V6 Engine Power Distribution: Balancing Techniques

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V6 Engine Evolution and Power Goals

The V6 engine has undergone significant evolution since its introduction in the early 20th century. Initially developed as a compromise between inline-four and V8 configurations, the V6 engine has transformed from a relatively rough, unbalanced power plant to a sophisticated, efficient, and powerful engine architecture widely adopted across automotive segments. The compact design, offering an optimal balance between performance and packaging efficiency, has made it a preferred choice for both mainstream and premium vehicle applications.

Early V6 engines suffered from inherent balance issues due to their 60-degree V-angle configuration, which created uneven firing intervals and significant vibration. The technological breakthrough came with the development of split-pin crankshafts and advanced balancing techniques in the 1980s, allowing manufacturers to achieve smoother operation without sacrificing power delivery characteristics.

The power goals for modern V6 engines have evolved dramatically over the past decade, driven by increasingly stringent emissions regulations and consumer demand for improved fuel efficiency without compromising performance. Current development targets focus on achieving specific power outputs exceeding 100 horsepower per liter in naturally aspirated configurations, while turbocharged variants regularly exceed 150 horsepower per liter. These ambitious targets represent a significant advancement from early V6 designs that typically produced 40-60 horsepower per liter.

Power distribution within V6 engines presents unique challenges due to the inherent firing order and cylinder arrangement. Engineers aim to achieve linear power delivery across the RPM range while minimizing NVH (Noise, Vibration, and Harshness) characteristics. The ideal power curve demonstrates progressive torque build-up from low RPM, with peak torque available in the mid-range and sustained power delivery at higher engine speeds.

Recent technological innovations have focused on variable valve timing, direct injection, and integrated exhaust manifolds to optimize power distribution throughout the operating range. These technologies allow for precise control of combustion events, enabling engineers to tailor power delivery characteristics to specific application requirements. Additionally, the integration of hybrid systems with V6 engines has created new opportunities for power distribution optimization, with electric motors providing torque fill at lower RPMs where traditional combustion engines are less efficient.

The future evolution of V6 engines will likely focus on further refinement of power distribution through advanced combustion strategies, including pre-chamber ignition, variable compression ratios, and sophisticated thermal management systems. These developments aim to extract maximum efficiency while maintaining the performance characteristics that have made V6 engines popular across diverse automotive applications.

Early V6 engines suffered from inherent balance issues due to their 60-degree V-angle configuration, which created uneven firing intervals and significant vibration. The technological breakthrough came with the development of split-pin crankshafts and advanced balancing techniques in the 1980s, allowing manufacturers to achieve smoother operation without sacrificing power delivery characteristics.

The power goals for modern V6 engines have evolved dramatically over the past decade, driven by increasingly stringent emissions regulations and consumer demand for improved fuel efficiency without compromising performance. Current development targets focus on achieving specific power outputs exceeding 100 horsepower per liter in naturally aspirated configurations, while turbocharged variants regularly exceed 150 horsepower per liter. These ambitious targets represent a significant advancement from early V6 designs that typically produced 40-60 horsepower per liter.

Power distribution within V6 engines presents unique challenges due to the inherent firing order and cylinder arrangement. Engineers aim to achieve linear power delivery across the RPM range while minimizing NVH (Noise, Vibration, and Harshness) characteristics. The ideal power curve demonstrates progressive torque build-up from low RPM, with peak torque available in the mid-range and sustained power delivery at higher engine speeds.

Recent technological innovations have focused on variable valve timing, direct injection, and integrated exhaust manifolds to optimize power distribution throughout the operating range. These technologies allow for precise control of combustion events, enabling engineers to tailor power delivery characteristics to specific application requirements. Additionally, the integration of hybrid systems with V6 engines has created new opportunities for power distribution optimization, with electric motors providing torque fill at lower RPMs where traditional combustion engines are less efficient.

The future evolution of V6 engines will likely focus on further refinement of power distribution through advanced combustion strategies, including pre-chamber ignition, variable compression ratios, and sophisticated thermal management systems. These developments aim to extract maximum efficiency while maintaining the performance characteristics that have made V6 engines popular across diverse automotive applications.

