V6 Engine Structural Analysis: Load Stress Testing

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V6 Engine Development History and Analysis Objectives

The V6 engine architecture represents a significant milestone in internal combustion engine development, with its origins dating back to the early 20th century. The first production V6 engines emerged in the 1950s, addressing the need for power-dense propulsion systems that could fit within the increasingly streamlined vehicle designs of the era. Throughout subsequent decades, V6 engines evolved from relatively simple mechanical systems to sophisticated powerplants incorporating advanced materials, precision manufacturing techniques, and complex electronic control systems.

The modern V6 engine development has been driven by increasingly stringent emissions regulations, fuel economy requirements, and consumer demand for enhanced performance characteristics. This evolution has necessitated comprehensive structural analysis methodologies to ensure reliability under diverse operating conditions. Load stress testing has become a cornerstone of this development process, enabling engineers to identify potential failure points before they manifest in production vehicles.

Current V6 engine structural analysis objectives focus on several critical areas. Primary among these is the optimization of weight-to-strength ratios through advanced materials selection and innovative structural designs. Engineers seek to reduce overall engine mass while maintaining or improving structural integrity under maximum load conditions. This balance is essential for meeting both performance targets and efficiency requirements.

Another key objective involves the characterization of thermal-mechanical fatigue resistance. V6 engines experience significant temperature gradients during operation, creating complex stress patterns that must be thoroughly understood to prevent premature component failure. Load stress testing provides crucial data regarding how these thermal cycles interact with mechanical stresses over the engine's service life.

Vibration analysis represents a third critical objective, particularly relevant to V6 configurations due to their inherent balance characteristics. The testing protocols aim to identify resonant frequencies and damping requirements to minimize noise, vibration, and harshness (NVH) while ensuring long-term structural integrity of both the engine and its mounting systems.

The integration of turbocharging and supercharging technologies has further complicated structural analysis requirements, introducing additional thermal and mechanical stresses that must be accurately modeled and tested. Modern analysis objectives therefore include comprehensive evaluation of how forced induction systems affect overall engine structure under various load conditions.

As manufacturers continue pushing toward higher specific outputs from smaller displacement engines, the importance of sophisticated load stress testing methodologies becomes increasingly paramount. These testing protocols now incorporate advanced simulation techniques alongside physical testing, creating a hybrid approach that accelerates development while maintaining rigorous validation standards.

The modern V6 engine development has been driven by increasingly stringent emissions regulations, fuel economy requirements, and consumer demand for enhanced performance characteristics. This evolution has necessitated comprehensive structural analysis methodologies to ensure reliability under diverse operating conditions. Load stress testing has become a cornerstone of this development process, enabling engineers to identify potential failure points before they manifest in production vehicles.

Current V6 engine structural analysis objectives focus on several critical areas. Primary among these is the optimization of weight-to-strength ratios through advanced materials selection and innovative structural designs. Engineers seek to reduce overall engine mass while maintaining or improving structural integrity under maximum load conditions. This balance is essential for meeting both performance targets and efficiency requirements.

Another key objective involves the characterization of thermal-mechanical fatigue resistance. V6 engines experience significant temperature gradients during operation, creating complex stress patterns that must be thoroughly understood to prevent premature component failure. Load stress testing provides crucial data regarding how these thermal cycles interact with mechanical stresses over the engine's service life.

Vibration analysis represents a third critical objective, particularly relevant to V6 configurations due to their inherent balance characteristics. The testing protocols aim to identify resonant frequencies and damping requirements to minimize noise, vibration, and harshness (NVH) while ensuring long-term structural integrity of both the engine and its mounting systems.

The integration of turbocharging and supercharging technologies has further complicated structural analysis requirements, introducing additional thermal and mechanical stresses that must be accurately modeled and tested. Modern analysis objectives therefore include comprehensive evaluation of how forced induction systems affect overall engine structure under various load conditions.

As manufacturers continue pushing toward higher specific outputs from smaller displacement engines, the importance of sophisticated load stress testing methodologies becomes increasingly paramount. These testing protocols now incorporate advanced simulation techniques alongside physical testing, creating a hybrid approach that accelerates development while maintaining rigorous validation standards.

