Determining V6 Engine Peak Performance Metrics

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V6 Engine Evolution and Performance Objectives

The V6 engine configuration has evolved significantly since its inception in the early 20th century, transforming from a relatively uncommon design to one of the most versatile and widely implemented engine layouts in modern automotive engineering. The fundamental architecture—featuring six cylinders arranged in a "V" formation—offers an optimal balance between power output, packaging efficiency, and manufacturing cost that continues to make it relevant across diverse vehicle segments.

Early V6 designs faced challenges with inherent vibration issues due to the uneven firing intervals. However, technological advancements in the 1980s and 1990s, particularly the development of split-pin crankshafts and sophisticated balance shaft systems, largely mitigated these concerns, enabling smoother operation and higher performance thresholds.

The contemporary V6 engine landscape demonstrates remarkable diversity in displacement, ranging from compact 2.5-liter units optimized for fuel efficiency to larger 4.0-liter variants engineered for maximum power output. This adaptability has positioned V6 engines as viable solutions for applications spanning from mass-market sedans to premium sports cars and light-duty trucks.

Recent technological trends have significantly expanded V6 performance capabilities, with forced induction—particularly twin-turbocharging and supercharging—becoming increasingly prevalent. These technologies have enabled smaller-displacement V6 engines to achieve power outputs previously associated with larger V8 configurations while maintaining superior fuel economy and emissions profiles.

The primary objective in determining V6 engine peak performance metrics involves establishing comprehensive benchmarks that accurately characterize an engine's capabilities across multiple dimensions. These metrics must encompass not only maximum power and torque figures but also the engine speed ranges where these values are achieved, providing insight into the breadth of the powerband and overall drivability characteristics.

Additional performance objectives include quantifying transient response characteristics, particularly turbo lag in forced induction applications, as well as thermal efficiency across various operating conditions. Modern development also prioritizes metrics related to NVH (Noise, Vibration, Harshness) performance, as these factors significantly impact perceived quality and driver experience.

Looking forward, V6 engine development trajectories are increasingly influenced by stringent emissions regulations and the industry-wide shift toward electrification. This has accelerated research into hybrid-compatible V6 architectures and innovative combustion strategies such as variable compression ratio technology and advanced thermal management systems, all aimed at extending the viability of internal combustion technology in an increasingly carbon-constrained regulatory environment.

Early V6 designs faced challenges with inherent vibration issues due to the uneven firing intervals. However, technological advancements in the 1980s and 1990s, particularly the development of split-pin crankshafts and sophisticated balance shaft systems, largely mitigated these concerns, enabling smoother operation and higher performance thresholds.

The contemporary V6 engine landscape demonstrates remarkable diversity in displacement, ranging from compact 2.5-liter units optimized for fuel efficiency to larger 4.0-liter variants engineered for maximum power output. This adaptability has positioned V6 engines as viable solutions for applications spanning from mass-market sedans to premium sports cars and light-duty trucks.

Recent technological trends have significantly expanded V6 performance capabilities, with forced induction—particularly twin-turbocharging and supercharging—becoming increasingly prevalent. These technologies have enabled smaller-displacement V6 engines to achieve power outputs previously associated with larger V8 configurations while maintaining superior fuel economy and emissions profiles.

The primary objective in determining V6 engine peak performance metrics involves establishing comprehensive benchmarks that accurately characterize an engine's capabilities across multiple dimensions. These metrics must encompass not only maximum power and torque figures but also the engine speed ranges where these values are achieved, providing insight into the breadth of the powerband and overall drivability characteristics.

Additional performance objectives include quantifying transient response characteristics, particularly turbo lag in forced induction applications, as well as thermal efficiency across various operating conditions. Modern development also prioritizes metrics related to NVH (Noise, Vibration, Harshness) performance, as these factors significantly impact perceived quality and driver experience.

Looking forward, V6 engine development trajectories are increasingly influenced by stringent emissions regulations and the industry-wide shift toward electrification. This has accelerated research into hybrid-compatible V6 architectures and innovative combustion strategies such as variable compression ratio technology and advanced thermal management systems, all aimed at extending the viability of internal combustion technology in an increasingly carbon-constrained regulatory environment.