Market Demand Analysis for V6 Engines

The global market for V6 engines continues to demonstrate robust demand despite increasing competition from alternative powertrain technologies. Current market analysis indicates that V6 engines maintain a significant market share in mid-size to large passenger vehicles, premium SUVs, and light commercial vehicles. This segment represents approximately 18 million units annually across global markets, with North America and China being the largest consumers.

Consumer preference studies reveal that V6 engines occupy a strategic middle ground in the automotive market, offering a compelling balance between the fuel economy of smaller four-cylinder engines and the raw power of larger V8 configurations. This positioning has proven particularly valuable as manufacturers face increasingly stringent emissions regulations while still needing to meet consumer expectations for performance.

Market research indicates several key drivers sustaining demand for V6 engines with advanced power distribution and balancing technologies. First, the premium vehicle segment continues to expand globally, with consumers willing to pay for enhanced driving dynamics and refinement that well-balanced V6 engines provide. Second, towing capacity requirements in recreational and light commercial applications favor the torque characteristics of properly balanced V6 configurations.

Regional market analysis shows divergent trends. In North America, V6 engines remain popular in pickup trucks and SUVs, where balanced power delivery across varying load conditions is essential. European markets show preference for V6 engines primarily in premium segments, with emphasis on NVH (Noise, Vibration, Harshness) characteristics that advanced balancing techniques can address. Asian markets demonstrate growing demand in the luxury segment, where smooth power delivery is a key differentiator.

Industry forecasts suggest that while overall internal combustion engine market share will gradually decline due to electrification, the V6 configuration with advanced balancing technologies will remain resilient in specific applications. Hybrid powertrains incorporating V6 engines are projected to see particular growth, leveraging the inherent balance advantages of the V6 configuration when integrated with electric motors.

Market surveys indicate that consumers consistently rank smoothness of operation and refined power delivery among their top five purchasing considerations in premium vehicle segments. This directly correlates with the benefits provided by advanced V6 balancing techniques, suggesting continued market opportunity for innovations in this space.

The commercial vehicle sector also presents significant growth potential for balanced V6 applications, particularly in markets transitioning from larger displacement engines to more efficient options that still deliver necessary torque characteristics for commercial applications.

Consumer preference studies reveal that V6 engines occupy a strategic middle ground in the automotive market, offering a compelling balance between the fuel economy of smaller four-cylinder engines and the raw power of larger V8 configurations. This positioning has proven particularly valuable as manufacturers face increasingly stringent emissions regulations while still needing to meet consumer expectations for performance.

Market research indicates several key drivers sustaining demand for V6 engines with advanced power distribution and balancing technologies. First, the premium vehicle segment continues to expand globally, with consumers willing to pay for enhanced driving dynamics and refinement that well-balanced V6 engines provide. Second, towing capacity requirements in recreational and light commercial applications favor the torque characteristics of properly balanced V6 configurations.

Regional market analysis shows divergent trends. In North America, V6 engines remain popular in pickup trucks and SUVs, where balanced power delivery across varying load conditions is essential. European markets show preference for V6 engines primarily in premium segments, with emphasis on NVH (Noise, Vibration, Harshness) characteristics that advanced balancing techniques can address. Asian markets demonstrate growing demand in the luxury segment, where smooth power delivery is a key differentiator.

Industry forecasts suggest that while overall internal combustion engine market share will gradually decline due to electrification, the V6 configuration with advanced balancing technologies will remain resilient in specific applications. Hybrid powertrains incorporating V6 engines are projected to see particular growth, leveraging the inherent balance advantages of the V6 configuration when integrated with electric motors.

Market surveys indicate that consumers consistently rank smoothness of operation and refined power delivery among their top five purchasing considerations in premium vehicle segments. This directly correlates with the benefits provided by advanced V6 balancing techniques, suggesting continued market opportunity for innovations in this space.

The commercial vehicle sector also presents significant growth potential for balanced V6 applications, particularly in markets transitioning from larger displacement engines to more efficient options that still deliver necessary torque characteristics for commercial applications.

Current V6 Power Distribution Challenges

Modern V6 engines face significant challenges in achieving optimal power distribution across all cylinders. The inherent design of V6 configurations creates natural imbalances due to the V-angle and firing order, resulting in uneven power delivery that manifests as vibration, reduced efficiency, and potential long-term reliability issues. These challenges are particularly pronounced at higher RPM ranges where imbalances become magnified.