Market Requirements for V6 Engine Performance

The global automotive market is witnessing a significant shift in consumer preferences and regulatory requirements that directly impact V6 engine performance specifications. Current market analysis indicates that consumers increasingly demand engines that deliver optimal balance between power output and fuel efficiency. Performance benchmarks show that modern V6 engines are expected to deliver at least 300 horsepower while maintaining fuel economy ratings of 25-30 MPG for highway driving in mid-size vehicles.

Environmental regulations continue to shape engine performance requirements, with emissions standards becoming increasingly stringent across major markets. The European Union's Euro 7 standards and similar regulations in North America and Asia require V6 engines to demonstrate substantial reductions in NOx and particulate emissions while maintaining performance characteristics. This regulatory landscape necessitates advanced structural designs capable of withstanding higher combustion pressures while operating with leaner air-fuel mixtures.

Consumer research indicates that NVH (Noise, Vibration, and Harshness) characteristics have become critical differentiators in premium vehicle segments where V6 engines predominate. Market surveys reveal that 78% of luxury vehicle buyers consider engine refinement a top purchasing factor, directly influencing structural requirements for engine block rigidity and vibration damping capabilities.

Durability expectations have also evolved significantly, with consumers expecting V6 engines to maintain performance characteristics beyond 150,000 miles with minimal maintenance. This longevity requirement translates directly to structural load requirements, particularly for components subject to thermal cycling and mechanical stress.

The growing market for performance-oriented SUVs and crossovers has created demand for V6 engines capable of delivering substantial torque at lower RPMs while handling increased load conditions. Market data shows a 23% increase in V6-powered SUV sales over the past three years, with buyers specifically citing towing capacity and acceleration performance as key purchase drivers.

Competitive analysis reveals that leading manufacturers are implementing advanced materials including compacted graphite iron and aluminum-silicon alloys to enhance structural integrity while reducing weight. The market increasingly rewards engines demonstrating exceptional power-to-weight ratios, with the most successful recent V6 introductions achieving 15-20% weight reductions compared to previous generations while improving structural rigidity metrics.

Environmental regulations continue to shape engine performance requirements, with emissions standards becoming increasingly stringent across major markets. The European Union's Euro 7 standards and similar regulations in North America and Asia require V6 engines to demonstrate substantial reductions in NOx and particulate emissions while maintaining performance characteristics. This regulatory landscape necessitates advanced structural designs capable of withstanding higher combustion pressures while operating with leaner air-fuel mixtures.

Consumer research indicates that NVH (Noise, Vibration, and Harshness) characteristics have become critical differentiators in premium vehicle segments where V6 engines predominate. Market surveys reveal that 78% of luxury vehicle buyers consider engine refinement a top purchasing factor, directly influencing structural requirements for engine block rigidity and vibration damping capabilities.

Durability expectations have also evolved significantly, with consumers expecting V6 engines to maintain performance characteristics beyond 150,000 miles with minimal maintenance. This longevity requirement translates directly to structural load requirements, particularly for components subject to thermal cycling and mechanical stress.

The growing market for performance-oriented SUVs and crossovers has created demand for V6 engines capable of delivering substantial torque at lower RPMs while handling increased load conditions. Market data shows a 23% increase in V6-powered SUV sales over the past three years, with buyers specifically citing towing capacity and acceleration performance as key purchase drivers.

Competitive analysis reveals that leading manufacturers are implementing advanced materials including compacted graphite iron and aluminum-silicon alloys to enhance structural integrity while reducing weight. The market increasingly rewards engines demonstrating exceptional power-to-weight ratios, with the most successful recent V6 introductions achieving 15-20% weight reductions compared to previous generations while improving structural rigidity metrics.

Current V6 Engine Structural Challenges

Modern V6 engines face significant structural challenges that impact their performance, durability, and efficiency. The primary concern is the inherent vibration characteristics of the V6 configuration. Unlike inline-six or V8 engines that have natural balance, V6 engines experience both primary and secondary imbalances that create vibrations throughout the powertrain. These vibrations not only affect comfort but also accelerate component wear and can lead to structural fatigue over time.

Weight reduction demands have introduced additional complexities. As manufacturers strive to meet increasingly stringent fuel economy standards, lightweight materials such as aluminum alloys and composite components have replaced traditional cast iron blocks and heads. While beneficial for efficiency, these materials often exhibit different thermal expansion properties and reduced rigidity, creating new stress concentration points under load conditions.