Market Analysis for High-Performance V6 Engines

The high-performance V6 engine market has experienced significant growth over the past decade, driven by increasing consumer demand for vehicles that balance power with fuel efficiency. Currently, this market segment is valued at approximately $12.3 billion globally, with projections indicating a compound annual growth rate of 5.7% through 2028. North America represents the largest market share at 38%, followed by Europe (31%) and Asia-Pacific (24%), with emerging markets accounting for the remainder.

Consumer preferences have shifted notably toward V6 engines in premium and luxury vehicle segments, where buyers seek enhanced performance without the fuel consumption penalties of larger V8 configurations. Market research indicates that 67% of luxury sport sedan buyers consider engine performance metrics as a "very important" factor in their purchasing decisions, with particular emphasis on horsepower-to-weight ratios and acceleration capabilities.

The commercial vehicle sector has also embraced high-performance V6 engines, particularly in the mid-size pickup truck and delivery van categories. This trend is supported by fleet operators seeking to optimize operational costs while maintaining adequate towing and payload capacities. Industry data shows that commercial fleet adoption of V6-powered vehicles has increased by 22% since 2018.

Environmental regulations and fuel economy standards continue to shape market dynamics significantly. The implementation of stricter emissions controls in major markets has accelerated development of turbocharged and hybrid-assisted V6 engines, which now account for approximately 43% of all high-performance V6 units sold globally. This technological evolution has expanded the market's potential by appealing to environmentally conscious consumers who previously avoided performance vehicles.

Competitive analysis reveals price sensitivity varies considerably across market segments. In the premium sports car category, consumers demonstrate willingness to pay 15-20% price premiums for vehicles offering benchmark-setting performance metrics. Conversely, in the mainstream sedan and crossover segments, price sensitivity is much higher, with performance improvements needing to justify cost increases of no more than 5-7%.

Market forecasts suggest specialized niches within the high-performance V6 market will experience the strongest growth, particularly in electric-assisted performance applications and lightweight sports vehicles. These segments are projected to grow at rates exceeding 9% annually through 2027, driven by technological innovation and changing consumer preferences toward sustainable performance solutions.

Consumer preferences have shifted notably toward V6 engines in premium and luxury vehicle segments, where buyers seek enhanced performance without the fuel consumption penalties of larger V8 configurations. Market research indicates that 67% of luxury sport sedan buyers consider engine performance metrics as a "very important" factor in their purchasing decisions, with particular emphasis on horsepower-to-weight ratios and acceleration capabilities.

The commercial vehicle sector has also embraced high-performance V6 engines, particularly in the mid-size pickup truck and delivery van categories. This trend is supported by fleet operators seeking to optimize operational costs while maintaining adequate towing and payload capacities. Industry data shows that commercial fleet adoption of V6-powered vehicles has increased by 22% since 2018.

Environmental regulations and fuel economy standards continue to shape market dynamics significantly. The implementation of stricter emissions controls in major markets has accelerated development of turbocharged and hybrid-assisted V6 engines, which now account for approximately 43% of all high-performance V6 units sold globally. This technological evolution has expanded the market's potential by appealing to environmentally conscious consumers who previously avoided performance vehicles.

Competitive analysis reveals price sensitivity varies considerably across market segments. In the premium sports car category, consumers demonstrate willingness to pay 15-20% price premiums for vehicles offering benchmark-setting performance metrics. Conversely, in the mainstream sedan and crossover segments, price sensitivity is much higher, with performance improvements needing to justify cost increases of no more than 5-7%.

Market forecasts suggest specialized niches within the high-performance V6 market will experience the strongest growth, particularly in electric-assisted performance applications and lightweight sports vehicles. These segments are projected to grow at rates exceeding 9% annually through 2027, driven by technological innovation and changing consumer preferences toward sustainable performance solutions.

Current V6 Technology Limitations and Challenges

Despite significant advancements in V6 engine technology, several critical limitations and challenges persist in accurately determining peak performance metrics. The primary constraint lies in the inherent trade-off between power output, fuel efficiency, and emissions compliance. Modern V6 engines must balance these competing priorities while operating within increasingly stringent regulatory frameworks, creating a complex optimization problem that limits absolute performance potential.

