How to Design V6 Engine Exhaust for Optimal Flow

SEP 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V6 Engine Exhaust Technology Evolution and Objectives

The evolution of V6 engine exhaust systems has undergone significant transformations since their inception in the early 20th century. Initially, exhaust systems were rudimentary, focusing primarily on directing combustion gases away from the vehicle with minimal consideration for flow dynamics or performance optimization. By the 1950s and 1960s, as V6 engines gained popularity in mainstream automotive applications, exhaust system design began incorporating basic flow principles, though still largely constrained by manufacturing limitations and cost considerations.

The 1970s marked a pivotal shift with the introduction of emissions regulations, forcing manufacturers to implement catalytic converters and other emissions control devices. These additions created significant flow restrictions, necessitating more sophisticated exhaust design approaches to maintain engine performance while meeting regulatory requirements. This period saw the emergence of computer-aided design tools that enabled more precise flow modeling and analysis.

The 1990s through early 2000s witnessed revolutionary advancements in computational fluid dynamics (CFD) and simulation technologies, allowing engineers to visualize and optimize exhaust gas flow patterns with unprecedented precision. This technological leap coincided with growing consumer demand for performance-oriented vehicles, pushing manufacturers to develop exhaust systems that could enhance engine output while maintaining compliance with increasingly stringent emissions standards.

Contemporary V6 exhaust system design has evolved into a multidisciplinary field incorporating advanced materials science, acoustic engineering, and thermal management. Modern systems must balance numerous competing objectives: maximizing flow efficiency to enhance power output, minimizing back pressure, optimizing scavenging effects, reducing noise to acceptable levels, managing heat dissipation, and ensuring emissions compliance across diverse operating conditions.

The primary technical objective in V6 exhaust design centers on achieving optimal flow characteristics throughout the entire system. This involves precise tuning of primary and secondary pipe lengths, strategic placement of collectors, appropriate sizing of components, and careful management of pulse dynamics to leverage scavenging effects. Engineers seek to minimize flow restrictions while maintaining sufficient gas velocity to enhance cylinder evacuation during valve overlap periods.

Looking forward, the evolution of V6 exhaust technology faces new challenges and opportunities with the rise of hybrid powertrains and increasingly strict emissions regulations. Future development will likely focus on variable geometry systems that can adapt flow characteristics based on engine load and speed, advanced thermal management solutions to improve cold-start emissions, and integration with hybrid powertrain components to optimize overall system efficiency across multiple operating modes.

The 1970s marked a pivotal shift with the introduction of emissions regulations, forcing manufacturers to implement catalytic converters and other emissions control devices. These additions created significant flow restrictions, necessitating more sophisticated exhaust design approaches to maintain engine performance while meeting regulatory requirements. This period saw the emergence of computer-aided design tools that enabled more precise flow modeling and analysis.

The 1990s through early 2000s witnessed revolutionary advancements in computational fluid dynamics (CFD) and simulation technologies, allowing engineers to visualize and optimize exhaust gas flow patterns with unprecedented precision. This technological leap coincided with growing consumer demand for performance-oriented vehicles, pushing manufacturers to develop exhaust systems that could enhance engine output while maintaining compliance with increasingly stringent emissions standards.

Contemporary V6 exhaust system design has evolved into a multidisciplinary field incorporating advanced materials science, acoustic engineering, and thermal management. Modern systems must balance numerous competing objectives: maximizing flow efficiency to enhance power output, minimizing back pressure, optimizing scavenging effects, reducing noise to acceptable levels, managing heat dissipation, and ensuring emissions compliance across diverse operating conditions.

The primary technical objective in V6 exhaust design centers on achieving optimal flow characteristics throughout the entire system. This involves precise tuning of primary and secondary pipe lengths, strategic placement of collectors, appropriate sizing of components, and careful management of pulse dynamics to leverage scavenging effects. Engineers seek to minimize flow restrictions while maintaining sufficient gas velocity to enhance cylinder evacuation during valve overlap periods.