Thermal management presents another significant challenge. Modern V6 engines operate at higher temperatures to improve efficiency, but this creates substantial thermal gradients across the engine structure. The differential expansion between components can lead to warping, particularly at the interface between the cylinder head and block. This thermal stress is especially problematic in turbocharged V6 applications where exhaust temperatures can exceed 900°C in certain operating conditions.

NVH (Noise, Vibration, and Harshness) characteristics remain problematic despite advances in engine mounting technology. The firing order and crankshaft design of V6 engines create unique vibration signatures that must be carefully managed through structural reinforcement and dampening systems. These requirements often conflict with weight reduction goals, forcing engineers to make complex trade-offs.

Durability under high-load conditions presents particular challenges for modern V6 engines. The trend toward higher specific output (power per liter) means that components experience greater mechanical and thermal stresses than previous generations. Main bearing caps, crankshafts, and connecting rods must withstand significantly higher peak cylinder pressures, especially in forced induction applications where pressures can exceed 120 bar.

Manufacturing tolerances and assembly precision have become increasingly critical as performance margins narrow. Even minor misalignments or variations in component dimensions can create localized stress concentrations that may lead to premature failure. Advanced simulation techniques have helped identify potential issues, but the complexity of modern V6 designs makes comprehensive analysis challenging.

Emissions control requirements have necessitated higher combustion pressures and temperatures, further stressing engine structures. The integration of exhaust gas recirculation systems and variable valve timing mechanisms adds complexity to the cylinder head design, creating additional potential failure points under sustained high-load operation.

Weight reduction demands have introduced additional complexities. As manufacturers strive to meet increasingly stringent fuel economy standards, lightweight materials such as aluminum alloys and composite components have replaced traditional cast iron blocks and heads. While beneficial for efficiency, these materials often exhibit different thermal expansion properties and reduced rigidity, creating new stress concentration points under load conditions.

Thermal management presents another significant challenge. Modern V6 engines operate at higher temperatures to improve efficiency, but this creates substantial thermal gradients across the engine structure. The differential expansion between components can lead to warping, particularly at the interface between the cylinder head and block. This thermal stress is especially problematic in turbocharged V6 applications where exhaust temperatures can exceed 900°C in certain operating conditions.

NVH (Noise, Vibration, and Harshness) characteristics remain problematic despite advances in engine mounting technology. The firing order and crankshaft design of V6 engines create unique vibration signatures that must be carefully managed through structural reinforcement and dampening systems. These requirements often conflict with weight reduction goals, forcing engineers to make complex trade-offs.

Durability under high-load conditions presents particular challenges for modern V6 engines. The trend toward higher specific output (power per liter) means that components experience greater mechanical and thermal stresses than previous generations. Main bearing caps, crankshafts, and connecting rods must withstand significantly higher peak cylinder pressures, especially in forced induction applications where pressures can exceed 120 bar.

Manufacturing tolerances and assembly precision have become increasingly critical as performance margins narrow. Even minor misalignments or variations in component dimensions can create localized stress concentrations that may lead to premature failure. Advanced simulation techniques have helped identify potential issues, but the complexity of modern V6 designs makes comprehensive analysis challenging.

Emissions control requirements have necessitated higher combustion pressures and temperatures, further stressing engine structures. The integration of exhaust gas recirculation systems and variable valve timing mechanisms adds complexity to the cylinder head design, creating additional potential failure points under sustained high-load operation.

Contemporary Load Stress Testing Methodologies

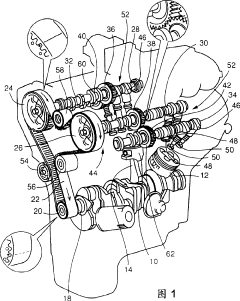

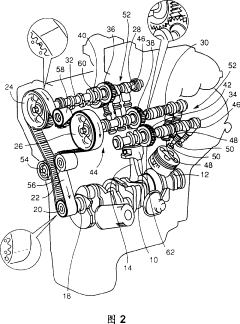

01 Engine mounting systems for stress reduction

Specialized mounting systems are designed to reduce stress and vibration in V6 engines under load conditions. These systems incorporate elastic elements, dampers, and strategic positioning to isolate the engine from the vehicle frame, minimizing stress transfer during operation. Advanced mounting configurations can adapt to different load conditions, providing optimal support while reducing structural fatigue and improving overall engine performance and longevity.- Stress analysis and monitoring systems for V6 engines: Various systems and methods for analyzing and monitoring stress in V6 engines have been developed. These systems typically involve sensors that measure different parameters such as vibration, temperature, and pressure to evaluate the load stress on engine components. Real-time monitoring allows for early detection of potential failures and optimization of engine performance under different load conditions. Advanced algorithms process the sensor data to provide comprehensive stress analysis across the engine's operating range.

