How to Test V6 Engine Gasket Material for Performance

SEP 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V6 Engine Gasket Material Testing Background and Objectives

Engine gasket materials have evolved significantly over the past century, transitioning from simple cork and paper compositions to advanced multi-layer steel (MLS) and elastomeric compounds. This evolution has been driven by increasingly demanding engine environments, particularly in V6 configurations where compact design creates unique sealing challenges. The modern V6 engine operates under extreme temperature variations (from -40°C to over 200°C), high combustion pressures exceeding 200 bar, and complex vibration patterns that place extraordinary demands on gasket materials.

The primary objective of V6 engine gasket material testing is to evaluate and validate the performance characteristics that ensure reliable sealing under these extreme operating conditions. Testing protocols must assess multiple critical parameters including thermal stability, compression set resistance, fluid compatibility, and long-term durability. These evaluations must accurately predict real-world performance across the entire lifecycle of the engine, typically targeting 150,000+ miles of operation without failure.

Historical testing methodologies have often failed to capture the complex interaction of forces acting on gasket materials in modern V6 engines. Traditional static compression testing, while valuable, cannot fully replicate the dynamic thermal cycling and vibration patterns experienced in actual engine operation. This has led to premature gasket failures despite materials passing conventional qualification tests.

Current testing objectives must address these limitations by developing comprehensive protocols that combine laboratory simulation with accelerated real-world testing. The goal is to establish standardized yet adaptable testing methodologies that can accurately predict gasket performance across various V6 engine designs, from naturally aspirated to turbocharged and hybrid applications.

Industry standards such as ASTM F38, DIN 3535, and SAE J1086 provide baseline testing frameworks, but these must be supplemented with OEM-specific protocols that address the unique characteristics of modern V6 engines. Testing objectives should include quantifiable metrics for compression stress relaxation, micro-sealing capability under thermal cycling, chemical resistance to modern coolants and oils, and torque retention under vibration.

The ultimate aim of gasket material testing is to balance competing requirements: maintaining perfect sealing integrity while accommodating the relative movement between engine components, withstanding aggressive chemical environments, and maintaining these properties throughout the engine's service life. This requires a holistic testing approach that evaluates not just individual material properties but the integrated performance of the gasket system within the specific V6 engine architecture.

The primary objective of V6 engine gasket material testing is to evaluate and validate the performance characteristics that ensure reliable sealing under these extreme operating conditions. Testing protocols must assess multiple critical parameters including thermal stability, compression set resistance, fluid compatibility, and long-term durability. These evaluations must accurately predict real-world performance across the entire lifecycle of the engine, typically targeting 150,000+ miles of operation without failure.

Historical testing methodologies have often failed to capture the complex interaction of forces acting on gasket materials in modern V6 engines. Traditional static compression testing, while valuable, cannot fully replicate the dynamic thermal cycling and vibration patterns experienced in actual engine operation. This has led to premature gasket failures despite materials passing conventional qualification tests.

Current testing objectives must address these limitations by developing comprehensive protocols that combine laboratory simulation with accelerated real-world testing. The goal is to establish standardized yet adaptable testing methodologies that can accurately predict gasket performance across various V6 engine designs, from naturally aspirated to turbocharged and hybrid applications.

Industry standards such as ASTM F38, DIN 3535, and SAE J1086 provide baseline testing frameworks, but these must be supplemented with OEM-specific protocols that address the unique characteristics of modern V6 engines. Testing objectives should include quantifiable metrics for compression stress relaxation, micro-sealing capability under thermal cycling, chemical resistance to modern coolants and oils, and torque retention under vibration.

The ultimate aim of gasket material testing is to balance competing requirements: maintaining perfect sealing integrity while accommodating the relative movement between engine components, withstanding aggressive chemical environments, and maintaining these properties throughout the engine's service life. This requires a holistic testing approach that evaluates not just individual material properties but the integrated performance of the gasket system within the specific V6 engine architecture.

Market Requirements for High-Performance Gasket Materials

The automotive gasket market is experiencing significant growth, driven by increasing demand for high-performance engines, particularly V6 configurations that balance power and efficiency. Current market analysis indicates that gasket materials for V6 engines must meet increasingly stringent requirements across multiple performance dimensions to satisfy both manufacturers and end-users.

