How to Predict V6 Engine Combustion Anomalies

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V6 Engine Combustion Technology Background and Objectives

V6 engine combustion technology has evolved significantly over the past decades, transitioning from purely mechanical systems to sophisticated electronically controlled powertrains. The development trajectory began with carbureted V6 engines in the 1950s, progressing through fuel injection systems in the 1980s, and advancing to today's direct injection technologies with variable valve timing. This evolution has been driven by increasingly stringent emissions regulations, fuel economy requirements, and consumer demand for improved performance and reliability.

Recent technological advancements have focused on optimizing combustion efficiency while minimizing environmental impact. Modern V6 engines employ complex systems including turbocharging, variable compression ratios, and cylinder deactivation to balance power delivery with fuel economy. Despite these innovations, combustion anomalies remain a persistent challenge that can lead to reduced efficiency, increased emissions, and potential engine damage.

Combustion anomalies in V6 engines encompass various phenomena including pre-ignition, knock, misfire, and incomplete combustion. These issues have become more prevalent as manufacturers push the boundaries of performance within tighter operating parameters. The industry trend toward downsized, high-output engines has exacerbated these challenges, creating a critical need for advanced prediction and prevention technologies.

The primary objective of combustion anomaly prediction technology is to develop robust systems capable of identifying potential combustion irregularities before they manifest as performance issues or component damage. This involves creating algorithms that can process real-time sensor data to detect subtle variations in combustion parameters that precede anomalous events.

Secondary objectives include reducing calibration time during engine development, enabling adaptive control strategies that can respond to changing operating conditions, and extending engine longevity through preventive measures. The ultimate goal is to create self-diagnosing engines that can maintain optimal combustion characteristics throughout their operational life.

Current prediction methodologies rely heavily on pressure sensors, ion-sensing technology, and vibration analysis. However, these approaches often suffer from limited predictive horizons and insufficient accuracy under varying operating conditions. The technological trajectory is now moving toward integrated systems that combine multiple sensing modalities with machine learning algorithms to achieve more reliable prediction capabilities.

As the automotive industry continues its transition toward electrification, the role of combustion prediction technology extends beyond traditional applications to include hybrid powertrains where combustion engines operate under even more variable conditions. This evolution presents both challenges and opportunities for developing next-generation prediction systems that can accommodate the unique requirements of modern propulsion architectures.

Recent technological advancements have focused on optimizing combustion efficiency while minimizing environmental impact. Modern V6 engines employ complex systems including turbocharging, variable compression ratios, and cylinder deactivation to balance power delivery with fuel economy. Despite these innovations, combustion anomalies remain a persistent challenge that can lead to reduced efficiency, increased emissions, and potential engine damage.

Combustion anomalies in V6 engines encompass various phenomena including pre-ignition, knock, misfire, and incomplete combustion. These issues have become more prevalent as manufacturers push the boundaries of performance within tighter operating parameters. The industry trend toward downsized, high-output engines has exacerbated these challenges, creating a critical need for advanced prediction and prevention technologies.

The primary objective of combustion anomaly prediction technology is to develop robust systems capable of identifying potential combustion irregularities before they manifest as performance issues or component damage. This involves creating algorithms that can process real-time sensor data to detect subtle variations in combustion parameters that precede anomalous events.

Secondary objectives include reducing calibration time during engine development, enabling adaptive control strategies that can respond to changing operating conditions, and extending engine longevity through preventive measures. The ultimate goal is to create self-diagnosing engines that can maintain optimal combustion characteristics throughout their operational life.

Current prediction methodologies rely heavily on pressure sensors, ion-sensing technology, and vibration analysis. However, these approaches often suffer from limited predictive horizons and insufficient accuracy under varying operating conditions. The technological trajectory is now moving toward integrated systems that combine multiple sensing modalities with machine learning algorithms to achieve more reliable prediction capabilities.

As the automotive industry continues its transition toward electrification, the role of combustion prediction technology extends beyond traditional applications to include hybrid powertrains where combustion engines operate under even more variable conditions. This evolution presents both challenges and opportunities for developing next-generation prediction systems that can accommodate the unique requirements of modern propulsion architectures.

