize performance and efficiency. These systems employ sensors and microprocessors to monitor and adjust engine parameters in real-time, including fuel injection timing, ignition timing, and air-fuel ratios. Advanced control algorithms can model and predict engine behavior under various operating conditions, allowing for precise adjustments that maximize efficiency while maintaining performance. Some systems also incorporate machine learning to continuously improve engine operation based on usage patterns.

- Alternative cycle models for V6 engines: Research into alternative thermodynamic cycles for V6 engines has led to innovations beyond the traditional Otto cycle. These include modified Atkinson cycles, Miller cycles, and hybrid cycle approaches that can significantly improve efficiency under specific operating conditions. By altering the compression and expansion ratios or implementing variable cycle operation, these alternative models can achieve better fuel economy while maintaining adequate power output. Some designs incorporate phase-change materials or novel working fluids to enhance the thermodynamic properties of the cycle.

- Mechanical design optimizations for V6 efficiency: Mechanical improvements to V6 engine components can significantly enhance cycle efficiency. These include redesigned pistons and connecting rods to reduce friction, lightweight materials to decrease reciprocating mass, and optimized intake and exhaust manifolds to improve gas flow dynamics. Advanced bearing technologies and surface treatments reduce mechanical losses, while innovative valve train designs minimize pumping losses. Some designs also incorporate variable compression ratio mechanisms that can adapt to different operating conditions for maximum efficiency.

02 Thermal management systems for V6 engines

Efficient thermal management systems play a crucial role in improving V6 engine efficiency. These systems regulate engine temperature to optimize combustion conditions and reduce friction losses. Advanced cooling systems, heat recovery mechanisms, and thermal barrier coatings help maintain ideal operating temperatures, prevent overheating, and capture waste heat for improved overall engine efficiency.Expand Specific Solutions03 Electronic control systems for V6 engine efficiency

Electronic control systems are implemented to monitor and adjust V6 engine parameters in real-time for maximum efficiency. These systems use sensors and advanced algorithms to optimize fuel injection timing, ignition timing, air-fuel ratios, and other critical parameters. Computer models simulate engine cycles to predict performance under various conditions, allowing for precise adjustments that improve fuel economy and reduce emissions.Expand Specific Solutions04 Innovative V6 engine designs for improved efficiency

Novel V6 engine designs incorporate structural modifications to enhance efficiency. These include optimized cylinder configurations, reduced friction components, lightweight materials, and improved intake/exhaust systems. Some designs feature variable displacement technology that allows the engine to operate on fewer cylinders during light load conditions, significantly improving fuel efficiency without sacrificing performance when needed.Expand Specific Solutions05 Hybrid and alternative cycle models for V6 engines

Hybrid and alternative cycle models combine traditional V6 engine operation with innovative technologies to achieve higher efficiency. These include Atkinson/Miller cycle adaptations, split-cycle configurations, and integration with electric motors in hybrid systems. Such approaches modify the conventional four-stroke cycle to extract more work from the same amount of fuel, often by adjusting compression and expansion ratios independently or recovering energy that would otherwise be lost.Expand Specific Solutions

Leading V6 Engine Manufacturers and Research Institutions

The V6 engine cycle model development landscape is currently in a growth phase, with increasing market demand driven by stringent efficiency regulations. The market is characterized by a mix of established automotive manufacturers (Toyota, BMW, Hyundai, Volvo Penta) and specialized technology providers (Tula Technology, AVL List). Technical maturity varies significantly across players, with companies like Robert Bosch, GM Global Technology, and Toyota demonstrating advanced capabilities in thermodynamic modeling and combustion optimization. Academic institutions including Beihang University and Nanjing University of Aeronautics & Astronautics are contributing fundamental research, while specialized firms like IFP Energies Nouvelles and Sherpa Engineering offer sophisticated simulation tools. The competitive landscape is evolving as electrification pressures drive innovation in traditional combustion technology.

GM Global Technology Operations LLC

Technical Solution: GM has developed advanced V6 engine cycle models focusing on predictive combustion simulation techniques. Their approach integrates detailed chemical kinetics with computational fluid dynamics (CFD) to accurately predict combustion behavior across various operating conditions. GM's methodology incorporates real-time cylinder pressure analysis and heat release calculations to optimize valve timing and fuel injection strategies. Their models account for transient thermal management, including coolant flow optimization and thermal barrier coatings to reduce heat losses. GM has implemented machine learning algorithms to continuously refine their models based on dynamometer test data, allowing for rapid calibration adjustments to maximize efficiency. The company has also developed specialized sub-models for friction reduction and exhaust energy recovery systems specifically tailored for V6 architectures.

Strengths: Comprehensive integration of thermal management, combustion modeling, and real-world validation processes. Extensive testing infrastructure and data collection capabilities. Weaknesses: Models may be overly complex for rapid development cycles, requiring significant computational resources and specialized expertise to implement effectively.

