V6 Engine Cooling Techniques: State-of-the-Art Methods

SEP 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V6 Engine Cooling Evolution and Objectives

The evolution of V6 engine cooling systems represents a fascinating journey through automotive engineering history, marked by continuous innovation to meet increasing performance demands while maintaining optimal operating temperatures. Initially, V6 engines relied on simple air cooling methods, which gradually gave way to more sophisticated liquid cooling systems in the 1950s and 1960s as engine power outputs increased.

The 1970s and 1980s witnessed significant advancements with the introduction of closed-loop cooling systems and improved coolant formulations, addressing the thermal management challenges posed by higher compression ratios and fuel efficiency requirements. By the 1990s, electronic control systems began to revolutionize cooling management, enabling more precise temperature regulation based on real-time engine operating conditions.

The early 2000s marked a turning point with the development of split cooling systems that could maintain different temperature zones within the engine block, optimizing combustion efficiency while protecting critical components. This period also saw the integration of variable-speed electric water pumps, replacing mechanical pumps to reduce parasitic power losses and improve overall efficiency.

Current state-of-the-art cooling techniques for V6 engines incorporate advanced materials such as ceramic-coated components and composite radiators that offer superior heat dissipation properties. Precision cooling strategies now target specific high-heat areas within the engine, rather than applying uniform cooling across all components, resulting in more efficient thermal management.

The primary objectives of modern V6 engine cooling technology focus on several key areas: reducing warm-up times to minimize emissions during cold starts; maintaining optimal operating temperatures under varying load conditions; enabling higher power outputs without thermal degradation; and contributing to overall vehicle efficiency through reduced weight and power consumption of cooling components.

Future development trajectories point toward integrated thermal management systems that coordinate engine cooling with transmission, battery, and cabin climate control systems in a holistic approach. Additionally, research is advancing in the areas of phase-change cooling materials, nanofluids with enhanced thermal conductivity, and intelligent predictive cooling algorithms that anticipate thermal loads based on driving conditions and navigation data.

As emissions regulations continue to tighten globally, cooling system development increasingly aims to support higher combustion temperatures for improved efficiency while simultaneously protecting engine components and catalytic systems from thermal damage, creating a complex engineering balance that drives continuous innovation in this field.

The 1970s and 1980s witnessed significant advancements with the introduction of closed-loop cooling systems and improved coolant formulations, addressing the thermal management challenges posed by higher compression ratios and fuel efficiency requirements. By the 1990s, electronic control systems began to revolutionize cooling management, enabling more precise temperature regulation based on real-time engine operating conditions.

The early 2000s marked a turning point with the development of split cooling systems that could maintain different temperature zones within the engine block, optimizing combustion efficiency while protecting critical components. This period also saw the integration of variable-speed electric water pumps, replacing mechanical pumps to reduce parasitic power losses and improve overall efficiency.

Current state-of-the-art cooling techniques for V6 engines incorporate advanced materials such as ceramic-coated components and composite radiators that offer superior heat dissipation properties. Precision cooling strategies now target specific high-heat areas within the engine, rather than applying uniform cooling across all components, resulting in more efficient thermal management.

The primary objectives of modern V6 engine cooling technology focus on several key areas: reducing warm-up times to minimize emissions during cold starts; maintaining optimal operating temperatures under varying load conditions; enabling higher power outputs without thermal degradation; and contributing to overall vehicle efficiency through reduced weight and power consumption of cooling components.

Future development trajectories point toward integrated thermal management systems that coordinate engine cooling with transmission, battery, and cabin climate control systems in a holistic approach. Additionally, research is advancing in the areas of phase-change cooling materials, nanofluids with enhanced thermal conductivity, and intelligent predictive cooling algorithms that anticipate thermal loads based on driving conditions and navigation data.

As emissions regulations continue to tighten globally, cooling system development increasingly aims to support higher combustion temperatures for improved efficiency while simultaneously protecting engine components and catalytic systems from thermal damage, creating a complex engineering balance that drives continuous innovation in this field.

