How to Optimize Intake Air Temperature for V6 Engines

SEP 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V6 Engine Intake Air Temperature Evolution and Objectives

The evolution of intake air temperature management in V6 engines has undergone significant transformation since the introduction of these powerplants in the early 20th century. Initially, V6 engines operated with minimal temperature control systems, relying primarily on ambient conditions and basic mechanical designs. By the 1970s and 1980s, as emissions regulations tightened globally, manufacturers began implementing rudimentary temperature control mechanisms to improve combustion efficiency and reduce harmful emissions.

The technological leap occurred in the 1990s with the widespread adoption of electronic engine management systems, enabling more precise control over intake air parameters. This period marked the transition from passive to active temperature management strategies, with the introduction of variable intake systems and electronically controlled throttle bodies that could adapt to changing operating conditions.

Current state-of-the-art V6 engines employ sophisticated thermal management systems incorporating multiple sensors, electronic control units, and adaptive algorithms that continuously optimize intake air temperature based on various parameters including engine load, ambient conditions, and driver behavior patterns. These systems represent the culmination of decades of engineering refinement aimed at balancing performance, efficiency, and emissions compliance.

The primary objective of intake air temperature optimization in modern V6 engines centers on achieving an optimal balance between volumetric efficiency and combustion stability. Lower intake temperatures increase air density, potentially delivering more oxygen molecules to the combustion chamber and enhancing power output. However, excessively cold intake air can negatively impact fuel atomization and vaporization, particularly during cold starts and low-load operation.

Conversely, warmer intake air promotes better fuel vaporization and more homogeneous air-fuel mixtures, benefiting emissions control and combustion stability at the expense of maximum power potential. The technical challenge lies in developing systems that can dynamically adjust intake temperatures across the entire operating envelope of the engine.

Secondary objectives include minimizing knock tendency in turbocharged and high-compression V6 applications, reducing warm-up periods to accelerate catalyst light-off, and maintaining consistent performance across varying ambient conditions from arctic cold to desert heat. Additionally, modern systems must balance these technical requirements with packaging constraints, cost considerations, and reliability targets expected in contemporary automotive applications.

The future trajectory of intake air temperature management points toward increasingly predictive systems that leverage machine learning algorithms to anticipate optimal temperature settings based on historical data, navigation information, and connected vehicle inputs, further enhancing the efficiency and performance envelope of V6 engine designs.

The technological leap occurred in the 1990s with the widespread adoption of electronic engine management systems, enabling more precise control over intake air parameters. This period marked the transition from passive to active temperature management strategies, with the introduction of variable intake systems and electronically controlled throttle bodies that could adapt to changing operating conditions.

Current state-of-the-art V6 engines employ sophisticated thermal management systems incorporating multiple sensors, electronic control units, and adaptive algorithms that continuously optimize intake air temperature based on various parameters including engine load, ambient conditions, and driver behavior patterns. These systems represent the culmination of decades of engineering refinement aimed at balancing performance, efficiency, and emissions compliance.

The primary objective of intake air temperature optimization in modern V6 engines centers on achieving an optimal balance between volumetric efficiency and combustion stability. Lower intake temperatures increase air density, potentially delivering more oxygen molecules to the combustion chamber and enhancing power output. However, excessively cold intake air can negatively impact fuel atomization and vaporization, particularly during cold starts and low-load operation.

Conversely, warmer intake air promotes better fuel vaporization and more homogeneous air-fuel mixtures, benefiting emissions control and combustion stability at the expense of maximum power potential. The technical challenge lies in developing systems that can dynamically adjust intake temperatures across the entire operating envelope of the engine.

Secondary objectives include minimizing knock tendency in turbocharged and high-compression V6 applications, reducing warm-up periods to accelerate catalyst light-off, and maintaining consistent performance across varying ambient conditions from arctic cold to desert heat. Additionally, modern systems must balance these technical requirements with packaging constraints, cost considerations, and reliability targets expected in contemporary automotive applications.