The primary technical obstacle lies in the inherent geometry of the V6 layout. Unlike inline-six engines that feature natural primary and secondary balance, V6 engines generate complex forces that must be carefully managed. The 60-degree V6 configuration, while compact and widely adopted, creates inherent first-order imbalances that require sophisticated counterbalancing mechanisms. Meanwhile, 90-degree V6 designs, though beneficial for packaging in certain vehicle platforms, introduce even more complex balancing requirements.

Combustion pressure variations between cylinders represent another significant challenge. Manufacturing tolerances, fuel delivery inconsistencies, and intake/exhaust flow differences can result in cylinder-to-cylinder power variations of up to 8-12%. These variations not only impact overall engine smoothness but also create hotspots that accelerate component wear and reduce engine longevity.

The integration of modern technologies has introduced additional complexities. Variable valve timing, cylinder deactivation, and turbocharging systems can dramatically alter the power distribution characteristics across operating conditions. Engineers must now balance traditional mechanical solutions with sophisticated electronic control strategies to maintain optimal power distribution across an increasingly wide operating envelope.

Thermal management presents another critical challenge. Uneven heat distribution across cylinders can lead to warping, increased friction, and accelerated wear. The center cylinders typically operate at higher temperatures than the outer cylinders, creating thermal gradients that must be carefully managed through cooling system design and materials selection.

NVH (Noise, Vibration, Harshness) considerations further complicate power distribution solutions. As vehicles become quieter and consumer expectations for refinement increase, even minor imbalances that were previously masked by overall noise levels now become noticeable quality issues. This has driven the need for more precise balancing techniques and additional vibration damping systems.

Emissions regulations and fuel economy targets add another dimension to the challenge. Solutions that optimize power distribution must simultaneously support efficient combustion across all operating conditions to meet increasingly stringent emissions standards while maintaining competitive performance characteristics.

The primary technical obstacle lies in the inherent geometry of the V6 layout. Unlike inline-six engines that feature natural primary and secondary balance, V6 engines generate complex forces that must be carefully managed. The 60-degree V6 configuration, while compact and widely adopted, creates inherent first-order imbalances that require sophisticated counterbalancing mechanisms. Meanwhile, 90-degree V6 designs, though beneficial for packaging in certain vehicle platforms, introduce even more complex balancing requirements.

Combustion pressure variations between cylinders represent another significant challenge. Manufacturing tolerances, fuel delivery inconsistencies, and intake/exhaust flow differences can result in cylinder-to-cylinder power variations of up to 8-12%. These variations not only impact overall engine smoothness but also create hotspots that accelerate component wear and reduce engine longevity.

The integration of modern technologies has introduced additional complexities. Variable valve timing, cylinder deactivation, and turbocharging systems can dramatically alter the power distribution characteristics across operating conditions. Engineers must now balance traditional mechanical solutions with sophisticated electronic control strategies to maintain optimal power distribution across an increasingly wide operating envelope.

Thermal management presents another critical challenge. Uneven heat distribution across cylinders can lead to warping, increased friction, and accelerated wear. The center cylinders typically operate at higher temperatures than the outer cylinders, creating thermal gradients that must be carefully managed through cooling system design and materials selection.

NVH (Noise, Vibration, Harshness) considerations further complicate power distribution solutions. As vehicles become quieter and consumer expectations for refinement increase, even minor imbalances that were previously masked by overall noise levels now become noticeable quality issues. This has driven the need for more precise balancing techniques and additional vibration damping systems.

Emissions regulations and fuel economy targets add another dimension to the challenge. Solutions that optimize power distribution must simultaneously support efficient combustion across all operating conditions to meet increasingly stringent emissions standards while maintaining competitive performance characteristics.

Current Balancing Techniques

01 V6 Engine Power Distribution Systems

V6 engines require specialized power distribution systems to efficiently deliver power from the engine to various vehicle components. These systems typically include power transfer mechanisms, electronic control units, and distribution networks that optimize the engine's performance. Advanced power distribution systems in V6 engines help balance power output across all cylinders, resulting in smoother operation and improved fuel efficiency.- V6 Engine Power Distribution Systems: V6 engines require specialized power distribution systems to efficiently deliver power from the engine to various vehicle components. These systems typically include power management units, distribution networks, and control mechanisms that optimize the engine's performance. Advanced power distribution systems in V6 engines help balance power output across all cylinders, resulting in smoother operation and improved fuel efficiency.