Market Demand Analysis for Combustion Anomaly Detection

The global market for combustion anomaly detection in V6 engines has experienced significant growth in recent years, driven primarily by stringent emission regulations, increasing focus on fuel efficiency, and the rising demand for vehicle reliability. The automotive industry's shift towards more sophisticated engine management systems has created a substantial market opportunity for advanced combustion anomaly prediction technologies.

Market research indicates that the automotive diagnostic equipment market, which includes combustion anomaly detection systems, is projected to reach $45 billion by 2025, with a compound annual growth rate of 5.7%. Within this broader market, the engine diagnostic segment represents approximately 30% of the total value, highlighting the economic significance of combustion monitoring solutions.

The primary market segments demanding combustion anomaly detection technologies include automotive manufacturers, aftermarket service providers, fleet management companies, and performance tuning specialists. Original Equipment Manufacturers (OEMs) constitute the largest segment, as they increasingly integrate predictive maintenance capabilities into their vehicle offerings to enhance customer satisfaction and reduce warranty claims.

Regional analysis reveals varying levels of market maturity. North America and Europe lead in adoption due to their stringent emission standards and higher consumer expectations for vehicle performance. The Asia-Pacific region, particularly China and India, represents the fastest-growing market segment with projected growth rates exceeding 8% annually, driven by rapid automotive industry expansion and increasing regulatory pressure.

Consumer demand patterns indicate a growing preference for vehicles with advanced diagnostic capabilities. A recent industry survey revealed that 67% of new vehicle buyers consider predictive maintenance features as "important" or "very important" in their purchasing decisions. This consumer sentiment is reinforcing manufacturer investment in combustion anomaly detection technologies.

The commercial vehicle sector presents a particularly promising market opportunity. Fleet operators face significant financial pressures from unplanned downtime, with studies showing that each day of vehicle downtime costs between $400-$700 in lost revenue, not including repair expenses. Predictive combustion anomaly detection systems that can reduce these incidents offer compelling return on investment for fleet managers.

Market challenges include price sensitivity among aftermarket consumers and the technical complexity of retrofitting older vehicles with advanced diagnostic systems. However, the increasing availability of affordable sensor technology and edge computing solutions is gradually addressing these barriers to market expansion.

Market research indicates that the automotive diagnostic equipment market, which includes combustion anomaly detection systems, is projected to reach $45 billion by 2025, with a compound annual growth rate of 5.7%. Within this broader market, the engine diagnostic segment represents approximately 30% of the total value, highlighting the economic significance of combustion monitoring solutions.

The primary market segments demanding combustion anomaly detection technologies include automotive manufacturers, aftermarket service providers, fleet management companies, and performance tuning specialists. Original Equipment Manufacturers (OEMs) constitute the largest segment, as they increasingly integrate predictive maintenance capabilities into their vehicle offerings to enhance customer satisfaction and reduce warranty claims.

Regional analysis reveals varying levels of market maturity. North America and Europe lead in adoption due to their stringent emission standards and higher consumer expectations for vehicle performance. The Asia-Pacific region, particularly China and India, represents the fastest-growing market segment with projected growth rates exceeding 8% annually, driven by rapid automotive industry expansion and increasing regulatory pressure.

Consumer demand patterns indicate a growing preference for vehicles with advanced diagnostic capabilities. A recent industry survey revealed that 67% of new vehicle buyers consider predictive maintenance features as "important" or "very important" in their purchasing decisions. This consumer sentiment is reinforcing manufacturer investment in combustion anomaly detection technologies.

The commercial vehicle sector presents a particularly promising market opportunity. Fleet operators face significant financial pressures from unplanned downtime, with studies showing that each day of vehicle downtime costs between $400-$700 in lost revenue, not including repair expenses. Predictive combustion anomaly detection systems that can reduce these incidents offer compelling return on investment for fleet managers.

Market challenges include price sensitivity among aftermarket consumers and the technical complexity of retrofitting older vehicles with advanced diagnostic systems. However, the increasing availability of affordable sensor technology and edge computing solutions is gradually addressing these barriers to market expansion.

Current Challenges in V6 Engine Combustion Monitoring

The monitoring of combustion processes in V6 engines presents significant challenges due to the complex interplay of mechanical, thermal, and chemical factors. Current monitoring systems often struggle with real-time detection capabilities, particularly when identifying subtle anomalies that precede major combustion issues. Traditional sensors typically measure secondary parameters such as temperature, pressure, and exhaust composition, but these provide only indirect indicators of combustion quality and efficiency.