The future trajectory of intake air temperature management points toward increasingly predictive systems that leverage machine learning algorithms to anticipate optimal temperature settings based on historical data, navigation information, and connected vehicle inputs, further enhancing the efficiency and performance envelope of V6 engine designs.

Market Demand Analysis for Optimized V6 Engine Performance

The global automotive industry is witnessing a significant shift towards optimizing engine performance while meeting increasingly stringent emission standards. The market demand for optimized V6 engine performance, particularly through intake air temperature control, has grown substantially over the past five years. According to recent industry reports, the automotive thermal management market is projected to reach $45 billion by 2025, with intake air optimization systems representing a crucial segment of this growth.

Consumer preferences are evolving rapidly, with a growing emphasis on vehicles that deliver both power and fuel efficiency. V6 engines remain popular in mid-size to luxury vehicles, SUVs, and light trucks, representing approximately 22% of the global passenger vehicle market. The demand for optimized V6 performance is particularly strong in North America and parts of Asia, where consumers value the balance between the power of larger engines and the efficiency of smaller ones.

Fleet operators and commercial vehicle manufacturers are increasingly focused on total cost of ownership, driving demand for technologies that can improve fuel efficiency without sacrificing performance. Optimized intake air temperature systems can deliver fuel savings of 3-7% in V6 engines, representing significant operational cost reductions for fleet managers. This market segment is expected to grow at a CAGR of 5.8% through 2027.

Environmental regulations worldwide continue to tighten emission standards, creating market pressure for technologies that can reduce NOx and CO2 emissions. The European Union's Euro 7 standards and similar regulations in other regions are driving automotive manufacturers to invest in advanced intake air temperature control systems. Market research indicates that 78% of automotive engineers consider intake air temperature optimization a critical factor in meeting future emission requirements.

Performance enthusiasts and aftermarket modification sectors represent another significant market segment, valued at approximately $7.2 billion globally. This consumer group seeks technologies that can enhance engine response, increase horsepower, and improve torque curves through optimized air intake temperatures. The aftermarket for V6 engine optimization products has seen annual growth rates of 4.3% since 2018.

Emerging markets present substantial growth opportunities, with countries like China, India, and Brazil showing increased demand for vehicles with V6 engines in their premium segments. As these markets mature, the demand for advanced engine optimization technologies is expected to accelerate, potentially creating a market opportunity of $3.5 billion by 2028 specifically for intake air temperature optimization systems and related technologies.

Consumer preferences are evolving rapidly, with a growing emphasis on vehicles that deliver both power and fuel efficiency. V6 engines remain popular in mid-size to luxury vehicles, SUVs, and light trucks, representing approximately 22% of the global passenger vehicle market. The demand for optimized V6 performance is particularly strong in North America and parts of Asia, where consumers value the balance between the power of larger engines and the efficiency of smaller ones.

Fleet operators and commercial vehicle manufacturers are increasingly focused on total cost of ownership, driving demand for technologies that can improve fuel efficiency without sacrificing performance. Optimized intake air temperature systems can deliver fuel savings of 3-7% in V6 engines, representing significant operational cost reductions for fleet managers. This market segment is expected to grow at a CAGR of 5.8% through 2027.

Environmental regulations worldwide continue to tighten emission standards, creating market pressure for technologies that can reduce NOx and CO2 emissions. The European Union's Euro 7 standards and similar regulations in other regions are driving automotive manufacturers to invest in advanced intake air temperature control systems. Market research indicates that 78% of automotive engineers consider intake air temperature optimization a critical factor in meeting future emission requirements.

Performance enthusiasts and aftermarket modification sectors represent another significant market segment, valued at approximately $7.2 billion globally. This consumer group seeks technologies that can enhance engine response, increase horsepower, and improve torque curves through optimized air intake temperatures. The aftermarket for V6 engine optimization products has seen annual growth rates of 4.3% since 2018.