Looking forward, the evolution of V6 exhaust technology faces new challenges and opportunities with the rise of hybrid powertrains and increasingly strict emissions regulations. Future development will likely focus on variable geometry systems that can adapt flow characteristics based on engine load and speed, advanced thermal management solutions to improve cold-start emissions, and integration with hybrid powertrain components to optimize overall system efficiency across multiple operating modes.

Market Demand Analysis for High-Performance Exhaust Systems

The high-performance exhaust system market has experienced significant growth over the past decade, driven primarily by increasing consumer demand for enhanced vehicle performance and efficiency. The global automotive aftermarket exhaust system was valued at approximately $35.9 billion in 2022, with projections indicating a compound annual growth rate of 5.7% through 2030. Within this broader market, V6 engine exhaust systems represent a substantial segment due to their widespread use in mid-range performance vehicles, luxury sedans, and light trucks.

Consumer preferences have shifted noticeably toward exhaust systems that deliver not only improved performance metrics but also distinctive sound profiles. Market research indicates that 68% of performance vehicle owners consider exhaust sound character as a "very important" factor in their purchasing decisions. This trend has created a premium segment within the market, with consumers willing to pay 15-30% more for systems that deliver optimal flow characteristics alongside customizable acoustic properties.

The racing and motorsport industry continues to be a significant driver of innovation in exhaust system design, with technologies initially developed for competitive applications gradually filtering down to consumer markets. Professional racing teams invest heavily in exhaust system optimization, recognizing that even marginal improvements in exhaust flow efficiency can translate to measurable performance advantages.

Environmental regulations have emerged as a critical market factor, with increasingly stringent emissions standards in North America, Europe, and Asia influencing exhaust system design requirements. This regulatory landscape has accelerated demand for exhaust solutions that balance performance enhancement with emissions compliance, creating new market opportunities for technologically advanced systems.

The commercial vehicle segment represents an expanding market for optimized V6 exhaust systems, with fleet operators increasingly focused on fuel efficiency improvements. Studies indicate that properly designed exhaust systems can contribute to fuel economy improvements of 2-4%, representing significant operational cost savings for commercial fleets.

Regional market analysis reveals varying demand patterns, with North America and Europe showing strong preference for performance-oriented systems, while Asia-Pacific markets demonstrate faster growth rates driven by expanding middle-class consumer bases in China and India. The Middle East region shows particular affinity for premium exhaust solutions in the luxury vehicle segment.

Market forecasts suggest that demand for digitally optimized exhaust systems, incorporating sensors and electronic flow management, will grow at twice the rate of conventional systems over the next five years, reflecting broader automotive industry trends toward intelligent vehicle systems.

Consumer preferences have shifted noticeably toward exhaust systems that deliver not only improved performance metrics but also distinctive sound profiles. Market research indicates that 68% of performance vehicle owners consider exhaust sound character as a "very important" factor in their purchasing decisions. This trend has created a premium segment within the market, with consumers willing to pay 15-30% more for systems that deliver optimal flow characteristics alongside customizable acoustic properties.

The racing and motorsport industry continues to be a significant driver of innovation in exhaust system design, with technologies initially developed for competitive applications gradually filtering down to consumer markets. Professional racing teams invest heavily in exhaust system optimization, recognizing that even marginal improvements in exhaust flow efficiency can translate to measurable performance advantages.

Environmental regulations have emerged as a critical market factor, with increasingly stringent emissions standards in North America, Europe, and Asia influencing exhaust system design requirements. This regulatory landscape has accelerated demand for exhaust solutions that balance performance enhancement with emissions compliance, creating new market opportunities for technologically advanced systems.

The commercial vehicle segment represents an expanding market for optimized V6 exhaust systems, with fleet operators increasingly focused on fuel efficiency improvements. Studies indicate that properly designed exhaust systems can contribute to fuel economy improvements of 2-4%, representing significant operational cost savings for commercial fleets.