One of the primary challenges is the integration of multiple sensor data streams into a coherent monitoring framework. V6 engines generate vast amounts of operational data across different cylinders, creating difficulties in synchronizing and interpreting this information to identify meaningful patterns indicative of combustion anomalies. The heterogeneity of data formats and sampling rates further complicates this integration process.

Signal-to-noise ratio presents another significant obstacle in combustion monitoring. Engine vibrations, thermal fluctuations, and electromagnetic interference can mask subtle combustion irregularities, making it difficult to distinguish between normal operational variations and genuine anomalies. This challenge is particularly pronounced in high-performance V6 engines where the margin between optimal combustion and anomalous behavior is increasingly narrow.

The dynamic nature of engine operation compounds these monitoring difficulties. As engines transition between different load conditions, speed ranges, and environmental contexts, the baseline parameters for "normal" combustion shift accordingly. Current monitoring systems often lack the adaptability to establish dynamic thresholds that account for these operational variations, resulting in either excessive false alarms or missed detection of genuine anomalies.

Computational limitations also constrain effective monitoring. Processing the volume of data required for comprehensive combustion analysis demands significant computing resources, particularly for real-time applications. Edge computing solutions integrated directly with engine control units often lack the processing power for sophisticated anomaly detection algorithms, while cloud-based solutions introduce latency issues that compromise the timeliness of anomaly detection.

Calibration and maintenance of monitoring systems represent ongoing challenges. Sensor degradation over time affects measurement accuracy, while environmental factors such as temperature extremes and humidity can alter sensor performance. Current systems typically lack robust self-diagnostic capabilities to identify when monitoring equipment itself is contributing to detection errors.

Finally, there exists a fundamental knowledge gap in understanding the complex precursors to combustion anomalies. The multifactorial nature of combustion irregularities means that predictive models must account for numerous variables and their interactions, many of which remain incompletely characterized in the scientific literature.

One of the primary challenges is the integration of multiple sensor data streams into a coherent monitoring framework. V6 engines generate vast amounts of operational data across different cylinders, creating difficulties in synchronizing and interpreting this information to identify meaningful patterns indicative of combustion anomalies. The heterogeneity of data formats and sampling rates further complicates this integration process.

Signal-to-noise ratio presents another significant obstacle in combustion monitoring. Engine vibrations, thermal fluctuations, and electromagnetic interference can mask subtle combustion irregularities, making it difficult to distinguish between normal operational variations and genuine anomalies. This challenge is particularly pronounced in high-performance V6 engines where the margin between optimal combustion and anomalous behavior is increasingly narrow.

The dynamic nature of engine operation compounds these monitoring difficulties. As engines transition between different load conditions, speed ranges, and environmental contexts, the baseline parameters for "normal" combustion shift accordingly. Current monitoring systems often lack the adaptability to establish dynamic thresholds that account for these operational variations, resulting in either excessive false alarms or missed detection of genuine anomalies.

Computational limitations also constrain effective monitoring. Processing the volume of data required for comprehensive combustion analysis demands significant computing resources, particularly for real-time applications. Edge computing solutions integrated directly with engine control units often lack the processing power for sophisticated anomaly detection algorithms, while cloud-based solutions introduce latency issues that compromise the timeliness of anomaly detection.

Calibration and maintenance of monitoring systems represent ongoing challenges. Sensor degradation over time affects measurement accuracy, while environmental factors such as temperature extremes and humidity can alter sensor performance. Current systems typically lack robust self-diagnostic capabilities to identify when monitoring equipment itself is contributing to detection errors.

Finally, there exists a fundamental knowledge gap in understanding the complex precursors to combustion anomalies. The multifactorial nature of combustion irregularities means that predictive models must account for numerous variables and their interactions, many of which remain incompletely characterized in the scientific literature.