Emerging markets present substantial growth opportunities, with countries like China, India, and Brazil showing increased demand for vehicles with V6 engines in their premium segments. As these markets mature, the demand for advanced engine optimization technologies is expected to accelerate, potentially creating a market opportunity of $3.5 billion by 2028 specifically for intake air temperature optimization systems and related technologies.

Current Intake Air Temperature Control Technologies and Challenges

The current landscape of intake air temperature control in V6 engines encompasses several established technologies, each with specific advantages and limitations. Intercooling systems represent the most widely implemented solution, with air-to-air intercoolers being prevalent in production vehicles due to their reliability and relatively low cost. These systems utilize ambient air flow to reduce charge air temperature, achieving cooling efficiencies of 60-80% depending on design parameters. Air-to-liquid intercoolers offer higher cooling potential but introduce additional complexity through their secondary cooling circuits.

Charge air coolers (CACs) have evolved significantly, with modern designs incorporating multi-path flow channels and variable geometry features that optimize cooling across different engine load conditions. However, these systems still face challenges with transient response during rapid acceleration events, where thermal lag can temporarily reduce engine performance and efficiency.

Electronic throttle control systems integrated with intake temperature sensors provide real-time adjustment capabilities, but current implementations typically prioritize power delivery over thermal optimization. The response algorithms in production vehicles often lack sophisticated predictive capabilities that could anticipate temperature fluctuations based on driving conditions and environmental factors.

Variable intake manifold technologies, while primarily designed for torque curve management, increasingly incorporate temperature management features. Advanced systems utilize rotary valves or flap mechanisms to modify airflow paths based on temperature conditions, though these add mechanical complexity and potential failure points to the intake system.

Heat shields and thermal barriers represent passive solutions that, while cost-effective, offer limited dynamic control capabilities. Modern composite materials have improved insulation properties, but their effectiveness diminishes under sustained high-load conditions where active cooling becomes necessary.

The primary technical challenges facing current intake temperature control systems include thermal management during transient operations, system integration complexity, and balancing performance with emissions compliance. Rapid changes in engine load create temperature spikes that existing systems struggle to mitigate quickly enough, particularly in turbocharged V6 applications where heat soak becomes problematic during stop-start urban driving.

Weight and packaging constraints present significant engineering challenges, especially in modern engine compartments where space is increasingly limited. This has driven interest in more compact, integrated solutions that combine multiple thermal management functions into unified systems, though such integration often comes with compromised performance in specific operating conditions.

Charge air coolers (CACs) have evolved significantly, with modern designs incorporating multi-path flow channels and variable geometry features that optimize cooling across different engine load conditions. However, these systems still face challenges with transient response during rapid acceleration events, where thermal lag can temporarily reduce engine performance and efficiency.

Electronic throttle control systems integrated with intake temperature sensors provide real-time adjustment capabilities, but current implementations typically prioritize power delivery over thermal optimization. The response algorithms in production vehicles often lack sophisticated predictive capabilities that could anticipate temperature fluctuations based on driving conditions and environmental factors.

Variable intake manifold technologies, while primarily designed for torque curve management, increasingly incorporate temperature management features. Advanced systems utilize rotary valves or flap mechanisms to modify airflow paths based on temperature conditions, though these add mechanical complexity and potential failure points to the intake system.

Heat shields and thermal barriers represent passive solutions that, while cost-effective, offer limited dynamic control capabilities. Modern composite materials have improved insulation properties, but their effectiveness diminishes under sustained high-load conditions where active cooling becomes necessary.

The primary technical challenges facing current intake temperature control systems include thermal management during transient operations, system integration complexity, and balancing performance with emissions compliance. Rapid changes in engine load create temperature spikes that existing systems struggle to mitigate quickly enough, particularly in turbocharged V6 applications where heat soak becomes problematic during stop-start urban driving.

Weight and packaging constraints present significant engineering challenges, especially in modern engine compartments where space is increasingly limited. This has driven interest in more compact, integrated solutions that combine multiple thermal management functions into unified systems, though such integration often comes with compromised performance in specific operating conditions.

