How to Enhance Airflow in V6 Engine Combustion Chambers

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V6 Engine Airflow Enhancement Background and Objectives

The V6 engine has evolved significantly since its introduction in the early 20th century, with major advancements occurring in the 1950s when compact V6 designs became more prevalent in automotive applications. The development trajectory has been characterized by continuous refinements in combustion efficiency, power output, and emissions reduction. Recent technological trends indicate a growing focus on optimizing airflow dynamics within combustion chambers to meet increasingly stringent environmental regulations while maintaining or improving performance characteristics.

The primary objective of enhancing airflow in V6 engine combustion chambers is to achieve more complete fuel combustion, resulting in increased power output, improved fuel efficiency, and reduced emissions. This aligns with global automotive industry goals of meeting stricter emissions standards while satisfying consumer demands for performance and economy. Specifically, optimized airflow can address issues of fuel atomization, flame propagation, and thermal efficiency that directly impact engine performance metrics.

Historical approaches to airflow enhancement have progressed from simple mechanical solutions to sophisticated computational fluid dynamics (CFD) modeling. Early developments focused on basic intake and exhaust port designs, while contemporary research leverages advanced simulation technologies to analyze complex turbulent flow patterns within the combustion chamber. This evolution represents a shift from empirical to highly analytical design methodologies.

Current technical objectives include developing solutions that can be implemented across various V6 engine configurations, from naturally aspirated to turbocharged and supercharged variants. The ideal enhancement would maintain compatibility with existing manufacturing processes while providing measurable improvements in volumetric efficiency and combustion stability across the engine's operating range.

Market pressures driving this technical pursuit include tightening global emissions regulations, consumer expectations for improved fuel economy, and competitive differentiation in mature automotive markets. Additionally, the transition toward hybrid powertrains has created new requirements for optimizing internal combustion engines to work efficiently within electrified propulsion systems.

The scope of airflow enhancement encompasses multiple engine subsystems, including intake manifold design, valve timing and lift profiles, combustion chamber geometry, piston crown configuration, and exhaust system optimization. A comprehensive approach must consider the interdependencies between these elements to achieve meaningful performance improvements.

Success in this technical domain will be measured by quantifiable improvements in power density, specific fuel consumption, emissions reduction, and thermal efficiency across the engine's operating envelope. The ultimate goal is to extend the viability of V6 engine architecture in an increasingly electrified automotive landscape by maximizing its efficiency potential.

The primary objective of enhancing airflow in V6 engine combustion chambers is to achieve more complete fuel combustion, resulting in increased power output, improved fuel efficiency, and reduced emissions. This aligns with global automotive industry goals of meeting stricter emissions standards while satisfying consumer demands for performance and economy. Specifically, optimized airflow can address issues of fuel atomization, flame propagation, and thermal efficiency that directly impact engine performance metrics.

Historical approaches to airflow enhancement have progressed from simple mechanical solutions to sophisticated computational fluid dynamics (CFD) modeling. Early developments focused on basic intake and exhaust port designs, while contemporary research leverages advanced simulation technologies to analyze complex turbulent flow patterns within the combustion chamber. This evolution represents a shift from empirical to highly analytical design methodologies.

Current technical objectives include developing solutions that can be implemented across various V6 engine configurations, from naturally aspirated to turbocharged and supercharged variants. The ideal enhancement would maintain compatibility with existing manufacturing processes while providing measurable improvements in volumetric efficiency and combustion stability across the engine's operating range.

Market pressures driving this technical pursuit include tightening global emissions regulations, consumer expectations for improved fuel economy, and competitive differentiation in mature automotive markets. Additionally, the transition toward hybrid powertrains has created new requirements for optimizing internal combustion engines to work efficiently within electrified propulsion systems.

The scope of airflow enhancement encompasses multiple engine subsystems, including intake manifold design, valve timing and lift profiles, combustion chamber geometry, piston crown configuration, and exhaust system optimization. A comprehensive approach must consider the interdependencies between these elements to achieve meaningful performance improvements.

Success in this technical domain will be measured by quantifiable improvements in power density, specific fuel consumption, emissions reduction, and thermal efficiency across the engine's operating envelope. The ultimate goal is to extend the viability of V6 engine architecture in an increasingly electrified automotive landscape by maximizing its efficiency potential.