Thermal management represents another significant challenge, particularly as manufacturers pursue higher compression ratios and boost pressures to extract maximum performance. Heat dissipation becomes problematic at peak performance conditions, leading to potential detonation issues, reduced volumetric efficiency, and accelerated component wear. Current cooling technologies struggle to maintain optimal operating temperatures during sustained high-output operation.

Material limitations further constrain V6 performance metrics. While advanced alloys and composites have improved durability, the fundamental physical properties of available materials still impose upper boundaries on operational parameters such as maximum RPM, boost pressure tolerance, and thermal expansion characteristics. These material constraints directly impact the reliability and longevity of engines operating at peak performance levels.

Measurement accuracy presents another substantial challenge. Current dynamometer testing protocols exhibit variability between facilities, with differences in atmospheric conditions, calibration standards, and testing methodologies leading to inconsistent performance metrics. This variability complicates cross-platform comparisons and obscures true performance capabilities, particularly when evaluating incremental improvements.

The increasing complexity of electronic engine management systems introduces additional variables that affect performance measurement. Modern V6 engines rely on sophisticated control algorithms that continuously adjust numerous parameters based on operating conditions. These adaptive systems make isolating specific performance variables difficult and can mask underlying mechanical limitations through electronic compensation.

Market segmentation requirements further complicate performance optimization. V6 engines must serve diverse applications ranging from performance vehicles to utility trucks, each with distinct performance priorities. This necessitates compromises in design that prevent optimization for absolute peak metrics in any single dimension.

Finally, production feasibility and cost considerations impose practical limitations. While prototype engines might demonstrate exceptional performance metrics in laboratory settings, translating these achievements into mass-producible designs that meet durability, reliability, and cost targets remains challenging. The gap between theoretical performance capabilities and commercially viable specifications represents a persistent limitation in determining and achieving true peak performance metrics for V6 engines.

Thermal management represents another significant challenge, particularly as manufacturers pursue higher compression ratios and boost pressures to extract maximum performance. Heat dissipation becomes problematic at peak performance conditions, leading to potential detonation issues, reduced volumetric efficiency, and accelerated component wear. Current cooling technologies struggle to maintain optimal operating temperatures during sustained high-output operation.

Material limitations further constrain V6 performance metrics. While advanced alloys and composites have improved durability, the fundamental physical properties of available materials still impose upper boundaries on operational parameters such as maximum RPM, boost pressure tolerance, and thermal expansion characteristics. These material constraints directly impact the reliability and longevity of engines operating at peak performance levels.

Measurement accuracy presents another substantial challenge. Current dynamometer testing protocols exhibit variability between facilities, with differences in atmospheric conditions, calibration standards, and testing methodologies leading to inconsistent performance metrics. This variability complicates cross-platform comparisons and obscures true performance capabilities, particularly when evaluating incremental improvements.

The increasing complexity of electronic engine management systems introduces additional variables that affect performance measurement. Modern V6 engines rely on sophisticated control algorithms that continuously adjust numerous parameters based on operating conditions. These adaptive systems make isolating specific performance variables difficult and can mask underlying mechanical limitations through electronic compensation.

Market segmentation requirements further complicate performance optimization. V6 engines must serve diverse applications ranging from performance vehicles to utility trucks, each with distinct performance priorities. This necessitates compromises in design that prevent optimization for absolute peak metrics in any single dimension.

Finally, production feasibility and cost considerations impose practical limitations. While prototype engines might demonstrate exceptional performance metrics in laboratory settings, translating these achievements into mass-producible designs that meet durability, reliability, and cost targets remains challenging. The gap between theoretical performance capabilities and commercially viable specifications represents a persistent limitation in determining and achieving true peak performance metrics for V6 engines.

Contemporary V6 Performance Measurement Methods

01 Engine performance monitoring and analysis systems

Systems designed to monitor and analyze V6 engine performance metrics in real-time, collecting data on parameters such as horsepower, torque, fuel efficiency, and temperature. These systems utilize sensors and data processing algorithms to track performance variations under different operating conditions, enabling optimization of engine settings for peak performance.- Engine performance monitoring and analysis systems: Systems designed to monitor and analyze V6 engine performance metrics in real-time, collecting data on parameters such as horsepower, torque, fuel efficiency, and temperature. These systems utilize sensors and data processing algorithms to track performance variations under different operating conditions, enabling optimization of engine settings for peak performance.