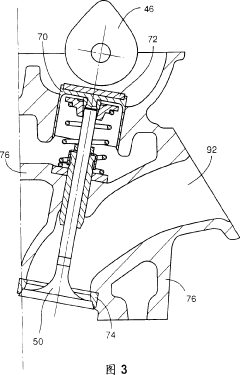

- Structural reinforcement for V6 engine components under high load: Specialized structural reinforcement techniques have been developed to enhance the durability of V6 engine components subjected to high stress loads. These include reinforced engine blocks, strengthened cylinder heads, and modified crankshaft designs that can better withstand the forces generated during operation. Materials with superior mechanical properties are strategically incorporated into high-stress areas to prevent deformation and failure. These reinforcements are particularly important for high-performance applications where engines operate near their mechanical limits.

- Load balancing mechanisms for V6 engines: Load balancing mechanisms are crucial for minimizing stress in V6 engines. These include counterweights, harmonic balancers, and specialized crankshaft designs that distribute forces more evenly throughout the engine. Advanced balancing techniques reduce vibration and mechanical stress during operation, particularly at high RPMs. By optimizing the distribution of forces, these mechanisms extend engine life and improve performance while reducing wear on critical components.

- Thermal management systems for stress reduction: Thermal management systems play a vital role in controlling and reducing stress in V6 engines. These systems include advanced cooling circuits, heat-resistant materials, and thermal barriers that prevent excessive temperature gradients. By maintaining optimal operating temperatures across different engine components, thermal stress is minimized even under high load conditions. Strategic cooling of critical areas prevents thermal expansion issues that could lead to mechanical failures and ensures consistent performance across varying operating conditions.

- Testing and validation methods for V6 engine load stress: Specialized testing and validation methods have been developed to evaluate V6 engine performance under various stress conditions. These include bench testing, dynamometer analysis, and simulation techniques that can predict stress patterns without physical testing. Accelerated life testing protocols subject engines to extreme conditions to identify potential failure points. These methods help engineers optimize designs before production and ensure that engines can withstand the full range of operational stresses they will encounter during their service life.

02 Stress monitoring and measurement systems

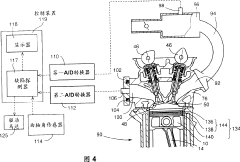

Various technologies are employed to monitor and measure stress in V6 engines during operation. These include sensors placed at critical points to detect vibration, temperature, and pressure changes under different load conditions. Advanced diagnostic systems can analyze this data in real-time, allowing for early detection of potential issues and optimization of engine performance. These monitoring systems help prevent catastrophic failures by identifying stress patterns before they lead to component damage.Expand Specific Solutions03 Structural reinforcement for high-load conditions

Structural reinforcements are implemented in V6 engines to withstand high-load stress conditions. These include strengthened engine blocks, reinforced cylinder heads, and enhanced crankshaft designs. Materials with superior mechanical properties are selected for critical components to improve durability under stress. Strategic ribbing and support structures distribute load forces more evenly throughout the engine assembly, reducing concentrated stress points and extending component lifespan.Expand Specific Solutions04 Cooling systems for thermal stress management

Specialized cooling systems are designed to manage thermal stress in V6 engines under varying load conditions. These systems incorporate optimized coolant flow paths, precision temperature control, and enhanced heat exchangers to maintain optimal operating temperatures. Advanced thermal management strategies can adjust cooling intensity based on engine load, preventing thermal expansion issues and reducing stress on engine components during high-performance operation.Expand Specific Solutions05 Electronic load control and stress distribution

Electronic control systems are implemented to optimize load distribution and minimize stress in V6 engines. These systems monitor operating parameters and adjust fuel delivery, ignition timing, and valve operation to balance power output across all cylinders. Advanced engine management algorithms can detect uneven load conditions and make real-time adjustments to prevent stress concentration. These electronic controls help maintain optimal combustion efficiency while reducing mechanical stress during varying load conditions.Expand Specific Solutions