Temperature resistance has emerged as a primary market requirement, with modern V6 engines operating at higher temperatures to maximize efficiency. High-performance gasket materials must withstand sustained temperatures of 150-200°C in normal operation, with peak tolerance capabilities extending to 250-300°C during extreme conditions. This requirement has intensified as manufacturers push thermal efficiency boundaries.

Chemical resistance represents another critical market demand, as gasket materials must maintain integrity when exposed to engine oils, coolants, and fuel additives with varying chemical compositions. The increasing use of synthetic oils and advanced coolant formulations has elevated the importance of this requirement, with manufacturers seeking materials that demonstrate minimal degradation over extended exposure periods.

Compression set resistance ranks high among customer requirements, with the market demanding gasket materials that maintain sealing force under dynamic loading conditions. Industry benchmarks now expect high-performance gaskets to retain at least 85% of their original thickness after compression cycling tests, significantly higher than previous standards of 70-75%.

Durability expectations have increased substantially, with OEMs and aftermarket customers requiring gasket lifespans that match or exceed engine rebuild intervals. Market research indicates that premium segment customers expect gasket performance guarantees of 100,000+ miles, while commercial applications often demand 250,000+ miles without failure.

Cost-effectiveness remains a balancing factor in market requirements, with manufacturers seeking materials that deliver enhanced performance without proportional price increases. The competitive landscape has established price sensitivity thresholds that vary by application segment, with performance automotive applications tolerating premium pricing more readily than mass-market applications.

Environmental compliance has emerged as a growing market requirement, with regulations increasingly restricting certain material components. Manufacturers now demand gasket materials free from asbestos, certain heavy metals, and specific chemical compounds, while simultaneously requiring recyclability or reduced environmental impact during production and disposal.

Testing protocol standardization has become a market requirement itself, with customers expecting comprehensive performance validation across multiple parameters. This has driven demand for materials that can demonstrate compliance with industry standards such as ASTM D2000, SAE J2236, and manufacturer-specific testing protocols that simulate real-world operating conditions.

Temperature resistance has emerged as a primary market requirement, with modern V6 engines operating at higher temperatures to maximize efficiency. High-performance gasket materials must withstand sustained temperatures of 150-200°C in normal operation, with peak tolerance capabilities extending to 250-300°C during extreme conditions. This requirement has intensified as manufacturers push thermal efficiency boundaries.

Chemical resistance represents another critical market demand, as gasket materials must maintain integrity when exposed to engine oils, coolants, and fuel additives with varying chemical compositions. The increasing use of synthetic oils and advanced coolant formulations has elevated the importance of this requirement, with manufacturers seeking materials that demonstrate minimal degradation over extended exposure periods.

Compression set resistance ranks high among customer requirements, with the market demanding gasket materials that maintain sealing force under dynamic loading conditions. Industry benchmarks now expect high-performance gaskets to retain at least 85% of their original thickness after compression cycling tests, significantly higher than previous standards of 70-75%.

Durability expectations have increased substantially, with OEMs and aftermarket customers requiring gasket lifespans that match or exceed engine rebuild intervals. Market research indicates that premium segment customers expect gasket performance guarantees of 100,000+ miles, while commercial applications often demand 250,000+ miles without failure.

Cost-effectiveness remains a balancing factor in market requirements, with manufacturers seeking materials that deliver enhanced performance without proportional price increases. The competitive landscape has established price sensitivity thresholds that vary by application segment, with performance automotive applications tolerating premium pricing more readily than mass-market applications.

Environmental compliance has emerged as a growing market requirement, with regulations increasingly restricting certain material components. Manufacturers now demand gasket materials free from asbestos, certain heavy metals, and specific chemical compounds, while simultaneously requiring recyclability or reduced environmental impact during production and disposal.

Testing protocol standardization has become a market requirement itself, with customers expecting comprehensive performance validation across multiple parameters. This has driven demand for materials that can demonstrate compliance with industry standards such as ASTM D2000, SAE J2236, and manufacturer-specific testing protocols that simulate real-world operating conditions.