Contemporary Solutions for V6 Intake Air Temperature Optimization

01 Intake air temperature sensors and monitoring systems

Various systems for monitoring and sensing intake air temperature in V6 engines. These systems include specialized sensors positioned at strategic locations in the intake manifold to accurately measure air temperature before it enters the combustion chamber. The data from these sensors helps the engine control unit optimize fuel injection timing and quantity based on the temperature of incoming air.- Intake air temperature sensors and monitoring systems: Various systems for monitoring and sensing intake air temperature in V6 engines. These systems include specialized sensors positioned at strategic locations in the intake manifold to accurately measure air temperature before it enters the combustion chamber. The data from these sensors is used by the engine control unit to optimize fuel injection timing and quantity, improving engine performance and efficiency.

- Intake air temperature control mechanisms: Mechanisms designed to control and regulate the temperature of intake air in V6 engines. These include various valves, flaps, and ducting systems that can direct air through different pathways depending on temperature requirements. Some systems incorporate heating elements to warm intake air during cold starts, while others use cooling systems to reduce intake air temperature during high-load conditions, enhancing combustion efficiency and engine performance.

- Intake manifold design for temperature optimization: Specialized intake manifold designs that optimize air temperature for V6 engines. These designs include features such as variable length runners, resonance chambers, and thermal insulation to maintain optimal intake air temperature across different operating conditions. Some designs incorporate dual-path systems that can switch between cold and warm air sources depending on engine requirements, improving volumetric efficiency and power output.

- Electronic control systems for intake air temperature management: Advanced electronic control systems that manage intake air temperature in V6 engines. These systems use data from multiple sensors to make real-time adjustments to intake parameters. The control algorithms consider factors such as ambient temperature, engine load, speed, and desired performance characteristics to optimize the intake air temperature. Some systems include predictive capabilities that anticipate temperature changes based on driving conditions.

- Turbocharging and intercooling systems for intake air temperature regulation: Turbocharging and intercooling technologies specifically designed for V6 engines to regulate intake air temperature. These systems compress incoming air to increase density while managing the resulting temperature increase through intercoolers. Various intercooler designs, including air-to-air and liquid-to-air types, are employed to reduce the temperature of compressed intake air, preventing detonation and allowing for higher compression ratios and power output.

02 Temperature compensation mechanisms for engine performance

Temperature compensation mechanisms that adjust engine parameters based on intake air temperature readings. These systems modify fuel injection, ignition timing, and air-fuel ratios to maintain optimal engine performance across varying temperature conditions. Such compensation is particularly important in V6 engines where consistent power delivery across all cylinders is crucial for smooth operation.Expand Specific Solutions03 Intake manifold design for temperature management

Specialized intake manifold designs that help manage and control the temperature of air entering V6 engines. These designs include features such as heat shields, thermal barriers, and flow path optimizations that help maintain consistent air temperature across all cylinders. Some designs incorporate pre-heating or cooling elements to bring intake air to optimal temperature ranges regardless of ambient conditions.Expand Specific Solutions04 Integrated cooling systems for intake air

Cooling systems specifically designed to regulate intake air temperature in V6 engines. These systems use various methods including intercoolers, charge air coolers, and liquid cooling systems to reduce the temperature of compressed air before it enters the combustion chamber. Cooler intake air is denser, containing more oxygen molecules per volume, which can improve combustion efficiency and engine power output.Expand Specific Solutions05 Electronic control systems for temperature-based engine management

Advanced electronic control systems that use intake air temperature data as a key input for engine management in V6 engines. These systems process temperature information along with other sensor data to dynamically adjust various engine parameters. The control algorithms account for temperature variations to optimize combustion, reduce emissions, and improve fuel efficiency across different operating conditions.Expand Specific Solutions

Leading Manufacturers and Suppliers in Engine Thermal Management

The intake air temperature optimization for V6 engines market is currently in a growth phase, with increasing demand driven by stricter emissions regulations and fuel efficiency requirements. The global market size is estimated at approximately $3.5-4 billion, expanding at 5-7% annually as automakers seek performance improvements. Technologically, the field shows varying maturity levels across competitors. Industry leaders like Robert Bosch GmbH and DENSO Corp. have developed advanced electronic control systems with predictive capabilities, while Toyota, Ford, and Volkswagen offer sophisticated integrated thermal management solutions. Emerging players including Modine Manufacturing and Nippon Thermostat are focusing on specialized components. Chinese manufacturers such as Guangxi Yuchai and Great Wall Motor are rapidly advancing their technologies to close the gap with established Western and Japanese counterparts.