Existing Anomaly Prediction Solutions for V6 Engines

01 Combustion anomaly detection systems

Various systems have been developed to detect combustion anomalies in V6 engines. These systems utilize sensors to monitor parameters such as pressure, temperature, and vibration during the combustion process. By analyzing these parameters, the systems can identify irregular combustion patterns, misfires, or other anomalies that may affect engine performance. Early detection of these anomalies allows for timely intervention, preventing potential damage to the engine and maintaining optimal performance.- Detection and diagnosis of combustion anomalies in V6 engines: Various methods and systems for detecting and diagnosing combustion anomalies in V6 engines have been developed. These include sensors and monitoring systems that can identify irregular combustion patterns, misfires, and other anomalies in real-time. Advanced diagnostic tools can analyze engine performance data to pinpoint specific cylinders experiencing issues, allowing for targeted maintenance and repairs. These detection systems help prevent engine damage and maintain optimal performance.

- Fuel injection control systems to prevent combustion anomalies: Specialized fuel injection control systems have been developed to prevent combustion anomalies in V6 engines. These systems precisely regulate fuel delivery timing and quantity to each cylinder, ensuring optimal air-fuel mixture. By adjusting injection parameters based on engine load, temperature, and other operating conditions, these systems can minimize irregular combustion events. Advanced electronic control units continuously monitor and adjust fuel delivery to maintain stable combustion across all cylinders.

- Structural modifications to reduce combustion anomalies: Structural modifications to V6 engine components can help reduce combustion anomalies. These include redesigned combustion chambers, improved piston geometry, and enhanced valve configurations that promote more complete and consistent fuel burning. Modified intake manifolds can improve air distribution to each cylinder, while reinforced components can withstand irregular combustion events. These structural changes address inherent design challenges in V6 engines that can lead to combustion anomalies.

- Thermal management solutions for combustion stability: Thermal management solutions play a crucial role in maintaining combustion stability in V6 engines. Advanced cooling systems help maintain uniform temperatures across all cylinders, preventing hot spots that can lead to pre-ignition or knocking. Temperature-regulated components ensure consistent combustion conditions regardless of operating environment. These solutions include improved coolant circulation, strategic heat shielding, and materials with enhanced thermal properties to manage heat distribution throughout the engine.

- Electronic control systems for anomaly prevention and correction: Sophisticated electronic control systems have been developed to prevent and correct combustion anomalies in V6 engines. These systems use real-time data from multiple sensors to adjust ignition timing, air-fuel ratios, and other parameters to maintain optimal combustion. When anomalies are detected, these systems can implement corrective measures such as cylinder deactivation or adaptive timing adjustments. Machine learning algorithms can also predict potential combustion issues before they occur, allowing for preventive adjustments.

02 Fuel injection optimization for V6 engines

Optimizing fuel injection systems is crucial for preventing combustion anomalies in V6 engines. Advanced fuel injection technologies enable precise control over the timing, duration, and pattern of fuel delivery to each cylinder. This precision helps maintain balanced combustion across all cylinders, reducing the likelihood of anomalies such as knocking or incomplete combustion. Adaptive fuel injection systems can also adjust parameters in real-time based on operating conditions, further enhancing combustion stability.Expand Specific Solutions03 Thermal management solutions for combustion stability

Effective thermal management is essential for maintaining stable combustion in V6 engines. Innovations in cooling systems, heat dissipation, and temperature regulation help prevent overheating that can lead to combustion anomalies. These solutions include advanced coolant circulation designs, improved heat exchanger efficiency, and strategic placement of cooling channels. By maintaining optimal operating temperatures throughout the engine, these systems help prevent pre-ignition, detonation, and other temperature-related combustion issues.Expand Specific Solutions04 Cylinder pressure balancing techniques

Balancing cylinder pressures across all six cylinders is critical for preventing combustion anomalies in V6 engines. Various techniques have been developed to achieve this balance, including advanced valve timing systems, intake manifold design optimizations, and electronic control units that monitor and adjust combustion parameters. These systems work together to ensure that each cylinder receives the same air-fuel mixture and experiences similar compression conditions, resulting in more uniform combustion and reduced anomalies.Expand Specific Solutions05 Combustion chamber design improvements

Innovations in combustion chamber design have significantly reduced the occurrence of combustion anomalies in V6 engines. These improvements include optimized chamber geometry, piston crown designs that enhance turbulence for better fuel-air mixing, and strategic positioning of spark plugs for more efficient flame propagation. Advanced materials and coatings are also used to reduce hot spots and improve thermal efficiency. These design enhancements collectively contribute to more stable and complete combustion, minimizing the risk of anomalies.Expand Specific Solutions