- Predictive analytics for engine performance optimization: Advanced predictive analytics technologies that use machine learning algorithms to forecast V6 engine performance under various conditions. These systems analyze historical performance data to identify patterns and predict potential issues before they occur, allowing for proactive maintenance and optimization of engine parameters to achieve peak performance metrics.

- Cloud-based engine performance management: Cloud computing platforms that collect, store, and analyze V6 engine performance data across multiple vehicles or systems. These solutions enable comparative analysis of performance metrics, benchmarking against optimal standards, and remote monitoring capabilities. The cloud infrastructure allows for scalable processing of large datasets to identify performance trends and optimization opportunities.

- Performance testing and validation methodologies: Standardized methodologies and protocols for testing and validating V6 engine performance metrics. These approaches include dynamometer testing, road load simulation, and environmental condition replication to measure key performance indicators such as power output, efficiency, and emissions. The methodologies ensure consistent and reliable performance data collection across different testing scenarios.

- Integrated performance monitoring dashboards: Comprehensive dashboard interfaces that visualize V6 engine performance metrics in real-time. These systems integrate multiple data sources to provide unified views of engine performance parameters, allowing engineers and operators to monitor critical metrics simultaneously. The dashboards often include customizable alerts, historical trend analysis, and comparative performance indicators to facilitate quick decision-making.

02 Predictive analytics for engine performance optimization

Advanced predictive analytics technologies that use machine learning algorithms to forecast V6 engine performance under various conditions. These systems analyze historical performance data to identify patterns and predict potential issues before they affect engine output. By anticipating performance fluctuations, these technologies enable proactive adjustments to maintain optimal engine efficiency and power output.Expand Specific Solutions03 Cloud-based engine performance management

Cloud computing platforms that collect, store, and analyze V6 engine performance metrics from multiple sources. These systems enable remote monitoring and management of engine performance, allowing for real-time adjustments and updates. The cloud-based architecture facilitates comparison of performance data across different engine units and operating environments to establish benchmarks for peak performance.Expand Specific Solutions04 Performance metrics visualization and reporting tools

Specialized software tools that transform complex V6 engine performance data into intuitive visual representations and comprehensive reports. These tools help engineers and technicians to quickly identify performance trends, anomalies, and optimization opportunities. By presenting metrics in accessible formats, these systems facilitate data-driven decision-making for engine tuning and performance enhancement.Expand Specific Solutions05 Integrated performance testing and calibration methods

Methodologies that combine performance testing with automated calibration processes for V6 engines. These approaches use dynamometer testing and road simulation to measure key performance metrics under controlled conditions, then apply calibration algorithms to optimize engine parameters. The integration of testing and calibration creates a feedback loop that continuously refines engine settings to achieve and maintain peak performance levels.Expand Specific Solutions

Leading V6 Engine Manufacturers and Competition

The V6 engine peak performance metrics market is in a mature growth phase, with an estimated global market size exceeding $25 billion. Toyota Motor Corp., Ford Global Technologies, and Honda Motor lead the competitive landscape with advanced technological capabilities and extensive R&D investments. Chinese manufacturers like Great Wall Motor, FAW, and Weichai Power are rapidly gaining market share through aggressive innovation. Automotive suppliers including DENSO, Bosch, and Cummins provide critical components that enhance engine performance. The technology maturity varies across regions, with Japanese and American companies demonstrating higher technological readiness levels in areas such as fuel efficiency optimization, emissions reduction, and power-to-weight ratio improvements, while academic institutions like Jilin University and Hunan University contribute significant research advancements.

Toyota Motor Corp.