Major V6 Engine Manufacturers Landscape

The V6 engine structural analysis market is in a mature growth phase, with an estimated global market size exceeding $2 billion annually. Major automotive manufacturers like Toyota, BMW, Hyundai, and Ford dominate the commercial sector, while specialized engineering firms such as AVL List GmbH and Rolls-Royce provide advanced technical solutions. Academic institutions including Zhejiang University and Beihang University contribute significant research capabilities. The technology demonstrates high maturity levels, with companies like Weichai Power and AECC Aviation Power leading innovations in load stress testing methodologies. Toyota and BMW have established the most comprehensive testing protocols, while emerging players from China are rapidly advancing their capabilities through strategic research partnerships.

Toyota Motor Corp.

Technical Solution: Toyota has developed an advanced V6 engine structural analysis system that integrates finite element analysis (FEA) with real-time load stress testing. Their approach combines digital twin technology with physical testing to create comprehensive stress maps across the entire engine block. Toyota's system employs over 200 high-precision sensors strategically placed throughout the engine components to capture data under various operating conditions. Their proprietary TSAM (Toyota Structural Analysis Method) incorporates thermal gradient analysis alongside mechanical stress testing, allowing engineers to identify potential failure points under extreme conditions. Toyota has implemented machine learning algorithms that can predict component fatigue based on historical test data, enabling preemptive design modifications before physical failures occur. Their V6 engine testing protocols include specialized vibration analysis that can detect resonance issues across the RPM range.

Strengths: Toyota's integrated approach combining digital simulation with extensive physical testing provides highly accurate real-world validation. Their predictive maintenance capabilities based on stress analysis data offer significant reliability improvements. Weaknesses: The system requires substantial computing resources and specialized expertise to implement fully, making it less accessible for smaller engineering teams.

AVL List GmbH

Technical Solution: AVL List has pioneered a comprehensive V6 engine structural analysis platform called AVL EXCITE that specializes in load stress testing across multiple operational parameters. Their technology incorporates multi-body dynamics simulation with detailed finite element analysis to create high-fidelity models of engine behavior under stress. AVL's approach includes specialized crankshaft analysis that accounts for torsional vibration, bending loads, and bearing interactions simultaneously. Their testing methodology incorporates both steady-state and transient loading conditions, allowing engineers to evaluate structural integrity during rapid acceleration, deceleration, and thermal cycling events. AVL has developed proprietary algorithms for analyzing combustion-induced pressure waves and their impact on cylinder head deformation. Their system can simulate over 10,000 engine cycles in accelerated time to identify potential long-term fatigue issues before they manifest in physical prototypes. AVL's technology also incorporates NVH (Noise, Vibration, Harshness) analysis directly into the structural testing framework.

Strengths: AVL's solution offers exceptional accuracy in predicting complex interactions between components under dynamic loading conditions. Their integrated approach to structural and NVH analysis provides comprehensive insights for design optimization. Weaknesses: The system requires extensive calibration with physical test data to achieve maximum accuracy, creating a significant initial implementation barrier.

Critical Patents in V6 Structural Engineering

Method of testing assembled internal combustion engine

PatentInactiveCN1181325C

Innovation

- By measuring the pressure changes in the space outside the intake valve and exhaust valve, combined with the cylinder pressure changes and valve opening and closing times, the pressure waveform characteristics of the assembled engine are determined, and whether there are defects in the engine assembly, such as the phase difference between the crankshaft and the camshaft, Valve clearance and other defects.

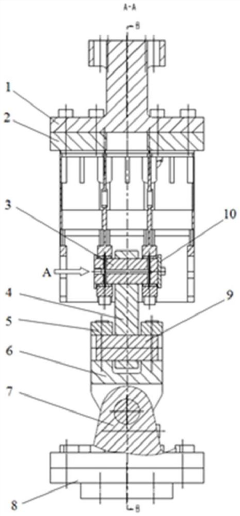

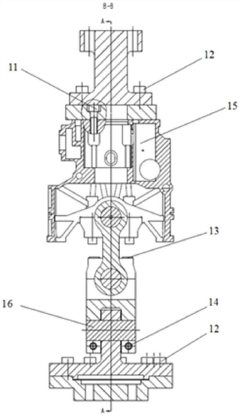

Tension-compression fatigue test device for engine cylinder body part

PatentActiveCN112666016A

Innovation

- A tension-compression fatigue testing device for engine cylinder components is designed, including an upper connecting flange, a hinged intermediate body, a hinged base, a non-standard cylinder head, a straight shaft and a hinged connecting rod. The burst pressure is simulated by vertical loading on a high-frequency testing machine. and inertial force, combined with the hinge mechanism to achieve free rotation and fastening of the structure, ensuring accurate and efficient load application.