Current Gasket Testing Methodologies and Limitations

The current landscape of V6 engine gasket testing methodologies encompasses a range of standardized procedures designed to evaluate material performance under various operating conditions. Compression set testing remains one of the most fundamental approaches, measuring a gasket material's ability to return to its original thickness after compression. This test typically involves compressing samples between metal plates at elevated temperatures (150-200°C) for extended periods (70-336 hours), then measuring recovery after release. While effective for basic resilience assessment, this method often fails to replicate the dynamic thermal cycling experienced in actual engine operations.

Fluid resistance testing evaluates gasket material compatibility with engine fluids including coolant, oil, and fuel. Standard procedures involve immersing material samples in these fluids at elevated temperatures (typically 100-150°C) for periods ranging from 70 to 1000 hours, followed by measurement of dimensional changes, weight fluctuation, and mechanical property alterations. A significant limitation is that these tests rarely combine fluid exposure with simultaneous mechanical stress, creating a disconnect from real-world conditions.

Thermal cycling tests attempt to simulate the repeated heating and cooling cycles experienced by engine gaskets. Current methodologies typically cycle between room temperature and maximum operating temperature (up to 250°C for modern V6 engines) for hundreds or thousands of cycles. However, these tests often fail to accurately replicate the rapid temperature transitions and thermal gradients present across different regions of actual engine gaskets.

Pressure resistance testing evaluates a gasket's ability to maintain a seal under various pressure conditions. Standard tests apply static pressure (typically 0.5-3.0 MPa) to gasket materials, but frequently neglect the pulsating pressure patterns characteristic of internal combustion engines. This limitation results in potentially misleading performance predictions for materials that may perform adequately under static conditions but fail under dynamic pressure fluctuations.

Accelerated aging tests attempt to predict long-term performance by exposing gasket materials to elevated temperatures and pressures. Current methodologies typically involve exposure to temperatures 20-50°C above normal operating conditions for periods of 500-1000 hours. A significant limitation is the questionable correlation between accelerated aging results and actual field performance, as the complex interaction of thermal, chemical, and mechanical stresses in real engines is difficult to replicate in laboratory settings.

Industry standards such as ASTM F38, F37, and F36 provide standardized testing protocols, but their generic nature often fails to address the specific demands of modern V6 engine designs with their higher operating temperatures, increased power density, and more complex cooling systems. This disconnect between standardized testing and actual application requirements represents a critical gap in current gasket material evaluation methodologies.

Fluid resistance testing evaluates gasket material compatibility with engine fluids including coolant, oil, and fuel. Standard procedures involve immersing material samples in these fluids at elevated temperatures (typically 100-150°C) for periods ranging from 70 to 1000 hours, followed by measurement of dimensional changes, weight fluctuation, and mechanical property alterations. A significant limitation is that these tests rarely combine fluid exposure with simultaneous mechanical stress, creating a disconnect from real-world conditions.

Thermal cycling tests attempt to simulate the repeated heating and cooling cycles experienced by engine gaskets. Current methodologies typically cycle between room temperature and maximum operating temperature (up to 250°C for modern V6 engines) for hundreds or thousands of cycles. However, these tests often fail to accurately replicate the rapid temperature transitions and thermal gradients present across different regions of actual engine gaskets.

Pressure resistance testing evaluates a gasket's ability to maintain a seal under various pressure conditions. Standard tests apply static pressure (typically 0.5-3.0 MPa) to gasket materials, but frequently neglect the pulsating pressure patterns characteristic of internal combustion engines. This limitation results in potentially misleading performance predictions for materials that may perform adequately under static conditions but fail under dynamic pressure fluctuations.

Accelerated aging tests attempt to predict long-term performance by exposing gasket materials to elevated temperatures and pressures. Current methodologies typically involve exposure to temperatures 20-50°C above normal operating conditions for periods of 500-1000 hours. A significant limitation is the questionable correlation between accelerated aging results and actual field performance, as the complex interaction of thermal, chemical, and mechanical stresses in real engines is difficult to replicate in laboratory settings.

Industry standards such as ASTM F38, F37, and F36 provide standardized testing protocols, but their generic nature often fails to address the specific demands of modern V6 engine designs with their higher operating temperatures, increased power density, and more complex cooling systems. This disconnect between standardized testing and actual application requirements represents a critical gap in current gasket material evaluation methodologies.