Market Demand Analysis for Advanced Cooling Systems

The global market for advanced V6 engine cooling systems has experienced significant growth in recent years, driven primarily by increasing consumer demand for high-performance vehicles and stricter emissions regulations. According to industry reports, the automotive thermal management system market reached $45.8 billion in 2022 and is projected to grow at a CAGR of 5.2% through 2030, with cooling systems representing a substantial segment of this market.

Performance vehicle sales have shown resilience even during economic downturns, with premium and luxury vehicle segments—where V6 engines are common—growing at 7.3% annually since 2018. This trend indicates a robust demand for advanced cooling technologies that can support higher engine outputs while maintaining optimal operating temperatures.

Environmental regulations worldwide have become increasingly stringent, particularly regarding emissions and fuel efficiency. The European Union's Euro 7 standards, China's National VI regulations, and the United States' CAFE standards are compelling manufacturers to develop more efficient cooling systems that can help reduce emissions while maintaining or improving engine performance. This regulatory pressure has created a market pull for innovative cooling solutions.

The electrification trend in automotive design has paradoxically increased demand for advanced cooling in hybrid vehicles, where V6 engines are often paired with electric motors. These hybrid powertrains require sophisticated thermal management systems that can handle the complex heat distribution between conventional engines and electric components. Market analysis shows that hybrid vehicle sales increased by 22% in 2022, creating new opportunities for advanced cooling technologies.

Racing and motorsport applications continue to drive innovation in cooling technologies, with Formula 1 and endurance racing serving as technological testbeds. Technologies developed for these extreme applications often trickle down to consumer vehicles, creating premium market segments for advanced cooling solutions. The motorsport thermal management market alone was valued at $1.2 billion in 2022.

Aftermarket modifications represent another significant market segment, with performance enthusiasts willing to invest in upgraded cooling systems to enhance engine output and reliability. This market segment has grown by approximately 8% annually since 2019, with online sales channels showing particularly strong growth.

Regional analysis indicates that North America and Europe remain the largest markets for advanced V6 cooling systems, though the Asia-Pacific region—particularly China and India—shows the highest growth potential, with projected market expansion of 9.7% annually through 2028 as premium vehicle ownership increases in these emerging economies.

Performance vehicle sales have shown resilience even during economic downturns, with premium and luxury vehicle segments—where V6 engines are common—growing at 7.3% annually since 2018. This trend indicates a robust demand for advanced cooling technologies that can support higher engine outputs while maintaining optimal operating temperatures.

Environmental regulations worldwide have become increasingly stringent, particularly regarding emissions and fuel efficiency. The European Union's Euro 7 standards, China's National VI regulations, and the United States' CAFE standards are compelling manufacturers to develop more efficient cooling systems that can help reduce emissions while maintaining or improving engine performance. This regulatory pressure has created a market pull for innovative cooling solutions.

The electrification trend in automotive design has paradoxically increased demand for advanced cooling in hybrid vehicles, where V6 engines are often paired with electric motors. These hybrid powertrains require sophisticated thermal management systems that can handle the complex heat distribution between conventional engines and electric components. Market analysis shows that hybrid vehicle sales increased by 22% in 2022, creating new opportunities for advanced cooling technologies.

Racing and motorsport applications continue to drive innovation in cooling technologies, with Formula 1 and endurance racing serving as technological testbeds. Technologies developed for these extreme applications often trickle down to consumer vehicles, creating premium market segments for advanced cooling solutions. The motorsport thermal management market alone was valued at $1.2 billion in 2022.

Aftermarket modifications represent another significant market segment, with performance enthusiasts willing to invest in upgraded cooling systems to enhance engine output and reliability. This market segment has grown by approximately 8% annually since 2019, with online sales channels showing particularly strong growth.