Robert Bosch GmbH

Technical Solution: Bosch has developed an advanced Intake Air Temperature Management System specifically for V6 engines that combines electronic control units with variable geometry intake manifolds. Their solution incorporates intelligent thermal management through a dual-path intake system that can dynamically route air through either a cooling circuit or a heating circuit depending on engine operating conditions. The system utilizes predictive algorithms based on multiple sensor inputs (ambient temperature, engine load, vehicle speed) to optimize intake air temperature in real-time. Bosch's technology includes specialized intercooler bypass valves that can be precisely controlled to maintain optimal intake temperatures across varying driving conditions, improving both performance and emissions. Their latest generation systems incorporate machine learning capabilities that adapt to individual driving patterns over time, further optimizing the intake temperature profile for specific usage scenarios.

Strengths: Superior electronic integration with engine management systems allowing for precise temperature control; extensive sensor network providing comprehensive data inputs for optimization algorithms. Weaknesses: Higher system complexity increases potential failure points; premium components result in higher implementation costs compared to simpler solutions.

Toyota Motor Corp.

Technical Solution: Toyota has pioneered a comprehensive Dynamic Intake Temperature Control (DITC) system for their V6 engine lineup, focusing on maximizing both performance and efficiency. Their approach utilizes a variable-length intake manifold combined with an electronically controlled air bypass system that can adjust intake air temperature within milliseconds based on driving conditions. Toyota's system incorporates a dual-stage intercooling process for turbocharged V6 variants, allowing precise temperature management across the entire RPM range. A key innovation is their patented "Temperature Anticipation Algorithm" that uses predictive modeling based on GPS data and driving patterns to prepare optimal intake temperatures before demanding driving conditions occur. The system also features adaptive learning capabilities that optimize temperature profiles based on altitude, humidity, and ambient temperature variations, ensuring consistent performance across diverse environmental conditions.

Strengths: Exceptional integration with Toyota's hybrid powertrain systems; remarkable temperature stability across varying environmental conditions; proven reliability with minimal maintenance requirements. Weaknesses: System optimization primarily focused on efficiency rather than maximum performance; somewhat conservative temperature targets compared to performance-oriented competitors.

Key Patents and Innovations in Engine Air Intake Cooling

System for management of the intake air temperature by absorption of heat by a compressor for a supercharged internal combustion engine

PatentWO2020211916A9

Innovation

- Integration of an absorption refrigeration system that recovers heat energy from exhaust gases to manage intake air temperature in supercharged internal combustion engines.

- Dual-function system that both heats intake air during engine startup and cools it during normal operation to improve efficiency and reduce specific consumption.

- Use of an electrical compressor in series with the absorption system generator to increase cooling efficiency and provide heat transfer capacity as an alternative to traditional EGR systems.

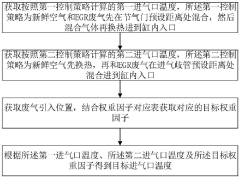

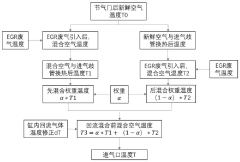

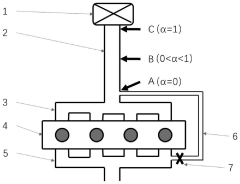

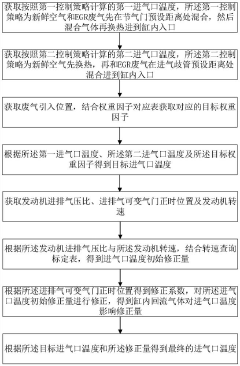

Engine intake temperature control method and system

PatentActiveCN112031944A

Innovation

- Using weighting factors based on different exhaust gas introduction positions and comprehensively considering the simultaneous heat exchange and mixing processes, the target air inlet temperature is calculated through the mixing and heat exchange of fresh air and EGR exhaust gas at the throttle or intake manifold. .