Regional market analysis reveals varying demand patterns, with North America and Europe showing strong preference for performance-oriented systems, while Asia-Pacific markets demonstrate faster growth rates driven by expanding middle-class consumer bases in China and India. The Middle East region shows particular affinity for premium exhaust solutions in the luxury vehicle segment.

Market forecasts suggest that demand for digitally optimized exhaust systems, incorporating sensors and electronic flow management, will grow at twice the rate of conventional systems over the next five years, reflecting broader automotive industry trends toward intelligent vehicle systems.

Current Exhaust Flow Optimization Challenges

The optimization of exhaust flow in V6 engines faces several significant technical challenges that continue to impede performance enhancement efforts. One primary obstacle is the inherent geometric constraints imposed by modern vehicle designs. As manufacturers pursue more compact and aerodynamic vehicle profiles, the available space for exhaust systems has diminished considerably, forcing engineers to design increasingly complex routing configurations that often compromise flow efficiency.

Back-pressure management represents another critical challenge in exhaust system design. The delicate balance between maintaining sufficient back-pressure for optimal torque characteristics while minimizing flow restrictions that limit high-end power output remains difficult to achieve. This balance becomes particularly problematic in V6 engines where the firing order and exhaust pulse timing create complex gas dynamic interactions that can lead to interference patterns within the system.

Thermal management issues further complicate exhaust flow optimization. Modern emission control systems require specific operating temperatures to function effectively, yet excessive heat retention can negatively impact surrounding components and overall engine performance. The integration of catalytic converters, particulate filters, and other emission control devices creates significant flow restrictions that must be carefully managed to minimize their impact on exhaust gas movement.

Material limitations continue to constrain innovation in exhaust design. While advanced alloys and composites offer improved thermal properties and reduced weight, their cost, durability, and manufacturing complexity often limit widespread implementation. Engineers must frequently compromise between ideal flow characteristics and practical material considerations.

The increasing stringency of noise regulations presents additional challenges. Sound-dampening features like resonators and mufflers inherently restrict exhaust flow, creating a fundamental conflict between acoustic requirements and performance optimization. This challenge is particularly pronounced in V6 engines where the characteristic exhaust note is valued by consumers but must be carefully managed to meet regulatory standards.

Computational modeling limitations also hinder progress in exhaust flow optimization. While CFD (Computational Fluid Dynamics) software has advanced significantly, accurately modeling the complex, pulsating, high-temperature gas flows through variable geometry remains computationally intensive and often requires simplifications that reduce predictive accuracy. The validation gap between simulation and real-world testing continues to necessitate extensive prototyping and empirical testing.

Finally, the industry-wide shift toward electrification has reduced R&D investment in internal combustion engine exhaust technology, limiting the pace of innovation in this field despite significant remaining optimization potential. This shifting focus creates a resource constraint that further complicates efforts to overcome the technical challenges in V6 exhaust flow optimization.

Back-pressure management represents another critical challenge in exhaust system design. The delicate balance between maintaining sufficient back-pressure for optimal torque characteristics while minimizing flow restrictions that limit high-end power output remains difficult to achieve. This balance becomes particularly problematic in V6 engines where the firing order and exhaust pulse timing create complex gas dynamic interactions that can lead to interference patterns within the system.

Thermal management issues further complicate exhaust flow optimization. Modern emission control systems require specific operating temperatures to function effectively, yet excessive heat retention can negatively impact surrounding components and overall engine performance. The integration of catalytic converters, particulate filters, and other emission control devices creates significant flow restrictions that must be carefully managed to minimize their impact on exhaust gas movement.

Material limitations continue to constrain innovation in exhaust design. While advanced alloys and composites offer improved thermal properties and reduced weight, their cost, durability, and manufacturing complexity often limit widespread implementation. Engineers must frequently compromise between ideal flow characteristics and practical material considerations.