Regional analysis indicates that North America and Europe remain the largest markets for advanced V6 cooling systems, though the Asia-Pacific region—particularly China and India—shows the highest growth potential, with projected market expansion of 9.7% annually through 2028 as premium vehicle ownership increases in these emerging economies.

Current Cooling Technologies and Challenges

Modern V6 engine cooling systems have evolved significantly to meet the increasing demands of higher performance and efficiency. The primary cooling technologies currently employed include liquid cooling systems, which remain the dominant approach. These systems utilize a mixture of water and ethylene glycol (antifreeze) circulated through engine blocks and cylinder heads to absorb and dissipate heat. Advanced coolant formulations now incorporate corrosion inhibitors and lubricants to extend system longevity and improve thermal efficiency.

Electronic cooling management systems represent a significant advancement in V6 engine cooling. Variable-speed electric water pumps have replaced traditional belt-driven pumps in premium applications, allowing for precise control of coolant flow based on actual engine thermal load rather than engine speed. This optimization reduces parasitic power losses and improves fuel economy by up to 2-3% in some applications.

Precision cooling techniques have emerged as a sophisticated approach where coolant is directed specifically to high-heat areas of the engine. This targeted cooling strategy maintains more uniform temperature distribution across the engine block and heads, reducing thermal stress and allowing for tighter manufacturing tolerances. Some manufacturers have implemented dual-circuit cooling systems that maintain different temperature zones within the engine for optimized performance.

Despite these advancements, significant challenges persist in V6 engine cooling technology. Increasing power density in downsized turbocharged V6 engines creates localized hotspots that are difficult to manage with conventional cooling methods. Cylinder heads, particularly in the vicinity of exhaust valves and turbocharger mounting points, experience extreme thermal loads exceeding 200°C during peak operation.

Material limitations present another substantial challenge. While aluminum alloys offer weight advantages, their thermal expansion characteristics can lead to warping and gasket failures under severe thermal cycling. Advanced composite materials show promise but remain cost-prohibitive for mass production applications.

Packaging constraints in modern vehicle designs further complicate cooling system optimization. The trend toward lower hood lines for aerodynamic efficiency reduces the available space for radiators and cooling passages. This spatial limitation forces engineers to develop more compact cooling solutions without compromising thermal capacity.

Environmental regulations add another layer of complexity, as traditional coolant formulations face increasing scrutiny due to their environmental impact. The industry is transitioning toward more environmentally friendly alternatives, though these often present different thermal properties that require system redesign.

Electronic cooling management systems represent a significant advancement in V6 engine cooling. Variable-speed electric water pumps have replaced traditional belt-driven pumps in premium applications, allowing for precise control of coolant flow based on actual engine thermal load rather than engine speed. This optimization reduces parasitic power losses and improves fuel economy by up to 2-3% in some applications.

Precision cooling techniques have emerged as a sophisticated approach where coolant is directed specifically to high-heat areas of the engine. This targeted cooling strategy maintains more uniform temperature distribution across the engine block and heads, reducing thermal stress and allowing for tighter manufacturing tolerances. Some manufacturers have implemented dual-circuit cooling systems that maintain different temperature zones within the engine for optimized performance.

Despite these advancements, significant challenges persist in V6 engine cooling technology. Increasing power density in downsized turbocharged V6 engines creates localized hotspots that are difficult to manage with conventional cooling methods. Cylinder heads, particularly in the vicinity of exhaust valves and turbocharger mounting points, experience extreme thermal loads exceeding 200°C during peak operation.

Material limitations present another substantial challenge. While aluminum alloys offer weight advantages, their thermal expansion characteristics can lead to warping and gasket failures under severe thermal cycling. Advanced composite materials show promise but remain cost-prohibitive for mass production applications.

Packaging constraints in modern vehicle designs further complicate cooling system optimization. The trend toward lower hood lines for aerodynamic efficiency reduces the available space for radiators and cooling passages. This spatial limitation forces engineers to develop more compact cooling solutions without compromising thermal capacity.