Key Industry Players in Engine Diagnostic Technologies

The V6 engine combustion anomaly prediction market is in a growth phase, with increasing demand driven by automotive and energy sectors seeking improved engine efficiency and reduced emissions. Major players include established automotive manufacturers like Toyota, Mazda, Nissan, and Volkswagen, alongside specialized engineering firms such as AVL List, FEV Motorentechnik, and Bosch. Research institutions like the University of Michigan and Harbin Institute of Technology contribute significant academic advancements. The technology maturity varies, with companies like Toyota, Bosch, and DENSO leading with advanced predictive systems, while newer entrants like Weichai Power are rapidly developing capabilities. Integration of AI and machine learning with traditional combustion analysis represents the current technological frontier in this approximately $2-3 billion market.

IFP Energies Nouvelles

Technical Solution: IFP Energies Nouvelles has developed advanced combustion diagnostic systems for V6 engines that combine real-time cylinder pressure analysis with sophisticated machine learning algorithms. Their approach integrates multiple sensor inputs (pressure, temperature, vibration, and acoustic emissions) with a proprietary neural network model trained on extensive combustion anomaly datasets. The system employs a two-stage detection methodology: first identifying deviations from normal combustion patterns through wavelet transform analysis of pressure signals, then classifying specific anomaly types (pre-ignition, knock, misfire) using a convolutional neural network. Their predictive models achieve over 95% accuracy in anomaly detection with a prediction window of up to 20 engine cycles before critical events occur, allowing for preventive control adjustments.

Strengths: Exceptional early detection capabilities with high accuracy rates; comprehensive multi-sensor approach provides redundancy; extensive validation across different V6 engine types. Weaknesses: System requires significant computational resources; initial calibration process is time-intensive; higher implementation cost compared to simpler detection systems.

Mazda Motor Corp.

Technical Solution: Mazda has pioneered a predictive combustion anomaly detection system for V6 engines centered around their SKYACTIV technology platform. Their approach utilizes a combination of in-cylinder pressure sensors and advanced signal processing techniques to identify combustion irregularities before they manifest as performance issues. Mazda's system employs a unique frequency domain analysis method that examines pressure oscillation patterns to detect incipient knock conditions and combustion instabilities. The technology incorporates a self-learning algorithm that continuously adapts to engine aging and environmental conditions, creating a dynamic baseline for "normal" combustion behavior. This adaptive baseline allows for more precise anomaly detection across varying operating conditions. Mazda has integrated this system with their i-ELOOP energy recovery system to ensure consistent sensor power even during transient engine operations, enhancing reliability of anomaly prediction.

Strengths: Highly adaptive to changing engine conditions and driver behavior patterns; seamless integration with existing engine control units; relatively low false positive rate compared to industry standards. Weaknesses: System performance degrades in extreme temperature conditions; requires periodic recalibration for optimal performance; limited effectiveness during rapid transient operations.

Core Sensor and Algorithm Innovations for Combustion Analysis

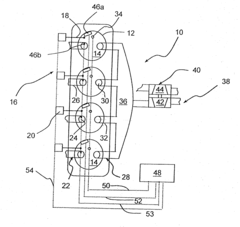

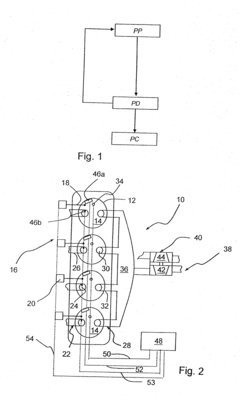

Abnormal combustion detection and characterization method for internal-combustion engines

PatentInactiveUS20130024087A1

Innovation

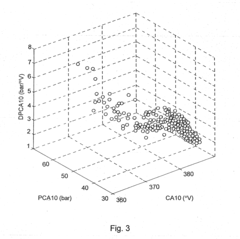

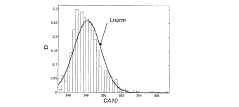

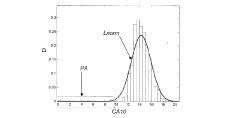

- A method using a multidimensional space with defined combustion indicators to represent normal and abnormal combustion, allowing real-time detection and characterization of abnormal combustion severity, enabling preventive measures during the same cycle.