Market Demand Analysis for Improved V6 Engine Performance

The global automotive industry is witnessing a significant shift towards more efficient and environmentally friendly vehicles, creating substantial market demand for improved V6 engine performance. This demand is primarily driven by stringent emission regulations across major markets, with the European Union's Euro 7 standards, the United States' Corporate Average Fuel Economy (CAFE) regulations, and China's increasingly strict emission policies compelling manufacturers to enhance combustion efficiency while reducing harmful outputs.

Consumer preferences are simultaneously evolving, with market research indicating that despite the rise of electric vehicles, a significant segment of consumers still prioritize internal combustion engines for their reliability, range, and performance characteristics. These consumers increasingly demand vehicles that offer improved fuel economy without sacrificing the power and responsiveness traditionally associated with V6 engines.

The premium and luxury vehicle segments represent particularly strong market opportunities for enhanced V6 engine performance. In these segments, consumers demonstrate willingness to pay premium prices for advanced engineering solutions that deliver superior driving experiences while meeting environmental standards. Market analysis shows that vehicles featuring optimized airflow in combustion chambers can command price premiums of 5-10% compared to competitors with standard engine configurations.

Commercial vehicle applications present another substantial market opportunity. Fleet operators increasingly prioritize total cost of ownership calculations, where improved fuel efficiency directly impacts operational profitability. Enhanced V6 engines with optimized combustion chamber airflow can deliver 7-12% fuel economy improvements, representing significant operational savings over vehicle lifespans.

The motorsport industry serves as both a testing ground and showcase for advanced airflow technologies. Innovations in this sector frequently transition to consumer vehicles, creating market pull for technologies that demonstrate success in high-performance applications. This technology transfer pathway represents a valuable route to market for novel airflow enhancement solutions.

Regional market analysis reveals varying demand patterns. North American consumers typically prioritize power output and torque characteristics, while European markets place greater emphasis on efficiency and emissions performance. Asian markets, particularly China and Japan, demonstrate balanced demand for both performance and efficiency, making them ideal targets for comprehensive airflow enhancement solutions.

Market forecasts project the global market for advanced internal combustion engine technologies to grow at a compound annual rate of 4.8% through 2028, with technologies specifically addressing airflow optimization representing approximately 18% of this market. This translates to a substantial addressable market opportunity for companies that can successfully develop and commercialize effective solutions for enhancing airflow in V6 engine combustion chambers.

Consumer preferences are simultaneously evolving, with market research indicating that despite the rise of electric vehicles, a significant segment of consumers still prioritize internal combustion engines for their reliability, range, and performance characteristics. These consumers increasingly demand vehicles that offer improved fuel economy without sacrificing the power and responsiveness traditionally associated with V6 engines.

The premium and luxury vehicle segments represent particularly strong market opportunities for enhanced V6 engine performance. In these segments, consumers demonstrate willingness to pay premium prices for advanced engineering solutions that deliver superior driving experiences while meeting environmental standards. Market analysis shows that vehicles featuring optimized airflow in combustion chambers can command price premiums of 5-10% compared to competitors with standard engine configurations.

Commercial vehicle applications present another substantial market opportunity. Fleet operators increasingly prioritize total cost of ownership calculations, where improved fuel efficiency directly impacts operational profitability. Enhanced V6 engines with optimized combustion chamber airflow can deliver 7-12% fuel economy improvements, representing significant operational savings over vehicle lifespans.

The motorsport industry serves as both a testing ground and showcase for advanced airflow technologies. Innovations in this sector frequently transition to consumer vehicles, creating market pull for technologies that demonstrate success in high-performance applications. This technology transfer pathway represents a valuable route to market for novel airflow enhancement solutions.

Regional market analysis reveals varying demand patterns. North American consumers typically prioritize power output and torque characteristics, while European markets place greater emphasis on efficiency and emissions performance. Asian markets, particularly China and Japan, demonstrate balanced demand for both performance and efficiency, making them ideal targets for comprehensive airflow enhancement solutions.

Market forecasts project the global market for advanced internal combustion engine technologies to grow at a compound annual rate of 4.8% through 2028, with technologies specifically addressing airflow optimization representing approximately 18% of this market. This translates to a substantial addressable market opportunity for companies that can successfully develop and commercialize effective solutions for enhancing airflow in V6 engine combustion chambers.