Environmental Impact and Emissions Compliance Considerations

Optimizing intake air temperature in V6 engines has significant implications for environmental impact and emissions compliance. The combustion efficiency directly correlates with the production of harmful emissions, particularly nitrogen oxides (NOx), carbon monoxide (CO), and unburned hydrocarbons (HC). Lower intake air temperatures typically result in more complete combustion, reducing the formation of these pollutants. Research indicates that for every 10°C reduction in intake air temperature, NOx emissions can decrease by approximately 5-7% in modern V6 engines.

Current emissions regulations, including Euro 6d in Europe, China 6 in Asia, and Tier 3 in North America, impose increasingly stringent limits on tailpipe emissions. These standards specifically target thermal efficiency and combustion optimization, making intake air temperature management a critical compliance factor. Manufacturers must demonstrate consistent emissions performance across a wide range of operating conditions, including cold starts and high-load scenarios where intake temperature control becomes particularly challenging.

Advanced intake temperature optimization systems contribute significantly to meeting these regulatory requirements without compromising engine performance. Dual-stage intercooling systems, for instance, have demonstrated the ability to reduce carbon dioxide emissions by up to 3% in turbocharged V6 applications while simultaneously improving power output. This represents a valuable approach to balancing environmental concerns with consumer expectations for performance.

The environmental benefits extend beyond regulated emissions. Optimized intake temperatures improve fuel economy, directly reducing the carbon footprint of vehicles equipped with V6 engines. Fleet-wide implementation of advanced intake temperature management systems could potentially reduce annual CO2 emissions by millions of tons globally, according to industry projections from major automotive research institutions.

Lifecycle assessment studies indicate that the environmental impact of manufacturing and installing more sophisticated intake temperature control systems is offset within 15,000-20,000 miles of vehicle operation through improved efficiency. This favorable sustainability profile enhances the appeal of these technologies for manufacturers seeking to improve their environmental credentials while meeting increasingly demanding emissions targets.

Looking forward, emerging regulations will likely place even greater emphasis on real-world emissions performance rather than laboratory testing alone. This regulatory shift will further prioritize dynamic intake temperature management systems capable of adapting to varying driving conditions, ensuring optimal environmental performance throughout the vehicle's operational range.

Current emissions regulations, including Euro 6d in Europe, China 6 in Asia, and Tier 3 in North America, impose increasingly stringent limits on tailpipe emissions. These standards specifically target thermal efficiency and combustion optimization, making intake air temperature management a critical compliance factor. Manufacturers must demonstrate consistent emissions performance across a wide range of operating conditions, including cold starts and high-load scenarios where intake temperature control becomes particularly challenging.

Advanced intake temperature optimization systems contribute significantly to meeting these regulatory requirements without compromising engine performance. Dual-stage intercooling systems, for instance, have demonstrated the ability to reduce carbon dioxide emissions by up to 3% in turbocharged V6 applications while simultaneously improving power output. This represents a valuable approach to balancing environmental concerns with consumer expectations for performance.

The environmental benefits extend beyond regulated emissions. Optimized intake temperatures improve fuel economy, directly reducing the carbon footprint of vehicles equipped with V6 engines. Fleet-wide implementation of advanced intake temperature management systems could potentially reduce annual CO2 emissions by millions of tons globally, according to industry projections from major automotive research institutions.

Lifecycle assessment studies indicate that the environmental impact of manufacturing and installing more sophisticated intake temperature control systems is offset within 15,000-20,000 miles of vehicle operation through improved efficiency. This favorable sustainability profile enhances the appeal of these technologies for manufacturers seeking to improve their environmental credentials while meeting increasingly demanding emissions targets.