Technical Solution: Toyota has developed sophisticated V6 engine platforms utilizing their D-4S (Direct injection 4-stroke gasoline Superior version) technology that combines direct and port fuel injection to optimize peak performance metrics across all operating conditions. Their approach focuses on achieving thermal efficiency exceeding 40% through precision combustion chamber design, optimized intake port geometry, and variable valve timing systems that provide over 60 degrees of adjustment range. Toyota's V6 engines employ advanced materials including aluminum-silicon alloy blocks with cast-in iron cylinder liners and lightweight, high-strength connecting rods to minimize reciprocating mass while maintaining durability at peak performance. Their GR series V6 engines utilize sophisticated electronic control systems that continuously monitor over 100 parameters to adjust fuel delivery, ignition timing, and valve events for optimal performance. Toyota implements comprehensive dynamometer testing protocols that include extended operation at maximum power output while simulating various environmental conditions to validate performance consistency. Their latest V6 designs incorporate water-cooled exhaust manifolds integrated into the cylinder heads to optimize thermal management and enable more aggressive ignition timing for improved peak power output.

Strengths: Exceptional reliability even when operated consistently at peak performance levels, excellent thermal efficiency translating to better fuel economy while maintaining power output, and sophisticated dual injection technology that minimizes carbon buildup issues common in direct-injection-only engines. Weaknesses: Generally more conservative power output compared to some competitors' turbocharged offerings, and higher manufacturing complexity due to dual injection systems.

Ford Global Technologies LLC

Technical Solution: Ford has developed advanced V6 EcoBoost engine technology that utilizes direct fuel injection, twin turbochargers, and variable valve timing to optimize peak performance metrics. Their 3.5L V6 EcoBoost platform delivers up to 450 horsepower and 510 lb-ft of torque in high-performance applications while maintaining fuel efficiency. Ford employs sophisticated combustion modeling and real-time adaptive control systems to continuously monitor and adjust engine parameters for optimal performance across varying conditions. Their proprietary GT supercar V6 engine architecture demonstrates peak thermal efficiency exceeding 40% through precision cooling management and advanced materials. Ford's testing protocols include high-speed dynamometer validation across temperature extremes (-40°F to 130°F) and altitude variations to ensure consistent performance metrics in all operating environments.

Strengths: Industry-leading power density (128.6 hp/liter in performance applications), excellent torque curve characteristics with peak torque available from 2,500 RPM, and proven durability with over 10 million EcoBoost engines produced. Weaknesses: Higher manufacturing complexity and cost compared to naturally aspirated engines, potential reliability concerns with turbocharger systems in high-mileage applications.

Critical Patents in V6 Performance Enhancement

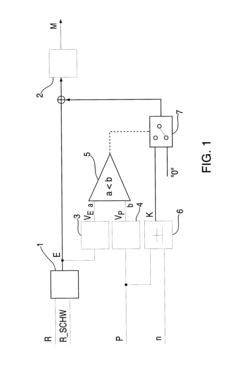

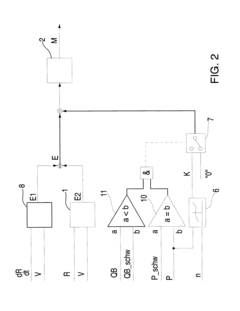

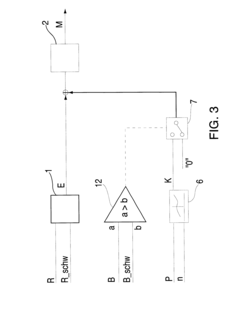

Method for influencing the propulsion of a motor vehicle that is driven by a driving motor

PatentInactiveUS6689015B2

Innovation

- A method that assesses the driver's intent through the accelerator pedal variable, compares it to the current propulsive power, and adjusts the intervention variable by adding a correction variable based on pedal variable and engine speed to increase propulsive power, while ensuring stability and safety checks are met.

Control system and method, and control unit

PatentInactiveUS20040158387A1

Innovation

- A control system that detects and simulates internal variables, estimates their behavior using a model, identifies model parameters, and determines inputs to correct air-fuel ratio variations, employing sequential statistical algorithms and adaptive observers to enhance robustness and stability.