Method for detecting abnormal combustion of internal combustion engine from combustion indicator distribution modelling

PatentInactiveJP2011106456A

Innovation

- A method involving combustion state modeling and analysis of combustion indicators using theoretical distribution laws to detect, characterize, and quantify abnormal combustion in real time, allowing for immediate corrective action during the same engine cycle.

Emissions Regulations Impact on Combustion Technology Development

Emissions regulations have become a primary driver for combustion technology development in the automotive industry, particularly for V6 engines where combustion anomalies can significantly impact compliance. The evolution of these regulations has followed an increasingly stringent trajectory, with major milestones including the introduction of Euro standards in Europe, CAFE standards in the United States, and similar frameworks in China and other major markets. Each regulatory update has progressively lowered permissible emission levels for nitrogen oxides (NOx), particulate matter (PM), carbon monoxide (CO), and hydrocarbons (HC).

These tightening regulations have directly influenced combustion technology development pathways, forcing manufacturers to implement sophisticated prediction and control systems for combustion anomalies. The transition from Euro 6 to Euro 7 standards, for instance, has necessitated real-world driving emissions testing rather than laboratory-only validation, creating new challenges for combustion stability prediction in V6 engines across varied operating conditions.

The regulatory landscape has also shifted toward lifecycle emissions assessment, considering not only tailpipe emissions but also production and end-of-life environmental impacts. This holistic approach has accelerated research into combustion anomaly prediction technologies that can optimize engine performance across multiple parameters simultaneously, rather than focusing solely on power output or fuel efficiency.

Regional variations in emissions standards have created complex compliance requirements for global automotive manufacturers. California's ZEV (Zero Emission Vehicle) mandate and China's dual-credit policy system have pushed companies to develop hybrid solutions where combustion anomaly prediction becomes critical during the transition between electric and internal combustion operation in V6 engines.

The regulatory timeline for phasing out internal combustion engines in various markets has created urgency in developing advanced combustion prediction technologies. With several European countries announcing bans on new internal combustion vehicles by 2030-2035, manufacturers are investing heavily in technologies that can predict and mitigate combustion anomalies to extend the viability of V6 engines in the interim period.

Financial penalties for non-compliance have become substantial, with manufacturers facing fines exceeding billions of dollars for fleet emissions target failures. This economic pressure has transformed combustion anomaly prediction from a performance optimization concern to a critical financial risk management tool, driving investment in advanced sensor technologies, real-time monitoring systems, and predictive algorithms specifically designed for V6 engine architectures.

These tightening regulations have directly influenced combustion technology development pathways, forcing manufacturers to implement sophisticated prediction and control systems for combustion anomalies. The transition from Euro 6 to Euro 7 standards, for instance, has necessitated real-world driving emissions testing rather than laboratory-only validation, creating new challenges for combustion stability prediction in V6 engines across varied operating conditions.

The regulatory landscape has also shifted toward lifecycle emissions assessment, considering not only tailpipe emissions but also production and end-of-life environmental impacts. This holistic approach has accelerated research into combustion anomaly prediction technologies that can optimize engine performance across multiple parameters simultaneously, rather than focusing solely on power output or fuel efficiency.

Regional variations in emissions standards have created complex compliance requirements for global automotive manufacturers. California's ZEV (Zero Emission Vehicle) mandate and China's dual-credit policy system have pushed companies to develop hybrid solutions where combustion anomaly prediction becomes critical during the transition between electric and internal combustion operation in V6 engines.

The regulatory timeline for phasing out internal combustion engines in various markets has created urgency in developing advanced combustion prediction technologies. With several European countries announcing bans on new internal combustion vehicles by 2030-2035, manufacturers are investing heavily in technologies that can predict and mitigate combustion anomalies to extend the viability of V6 engines in the interim period.

Financial penalties for non-compliance have become substantial, with manufacturers facing fines exceeding billions of dollars for fleet emissions target failures. This economic pressure has transformed combustion anomaly prediction from a performance optimization concern to a critical financial risk management tool, driving investment in advanced sensor technologies, real-time monitoring systems, and predictive algorithms specifically designed for V6 engine architectures.