Environmental regulations add another layer of complexity, as traditional coolant formulations face increasing scrutiny due to their environmental impact. The industry is transitioning toward more environmentally friendly alternatives, though these often present different thermal properties that require system redesign.

State-of-the-Art Cooling Methods and Implementation

01 Liquid cooling systems for V6 engines

Liquid cooling systems are commonly used in V6 engines to maintain optimal operating temperatures. These systems typically include water jackets, radiators, and coolant circulation pumps that work together to dissipate heat generated during engine operation. Advanced liquid cooling designs may incorporate precision flow control, optimized coolant passages, and strategic placement of cooling channels around critical engine components such as cylinder heads and combustion chambers.- Liquid cooling systems for V6 engines: Liquid cooling systems are commonly used in V6 engines to maintain optimal operating temperatures. These systems typically include water jackets, radiators, and coolant circulation pumps that work together to dissipate heat generated during engine operation. Advanced liquid cooling designs may incorporate precision flow control, optimized coolant passages, and strategic placement of cooling components to ensure uniform temperature distribution across all six cylinders.

- Air cooling techniques for V6 engines: Air cooling techniques for V6 engines utilize the flow of ambient air to remove heat from the engine components. These systems may include specialized fins on cylinder heads and blocks, directed air flow channels, and cooling fans to enhance heat dissipation. Air cooling designs are particularly beneficial for weight reduction and simplicity, though they typically provide less cooling capacity than liquid-based systems for high-performance V6 applications.

- Hybrid cooling systems for V6 engines: Hybrid cooling systems combine multiple cooling technologies to optimize temperature management in V6 engines. These systems may integrate liquid cooling for high-heat areas with air cooling for peripheral components, or incorporate oil cooling circuits alongside traditional coolant systems. Advanced hybrid designs may feature electronic control units that adjust cooling intensity based on engine load, ambient conditions, and operational parameters to maximize efficiency and performance.

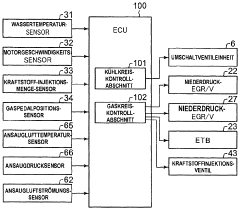

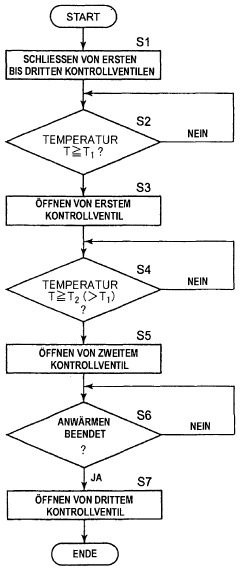

- Thermal management innovations for V6 engines: Modern V6 engines employ sophisticated thermal management innovations to optimize performance and efficiency. These include variable-flow coolant pumps, electronically controlled thermostats, split cooling circuits for different engine sections, and precision temperature sensors. Advanced thermal management systems can selectively cool specific engine components based on real-time operating conditions, reducing warm-up time and improving fuel efficiency while maintaining optimal operating temperatures.

- Specialized cooling for high-performance V6 engines: High-performance V6 engines require specialized cooling solutions to handle increased thermal loads. These may include enlarged cooling passages, high-capacity radiators, auxiliary oil coolers, and enhanced water pumps. Some designs incorporate targeted cooling for critical components such as cylinder heads, turbochargers, and exhaust manifolds. Advanced materials like aluminum alloys with superior thermal conductivity are often used to improve heat dissipation in performance applications.