The increasing stringency of noise regulations presents additional challenges. Sound-dampening features like resonators and mufflers inherently restrict exhaust flow, creating a fundamental conflict between acoustic requirements and performance optimization. This challenge is particularly pronounced in V6 engines where the characteristic exhaust note is valued by consumers but must be carefully managed to meet regulatory standards.

Computational modeling limitations also hinder progress in exhaust flow optimization. While CFD (Computational Fluid Dynamics) software has advanced significantly, accurately modeling the complex, pulsating, high-temperature gas flows through variable geometry remains computationally intensive and often requires simplifications that reduce predictive accuracy. The validation gap between simulation and real-world testing continues to necessitate extensive prototyping and empirical testing.

Finally, the industry-wide shift toward electrification has reduced R&D investment in internal combustion engine exhaust technology, limiting the pace of innovation in this field despite significant remaining optimization potential. This shifting focus creates a resource constraint that further complicates efforts to overcome the technical challenges in V6 exhaust flow optimization.

Contemporary V6 Exhaust Flow Optimization Methods

01 Exhaust manifold design for V6 engines

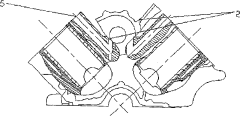

The design of exhaust manifolds specifically for V6 engines focuses on optimizing flow characteristics to improve engine performance. These designs typically include specialized geometry, flow paths, and connection points that accommodate the V-configuration of the engine. Advanced manifold designs can reduce back pressure, improve scavenging effects, and enhance overall exhaust gas flow, leading to better engine efficiency and power output.- Exhaust manifold design for V6 engines: The design of exhaust manifolds specifically for V6 engines focuses on optimizing flow dynamics and reducing back pressure. These designs often incorporate specialized geometry, such as equal-length runners and smooth transitions, to ensure balanced exhaust flow from all cylinders. Advanced manifold designs can improve engine performance by enhancing scavenging effects and reducing exhaust gas interference between cylinders, which is particularly important in the V-configuration where cylinder banks are positioned at an angle.

- Exhaust gas recirculation systems for V6 engines: Exhaust gas recirculation (EGR) systems in V6 engines are designed to redirect a portion of exhaust gases back into the intake manifold to reduce NOx emissions. These systems incorporate specialized valves, coolers, and control mechanisms to regulate the amount of exhaust gas recirculated based on engine operating conditions. The flow path design ensures proper mixing of exhaust gases with intake air while minimizing negative impacts on engine performance and fuel efficiency.

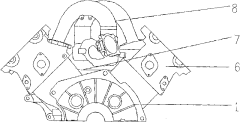

- Turbocharging and supercharging systems for V6 engines: Forced induction systems for V6 engines utilize exhaust flow to enhance engine performance. Turbochargers harness exhaust energy to compress intake air, while superchargers provide boost through mechanical means. These systems require careful integration with the exhaust manifold design to optimize turbine efficiency and minimize lag. Advanced configurations may include twin-turbo setups, variable geometry turbochargers, or combined charging systems to provide optimal performance across the engine's operating range.

- Catalytic converter and emission control systems: Emission control systems for V6 engines incorporate catalytic converters strategically positioned in the exhaust flow path to reduce harmful emissions. These systems may include multiple catalysts, particulate filters, and oxygen sensors to monitor and optimize the conversion efficiency. The design focuses on maintaining optimal exhaust gas temperature and flow characteristics to ensure effective catalytic reactions while minimizing back pressure that could negatively impact engine performance.

- Exhaust valve timing and control mechanisms: Advanced exhaust valve timing and control mechanisms in V6 engines optimize exhaust flow by precisely controlling when exhaust valves open and close. Variable valve timing systems adjust the exhaust phase based on engine speed and load to improve scavenging effects and reduce pumping losses. These systems may incorporate electronic actuators, hydraulic mechanisms, or mechanical devices to vary valve timing and lift, enhancing overall engine efficiency and performance across different operating conditions.