Robert Bosch GmbH

Technical Solution: Bosch has pioneered a multi-scale modeling approach for V6 engine cycle efficiency optimization. Their technology combines 0D/1D system models with 3D CFD simulations to balance computational efficiency with accuracy. Bosch's models feature advanced fuel spray dynamics simulation, incorporating detailed droplet evaporation and mixture formation processes critical for direct injection V6 engines. Their approach includes comprehensive modeling of the entire air path system, from intake to exhaust, with particular attention to turbocharger matching and variable valve timing effects. Bosch has developed proprietary algorithms for real-time combustion control based on these models, enabling cycle-by-cycle adjustments to maintain optimal efficiency. Their system incorporates detailed heat transfer models that account for spatial temperature variations within the cylinder and their effect on combustion propagation. Bosch's models are validated through extensive testing on production V6 engines across multiple vehicle platforms.

Strengths: Exceptional integration with electronic control systems, allowing direct implementation of model-based control strategies. Strong focus on practical applications and production feasibility. Weaknesses: Proprietary nature of models may limit academic collaboration and broader industry adoption. Models may prioritize robustness over capturing certain advanced combustion phenomena.

Key Thermodynamic Principles in V6 Engine Efficiency

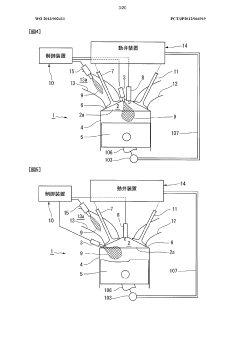

Six-cycle engine

PatentWO2013002411A1

Innovation

- A 6-cycle engine design that includes an in-cylinder injection injector for direct fuel injection into the combustion chamber, allowing for stratified combustion without relying on swirling air flow, thereby increasing the intake air amount and optimizing the intake port for high flow rates.

Emissions Regulations Impact on V6 Engine Development

Emissions regulations have become a primary driver in the evolution of V6 engine development, creating both challenges and opportunities for efficiency-focused cycle modeling. The global regulatory landscape has undergone significant transformation over the past decade, with major markets implementing increasingly stringent standards. The European Union's Euro 6d standards, the United States EPA's Tier 3 regulations, and China's China 6 standards have collectively pushed manufacturers toward substantial reductions in nitrogen oxides (NOx), particulate matter (PM), and carbon dioxide (CO2) emissions.

These regulations have fundamentally altered the approach to V6 engine cycle modeling by necessitating the integration of emissions performance as a primary design parameter rather than a secondary consideration. Engineers must now develop cycle models that simultaneously optimize for thermal efficiency while maintaining emissions compliance across a wider range of operating conditions, including cold starts and transient operations which traditionally produce higher emissions.

The regulatory focus on real-world driving emissions (RDE) testing has particularly impacted V6 engine development by expanding the operational envelope that must be modeled. Traditional cycle models focused primarily on steady-state conditions must now accurately predict performance across dynamic driving scenarios. This has increased computational complexity and required more sophisticated approaches to combustion modeling, including chemical kinetics simulations that can accurately predict emissions formation.

Carbon dioxide reduction targets have driven the integration of advanced technologies into V6 engine designs, including variable valve timing, cylinder deactivation, and advanced turbocharging. Each of these technologies introduces additional variables into cycle models, requiring more complex simulation frameworks that can capture their interactions and optimize their operation across diverse conditions.

Regional regulatory differences have further complicated V6 engine development, as manufacturers must design engines capable of meeting different standards across global markets. This has led to the development of modular cycle models with adjustable parameters that can be tuned to specific regulatory requirements, allowing for efficient global deployment while minimizing redesign costs.

Looking forward, upcoming regulations such as Euro 7 and increasingly stringent CAFE standards will continue to shape V6 engine cycle model development. The trend toward electrification and hybridization as compliance strategies means that future cycle models must also account for integration with electric powertrains, adding another layer of complexity to the development process. This regulatory-driven evolution has accelerated innovation in modeling techniques, with machine learning and artificial intelligence emerging as valuable tools for navigating the complex multi-objective optimization problems presented by modern emissions standards.

These regulations have fundamentally altered the approach to V6 engine cycle modeling by necessitating the integration of emissions performance as a primary design parameter rather than a secondary consideration. Engineers must now develop cycle models that simultaneously optimize for thermal efficiency while maintaining emissions compliance across a wider range of operating conditions, including cold starts and transient operations which traditionally produce higher emissions.

The regulatory focus on real-world driving emissions (RDE) testing has particularly impacted V6 engine development by expanding the operational envelope that must be modeled. Traditional cycle models focused primarily on steady-state conditions must now accurately predict performance across dynamic driving scenarios. This has increased computational complexity and required more sophisticated approaches to combustion modeling, including chemical kinetics simulations that can accurately predict emissions formation.

Carbon dioxide reduction targets have driven the integration of advanced technologies into V6 engine designs, including variable valve timing, cylinder deactivation, and advanced turbocharging. Each of these technologies introduces additional variables into cycle models, requiring more complex simulation frameworks that can capture their interactions and optimize their operation across diverse conditions.