02 Air cooling and ventilation techniques

Air cooling techniques for V6 engines utilize strategic airflow management to dissipate heat. These methods may include specialized fin designs, cooling ducts, and forced air systems that direct airflow to critical engine components. Some designs incorporate auxiliary fans or blowers to enhance cooling efficiency during high-load conditions or when the vehicle is stationary. Air cooling can be used as a primary cooling method or as a supplementary system working alongside liquid cooling.Expand Specific Solutions03 Thermal management systems and electronic control

Modern V6 engine cooling systems often incorporate advanced thermal management systems with electronic controls. These systems use temperature sensors, electronic control units, and actuators to regulate coolant flow, fan operation, and other cooling parameters based on real-time engine conditions. Smart cooling systems can adjust cooling intensity according to engine load, ambient temperature, and driving conditions, optimizing both engine performance and fuel efficiency while maintaining ideal operating temperatures.Expand Specific Solutions04 Oil cooling and lubrication systems

Oil cooling systems play a crucial role in V6 engine thermal management by removing heat from engine components while providing lubrication. These systems may include oil coolers, specialized oil passages, and temperature-regulated oil flow. Some advanced designs integrate the oil cooling system with the main engine cooling system for improved efficiency. Proper oil cooling helps prevent overheating of bearings, pistons, and other critical moving parts, extending engine life and maintaining performance.Expand Specific Solutions05 Innovative cooling technologies for high-performance V6 engines

High-performance V6 engines often employ innovative cooling technologies to manage the increased heat generated during high-output operation. These may include precision-cooled cylinder heads, dual-circuit cooling systems that separately regulate cylinder head and block temperatures, and advanced materials with superior thermal conductivity. Some systems incorporate targeted cooling for turbochargers or superchargers, intercoolers for intake air, and specialized cooling for electronic components. These technologies help maintain optimal performance while preventing heat-related damage under extreme conditions.Expand Specific Solutions

Leading Manufacturers and Cooling Solution Providers

The V6 engine cooling technology market is in a mature growth phase, characterized by established techniques and ongoing innovations. The global market size for automotive cooling systems is estimated at $25-30 billion, with V6 engine cooling representing a significant segment. Leading automotive manufacturers like Toyota, Honda, Ford, and Volkswagen demonstrate high technical maturity in this field, with advanced cooling solutions including precision liquid cooling, integrated thermal management systems, and electronic cooling control. Asian manufacturers such as Hyundai, Geely, and Chery are rapidly advancing their cooling technologies, while specialized engineering firms like IAV GmbH provide cutting-edge research and development services. The industry is evolving toward more efficient, environmentally friendly cooling solutions that optimize engine performance while meeting increasingly stringent emissions standards.

Toyota Motor Corp.

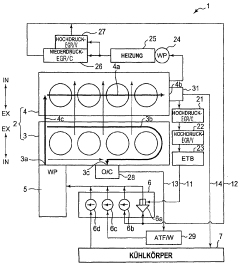

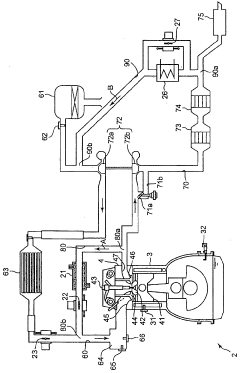

Technical Solution: Toyota has developed an advanced Dual-Circuit Cooling System specifically for their V6 engines that employs separate cooling circuits for the cylinder heads and block. This system allows for optimized temperature management across different engine components, enabling the cylinder heads to operate at higher temperatures for improved combustion efficiency while maintaining lower block temperatures for reduced friction. Toyota's system incorporates variable-flow electric water pumps that adjust coolant circulation based on engine load and temperature conditions, reducing parasitic power losses when full cooling capacity isn't needed. Their V6 engines also feature precision-engineered water jackets with optimized coolant flow paths that target high-heat areas around exhaust valves and combustion chambers. Additionally, Toyota has implemented advanced thermal management systems that rapidly bring engines to optimal operating temperatures, incorporating fast warm-up modes that improve fuel efficiency and reduce emissions during cold starts.

Strengths: Superior thermal efficiency with separate cooling circuits optimized for different engine components; reduced parasitic losses through variable electric water pumps; excellent cold-start emissions performance. Weaknesses: Higher system complexity increases manufacturing costs; requires more sophisticated electronic controls; potential reliability concerns with additional components like electric water pumps.