Standard Testing Protocols for V6 Engine Gaskets

01 High-temperature resistant gasket materials

Gasket materials for V6 engines must withstand high operating temperatures. Advanced composite materials incorporating graphite, ceramic fibers, and metal reinforcements provide excellent thermal resistance. These materials maintain their sealing properties under extreme temperature conditions, preventing leakage and ensuring engine efficiency. The high-temperature resistant formulations also offer improved durability and extended service life in the demanding environment of V6 engines.- High-temperature resistant gasket materials: V6 engine gaskets require materials that can withstand high operating temperatures. Advanced composite materials incorporating graphite, ceramic fibers, and metal reinforcements are used to maintain seal integrity under extreme thermal conditions. These materials prevent leakage and degradation when exposed to the high temperatures generated by V6 engines, ensuring long-term performance and reliability.

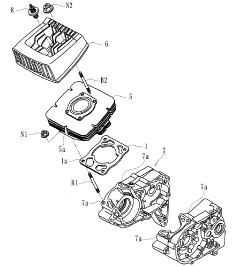

- Multi-layer gasket designs for V6 engines: Multi-layer metal and composite gasket designs provide superior sealing performance in V6 engines. These gaskets typically consist of several layers of different materials, each serving a specific function such as stress distribution, fluid sealing, or thermal management. The layered construction allows for better conformability to uneven surfaces while maintaining resilience under varying engine operating conditions.

- Chemical resistance properties of gasket materials: Gasket materials for V6 engines must resist degradation from exposure to engine fluids including oil, coolant, and fuel. Specialized elastomers, fluoroelastomers, and silicone compounds are formulated to maintain their physical properties and sealing capabilities despite continuous contact with these chemicals. This chemical resistance prevents premature gasket failure and extends service intervals for V6 engine applications.

- Compression and recovery characteristics: The ability of gasket materials to compress under bolt load and recover when load is reduced is critical for V6 engine performance. Materials with optimal compression set resistance maintain a proper seal during thermal cycling and vibration. Advanced elastomers and fiber-reinforced composites are engineered to provide the ideal balance of compressibility and recovery to accommodate the dynamic conditions present in V6 engine operation.

- Specialized coatings and surface treatments: Surface treatments and coatings enhance the performance of V6 engine gaskets by improving sealing properties and reducing friction. These include PTFE coatings, silicone sealants, and rubber-based compounds that fill microscopic imperfections in mating surfaces. Some gaskets feature active compounds that swell slightly upon contact with fluids to improve sealing. These treatments help prevent leakage and extend gasket life in demanding V6 engine environments.

02 Multi-layer gasket designs for V6 engines

Multi-layer gasket designs specifically engineered for V6 engines feature multiple metal layers with elastomeric coatings. These designs provide optimal compression recovery and stress distribution across cylinder head mating surfaces. The layered construction accommodates thermal expansion and contraction during engine operation cycles, maintaining seal integrity. Some designs incorporate embossed beads or stopper layers to create targeted sealing pressure zones for critical areas like combustion chambers and oil passages.Expand Specific Solutions03 Chemical resistance properties of gasket materials

Gasket materials for V6 engines are formulated to resist degradation from exposure to engine fluids including oil, coolant, and fuel. Fluoroelastomer compounds and specialized rubber formulations provide excellent chemical resistance while maintaining flexibility. These materials prevent swelling, shrinking, or deterioration that could compromise sealing performance. The chemical resistance properties ensure consistent gasket performance throughout the engine's operational life, even with modern engine oils and coolants that contain various additives.Expand Specific Solutions04 Compression set resistance and recovery characteristics

Advanced gasket materials for V6 engines exhibit superior compression set resistance, allowing them to maintain sealing force even after prolonged compression. These materials incorporate elastomeric compounds with memory properties that enable them to recover their original dimensions when compression is released. This characteristic is crucial for maintaining seal integrity during thermal cycling and vibration. Materials with optimized compression set resistance help prevent fluid leakage and maintain consistent clamping force across the entire gasket surface.Expand Specific Solutions05 Specialized coatings and surface treatments

Gasket materials for V6 engines often feature specialized coatings and surface treatments to enhance sealing performance. These include fluoropolymer coatings for reduced friction, silicone-based sealants for improved conformability, and rubber-based compounds for micro-sealing capabilities. Surface treatments can modify the material's surface energy to improve wetting and adhesion properties. These coatings help gaskets conform to minor surface imperfections in the mating components, ensuring complete sealing even with manufacturing variations in engine components.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Gasket Development