Real-time Monitoring System Integration Considerations

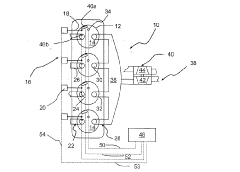

Integrating real-time monitoring systems for V6 engine combustion anomaly prediction requires careful consideration of hardware compatibility, data processing capabilities, and system architecture. Modern V6 engines typically incorporate multiple sensors including pressure transducers, temperature sensors, and knock sensors that generate substantial data streams. These monitoring systems must be designed to interface seamlessly with existing Engine Control Units (ECUs) while minimizing latency in data transmission and processing.

The integration architecture should follow a hierarchical approach, with sensor-level data collection feeding into local processing units before transmission to central analysis systems. This distributed processing model helps reduce network bandwidth requirements and enables preliminary anomaly detection at the edge. For V6 engines specifically, the monitoring system must account for the unique firing order and cylinder arrangement, ensuring synchronized data collection across all combustion chambers.

Communication protocols represent another critical consideration, with CAN bus remaining the industry standard for automotive applications. However, newer protocols such as Automotive Ethernet offer higher bandwidth capabilities necessary for advanced combustion analytics. The monitoring system should ideally support multiple protocols to ensure backward compatibility while enabling future expansion.

Data sampling rates present significant technical challenges, as combustion anomalies often manifest within microsecond timeframes. The monitoring system must balance high-frequency sampling with practical storage and processing limitations. Adaptive sampling techniques that increase resolution during detected anomaly precursors offer a promising approach to this challenge.

Power management considerations cannot be overlooked, particularly for systems intended for production vehicles rather than laboratory environments. The monitoring system should implement intelligent power states that activate full-resolution monitoring only when operating conditions suggest increased anomaly risk, thereby reducing overall energy consumption.

Security aspects of integrated monitoring systems have gained prominence as vehicles become increasingly connected. Encryption of sensitive combustion data, secure update mechanisms, and intrusion detection capabilities should be incorporated into the system architecture. This is especially important as predictive analytics increasingly rely on cloud computing resources, necessitating secure data transmission beyond the vehicle boundary.

Finally, the human-machine interface requires careful design to ensure that detected anomalies are communicated effectively to both service technicians and, when appropriate, drivers. Diagnostic interfaces should provide multiple levels of detail, from simple warning indicators to comprehensive combustion analysis visualizations for advanced troubleshooting scenarios.

The integration architecture should follow a hierarchical approach, with sensor-level data collection feeding into local processing units before transmission to central analysis systems. This distributed processing model helps reduce network bandwidth requirements and enables preliminary anomaly detection at the edge. For V6 engines specifically, the monitoring system must account for the unique firing order and cylinder arrangement, ensuring synchronized data collection across all combustion chambers.

Communication protocols represent another critical consideration, with CAN bus remaining the industry standard for automotive applications. However, newer protocols such as Automotive Ethernet offer higher bandwidth capabilities necessary for advanced combustion analytics. The monitoring system should ideally support multiple protocols to ensure backward compatibility while enabling future expansion.

Data sampling rates present significant technical challenges, as combustion anomalies often manifest within microsecond timeframes. The monitoring system must balance high-frequency sampling with practical storage and processing limitations. Adaptive sampling techniques that increase resolution during detected anomaly precursors offer a promising approach to this challenge.

Power management considerations cannot be overlooked, particularly for systems intended for production vehicles rather than laboratory environments. The monitoring system should implement intelligent power states that activate full-resolution monitoring only when operating conditions suggest increased anomaly risk, thereby reducing overall energy consumption.

Security aspects of integrated monitoring systems have gained prominence as vehicles become increasingly connected. Encryption of sensitive combustion data, secure update mechanisms, and intrusion detection capabilities should be incorporated into the system architecture. This is especially important as predictive analytics increasingly rely on cloud computing resources, necessitating secure data transmission beyond the vehicle boundary.

Finally, the human-machine interface requires careful design to ensure that detected anomalies are communicated effectively to both service technicians and, when appropriate, drivers. Diagnostic interfaces should provide multiple levels of detail, from simple warning indicators to comprehensive combustion analysis visualizations for advanced troubleshooting scenarios.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!