Ford Global Technologies LLC

Technical Solution: Ford has pioneered a comprehensive cooling solution for their V6 EcoBoost engines featuring an integrated exhaust manifold design that merges the exhaust manifold directly into the cylinder head. This innovative approach allows coolant to circulate around the exhaust ports, significantly reducing thermal stress and enabling higher compression ratios without detonation issues. Ford's system employs split cooling technology with computer-controlled rotary valves that can independently regulate coolant flow to different engine sections based on real-time thermal demands. Their V6 engines utilize precision-cast water jackets with targeted cooling channels that address specific hotspots identified through computational fluid dynamics (CFD) modeling. Ford has also implemented active grille shutters and advanced radiator designs with optimized fin density and tube configurations to enhance cooling efficiency while minimizing aerodynamic drag. Additionally, their cooling systems incorporate specialized high-temperature-resistant coolants with extended service intervals and improved heat transfer properties.

Strengths: Integrated exhaust manifold design significantly reduces thermal stress and enables higher compression ratios; sophisticated computer-controlled coolant flow management; excellent balance between performance and efficiency. Weaknesses: Complex casting requirements for integrated components increase manufacturing complexity; potential for higher repair costs if cylinder head replacement is needed; system requires more sophisticated electronic controls.

Key Patents and Innovations in Engine Cooling

engine cooling system with temperature-dependent control of the coolant path

PatentActiveDE102014002940A1

Innovation

- A system with a cylinder block and head, featuring water jackets and circulation paths, including a switching valve unit that directs coolant through the EGR cooler during cold running and switches to the cylinder block path when engine temperature rises, utilizing EGR gas heat for warm-up without overheating.

System and method for cooling an engine

PatentInactiveUS6830016B2

Innovation

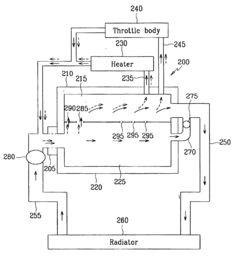

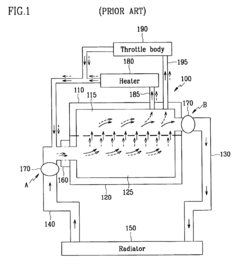

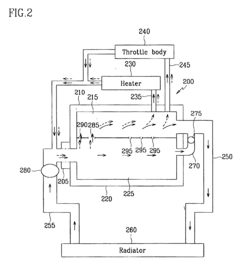

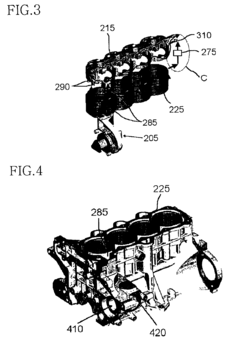

- A system and method for separately cooling the engine's cylinder block and cylinder head, utilizing a dual thermostat and coolant flow management system to optimize coolant circulation, with a primary and secondary pathway for coolant flow between the two, allowing for independent temperature control based on engine load and thermal thresholds.

Environmental Impact and Sustainability Considerations

The environmental impact of V6 engine cooling systems has become increasingly significant as automotive manufacturers face stricter emissions regulations and sustainability requirements. Traditional cooling methods often rely on glycol-based coolants containing ethylene glycol, which poses environmental hazards when improperly disposed of. These coolants can contaminate soil and water sources, causing harm to aquatic ecosystems and potentially entering the food chain. Recent advancements have led to the development of propylene glycol-based alternatives, which offer reduced toxicity while maintaining thermal efficiency.

Water consumption represents another critical environmental consideration in engine cooling systems. Conventional cooling circuits require substantial amounts of water during manufacturing processes and for the coolant mixture itself. In regions facing water scarcity, this dependency creates additional environmental pressure. Leading manufacturers have begun implementing closed-loop cooling systems that minimize water waste and reduce overall consumption throughout the engine's lifecycle.