- Electronic Control Units for V6 Engine Power Management: Electronic Control Units (ECUs) play a crucial role in managing power distribution in V6 engines. These sophisticated control systems monitor various engine parameters and adjust power delivery accordingly. ECUs optimize fuel injection timing, ignition timing, and air-fuel mixture to ensure optimal power distribution across all six cylinders. Advanced algorithms in these control units help maintain engine performance while maximizing fuel efficiency and reducing emissions.

- Power Distribution Networks for V6 Engine Applications: Specialized power distribution networks are designed for V6 engine applications to ensure efficient power delivery throughout the vehicle. These networks include high-current carrying conductors, junction boxes, and connection points that distribute power from the engine to various electrical systems. The design of these networks takes into account the unique power generation characteristics of V6 engines, ensuring stable voltage supply and protection against electrical overloads.

- Thermal Management in V6 Engine Power Distribution: Thermal management is a critical aspect of V6 engine power distribution systems. These engines generate significant heat during operation, which must be effectively managed to maintain optimal performance. Cooling systems, heat exchangers, and thermal sensors work together to monitor and regulate engine temperature. Advanced thermal management solutions help distribute heat evenly across the engine block, preventing hotspots and ensuring consistent power output from all cylinders.

- Power Balancing Technologies for V6 Engines: Power balancing technologies are essential for V6 engines to ensure smooth operation and optimal performance. These technologies include cylinder deactivation systems, variable valve timing, and advanced fuel injection strategies that help distribute power evenly across all cylinders. By balancing the power output, these technologies reduce vibration, improve fuel efficiency, and extend engine life. Modern V6 engines incorporate sophisticated sensors and actuators that continuously adjust power distribution based on driving conditions and load requirements.

02 Electronic Control Units for V6 Engine Power Management

Electronic Control Units (ECUs) play a crucial role in managing power distribution in V6 engines. These sophisticated control systems monitor various engine parameters and adjust power delivery accordingly. They incorporate sensors and algorithms to optimize combustion timing, fuel injection, and power output based on driving conditions. Modern ECUs for V6 engines feature adaptive learning capabilities that continuously refine power distribution for maximum efficiency and performance.Expand Specific Solutions03 Power Transmission and Torque Distribution in V6 Engines

V6 engines employ specialized mechanisms for transmitting and distributing torque across the powertrain. These systems include advanced gearing arrangements, torque converters, and differential systems that optimize power delivery to the wheels. Innovations in torque distribution technology help minimize power loss during transmission while maximizing traction and handling characteristics. These systems are particularly important in high-performance V6 applications where precise power control is essential.Expand Specific Solutions04 Thermal Management in V6 Engine Power Systems

Effective thermal management is critical for optimal power distribution in V6 engines. These systems regulate operating temperatures to ensure consistent power output and prevent overheating. Advanced cooling circuits, heat exchangers, and temperature-controlled components work together to maintain ideal thermal conditions throughout the engine. Proper thermal management extends engine life while allowing for maximum power extraction across various operating conditions.Expand Specific Solutions05 Alternative Power Distribution Technologies for V6 Engines

Emerging technologies are transforming power distribution in V6 engines, particularly in hybrid and electrified applications. These include integrated starter-generators, power-split devices, and advanced battery management systems that work alongside the V6 engine. Such technologies enable more flexible power routing, regenerative capabilities, and improved overall efficiency. These innovations represent the evolution of V6 power distribution systems to meet modern performance and emissions requirements.Expand Specific Solutions

Major V6 Engine Manufacturers

The V6 engine power distribution market is in a mature growth phase, with established technologies and significant competition among major automotive manufacturers. The global market size for V6 engines is substantial, driven by demand in premium vehicles, SUVs, and performance cars. In terms of technical maturity, companies like Toyota, Honda, and Ford have developed advanced balancing techniques, while Hyundai, Nissan, and Mercedes-Benz are innovating with variable valve timing and cylinder deactivation technologies. Emerging players such as Geely and Tata Motors are gaining ground with cost-effective solutions. The competitive landscape shows traditional manufacturers focusing on refinement while newer entrants emphasize efficiency and performance-to-cost ratio in their V6 power distribution systems.