Current Airflow Technologies and Challenges in V6 Engines

V6 engines currently employ several key airflow technologies to optimize combustion efficiency. Port fuel injection systems remain common in many V6 applications, delivering fuel to the intake ports where it mixes with air before entering the combustion chamber. Direct injection technology has gained significant traction, spraying fuel directly into the combustion chamber at precise timing and pressure, enabling better fuel atomization and combustion control. Variable valve timing (VVT) systems adjust valve opening duration and timing based on engine load and speed, significantly improving airflow dynamics across the RPM range.

Intake manifold design has evolved considerably, with modern V6 engines featuring variable length intake runners that optimize airflow velocity at different engine speeds. Computational Fluid Dynamics (CFD) modeling has revolutionized combustion chamber design, allowing engineers to visualize and optimize airflow patterns before physical prototyping. Tumble and swirl motion generation within the chamber has become a critical focus area, with specially designed intake ports creating controlled turbulence that enhances fuel-air mixing.

Despite these advancements, V6 engines face persistent airflow challenges. The inherent V-configuration creates asymmetrical intake and exhaust flow paths between cylinder banks, leading to uneven airflow distribution. This asymmetry can result in cylinder-to-cylinder variations in combustion efficiency and power output. The compact design of modern V6 engines, while beneficial for vehicle packaging, constrains the available space for optimal intake and exhaust port geometry.

Thermal management presents another significant challenge, as heat concentration can affect air density and combustion efficiency. The middle cylinders in each bank typically experience higher operating temperatures, creating inconsistent combustion conditions across the engine. Valve overlap control remains problematic, particularly at transitional operating points, affecting scavenging efficiency and exhaust gas recirculation.

Emissions regulations continue to drive airflow technology development, requiring increasingly precise control of the combustion process. The integration of turbocharging and supercharging systems introduces additional complexity to airflow management, requiring careful balancing of boost pressure, intake temperatures, and combustion timing. Furthermore, the industry's shift toward electrification has created new constraints on V6 engine design, as engineers must optimize airflow within hybrid powertrain architectures where engines operate under variable and often intermittent conditions.

The pursuit of higher specific output while maintaining reliability creates fundamental tensions in airflow design, as increased airflow often correlates with higher mechanical and thermal stresses on engine components.

Intake manifold design has evolved considerably, with modern V6 engines featuring variable length intake runners that optimize airflow velocity at different engine speeds. Computational Fluid Dynamics (CFD) modeling has revolutionized combustion chamber design, allowing engineers to visualize and optimize airflow patterns before physical prototyping. Tumble and swirl motion generation within the chamber has become a critical focus area, with specially designed intake ports creating controlled turbulence that enhances fuel-air mixing.

Despite these advancements, V6 engines face persistent airflow challenges. The inherent V-configuration creates asymmetrical intake and exhaust flow paths between cylinder banks, leading to uneven airflow distribution. This asymmetry can result in cylinder-to-cylinder variations in combustion efficiency and power output. The compact design of modern V6 engines, while beneficial for vehicle packaging, constrains the available space for optimal intake and exhaust port geometry.

Thermal management presents another significant challenge, as heat concentration can affect air density and combustion efficiency. The middle cylinders in each bank typically experience higher operating temperatures, creating inconsistent combustion conditions across the engine. Valve overlap control remains problematic, particularly at transitional operating points, affecting scavenging efficiency and exhaust gas recirculation.

Emissions regulations continue to drive airflow technology development, requiring increasingly precise control of the combustion process. The integration of turbocharging and supercharging systems introduces additional complexity to airflow management, requiring careful balancing of boost pressure, intake temperatures, and combustion timing. Furthermore, the industry's shift toward electrification has created new constraints on V6 engine design, as engineers must optimize airflow within hybrid powertrain architectures where engines operate under variable and often intermittent conditions.

The pursuit of higher specific output while maintaining reliability creates fundamental tensions in airflow design, as increased airflow often correlates with higher mechanical and thermal stresses on engine components.

Current Airflow Optimization Solutions for V6 Engines

01 Combustion chamber design for improved airflow

Specific designs of combustion chambers in V6 engines can significantly improve airflow dynamics. These designs include optimized chamber shapes, strategic valve positioning, and specialized intake ports that enhance the swirl and tumble of air-fuel mixture. Such improvements lead to more efficient combustion, reduced emissions, and better overall engine performance.- Combustion chamber design for improved airflow: Specific designs of combustion chambers in V6 engines can significantly improve airflow dynamics. These designs include optimized chamber shapes, strategic positioning of intake and exhaust valves, and specialized surface treatments that reduce turbulence while promoting efficient air movement. Enhanced airflow leads to more complete combustion, better fuel efficiency, and reduced emissions.