The V6 engine gasket material testing market is in a growth phase, driven by increasing demands for high-performance, durable engine components in the automotive industry. The market size is expanding as manufacturers seek materials that can withstand higher temperatures and pressures in modern engines. Technologically, the field is moderately mature but continues to evolve with advanced materials and testing methodologies. Key players include established automotive manufacturers like Honda, Toyota, and Mazda who conduct extensive in-house testing, alongside specialized gasket manufacturers such as NOK Corp., Nippon Reinz, and Federal-Mogul who lead innovation in this space. Japan Metal Gasket and ElringKlinger Marusan represent significant technical expertise in high-performance gasket materials, while research institutions like Zhejiang University contribute to fundamental material science advancements.

Honda Motor Co., Ltd.

Technical Solution: Honda employs a comprehensive testing methodology for V6 engine gasket materials that combines laboratory simulation and real-world validation. Their approach includes high-temperature cycling tests that simulate extreme engine operating conditions (120°C to 850°C), pressure boundary tests to evaluate sealing capabilities under various load conditions, and durability testing involving thermal shock resistance evaluation. Honda has developed proprietary test rigs that can simultaneously assess multiple environmental factors affecting gasket performance, including chemical resistance to engine fluids, vibration endurance, and compression set resistance. Their testing protocol incorporates advanced imaging techniques such as infrared thermography to identify potential leak paths and stress distribution analysis to optimize gasket design for their V6 engines. Honda's material selection process evaluates both traditional materials like multi-layer steel (MLS) and newer composite materials with nano-fillers for improved performance characteristics.

Strengths: Honda's integrated approach combining laboratory and real-world testing provides comprehensive performance data. Their extensive global manufacturing experience allows for rapid implementation of test results into production. Weaknesses: Their testing methodologies may be overly specialized for Honda's specific engine designs, potentially limiting broader applicability across different V6 configurations.

Japan Metal Gasket Co., Ltd.

Technical Solution: Japan Metal Gasket has developed specialized testing methodologies for V6 engine gasket materials that focus on the unique challenges of modern high-output engines. Their approach includes high-precision flatness measurement using laser interferometry with accuracy to 0.001mm to evaluate gasket conformability and sealing performance. The company employs custom-built thermal cycling chambers that can simulate extreme temperature gradients across the gasket surface (up to 200°C differential), replicating conditions at the interface between combustion chambers and cooling passages. Their testing protocol includes specialized equipment for evaluating micro-motion and fretting resistance, critical factors in preventing gasket failure in aluminum block V6 engines. Japan Metal Gasket utilizes advanced material analysis techniques including scanning electron microscopy (SEM) with energy-dispersive X-ray spectroscopy (EDX) to evaluate material degradation mechanisms after testing. They have pioneered the use of acoustic emission monitoring during gasket testing to detect microscopic changes in material structure before visible failure occurs, allowing for more precise determination of performance limits.

Strengths: Japan Metal Gasket's testing methodology excels in evaluating microscopic aspects of gasket performance that often predict long-term reliability. Their specialized equipment provides highly detailed data on specific failure mechanisms. Weaknesses: Their testing approach may be overly focused on metallurgical aspects while giving less attention to elastomeric components in composite gaskets. The specialized nature of their testing equipment may limit throughput for rapid material screening.

Critical Parameters and Failure Analysis in Gasket Performance

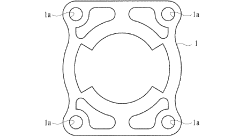

Gasket for internal combustion engine

PatentWO1989001102A1

Innovation

- A gasket with a coating layer containing 20-60% expanded graphite and 40-80% synthetic resin binder, applied to one or both sides of a metal or non-metal sheet, providing a high restoring force and improved friction coefficient and stress relaxation rate, while being cost-effective and suitable for internal combustion engines.