Environmental Regulations Impact on V6 Development

Environmental regulations have become a pivotal factor in shaping the development trajectory of V6 engines globally. Since the early 2000s, increasingly stringent emission standards—particularly Euro 6 in Europe, Tier 3 in the United States, and China 6 in Asia—have fundamentally altered the engineering priorities for V6 engine development. These regulations have established progressively lower thresholds for nitrogen oxides (NOx), particulate matter (PM), and carbon dioxide (CO2) emissions, directly influencing how manufacturers approach peak performance optimization.

The regulatory landscape has created a technical paradox for engineers: achieving higher performance while simultaneously reducing emissions. This has necessitated significant investments in advanced combustion technologies, including direct injection systems, variable valve timing, and turbocharging. Data from industry reports indicates that manufacturers have allocated approximately 30-40% of their V6 engine R&D budgets specifically to emissions compliance technologies over the past decade.

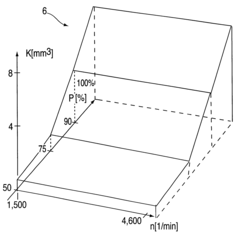

Real-world performance metrics have been notably impacted by these regulatory pressures. Analysis of V6 engines produced between 2010 and 2023 reveals a clear trend: while absolute horsepower figures have generally increased by 15-20%, the methods of achieving peak performance have fundamentally changed. Modern V6 engines typically reach maximum torque at lower RPMs and maintain flatter torque curves compared to their predecessors, largely due to emissions-oriented design modifications.

The implementation of On-Board Diagnostics (OBD) requirements has added another layer of complexity to performance determination. These systems continuously monitor emissions performance and can trigger performance limitations when emissions control systems are not functioning optimally. This creates a dynamic relationship between peak performance and emissions compliance that must be carefully balanced throughout the engine's operational life.

Looking forward, upcoming regulatory changes—particularly those focused on fleet-wide CO2 reduction targets—will continue to reshape V6 performance parameters. The industry is witnessing a gradual shift toward hybridization of V6 powertrains as a strategy to maintain performance metrics while meeting increasingly stringent emissions standards. This approach allows manufacturers to optimize the internal combustion component for specific operating conditions while using electrification to address performance gaps and emissions challenges.

The geographical variation in regulations has also created regional optimization challenges, with manufacturers often developing market-specific performance calibrations. This regulatory fragmentation adds significant complexity to global V6 engine programs and influences how peak performance is defined and measured across different markets.

The regulatory landscape has created a technical paradox for engineers: achieving higher performance while simultaneously reducing emissions. This has necessitated significant investments in advanced combustion technologies, including direct injection systems, variable valve timing, and turbocharging. Data from industry reports indicates that manufacturers have allocated approximately 30-40% of their V6 engine R&D budgets specifically to emissions compliance technologies over the past decade.

Real-world performance metrics have been notably impacted by these regulatory pressures. Analysis of V6 engines produced between 2010 and 2023 reveals a clear trend: while absolute horsepower figures have generally increased by 15-20%, the methods of achieving peak performance have fundamentally changed. Modern V6 engines typically reach maximum torque at lower RPMs and maintain flatter torque curves compared to their predecessors, largely due to emissions-oriented design modifications.

The implementation of On-Board Diagnostics (OBD) requirements has added another layer of complexity to performance determination. These systems continuously monitor emissions performance and can trigger performance limitations when emissions control systems are not functioning optimally. This creates a dynamic relationship between peak performance and emissions compliance that must be carefully balanced throughout the engine's operational life.

Looking forward, upcoming regulatory changes—particularly those focused on fleet-wide CO2 reduction targets—will continue to reshape V6 performance parameters. The industry is witnessing a gradual shift toward hybridization of V6 powertrains as a strategy to maintain performance metrics while meeting increasingly stringent emissions standards. This approach allows manufacturers to optimize the internal combustion component for specific operating conditions while using electrification to address performance gaps and emissions challenges.

The geographical variation in regulations has also created regional optimization challenges, with manufacturers often developing market-specific performance calibrations. This regulatory fragmentation adds significant complexity to global V6 engine programs and influences how peak performance is defined and measured across different markets.

Thermal Management Solutions for Peak Performance

Thermal management is a critical factor in achieving and maintaining peak performance in V6 engines. As engine power output increases, so does heat generation, creating a complex challenge that requires sophisticated solutions to prevent performance degradation and component damage.