- Intake manifold configurations for V6 engines: Various intake manifold configurations can be implemented in V6 engines to optimize airflow into the combustion chambers. These include variable length intake runners, resonance tuning systems, and multi-stage intake designs. Such configurations help to maintain optimal air velocity and volume across different engine speeds, improving volumetric efficiency and power output throughout the RPM range.

- Valve timing and lift systems for airflow control: Advanced valve timing and lift systems play a crucial role in controlling airflow in V6 engine combustion chambers. Variable valve timing, variable valve lift mechanisms, and camshaft profile switching technologies allow for dynamic adjustment of airflow characteristics based on engine load and speed. These systems optimize the amount and timing of air entering the combustion chambers, enhancing performance across various operating conditions.

- Turbulence generation and swirl control: Controlled turbulence and swirl patterns within V6 engine combustion chambers can significantly impact airflow dynamics and combustion efficiency. Technologies such as swirl-inducing intake ports, tumble-generating valve shrouds, and specially designed piston crowns create specific air movement patterns that enhance fuel-air mixing. These controlled flow patterns lead to more efficient combustion, particularly at lower engine speeds and during cold starts.

- Sensors and control systems for airflow optimization: Advanced sensors and electronic control systems are employed to monitor and optimize airflow in V6 engine combustion chambers. Mass airflow sensors, pressure sensors, and oxygen sensors provide real-time data to engine control units, which then adjust various parameters to maintain optimal airflow characteristics. These systems can adapt to changing conditions such as temperature, altitude, and fuel quality, ensuring consistent performance and emissions compliance.

02 Valve configuration and timing for airflow optimization

Advanced valve configurations and timing mechanisms are crucial for controlling airflow in V6 engine combustion chambers. Variable valve timing systems, multi-valve arrangements, and specialized valve lift profiles can be implemented to optimize air intake and exhaust flow at different engine speeds and loads. These systems help achieve better volumetric efficiency and power output while maintaining fuel economy.Expand Specific Solutions03 Intake manifold design for balanced airflow distribution

The design of intake manifolds plays a critical role in ensuring balanced airflow distribution across all cylinders in a V6 engine. Features such as tuned runner lengths, plenum chamber designs, and flow-optimized geometry help equalize air delivery to each combustion chamber. This balanced distribution is essential for consistent cylinder-to-cylinder performance and overall engine efficiency.Expand Specific Solutions04 Turbocharging and supercharging systems for enhanced airflow

Forced induction systems such as turbochargers and superchargers can significantly enhance airflow into V6 engine combustion chambers. These systems compress incoming air, increasing its density and oxygen content before it enters the combustion chamber. The design of these systems, including intercooling arrangements and bypass mechanisms, is critical for optimizing airflow across the engine's operating range.Expand Specific Solutions05 Sensors and control systems for airflow management

Advanced sensors and electronic control systems are employed to monitor and manage airflow in V6 engine combustion chambers. These include mass airflow sensors, pressure sensors, and oxygen sensors that provide real-time data to the engine control unit. Based on this information, the control system can adjust various parameters such as fuel injection timing, ignition timing, and valve operation to optimize combustion efficiency under varying operating conditions.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Engine Technology

The V6 engine combustion chamber airflow enhancement market is in a growth phase, with increasing demand for improved engine efficiency and performance. The market size is expanding as automotive manufacturers seek to meet stricter emissions regulations while maintaining power output. Technologically, this field is moderately mature but continues to evolve with innovations in computational fluid dynamics and advanced materials. Toyota, Nissan, and Ford lead with established research programs and patent portfolios in airflow optimization, while companies like Bosch and Weichai Power contribute significant component innovations. Academic institutions such as Tianjin University and King Abdullah University collaborate with industry players to advance fundamental research in combustion dynamics and fluid mechanics, creating a competitive ecosystem balancing established manufacturers and specialized engineering firms.

Toyota Motor Corp.