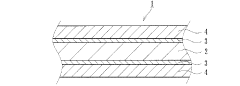

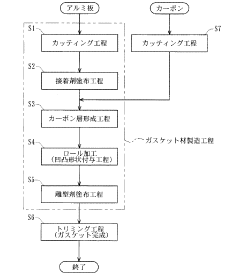

Engine gasket material and its manufacturing method

PatentInactiveJP2007092828A

Innovation

- An engine gasket material with carbon layers on both sides of an aluminum thin plate core, which follows the thermal expansion of aluminum engines, and includes a release agent and uneven surface to prevent fusion and maintain sealing performance.

Environmental Impact and Sustainability Considerations

The environmental impact of gasket materials and testing processes has become increasingly important in the automotive industry. Traditional gasket materials often contain harmful substances such as asbestos, which has been phased out due to health concerns, but many current materials still pose environmental challenges. When testing V6 engine gasket materials for performance, manufacturers must now consider the entire lifecycle environmental footprint, from raw material extraction through disposal or recycling.

Material selection represents a critical environmental decision point. Modern gasket materials incorporating recycled content or bio-based components can significantly reduce carbon footprint compared to conventional petroleum-based elastomers. Testing protocols should evaluate not only performance metrics but also leaching potential of harmful compounds during the gasket's operational life. This dual approach ensures both engine integrity and environmental safety throughout the product lifecycle.

Manufacturing processes for gasket materials contribute substantially to their environmental impact. Water-based adhesives and solvent-free production methods can reduce volatile organic compound (VOC) emissions by up to 85% compared to traditional manufacturing techniques. Performance testing should therefore include assessment of gaskets produced through both conventional and environmentally optimized manufacturing processes to determine if sustainability improvements affect functional performance.

Disposal considerations must be integrated into gasket material testing frameworks. The ability to separate gasket materials from metal components at end-of-life significantly impacts recyclability. Tests should evaluate how easily gaskets can be removed after extended thermal cycling and chemical exposure, simulating real-world conditions at vehicle end-of-life. Materials that maintain performance while allowing for easier separation represent an optimal balance between durability and sustainability.

Energy consumption during testing itself warrants attention from sustainability perspectives. Traditional accelerated aging tests often require continuous high-temperature operation of test engines, consuming significant energy. Advanced computational modeling and simulation techniques can reduce physical testing requirements by up to 40%, substantially decreasing the carbon footprint of the testing process while still providing reliable performance data.

Regulatory compliance regarding environmental standards varies globally but continues to trend toward stricter controls. Testing protocols must verify that gasket materials comply with regulations such as REACH in Europe, California Proposition 65, and emerging global standards limiting persistent organic pollutants. Forward-thinking manufacturers are already testing against anticipated future regulations, ensuring their gasket materials will remain compliant as environmental standards evolve.

Material selection represents a critical environmental decision point. Modern gasket materials incorporating recycled content or bio-based components can significantly reduce carbon footprint compared to conventional petroleum-based elastomers. Testing protocols should evaluate not only performance metrics but also leaching potential of harmful compounds during the gasket's operational life. This dual approach ensures both engine integrity and environmental safety throughout the product lifecycle.

Manufacturing processes for gasket materials contribute substantially to their environmental impact. Water-based adhesives and solvent-free production methods can reduce volatile organic compound (VOC) emissions by up to 85% compared to traditional manufacturing techniques. Performance testing should therefore include assessment of gaskets produced through both conventional and environmentally optimized manufacturing processes to determine if sustainability improvements affect functional performance.

Disposal considerations must be integrated into gasket material testing frameworks. The ability to separate gasket materials from metal components at end-of-life significantly impacts recyclability. Tests should evaluate how easily gaskets can be removed after extended thermal cycling and chemical exposure, simulating real-world conditions at vehicle end-of-life. Materials that maintain performance while allowing for easier separation represent an optimal balance between durability and sustainability.

Energy consumption during testing itself warrants attention from sustainability perspectives. Traditional accelerated aging tests often require continuous high-temperature operation of test engines, consuming significant energy. Advanced computational modeling and simulation techniques can reduce physical testing requirements by up to 40%, substantially decreasing the carbon footprint of the testing process while still providing reliable performance data.

Regulatory compliance regarding environmental standards varies globally but continues to trend toward stricter controls. Testing protocols must verify that gasket materials comply with regulations such as REACH in Europe, California Proposition 65, and emerging global standards limiting persistent organic pollutants. Forward-thinking manufacturers are already testing against anticipated future regulations, ensuring their gasket materials will remain compliant as environmental standards evolve.