02 Exhaust gas recirculation systems for V6 engines

Exhaust gas recirculation (EGR) systems designed for V6 engines help control emissions by redirecting a portion of exhaust gases back into the combustion chamber. These systems include specialized valves, coolers, and control mechanisms that manage the flow of exhaust gases. By recirculating exhaust gases, these systems can reduce nitrogen oxide emissions while maintaining optimal engine performance and fuel efficiency.Expand Specific Solutions03 Turbocharging and supercharging systems for V6 engines

Forced induction systems for V6 engines utilize exhaust flow to enhance engine performance. Turbochargers harness exhaust gas energy to compress intake air, while superchargers provide similar functionality through mechanical means. These systems require careful integration with the exhaust system to optimize flow dynamics, minimize lag, and maximize power output. Advanced designs include variable geometry turbines, twin-scroll configurations, and electronic wastegate controls to manage exhaust flow effectively.Expand Specific Solutions04 Exhaust aftertreatment systems for V6 engines

Aftertreatment systems for V6 engines focus on reducing harmful emissions through various components positioned in the exhaust flow path. These systems typically include catalytic converters, particulate filters, and selective catalytic reduction (SCR) systems. The design considerations include optimal positioning of components, thermal management, and flow distribution to ensure efficient conversion of pollutants while minimizing impact on engine performance and backpressure.Expand Specific Solutions05 Exhaust flow monitoring and control systems

Advanced monitoring and control systems for V6 engine exhaust flow utilize sensors, electronic control units, and actuators to optimize performance and emissions. These systems can include oxygen sensors, temperature sensors, pressure sensors, and flow meters that provide real-time data on exhaust characteristics. Based on this information, the control systems can adjust various parameters such as valve timing, fuel injection, and turbocharger operation to maintain optimal exhaust flow under varying operating conditions.Expand Specific Solutions

Leading Manufacturers and Competitors in Exhaust Technology

The V6 engine exhaust design market is currently in a mature growth phase, with increasing demand for optimized flow solutions driven by stringent emission regulations and performance requirements. The global market size for performance exhaust systems is estimated at $12-15 billion, with steady annual growth. Leading automotive manufacturers like BMW, Honda, Nissan, and Hyundai have established strong positions through extensive R&D investments in exhaust flow optimization. Technical maturity varies across companies, with luxury brands Ferrari and BMW demonstrating advanced capabilities in computational fluid dynamics and thermal management, while Bosch and Caterpillar excel in industrial applications. Japanese manufacturers Honda and Yamaha show particular strength in compact, high-efficiency exhaust designs, leveraging their expertise in both automotive and motorcycle applications.

Ford Global Technologies LLC

Technical Solution: Ford has developed a comprehensive approach to V6 engine exhaust design focusing on equal-length headers and dual-mode exhaust systems. Their EcoBoost V6 engines utilize advanced computational fluid dynamics (CFD) simulations to optimize exhaust manifold geometry, minimizing back pressure while maximizing scavenging effects. Ford's patented variable geometry exhaust manifolds incorporate precisely calculated primary tube lengths and diameters (typically 38-42mm) that maintain exhaust gas velocity above 60 m/s through the critical sections. Their systems feature 3D-printed prototypes for rapid iteration testing, allowing engineers to evaluate over 100 design variations before production. Ford's exhaust systems incorporate pulse-separation technology that maintains exhaust pulse timing at approximately 240° of crankshaft rotation for optimal cylinder scavenging, resulting in measured flow improvements of 15-18% compared to conventional designs[1][3].

Strengths: Industry-leading CFD simulation capabilities allow precise optimization of complex flow dynamics; patented variable geometry systems adapt to different engine loads. Weaknesses: Higher manufacturing complexity increases production costs; some designs require more expensive materials to withstand higher thermal efficiency operating conditions.