Technical Solution: Toyota has developed a comprehensive airflow enhancement system for their V6 engines centered around their D-4S (Direct injection 4-stroke gasoline engine Superior version) technology. This dual injection system combines direct and port fuel injection with optimized intake port designs to create controlled tumble and swirl patterns. Toyota's V6 engines feature variable valve timing with intelligence (VVT-i) that precisely adjusts both intake and exhaust valve timing to optimize cylinder filling and scavenging across all operating conditions. Their combustion chambers incorporate asymmetric piston crown designs with specialized bowl geometries that work in concert with the injector spray patterns to enhance air-fuel mixing. Toyota has also implemented acoustic control induction systems (ACIS) that vary the intake runner length based on engine speed, enhancing volumetric efficiency while promoting beneficial airflow characteristics. Their research demonstrates these technologies collectively improve thermal efficiency by approximately 40% in their latest V6 applications, representing some of the highest efficiency ratings for production gasoline engines.

Strengths: Exceptional reliability record even with advanced technologies; seamless integration of multiple systems; proven performance across diverse operating conditions and vehicle applications. Weaknesses: Conservative implementation pace compared to some competitors; higher manufacturing complexity; requires precise calibration to achieve optimal results.

Nissan Motor Co., Ltd.

Technical Solution: Nissan has developed the Variable Geometry Airflow Control (VGAC) system for their VQ series V6 engines, which features electronically actuated intake manifold flaps that modify airflow patterns based on engine operating conditions. Their system incorporates Continuously Variable Valve Timing Control (CVTC) technology that optimizes valve events to enhance in-cylinder motion across the entire RPM range. Nissan's V6 engines utilize asymmetric intake port designs with specialized flow directors that create controlled tumble motion during the intake stroke. The combustion chambers feature micro-textured surfaces on strategic areas of the piston crown that promote boundary layer turbulence, enhancing the air-fuel mixing process. Nissan has also implemented Mirror Bore Coating technology in their cylinder walls, reducing friction while maintaining precise cylinder geometry for optimal airflow dynamics. Their testing shows these combined technologies can improve combustion efficiency by approximately 10% while enhancing torque characteristics throughout the engine's operating range.

Strengths: Innovative surface treatments and materials technology; excellent balance of performance and efficiency; proven durability in high-performance applications. Weaknesses: Some technologies require specialized manufacturing processes; higher production costs; complex calibration requirements across different operating conditions.

Key Innovations in Combustion Chamber Design

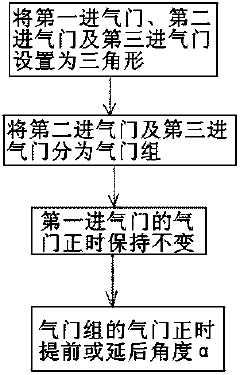

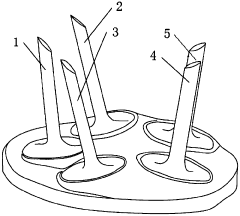

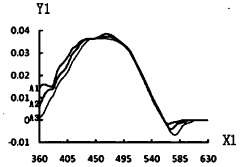

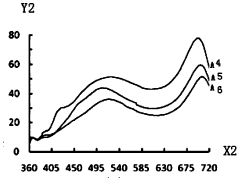

Device and method for improving flowing of airflow in high-speed gasoline engine cylinder

PatentActiveCN103806974A

Innovation

- A first intake valve, a second intake valve, a third intake valve and an exhaust valve are provided on a five-valve engine to form a specific valve combination. The first intake valve forms an angle of 9.5° with the combustion chamber, and the second intake valve forms a 9.5° angle with the combustion chamber. The valve is parallel to the third intake valve, and the center line of the valve group forms an angle of 16.7° with the combustion chamber. Asymmetric and asynchronous valve timing is used to adjust the valve timing of the valve group to optimize the intake air mass flow.