Energy efficiency of cooling systems directly impacts fuel consumption and emissions. Inefficient cooling mechanisms can increase parasitic losses, requiring the engine to work harder and consume more fuel. Advanced electronic cooling management systems optimize coolant flow based on real-time engine demands, reducing unnecessary energy expenditure. Variable-speed electric water pumps, replacing traditional belt-driven pumps, have demonstrated fuel economy improvements of 2-3% in modern V6 engines.

Material selection for cooling system components presents both challenges and opportunities for sustainability. Traditional radiators and heat exchangers often contain copper and aluminum, which require energy-intensive mining and processing. Recycled materials are increasingly being incorporated into cooling system manufacturing, with some components now containing up to 35% recycled content. Additionally, composite materials are being explored as alternatives to reduce weight and improve recyclability at end-of-life.

Lifecycle assessment studies indicate that cooling system optimization can reduce a V6 engine's carbon footprint by 5-8% over its operational lifespan. This includes considerations for manufacturing impacts, operational efficiency, and end-of-life disposal. Manufacturers are increasingly adopting design-for-disassembly principles to facilitate the recovery and recycling of cooling system components when vehicles reach end-of-life, further reducing environmental impact.

Regulatory frameworks worldwide are driving innovation in sustainable cooling technologies. The European Union's End-of-Life Vehicle Directive and similar regulations in other markets mandate specific recovery and recycling rates for vehicle components, including cooling systems. These requirements have accelerated research into biodegradable coolants and cooling system designs that minimize environmental impact throughout the product lifecycle.

Water consumption represents another critical environmental consideration in engine cooling systems. Conventional cooling circuits require substantial amounts of water during manufacturing processes and for the coolant mixture itself. In regions facing water scarcity, this dependency creates additional environmental pressure. Leading manufacturers have begun implementing closed-loop cooling systems that minimize water waste and reduce overall consumption throughout the engine's lifecycle.

Energy efficiency of cooling systems directly impacts fuel consumption and emissions. Inefficient cooling mechanisms can increase parasitic losses, requiring the engine to work harder and consume more fuel. Advanced electronic cooling management systems optimize coolant flow based on real-time engine demands, reducing unnecessary energy expenditure. Variable-speed electric water pumps, replacing traditional belt-driven pumps, have demonstrated fuel economy improvements of 2-3% in modern V6 engines.

Material selection for cooling system components presents both challenges and opportunities for sustainability. Traditional radiators and heat exchangers often contain copper and aluminum, which require energy-intensive mining and processing. Recycled materials are increasingly being incorporated into cooling system manufacturing, with some components now containing up to 35% recycled content. Additionally, composite materials are being explored as alternatives to reduce weight and improve recyclability at end-of-life.

Lifecycle assessment studies indicate that cooling system optimization can reduce a V6 engine's carbon footprint by 5-8% over its operational lifespan. This includes considerations for manufacturing impacts, operational efficiency, and end-of-life disposal. Manufacturers are increasingly adopting design-for-disassembly principles to facilitate the recovery and recycling of cooling system components when vehicles reach end-of-life, further reducing environmental impact.

Regulatory frameworks worldwide are driving innovation in sustainable cooling technologies. The European Union's End-of-Life Vehicle Directive and similar regulations in other markets mandate specific recovery and recycling rates for vehicle components, including cooling systems. These requirements have accelerated research into biodegradable coolants and cooling system designs that minimize environmental impact throughout the product lifecycle.

Materials Science Advancements for Cooling Efficiency

Materials science has emerged as a critical frontier in advancing V6 engine cooling efficiency. Recent developments in thermal management materials have significantly improved heat dissipation capabilities while reducing overall system weight. Nano-enhanced aluminum alloys, incorporating ceramic nanoparticles such as silicon carbide and aluminum oxide, demonstrate thermal conductivity improvements of 15-25% compared to traditional aluminum alloys used in engine blocks and cooling components.