Regional regulatory differences have further complicated V6 engine development, as manufacturers must design engines capable of meeting different standards across global markets. This has led to the development of modular cycle models with adjustable parameters that can be tuned to specific regulatory requirements, allowing for efficient global deployment while minimizing redesign costs.

Looking forward, upcoming regulations such as Euro 7 and increasingly stringent CAFE standards will continue to shape V6 engine cycle model development. The trend toward electrification and hybridization as compliance strategies means that future cycle models must also account for integration with electric powertrains, adding another layer of complexity to the development process. This regulatory-driven evolution has accelerated innovation in modeling techniques, with machine learning and artificial intelligence emerging as valuable tools for navigating the complex multi-objective optimization problems presented by modern emissions standards.

Computational Methods for Advanced Engine Simulation

Computational methods have revolutionized engine development processes, enabling engineers to create highly accurate V6 engine cycle models without extensive physical prototyping. These methods incorporate advanced mathematical algorithms, thermodynamic principles, and fluid dynamics to simulate complex engine operations across various operating conditions. Modern computational approaches typically employ finite element analysis (FEA), computational fluid dynamics (CFD), and chemical kinetics modeling to capture the intricate processes occurring within combustion chambers.

The evolution of computational power has significantly enhanced simulation capabilities, allowing for multi-physics models that simultaneously account for thermal management, structural integrity, and combustion efficiency. High-performance computing clusters now enable engineers to run thousands of simulation iterations to optimize V6 engine parameters within days rather than months. This acceleration in development cycles has become particularly crucial as manufacturers face increasing pressure to improve fuel efficiency while meeting stringent emissions regulations.

Machine learning algorithms have recently emerged as powerful tools for engine cycle modeling, capable of identifying non-intuitive relationships between design parameters and performance metrics. These algorithms can process vast datasets from both simulations and physical tests to create predictive models that continuously improve in accuracy. Neural networks, in particular, have demonstrated remarkable capabilities in predicting combustion characteristics under varying load conditions, enabling more precise control strategies for V6 engines.

Real-time simulation techniques represent another significant advancement, allowing engineers to evaluate engine performance across the entire operating envelope. These methods incorporate reduced-order models derived from more complex simulations to achieve computational efficiency without sacrificing critical accuracy factors. The integration of hardware-in-the-loop (HIL) testing with computational models creates a powerful development environment where control algorithms can be validated against virtual engine models before implementation in physical prototypes.

Open-source computational frameworks have democratized access to advanced simulation capabilities, fostering collaboration across research institutions and industry partners. Tools such as OpenFOAM for CFD analysis and Cantera for chemical kinetics modeling provide robust platforms for developing specialized V6 engine simulations. These frameworks allow for customization to address specific efficiency challenges, such as optimizing valve timing, fuel injection parameters, or exhaust gas recirculation strategies in V6 configurations.

The future of computational methods for V6 engine cycle modeling lies in quantum computing applications, which promise to solve currently intractable optimization problems by evaluating exponentially more design variations simultaneously. As these technologies mature, they will enable unprecedented levels of efficiency optimization by exploring design spaces that remain inaccessible with conventional computing approaches.

The evolution of computational power has significantly enhanced simulation capabilities, allowing for multi-physics models that simultaneously account for thermal management, structural integrity, and combustion efficiency. High-performance computing clusters now enable engineers to run thousands of simulation iterations to optimize V6 engine parameters within days rather than months. This acceleration in development cycles has become particularly crucial as manufacturers face increasing pressure to improve fuel efficiency while meeting stringent emissions regulations.

Machine learning algorithms have recently emerged as powerful tools for engine cycle modeling, capable of identifying non-intuitive relationships between design parameters and performance metrics. These algorithms can process vast datasets from both simulations and physical tests to create predictive models that continuously improve in accuracy. Neural networks, in particular, have demonstrated remarkable capabilities in predicting combustion characteristics under varying load conditions, enabling more precise control strategies for V6 engines.

Real-time simulation techniques represent another significant advancement, allowing engineers to evaluate engine performance across the entire operating envelope. These methods incorporate reduced-order models derived from more complex simulations to achieve computational efficiency without sacrificing critical accuracy factors. The integration of hardware-in-the-loop (HIL) testing with computational models creates a powerful development environment where control algorithms can be validated against virtual engine models before implementation in physical prototypes.

Open-source computational frameworks have democratized access to advanced simulation capabilities, fostering collaboration across research institutions and industry partners. Tools such as OpenFOAM for CFD analysis and Cantera for chemical kinetics modeling provide robust platforms for developing specialized V6 engine simulations. These frameworks allow for customization to address specific efficiency challenges, such as optimizing valve timing, fuel injection parameters, or exhaust gas recirculation strategies in V6 configurations.

The future of computational methods for V6 engine cycle modeling lies in quantum computing applications, which promise to solve currently intractable optimization problems by evaluating exponentially more design variations simultaneously. As these technologies mature, they will enable unprecedented levels of efficiency optimization by exploring design spaces that remain inaccessible with conventional computing approaches.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!