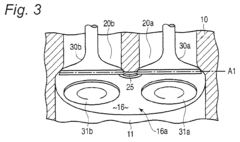

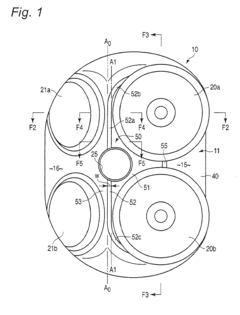

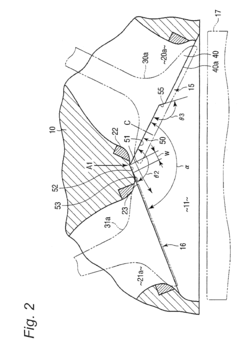

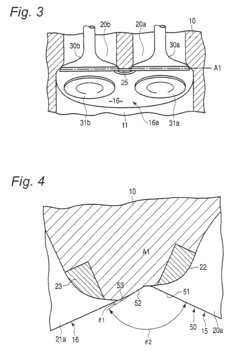

Combustion chamber construction for engine

PatentActiveEP2423483A1

Innovation

- A combustion chamber construction featuring an inlet side sloping surface, an exhaust side sloping surface, and a flow improving portion with a recessed inlet flow surface and a connected exhaust side guide surface, where the angle between the inlet flow surface and the exhaust side guide surface is smaller than the angle between the exhaust surface and the guide surface, and a shroud portion on the side farther from the exhaust port, with a stepped portion connecting the shroud and the inlet flow surface, all precision-machined to maintain consistent flow angles.

Emissions Regulations Impact on Engine Design

Emissions regulations have become increasingly stringent worldwide, fundamentally reshaping engine design priorities and approaches. For V6 engines specifically, these regulations have accelerated innovation in combustion chamber design with particular focus on airflow enhancement. The European Union's Euro 7 standards, the United States EPA's Tier 3 regulations, and China's National 6 standards all mandate substantial reductions in NOx, particulate matter, and carbon emissions, directly influencing how engineers approach airflow optimization.

These regulatory frameworks have shifted design priorities from pure performance to a balance of power delivery and emissions compliance. Manufacturers must now design combustion chambers that promote more complete fuel burning through optimized air-fuel mixture formation. This has led to the development of more sophisticated intake geometries that create controlled turbulence patterns within the combustion chamber, enhancing fuel atomization and reducing emissions formation.

The regulatory timeline has created distinct development phases in V6 engine evolution. Pre-2010 designs focused primarily on performance metrics, while the 2010-2020 period saw rapid adaptation to meet intermediate emissions targets through refinements in existing architectures. Current designs represent a fundamental rethinking of combustion chamber geometry, with computational fluid dynamics playing a central role in optimizing airflow patterns.

Variable valve timing and lift systems have gained prominence as regulatory solutions, allowing engines to optimize airflow characteristics across different operating conditions. These systems can alter intake runner geometry and valve opening profiles to maintain ideal combustion parameters while meeting emissions requirements. Direct injection systems, working in concert with optimized airflow, have become standard equipment to meet particulate matter limitations.

The regulatory landscape has also accelerated the adoption of thermal management strategies within combustion chambers. Engineers now design airflow patterns that help maintain optimal combustion temperatures, reducing the formation of NOx during high-temperature operation while ensuring complete combustion to minimize hydrocarbon emissions during cold-start conditions.

Looking forward, upcoming regulations will likely require even more sophisticated approaches to airflow management. The industry is moving toward multi-stage variable geometry systems that can dynamically alter combustion chamber characteristics based on real-time emissions monitoring. This represents a paradigm shift from static design optimization to adaptive combustion systems that continuously balance performance and emissions compliance.

These regulatory frameworks have shifted design priorities from pure performance to a balance of power delivery and emissions compliance. Manufacturers must now design combustion chambers that promote more complete fuel burning through optimized air-fuel mixture formation. This has led to the development of more sophisticated intake geometries that create controlled turbulence patterns within the combustion chamber, enhancing fuel atomization and reducing emissions formation.

The regulatory timeline has created distinct development phases in V6 engine evolution. Pre-2010 designs focused primarily on performance metrics, while the 2010-2020 period saw rapid adaptation to meet intermediate emissions targets through refinements in existing architectures. Current designs represent a fundamental rethinking of combustion chamber geometry, with computational fluid dynamics playing a central role in optimizing airflow patterns.

Variable valve timing and lift systems have gained prominence as regulatory solutions, allowing engines to optimize airflow characteristics across different operating conditions. These systems can alter intake runner geometry and valve opening profiles to maintain ideal combustion parameters while meeting emissions requirements. Direct injection systems, working in concert with optimized airflow, have become standard equipment to meet particulate matter limitations.

The regulatory landscape has also accelerated the adoption of thermal management strategies within combustion chambers. Engineers now design airflow patterns that help maintain optimal combustion temperatures, reducing the formation of NOx during high-temperature operation while ensuring complete combustion to minimize hydrocarbon emissions during cold-start conditions.