Looking forward, emerging regulations will likely place even greater emphasis on real-world emissions performance rather than laboratory testing alone. This regulatory shift will further prioritize dynamic intake temperature management systems capable of adapting to varying driving conditions, ensuring optimal environmental performance throughout the vehicle's operational range.

Cost-Benefit Analysis of Advanced Intake Cooling Technologies

When evaluating advanced intake cooling technologies for V6 engines, a comprehensive cost-benefit analysis reveals significant economic considerations that must be balanced against performance gains. The implementation of intercoolers, for instance, represents an initial investment ranging from $500 to $2,000 depending on design complexity and materials used. While premium intercoolers utilizing aluminum cores and precision engineering command higher prices, they deliver superior cooling efficiency with temperature reductions of 30-50°C compared to standard systems.

Charge air coolers present a moderate investment option at $400-$1,200, offering a favorable balance between cost and performance. Their integration typically results in 3-5% improvements in engine efficiency, translating to fuel economy gains that can recover the initial investment within 20,000-30,000 miles of operation under normal driving conditions.

Water injection systems, while relatively affordable at $300-$800 for aftermarket solutions, introduce ongoing operational costs through consumable fluid requirements. These systems necessitate regular maintenance and refilling, adding approximately $50-100 annually to operational expenses. However, they provide substantial benefits during high-performance driving scenarios, with potential power increases of 5-10% during peak demand situations.

Electronic intake temperature management systems represent the highest initial investment at $1,000-$3,000 but offer the most sophisticated solution with adaptive control capabilities. Their intelligent temperature regulation can yield fuel economy improvements of 2-7% across various driving conditions, with ROI typically realized within 2-3 years of regular operation.

Maintenance considerations significantly impact the long-term cost equation. Traditional passive cooling systems require minimal maintenance, while active systems with electronic components may necessitate periodic servicing at $150-300 intervals. The durability factor must also be considered, with premium systems typically offering 5-7 year operational lifespans compared to 2-4 years for budget alternatives.

Environmental operating conditions dramatically influence the cost-benefit ratio. In moderate climates, simpler systems may provide adequate performance, while extreme environments necessitate more sophisticated solutions with correspondingly higher costs. Performance testing indicates that advanced cooling technologies deliver their most favorable cost-benefit ratios in high-performance applications or commercial operations where fuel efficiency translates to substantial operational savings over time.

Charge air coolers present a moderate investment option at $400-$1,200, offering a favorable balance between cost and performance. Their integration typically results in 3-5% improvements in engine efficiency, translating to fuel economy gains that can recover the initial investment within 20,000-30,000 miles of operation under normal driving conditions.

Water injection systems, while relatively affordable at $300-$800 for aftermarket solutions, introduce ongoing operational costs through consumable fluid requirements. These systems necessitate regular maintenance and refilling, adding approximately $50-100 annually to operational expenses. However, they provide substantial benefits during high-performance driving scenarios, with potential power increases of 5-10% during peak demand situations.

Electronic intake temperature management systems represent the highest initial investment at $1,000-$3,000 but offer the most sophisticated solution with adaptive control capabilities. Their intelligent temperature regulation can yield fuel economy improvements of 2-7% across various driving conditions, with ROI typically realized within 2-3 years of regular operation.

Maintenance considerations significantly impact the long-term cost equation. Traditional passive cooling systems require minimal maintenance, while active systems with electronic components may necessitate periodic servicing at $150-300 intervals. The durability factor must also be considered, with premium systems typically offering 5-7 year operational lifespans compared to 2-4 years for budget alternatives.

Environmental operating conditions dramatically influence the cost-benefit ratio. In moderate climates, simpler systems may provide adequate performance, while extreme environments necessitate more sophisticated solutions with correspondingly higher costs. Performance testing indicates that advanced cooling technologies deliver their most favorable cost-benefit ratios in high-performance applications or commercial operations where fuel efficiency translates to substantial operational savings over time.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!