GM Global Technology Operations LLC

Technical Solution: GM's V6 engine power distribution technology employs Active Fuel Management (AFM) that selectively deactivates cylinders during light load conditions, transitioning between 6 and 4 cylinder operation seamlessly. Their Dynamic Skip Fire (DSF) technology represents an advancement beyond traditional cylinder deactivation, allowing individual cylinders to be fired or skipped based on real-time power demands[1]. GM's V6 engines utilize sophisticated electronic throttle control systems with integrated torque management algorithms that optimize power delivery across the RPM range. The company has also implemented dual-equal variable valve timing on both intake and exhaust camshafts to enhance power distribution while maintaining fuel efficiency[2]. Additionally, GM's V6 engines feature direct injection systems with precisely controlled fuel delivery timing and multiple injection events per cycle to balance power output, emissions control, and fuel economy across varying operating conditions[3].

Strengths: Advanced cylinder deactivation technology provides excellent balance between performance and fuel economy; sophisticated electronic control systems enable precise power management across diverse driving conditions. Weaknesses: Complex systems require more sophisticated maintenance; potential reliability concerns with advanced cylinder deactivation hardware over extended vehicle life.

Ford Global Technologies LLC

Technical Solution: Ford's approach to V6 engine power distribution balancing centers around their EcoBoost technology, which combines turbocharging, direct fuel injection, and variable valve timing. For their V6 engines, Ford implements twin independent variable camshaft timing (Ti-VCT) that allows for precise control of valve events on both intake and exhaust sides, optimizing power delivery across the entire RPM range[1]. Their power distribution strategy includes advanced electronic throttle control with integrated torque management that continuously adjusts air-fuel ratios and ignition timing to balance performance and efficiency. Ford's V6 engines utilize sophisticated knock sensors and cylinder pressure monitoring to enable operation at optimal compression ratios while preventing detonation. The company has also developed active vibration control systems that counteract inherent V6 engine vibrations through precisely timed engine mounts and powertrain control module interventions[2]. Additionally, Ford employs advanced cooling systems with targeted jet cooling for critical engine components to maintain thermal balance across all cylinders, ensuring consistent power output under varying load conditions[3].

Strengths: EcoBoost technology delivers excellent power density and torque across wide RPM ranges; sophisticated electronic controls enable precise balancing of performance and efficiency. Weaknesses: Turbocharging adds complexity and potential long-term reliability concerns; higher operating temperatures require more sophisticated cooling systems.

Key V6 Balancing Patents

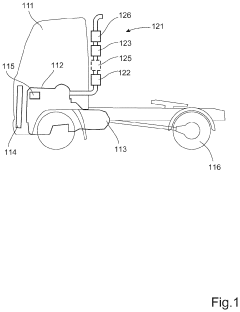

A method and a control system for controlling an internal combustion engine

PatentActiveUS20220163003A1

Innovation

- A method and control system that adjusts fuel injection in a four-stroke ICE to heat exhaust gases to a specific temperature by selectively regulating cylinder groups and altering fuel amounts in consecutive induction strokes, ensuring the DPF and SCR units operate effectively during low load conditions, thereby reducing the need for parked regeneration and extending component lifespan.