Looking forward, upcoming regulations will likely require even more sophisticated approaches to airflow management. The industry is moving toward multi-stage variable geometry systems that can dynamically alter combustion chamber characteristics based on real-time emissions monitoring. This represents a paradigm shift from static design optimization to adaptive combustion systems that continuously balance performance and emissions compliance.

Materials Science Advancements for Combustion Chambers

Recent advancements in materials science have revolutionized the design and performance capabilities of combustion chambers in V6 engines. Traditional materials like cast iron and aluminum alloys are being supplemented or replaced by innovative composites and ceramics that offer superior thermal management properties. These next-generation materials can withstand higher operating temperatures while maintaining structural integrity, directly contributing to enhanced airflow dynamics within the combustion chamber.

Ceramic-coated components, particularly those utilizing zirconium oxide and silicon nitride, have demonstrated exceptional heat resistance capabilities, allowing engineers to design combustion chambers with tighter tolerances. The reduced thermal expansion of these materials maintains optimal geometry during operation across varying temperature ranges, preserving carefully engineered airflow patterns even under extreme conditions.

Carbon fiber reinforced polymers (CFRPs) and metal matrix composites are being integrated into specific combustion chamber components where weight reduction is critical. These materials offer strength-to-weight ratios significantly higher than conventional metals, enabling the creation of more intricate internal geometries that optimize swirl patterns and turbulence generation without compromising structural integrity.

Surface engineering technologies have advanced considerably, with developments in plasma-sprayed coatings and physical vapor deposition techniques allowing for micro-textured combustion chamber surfaces. These precisely engineered surface characteristics can reduce boundary layer effects and promote more efficient air-fuel mixing. Hydrophobic coatings derived from biomimetic research are showing promise in reducing carbon deposits that can disrupt designed airflow patterns over time.

Thermal barrier coatings (TBCs) incorporating rare earth elements have demonstrated remarkable insulation properties, allowing combustion chamber walls to operate at lower temperatures. This thermal management advantage permits more aggressive intake port designs that maximize volumetric efficiency without risking material failure, directly enhancing airflow characteristics throughout the combustion cycle.

Smart materials with adaptive properties are emerging as potential game-changers for future combustion chamber designs. Shape memory alloys and piezoelectric materials could enable dynamic geometry adjustments during operation, optimizing airflow characteristics in real-time based on engine load and environmental conditions. While still primarily in research phases, these materials represent the frontier of combustion chamber material science, potentially enabling unprecedented levels of airflow control and combustion efficiency.

Ceramic-coated components, particularly those utilizing zirconium oxide and silicon nitride, have demonstrated exceptional heat resistance capabilities, allowing engineers to design combustion chambers with tighter tolerances. The reduced thermal expansion of these materials maintains optimal geometry during operation across varying temperature ranges, preserving carefully engineered airflow patterns even under extreme conditions.

Carbon fiber reinforced polymers (CFRPs) and metal matrix composites are being integrated into specific combustion chamber components where weight reduction is critical. These materials offer strength-to-weight ratios significantly higher than conventional metals, enabling the creation of more intricate internal geometries that optimize swirl patterns and turbulence generation without compromising structural integrity.

Surface engineering technologies have advanced considerably, with developments in plasma-sprayed coatings and physical vapor deposition techniques allowing for micro-textured combustion chamber surfaces. These precisely engineered surface characteristics can reduce boundary layer effects and promote more efficient air-fuel mixing. Hydrophobic coatings derived from biomimetic research are showing promise in reducing carbon deposits that can disrupt designed airflow patterns over time.

Thermal barrier coatings (TBCs) incorporating rare earth elements have demonstrated remarkable insulation properties, allowing combustion chamber walls to operate at lower temperatures. This thermal management advantage permits more aggressive intake port designs that maximize volumetric efficiency without risking material failure, directly enhancing airflow characteristics throughout the combustion cycle.

Smart materials with adaptive properties are emerging as potential game-changers for future combustion chamber designs. Shape memory alloys and piezoelectric materials could enable dynamic geometry adjustments during operation, optimizing airflow characteristics in real-time based on engine load and environmental conditions. While still primarily in research phases, these materials represent the frontier of combustion chamber material science, potentially enabling unprecedented levels of airflow control and combustion efficiency.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!