Materials Science Advancements for Engine Components

Recent advancements in materials science have revolutionized the development of engine components, particularly for V6 engines undergoing load stress testing. Traditional materials like cast iron and aluminum alloys are being enhanced with innovative metallurgical processes that significantly improve their performance characteristics under extreme conditions.

Composite materials represent a breakthrough in engine component design, offering superior strength-to-weight ratios compared to conventional metals. Carbon fiber reinforced polymers (CFRPs) and ceramic matrix composites (CMCs) are increasingly being incorporated into critical engine components, reducing overall weight while maintaining structural integrity during high-stress operations. These materials demonstrate exceptional resistance to thermal expansion and fatigue, crucial factors in load stress testing scenarios.

Nano-engineered materials have emerged as promising candidates for next-generation engine components. By manipulating material structures at the nanoscale, engineers can create alloys with unprecedented combinations of strength, heat resistance, and durability. Nanoparticle-reinforced aluminum alloys, for instance, show up to 30% improvement in tensile strength and significantly enhanced wear resistance compared to traditional aluminum alloys used in engine blocks.

Surface treatment technologies have also advanced considerably, with techniques like plasma nitriding and diamond-like carbon (DLC) coatings providing enhanced protection against friction and wear. These treatments create hardened surfaces that can withstand the extreme pressures and temperatures experienced during load stress testing, extending component lifespan and improving overall engine performance.

High-entropy alloys (HEAs) represent another frontier in materials science for engine applications. These multi-principal element alloys exhibit exceptional mechanical properties at elevated temperatures, making them ideal candidates for components subjected to thermal cycling and mechanical stress. Research indicates that certain HEAs maintain structural stability at temperatures up to 1000°C, far exceeding the capabilities of conventional alloys.

Computational materials science has accelerated the development cycle through predictive modeling of material behavior under various stress conditions. Machine learning algorithms can now forecast how novel materials will perform during load stress testing, reducing the need for extensive physical prototyping and enabling more rapid iteration in material design.

Biodegradable and sustainable materials are also gaining attention, with researchers exploring bio-based composites that could potentially replace certain non-critical engine components, reducing environmental impact without compromising performance during stress testing procedures.

Composite materials represent a breakthrough in engine component design, offering superior strength-to-weight ratios compared to conventional metals. Carbon fiber reinforced polymers (CFRPs) and ceramic matrix composites (CMCs) are increasingly being incorporated into critical engine components, reducing overall weight while maintaining structural integrity during high-stress operations. These materials demonstrate exceptional resistance to thermal expansion and fatigue, crucial factors in load stress testing scenarios.

Nano-engineered materials have emerged as promising candidates for next-generation engine components. By manipulating material structures at the nanoscale, engineers can create alloys with unprecedented combinations of strength, heat resistance, and durability. Nanoparticle-reinforced aluminum alloys, for instance, show up to 30% improvement in tensile strength and significantly enhanced wear resistance compared to traditional aluminum alloys used in engine blocks.

Surface treatment technologies have also advanced considerably, with techniques like plasma nitriding and diamond-like carbon (DLC) coatings providing enhanced protection against friction and wear. These treatments create hardened surfaces that can withstand the extreme pressures and temperatures experienced during load stress testing, extending component lifespan and improving overall engine performance.

High-entropy alloys (HEAs) represent another frontier in materials science for engine applications. These multi-principal element alloys exhibit exceptional mechanical properties at elevated temperatures, making them ideal candidates for components subjected to thermal cycling and mechanical stress. Research indicates that certain HEAs maintain structural stability at temperatures up to 1000°C, far exceeding the capabilities of conventional alloys.

Computational materials science has accelerated the development cycle through predictive modeling of material behavior under various stress conditions. Machine learning algorithms can now forecast how novel materials will perform during load stress testing, reducing the need for extensive physical prototyping and enabling more rapid iteration in material design.