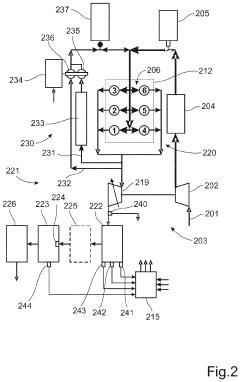

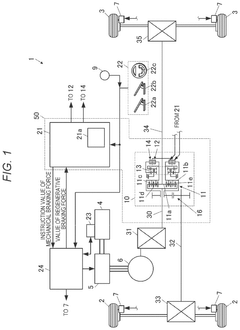

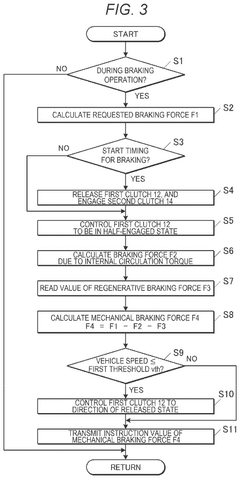

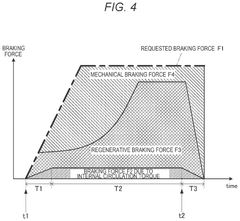

Power distribution apparatus for electric vehicle

PatentActiveUS12103405B2

Innovation

- A power distribution apparatus with a mechanism that includes a first clutch to maintain a 50:50 power distribution ratio during straight travel and a second clutch to adjust the power distribution ratio to 40:60 in favor of the rear wheels during braking, controlled by a controller that sets the second clutch to an engaged state and the first clutch to a half-engaged state during regenerative braking.

Emissions Regulations Impact

Emissions regulations have become a pivotal factor in the development and implementation of V6 engine power distribution balancing techniques. Over the past decade, increasingly stringent global emissions standards have fundamentally reshaped how manufacturers approach engine design, particularly for V6 configurations where power balance directly impacts emissions performance.

The European Union's Euro 6d standards and the United States' EPA Tier 3 regulations have established particularly challenging NOx, CO2, and particulate matter limits that directly influence V6 engine balancing strategies. These regulations have accelerated the shift from traditional mechanical balancing approaches toward more sophisticated electronic control systems capable of real-time combustion optimization.

Manufacturers must now design V6 engines with balancing techniques that not only ensure smooth operation but also maintain optimal air-fuel ratios across all cylinders under varying load conditions. This regulatory pressure has led to innovations such as cylinder deactivation systems that must maintain balance while operating with fewer active cylinders, requiring more complex harmonic balancing solutions.

The introduction of Real Driving Emissions (RDE) testing has further complicated V6 engine development, as balancing techniques must now perform effectively across a much wider range of operating conditions than previously required under laboratory testing regimes. This has driven the adoption of adaptive balancing systems that continuously adjust to maintain emissions compliance.

Cold-start emissions requirements have particularly influenced balancing technology, as V6 engines must reach optimal operating temperatures quickly while maintaining balance during thermal transition phases. This has led to the development of specialized warm-up balancing strategies that temporarily sacrifice some smoothness for emissions compliance.

Regional variations in emissions standards create additional challenges for global V6 engine platforms. Manufacturers must design balancing systems with sufficient adaptability to meet diverse regulatory requirements without requiring fundamental redesigns for different markets. This has increased the importance of software-controlled balancing solutions that can be calibrated for specific regional requirements.

Looking forward, upcoming Euro 7 and next-generation EPA standards will likely demand even more precise balancing techniques to achieve the required emissions performance, potentially accelerating the integration of AI-driven predictive balancing algorithms that can anticipate and compensate for combustion variations before they impact emissions.

The European Union's Euro 6d standards and the United States' EPA Tier 3 regulations have established particularly challenging NOx, CO2, and particulate matter limits that directly influence V6 engine balancing strategies. These regulations have accelerated the shift from traditional mechanical balancing approaches toward more sophisticated electronic control systems capable of real-time combustion optimization.

Manufacturers must now design V6 engines with balancing techniques that not only ensure smooth operation but also maintain optimal air-fuel ratios across all cylinders under varying load conditions. This regulatory pressure has led to innovations such as cylinder deactivation systems that must maintain balance while operating with fewer active cylinders, requiring more complex harmonic balancing solutions.

The introduction of Real Driving Emissions (RDE) testing has further complicated V6 engine development, as balancing techniques must now perform effectively across a much wider range of operating conditions than previously required under laboratory testing regimes. This has driven the adoption of adaptive balancing systems that continuously adjust to maintain emissions compliance.

Cold-start emissions requirements have particularly influenced balancing technology, as V6 engines must reach optimal operating temperatures quickly while maintaining balance during thermal transition phases. This has led to the development of specialized warm-up balancing strategies that temporarily sacrifice some smoothness for emissions compliance.

Regional variations in emissions standards create additional challenges for global V6 engine platforms. Manufacturers must design balancing systems with sufficient adaptability to meet diverse regulatory requirements without requiring fundamental redesigns for different markets. This has increased the importance of software-controlled balancing solutions that can be calibrated for specific regional requirements.