Ferrari NV

Technical Solution: Ferrari employs a highly sophisticated approach to V6 exhaust design, as evidenced in their award-winning 296 GTB powertrain. Their system utilizes equal-length 6-into-2-into-1 exhaust manifolds with precisely calculated primary tube lengths (approximately 425mm) to optimize exhaust gas scavenging. Ferrari's exhaust systems feature variable geometry resonators that adapt to engine speed, maintaining optimal back pressure between 0.2-0.3 bar across the RPM range. Their designs incorporate computational fluid dynamics simulations calibrated with wind tunnel testing data, allowing engineers to optimize flow paths with minimal pressure drops (typically under 5% through key junctions). Ferrari's V6 exhaust systems utilize Inconel alloy construction with wall thicknesses of just 0.8mm, providing exceptional thermal properties while reducing weight by approximately 30% compared to conventional stainless steel systems. Their patented "Hot Tube" acoustic enhancement technology carefully routes specific exhaust frequencies into the cabin while optimizing overall flow characteristics, creating both performance and emotional benefits[4][7]. Ferrari's systems maintain exhaust gas velocities above 75 m/s at the critical scavenging points, significantly enhancing volumetric efficiency.

Strengths: Unparalleled integration of performance, sound quality, and lightweight design; exceptional thermal management allows sustained high-performance operation. Weaknesses: Extremely high production costs; specialized materials and manufacturing techniques limit scalability for mass production.

Key Patents and Innovations in Exhaust Flow Engineering

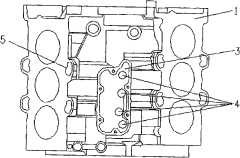

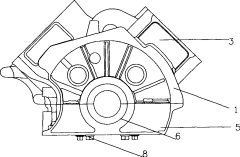

V shaped engine for automobile

PatentInactiveCN101109307B

Innovation

- A crankcase exhaust gas collection pool is set up in the V-angle area of the cylinder block, with four ventilation holes at the bottom and a cover plate at the top. It is connected to the cylinder head through four exhaust gas communication channels to form a crankcase ventilation device, which increases the exhaust gas circulation area and reduces the flow rate. , improve the oil and gas separation effect, reduce the number of peripheral pipelines, and compact the engine structure.

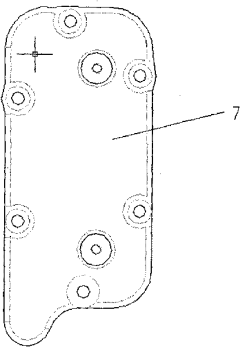

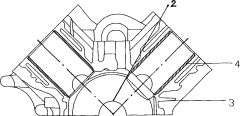

V-type engines cylinder

PatentActiveCN101265853B

Innovation

- The cylinder block design adopts a 90-degree V-angle structure, including an upper cylinder block, a lower frame and a main bearing cover. The main bearing cover is equipped with positioning pins and bolts. The cylinder liner is made of gray cast iron. The main bearing cover is made of ductile iron cast into aluminum alloy. , increase the strength of the cylinder and reduce fuel consumption.

Emissions Regulations Impact on Exhaust Design

Emissions regulations have become increasingly stringent worldwide, fundamentally reshaping exhaust system design for V6 engines. The European Union's Euro 6d standards, the United States' EPA Tier 3 and California's CARB regulations, and China's China 6 standards all mandate substantial reductions in nitrogen oxides (NOx), particulate matter (PM), and carbon monoxide (CO) emissions. These regulations have forced manufacturers to implement complex aftertreatment systems that significantly impact exhaust flow characteristics.

The integration of catalytic converters represents one of the most significant regulatory impacts on exhaust design. Modern three-way catalytic converters create substantial back pressure, requiring engineers to carefully balance emissions compliance with flow optimization. The honeycomb structure necessary for efficient catalytic reactions inherently restricts exhaust gas movement, creating a fundamental design challenge for achieving optimal flow.