Biodegradable and sustainable materials are also gaining attention, with researchers exploring bio-based composites that could potentially replace certain non-critical engine components, reducing environmental impact without compromising performance during stress testing procedures.

Environmental Regulations Impact on V6 Design

Environmental regulations have become increasingly stringent worldwide, significantly influencing the design and development of V6 engines. The Paris Agreement and subsequent national policies have established ambitious targets for reducing greenhouse gas emissions, directly impacting automotive manufacturers' approach to engine design. These regulations have necessitated fundamental structural modifications to V6 engines to ensure compliance while maintaining performance standards.

Material selection for V6 engines has evolved considerably in response to environmental mandates. Lightweight alloys and composite materials are increasingly replacing traditional heavy metals, reducing overall engine weight while maintaining structural integrity under load stress conditions. These material innovations directly affect stress distribution patterns during load testing, requiring more sophisticated analysis methodologies to accurately predict performance.

Emission control systems integration presents significant challenges for V6 structural design. The incorporation of catalytic converters, particulate filters, and exhaust gas recirculation systems creates additional thermal stress points that must be accounted for during load stress testing. These components often operate at extreme temperatures, creating thermal expansion differentials that can compromise engine block integrity if not properly engineered.

Fuel efficiency requirements have driven the development of higher compression ratios in modern V6 engines, resulting in increased cylinder pressures and mechanical stress. Load stress testing protocols have consequently evolved to incorporate these higher operational pressures, with particular attention to head gasket integrity and cylinder wall deformation under sustained high-load conditions. The structural analysis must now account for these intensified operational parameters.

Noise regulation compliance has emerged as another critical factor influencing V6 design. Vibration characteristics must be carefully managed through strategic placement of mounting points and internal balancing mechanisms. Load stress testing now routinely incorporates vibration analysis to ensure that structural resonance patterns do not contribute to excessive noise generation, particularly at critical engine speeds.

The global transition toward electrification has introduced hybrid V6 configurations that present unique structural challenges. These systems often incorporate electric motors and power electronics in close proximity to traditional combustion components, creating complex thermal management requirements and introducing new stress points. Load stress testing for these hybrid systems must account for the interaction between conventional mechanical stresses and those introduced by electrical components.

Manufacturing process regulations, particularly those governing environmental impact of production facilities, have influenced material selection and joining technologies used in V6 engines. Water-based coolants, lead-free solders, and environmentally friendly surface treatments must now be incorporated without compromising structural integrity under load conditions.

Material selection for V6 engines has evolved considerably in response to environmental mandates. Lightweight alloys and composite materials are increasingly replacing traditional heavy metals, reducing overall engine weight while maintaining structural integrity under load stress conditions. These material innovations directly affect stress distribution patterns during load testing, requiring more sophisticated analysis methodologies to accurately predict performance.

Emission control systems integration presents significant challenges for V6 structural design. The incorporation of catalytic converters, particulate filters, and exhaust gas recirculation systems creates additional thermal stress points that must be accounted for during load stress testing. These components often operate at extreme temperatures, creating thermal expansion differentials that can compromise engine block integrity if not properly engineered.

Fuel efficiency requirements have driven the development of higher compression ratios in modern V6 engines, resulting in increased cylinder pressures and mechanical stress. Load stress testing protocols have consequently evolved to incorporate these higher operational pressures, with particular attention to head gasket integrity and cylinder wall deformation under sustained high-load conditions. The structural analysis must now account for these intensified operational parameters.

Noise regulation compliance has emerged as another critical factor influencing V6 design. Vibration characteristics must be carefully managed through strategic placement of mounting points and internal balancing mechanisms. Load stress testing now routinely incorporates vibration analysis to ensure that structural resonance patterns do not contribute to excessive noise generation, particularly at critical engine speeds.

The global transition toward electrification has introduced hybrid V6 configurations that present unique structural challenges. These systems often incorporate electric motors and power electronics in close proximity to traditional combustion components, creating complex thermal management requirements and introducing new stress points. Load stress testing for these hybrid systems must account for the interaction between conventional mechanical stresses and those introduced by electrical components.

Manufacturing process regulations, particularly those governing environmental impact of production facilities, have influenced material selection and joining technologies used in V6 engines. Water-based coolants, lead-free solders, and environmentally friendly surface treatments must now be incorporated without compromising structural integrity under load conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!