Looking forward, upcoming Euro 7 and next-generation EPA standards will likely demand even more precise balancing techniques to achieve the required emissions performance, potentially accelerating the integration of AI-driven predictive balancing algorithms that can anticipate and compensate for combustion variations before they impact emissions.

Fuel Efficiency Trade-offs

The optimization of V6 engine power distribution systems inevitably creates a complex relationship with fuel efficiency. When engineers implement balancing techniques to enhance power delivery and reduce vibration, they must carefully consider the resulting impact on fuel consumption patterns.

Primary among these considerations is the trade-off between power output and fuel economy. More aggressive balancing techniques that prioritize maximum power delivery often result in increased fuel consumption, particularly at higher RPM ranges. Data from industry testing shows that optimizing solely for power distribution can increase fuel consumption by 8-12% compared to balanced approaches.

Weight distribution represents another critical factor in this equation. Additional balancing components such as counterweights, harmonic balancers, and reinforced mounting systems add mass to the engine assembly. Each additional kilogram requires more energy to accelerate, directly impacting the vehicle's overall efficiency. Modern engineering approaches have reduced this penalty through lightweight materials, but the fundamental physics remains unchanged.

Combustion efficiency also plays a significant role in this relationship. Balancing techniques that create more uniform power pulses throughout the engine cycle can improve combustion consistency, potentially offsetting some efficiency losses. Advanced electronic control systems that adapt timing based on engine balance conditions have demonstrated fuel savings of 3-5% in real-world testing scenarios.

The thermal management implications of different balancing approaches further complicate efficiency considerations. More aggressive power distribution strategies often generate additional heat that must be managed through cooling systems, creating parasitic power losses that affect overall efficiency. Thermal modeling suggests these losses can account for 2-4% of total efficiency reduction.

Maintenance intervals and longevity considerations also factor into long-term efficiency calculations. Better-balanced engines typically experience reduced wear patterns, extending service life and maintaining optimal efficiency characteristics over longer periods. This translates to fewer replacement parts and reduced lifetime carbon footprint, though these benefits are difficult to quantify in standard efficiency metrics.

Market positioning ultimately determines which balance of these factors manufacturers pursue. Performance-oriented V6 applications typically accept greater fuel consumption penalties in exchange for superior power characteristics, while economy-focused implementations prioritize efficiency at the expense of absolute power delivery smoothness.

Primary among these considerations is the trade-off between power output and fuel economy. More aggressive balancing techniques that prioritize maximum power delivery often result in increased fuel consumption, particularly at higher RPM ranges. Data from industry testing shows that optimizing solely for power distribution can increase fuel consumption by 8-12% compared to balanced approaches.

Weight distribution represents another critical factor in this equation. Additional balancing components such as counterweights, harmonic balancers, and reinforced mounting systems add mass to the engine assembly. Each additional kilogram requires more energy to accelerate, directly impacting the vehicle's overall efficiency. Modern engineering approaches have reduced this penalty through lightweight materials, but the fundamental physics remains unchanged.

Combustion efficiency also plays a significant role in this relationship. Balancing techniques that create more uniform power pulses throughout the engine cycle can improve combustion consistency, potentially offsetting some efficiency losses. Advanced electronic control systems that adapt timing based on engine balance conditions have demonstrated fuel savings of 3-5% in real-world testing scenarios.

The thermal management implications of different balancing approaches further complicate efficiency considerations. More aggressive power distribution strategies often generate additional heat that must be managed through cooling systems, creating parasitic power losses that affect overall efficiency. Thermal modeling suggests these losses can account for 2-4% of total efficiency reduction.

Maintenance intervals and longevity considerations also factor into long-term efficiency calculations. Better-balanced engines typically experience reduced wear patterns, extending service life and maintaining optimal efficiency characteristics over longer periods. This translates to fewer replacement parts and reduced lifetime carbon footprint, though these benefits are difficult to quantify in standard efficiency metrics.

Market positioning ultimately determines which balance of these factors manufacturers pursue. Performance-oriented V6 applications typically accept greater fuel consumption penalties in exchange for superior power characteristics, while economy-focused implementations prioritize efficiency at the expense of absolute power delivery smoothness.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!