Carbon-based materials represent another breakthrough area, with graphene-enhanced composites showing exceptional thermal conductivity values exceeding 1000 W/mK - nearly five times that of copper. These materials are being integrated into cooling system components through advanced manufacturing techniques including powder metallurgy and additive manufacturing processes, enabling complex geometries previously impossible with conventional materials.

Phase-change materials (PCMs) have revolutionized temperature regulation in V6 engines by absorbing excess heat during high-load operations and releasing it during cooler operating conditions. Microencapsulated PCMs with tailored melting points between 80-120°C are being embedded in coolant reservoirs and critical engine components, providing thermal buffering that reduces temperature fluctuations by up to 40%.

Surface engineering advancements have yielded hydrophobic and oleophobic coatings that significantly reduce fouling and scaling in cooling passages. These nano-structured surfaces maintain optimal heat transfer efficiency over extended operating periods, with field tests showing 30% reduction in maintenance requirements and sustained cooling performance over 100,000+ miles of operation.

Polymer-metal hybrid materials offer compelling weight reduction opportunities while maintaining thermal performance. Glass-fiber reinforced polyamide composites with metallic fillers are increasingly replacing traditional metal components in peripheral cooling system applications, reducing weight by up to 40% while providing 85% of the thermal performance of all-metal alternatives.

Ceramic matrix composites (CMCs) are finding applications in high-temperature zones of modern V6 engines, particularly in turbocharger components and exhaust gas recirculation systems. These materials withstand temperatures exceeding 1000°C while maintaining structural integrity and thermal management properties, enabling more efficient heat recovery systems that contribute to overall cooling efficiency.

The integration of these advanced materials into V6 engine cooling systems has collectively enabled more compact cooling architectures, reduced parasitic power losses, and improved thermal efficiency across the entire operating range. Ongoing research focuses on bio-inspired materials and structures that mimic natural cooling mechanisms, promising the next generation of cooling solutions.

Carbon-based materials represent another breakthrough area, with graphene-enhanced composites showing exceptional thermal conductivity values exceeding 1000 W/mK - nearly five times that of copper. These materials are being integrated into cooling system components through advanced manufacturing techniques including powder metallurgy and additive manufacturing processes, enabling complex geometries previously impossible with conventional materials.

Phase-change materials (PCMs) have revolutionized temperature regulation in V6 engines by absorbing excess heat during high-load operations and releasing it during cooler operating conditions. Microencapsulated PCMs with tailored melting points between 80-120°C are being embedded in coolant reservoirs and critical engine components, providing thermal buffering that reduces temperature fluctuations by up to 40%.

Surface engineering advancements have yielded hydrophobic and oleophobic coatings that significantly reduce fouling and scaling in cooling passages. These nano-structured surfaces maintain optimal heat transfer efficiency over extended operating periods, with field tests showing 30% reduction in maintenance requirements and sustained cooling performance over 100,000+ miles of operation.

Polymer-metal hybrid materials offer compelling weight reduction opportunities while maintaining thermal performance. Glass-fiber reinforced polyamide composites with metallic fillers are increasingly replacing traditional metal components in peripheral cooling system applications, reducing weight by up to 40% while providing 85% of the thermal performance of all-metal alternatives.

Ceramic matrix composites (CMCs) are finding applications in high-temperature zones of modern V6 engines, particularly in turbocharger components and exhaust gas recirculation systems. These materials withstand temperatures exceeding 1000°C while maintaining structural integrity and thermal management properties, enabling more efficient heat recovery systems that contribute to overall cooling efficiency.

The integration of these advanced materials into V6 engine cooling systems has collectively enabled more compact cooling architectures, reduced parasitic power losses, and improved thermal efficiency across the entire operating range. Ongoing research focuses on bio-inspired materials and structures that mimic natural cooling mechanisms, promising the next generation of cooling solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!