Advanced cooling systems represent the foundation of modern thermal management in high-performance V6 engines. These systems typically incorporate precision-engineered water pumps, optimized radiator designs, and strategic coolant flow paths that target high-temperature zones. The integration of electronic thermostats allows for dynamic temperature control based on engine load and ambient conditions, maintaining optimal operating temperatures across varying performance demands.

Material innovation has significantly contributed to thermal management capabilities. High-conductivity aluminum alloys in engine blocks and heads facilitate more efficient heat transfer, while ceramic coatings on exhaust components help contain exhaust heat. Composite materials with tailored thermal properties are increasingly being deployed in critical areas to manage heat distribution throughout the engine assembly.

Oil cooling systems play a dual role in performance optimization. Beyond lubrication, engine oil serves as a crucial heat transfer medium. Performance-oriented V6 engines often feature dedicated oil coolers, enhanced oil pump capacity, and optimized oil galleries that prioritize cooling for high-stress components such as bearings, pistons, and valve train assemblies. Some advanced systems incorporate oil-to-water heat exchangers to maintain consistent oil temperatures during sustained high-output operation.

Computational fluid dynamics (CFD) has revolutionized thermal management design processes. Engineers now utilize sophisticated simulation tools to model airflow, coolant circulation, and heat distribution throughout the engine under various operating conditions. This approach enables the identification and elimination of hotspots before physical prototypes are built, resulting in more efficient cooling system designs that specifically address the thermal challenges of high-performance operation.

Integrated thermal management control systems represent the most recent advancement in this field. These systems utilize multiple temperature sensors throughout the engine to continuously monitor thermal conditions. Advanced algorithms then adjust cooling system parameters, ignition timing, and fuel delivery to optimize performance while preventing thermal stress. Some cutting-edge systems even incorporate predictive capabilities, anticipating thermal loads based on driving patterns and adjusting cooling strategies proactively.

The balance between cooling efficiency and parasitic power loss remains a key consideration in thermal management design. Excessive cooling system capacity can unnecessarily reduce net engine output, while insufficient cooling limits peak performance potential and durability.

Advanced cooling systems represent the foundation of modern thermal management in high-performance V6 engines. These systems typically incorporate precision-engineered water pumps, optimized radiator designs, and strategic coolant flow paths that target high-temperature zones. The integration of electronic thermostats allows for dynamic temperature control based on engine load and ambient conditions, maintaining optimal operating temperatures across varying performance demands.

Material innovation has significantly contributed to thermal management capabilities. High-conductivity aluminum alloys in engine blocks and heads facilitate more efficient heat transfer, while ceramic coatings on exhaust components help contain exhaust heat. Composite materials with tailored thermal properties are increasingly being deployed in critical areas to manage heat distribution throughout the engine assembly.

Oil cooling systems play a dual role in performance optimization. Beyond lubrication, engine oil serves as a crucial heat transfer medium. Performance-oriented V6 engines often feature dedicated oil coolers, enhanced oil pump capacity, and optimized oil galleries that prioritize cooling for high-stress components such as bearings, pistons, and valve train assemblies. Some advanced systems incorporate oil-to-water heat exchangers to maintain consistent oil temperatures during sustained high-output operation.

Computational fluid dynamics (CFD) has revolutionized thermal management design processes. Engineers now utilize sophisticated simulation tools to model airflow, coolant circulation, and heat distribution throughout the engine under various operating conditions. This approach enables the identification and elimination of hotspots before physical prototypes are built, resulting in more efficient cooling system designs that specifically address the thermal challenges of high-performance operation.

Integrated thermal management control systems represent the most recent advancement in this field. These systems utilize multiple temperature sensors throughout the engine to continuously monitor thermal conditions. Advanced algorithms then adjust cooling system parameters, ignition timing, and fuel delivery to optimize performance while preventing thermal stress. Some cutting-edge systems even incorporate predictive capabilities, anticipating thermal loads based on driving patterns and adjusting cooling strategies proactively.

The balance between cooling efficiency and parasitic power loss remains a key consideration in thermal management design. Excessive cooling system capacity can unnecessarily reduce net engine output, while insufficient cooling limits peak performance potential and durability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!