Durability Testing Under Extreme Operating Conditions

Durability testing of V6 engine gasket materials under extreme operating conditions represents a critical phase in performance evaluation. These tests simulate the harshest environments the gasket will encounter throughout its service life, often exceeding normal operating parameters to establish safety margins and reliability benchmarks.

Temperature cycling tests form the cornerstone of extreme condition evaluation, with gaskets subjected to rapid fluctuations between -40°C and 200°C. This process, repeated for thousands of cycles, reveals how thermal expansion and contraction affect the gasket's sealing properties and structural integrity over time. Modern testing protocols typically include at least 5,000 complete temperature cycles to validate long-term performance.

Pressure resistance testing under extreme conditions involves subjecting gaskets to pressures 150-200% above maximum rated engine pressure. These tests are conducted while simultaneously exposing materials to engine fluids and varying temperatures, creating a multi-stress environment that accelerates potential failure mechanisms. Advanced testing facilities employ computerized systems that can precisely control pressure variations to simulate engine load fluctuations during extreme driving conditions.

Chemical resistance evaluation exposes gasket materials to concentrated versions of engine fluids, including aggressive fuel additives, coolant mixtures with varying pH levels, and oil formulations at elevated temperatures. Materials must maintain their physical properties and sealing capabilities despite prolonged contact with these substances under high-temperature conditions. Industry standards typically require 1,000+ hours of continuous exposure without significant degradation.

Vibration and mechanical stress testing simulates extreme engine conditions by subjecting gaskets to amplified vibration frequencies and mechanical loads. Modern testing equipment can reproduce the specific vibration signatures of V6 engines operating under maximum load, often at frequencies between 20-2000 Hz and at amplitudes significantly higher than normal operation.

Accelerated aging protocols compress years of environmental exposure into weeks or months of testing. These tests combine UV radiation, ozone exposure, humidity cycling, and temperature fluctuations to simulate long-term environmental effects. The most rigorous protocols include salt spray exposure to evaluate corrosion resistance at material interfaces.

Failure mode analysis during extreme condition testing provides valuable insights beyond simple pass/fail results. High-resolution imaging techniques and real-time monitoring allow engineers to observe how gasket materials deform, wear, or degrade under specific extreme conditions, informing design improvements and material formulation refinements.

Temperature cycling tests form the cornerstone of extreme condition evaluation, with gaskets subjected to rapid fluctuations between -40°C and 200°C. This process, repeated for thousands of cycles, reveals how thermal expansion and contraction affect the gasket's sealing properties and structural integrity over time. Modern testing protocols typically include at least 5,000 complete temperature cycles to validate long-term performance.

Pressure resistance testing under extreme conditions involves subjecting gaskets to pressures 150-200% above maximum rated engine pressure. These tests are conducted while simultaneously exposing materials to engine fluids and varying temperatures, creating a multi-stress environment that accelerates potential failure mechanisms. Advanced testing facilities employ computerized systems that can precisely control pressure variations to simulate engine load fluctuations during extreme driving conditions.

Chemical resistance evaluation exposes gasket materials to concentrated versions of engine fluids, including aggressive fuel additives, coolant mixtures with varying pH levels, and oil formulations at elevated temperatures. Materials must maintain their physical properties and sealing capabilities despite prolonged contact with these substances under high-temperature conditions. Industry standards typically require 1,000+ hours of continuous exposure without significant degradation.

Vibration and mechanical stress testing simulates extreme engine conditions by subjecting gaskets to amplified vibration frequencies and mechanical loads. Modern testing equipment can reproduce the specific vibration signatures of V6 engines operating under maximum load, often at frequencies between 20-2000 Hz and at amplitudes significantly higher than normal operation.

Accelerated aging protocols compress years of environmental exposure into weeks or months of testing. These tests combine UV radiation, ozone exposure, humidity cycling, and temperature fluctuations to simulate long-term environmental effects. The most rigorous protocols include salt spray exposure to evaluate corrosion resistance at material interfaces.

Failure mode analysis during extreme condition testing provides valuable insights beyond simple pass/fail results. High-resolution imaging techniques and real-time monitoring allow engineers to observe how gasket materials deform, wear, or degrade under specific extreme conditions, informing design improvements and material formulation refinements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!