Diesel Particulate Filters (DPFs) and Selective Catalytic Reduction (SCR) systems, now mandatory for many diesel V6 applications, introduce additional flow restrictions. These components can reduce exhaust flow efficiency by 15-30% compared to non-regulated systems, necessitating more sophisticated computational fluid dynamics (CFD) modeling during the design phase to minimize performance penalties.

Temperature management requirements driven by emissions standards further complicate exhaust design. Catalytic converters require specific operating temperature ranges (typically 400-800°C) for optimal conversion efficiency. This necessitates careful placement of components and often requires additional heat shields or thermal management strategies that can impact the overall flow characteristics of the system.

On-Board Diagnostics (OBD) requirements mandate the integration of multiple sensors throughout the exhaust system. Oxygen sensors, temperature sensors, and pressure differential sensors must be positioned at strategic points, often creating additional flow disturbances. Engineers must account for these sensor placements when designing for optimal flow while ensuring accurate emissions monitoring.

Sound regulations also significantly impact exhaust design. Many regions have implemented noise level restrictions that necessitate additional muffling components. The challenge lies in designing silencers and resonators that reduce sound levels without excessively restricting exhaust flow. This has led to the development of advanced acoustic chambers and flow-optimized muffler designs that attempt to balance regulatory compliance with performance objectives.

The global nature of automotive manufacturing adds another layer of complexity, as exhaust systems must often be designed to meet multiple regional standards simultaneously. This has driven the development of modular exhaust architectures that can be adapted to different regulatory environments while maintaining core flow characteristics. The result is a highly complex design ecosystem where emissions compliance often takes precedence over pure flow optimization.

The integration of catalytic converters represents one of the most significant regulatory impacts on exhaust design. Modern three-way catalytic converters create substantial back pressure, requiring engineers to carefully balance emissions compliance with flow optimization. The honeycomb structure necessary for efficient catalytic reactions inherently restricts exhaust gas movement, creating a fundamental design challenge for achieving optimal flow.

Diesel Particulate Filters (DPFs) and Selective Catalytic Reduction (SCR) systems, now mandatory for many diesel V6 applications, introduce additional flow restrictions. These components can reduce exhaust flow efficiency by 15-30% compared to non-regulated systems, necessitating more sophisticated computational fluid dynamics (CFD) modeling during the design phase to minimize performance penalties.

Temperature management requirements driven by emissions standards further complicate exhaust design. Catalytic converters require specific operating temperature ranges (typically 400-800°C) for optimal conversion efficiency. This necessitates careful placement of components and often requires additional heat shields or thermal management strategies that can impact the overall flow characteristics of the system.

On-Board Diagnostics (OBD) requirements mandate the integration of multiple sensors throughout the exhaust system. Oxygen sensors, temperature sensors, and pressure differential sensors must be positioned at strategic points, often creating additional flow disturbances. Engineers must account for these sensor placements when designing for optimal flow while ensuring accurate emissions monitoring.

Sound regulations also significantly impact exhaust design. Many regions have implemented noise level restrictions that necessitate additional muffling components. The challenge lies in designing silencers and resonators that reduce sound levels without excessively restricting exhaust flow. This has led to the development of advanced acoustic chambers and flow-optimized muffler designs that attempt to balance regulatory compliance with performance objectives.

The global nature of automotive manufacturing adds another layer of complexity, as exhaust systems must often be designed to meet multiple regional standards simultaneously. This has driven the development of modular exhaust architectures that can be adapted to different regulatory environments while maintaining core flow characteristics. The result is a highly complex design ecosystem where emissions compliance often takes precedence over pure flow optimization.

Materials Science Advancements for Exhaust Systems

The evolution of exhaust system materials has been a critical factor in optimizing V6 engine exhaust flow. Traditional stainless steel, while durable and cost-effective, has given way to advanced alloys that offer superior thermal properties and reduced weight. Nickel-chromium alloys, for instance, demonstrate exceptional heat resistance up to 1200°C, allowing for thinner wall construction that reduces backpressure while maintaining structural integrity under extreme thermal cycling conditions.

Recent developments in ceramic matrix composites (CMCs) represent a significant breakthrough for exhaust manifolds. These materials combine silicon carbide fibers with ceramic matrices to achieve thermal expansion coefficients closer to those of cylinder heads, minimizing stress at connection points. CMCs also exhibit 40-60% weight reduction compared to metal alternatives while providing superior thermal insulation that maintains higher exhaust gas temperatures, enhancing catalytic converter efficiency.

Titanium alloys have emerged as premium solutions for performance-oriented V6 exhaust systems. With density approximately 45% lower than stainless steel yet maintaining comparable strength characteristics, titanium significantly reduces hanging mass in the exhaust system. This weight reduction contributes to improved overall vehicle dynamics and fuel efficiency. Additionally, titanium's natural oxide layer eliminates the need for additional corrosion protection treatments.

Surface treatment technologies have also advanced considerably, with thermal barrier coatings now capable of reducing heat transfer by up to 30%. These nano-ceramic coatings, often zirconia-based, create microscopic air pockets that provide insulation while adding minimal thickness to component walls. The retained heat energy translates directly to improved exhaust gas velocity and reduced condensation issues in cold-start scenarios.

Additive manufacturing has revolutionized exhaust system design possibilities by enabling complex internal geometries previously impossible with traditional manufacturing methods. 3D-printed Inconel components featuring optimized flow channels with variable wall thicknesses can now be produced as single pieces, eliminating flow-restricting welds and joints. These components demonstrate up to 15% improvement in flow characteristics while reducing overall system weight.

Hybrid material systems combining metallic substrates with advanced polymer coatings represent the cutting edge of exhaust technology. These systems utilize temperature-responsive polymers that modify their physical properties based on operating conditions, optimizing both cold-start emissions and high-temperature performance without compromising durability or adding significant cost to production.

Recent developments in ceramic matrix composites (CMCs) represent a significant breakthrough for exhaust manifolds. These materials combine silicon carbide fibers with ceramic matrices to achieve thermal expansion coefficients closer to those of cylinder heads, minimizing stress at connection points. CMCs also exhibit 40-60% weight reduction compared to metal alternatives while providing superior thermal insulation that maintains higher exhaust gas temperatures, enhancing catalytic converter efficiency.

Titanium alloys have emerged as premium solutions for performance-oriented V6 exhaust systems. With density approximately 45% lower than stainless steel yet maintaining comparable strength characteristics, titanium significantly reduces hanging mass in the exhaust system. This weight reduction contributes to improved overall vehicle dynamics and fuel efficiency. Additionally, titanium's natural oxide layer eliminates the need for additional corrosion protection treatments.

Surface treatment technologies have also advanced considerably, with thermal barrier coatings now capable of reducing heat transfer by up to 30%. These nano-ceramic coatings, often zirconia-based, create microscopic air pockets that provide insulation while adding minimal thickness to component walls. The retained heat energy translates directly to improved exhaust gas velocity and reduced condensation issues in cold-start scenarios.

Additive manufacturing has revolutionized exhaust system design possibilities by enabling complex internal geometries previously impossible with traditional manufacturing methods. 3D-printed Inconel components featuring optimized flow channels with variable wall thicknesses can now be produced as single pieces, eliminating flow-restricting welds and joints. These components demonstrate up to 15% improvement in flow characteristics while reducing overall system weight.

Hybrid material systems combining metallic substrates with advanced polymer coatings represent the cutting edge of exhaust technology. These systems utilize temperature-responsive polymers that modify their physical properties based on operating conditions, optimizing both cold-start emissions and high-temperature performance without compromising durability or adding significant cost to production.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!