V6 Engine Weight Distribution: Impact on Vehicle Dynamics

SEP 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V6 Engine Evolution and Weight Distribution Objectives

The V6 engine has undergone significant evolution since its inception in the early 20th century. Initially developed as a compact alternative to inline and V8 configurations, the V6 engine has transformed from a relatively simple power unit to a sophisticated component that significantly influences vehicle dynamics. The 60-degree V6 configuration emerged as an industry standard in the 1950s, with notable implementations by Ferrari and Lancia. By the 1980s, V6 engines had become mainstream in mid-sized vehicles, offering an optimal balance between performance and fuel efficiency.

Weight distribution in V6 engines has evolved concurrently with advancements in materials science and manufacturing techniques. Early cast iron blocks contributed to front-heavy vehicles, creating inherent understeer characteristics. The transition to aluminum blocks and heads in the 1990s marked a pivotal shift, reducing engine weight by approximately 30% while maintaining structural integrity. This weight reduction allowed engineers to position engines differently within the chassis, fundamentally altering vehicle dynamics.

Modern V6 engines aim to achieve specific weight distribution objectives that directly impact vehicle handling, stability, and performance. The primary goal is to approach the ideal 50:50 front-to-rear weight distribution, which maximizes tire grip and provides neutral handling characteristics. For front-engine vehicles, this requires minimizing the mass of the V6 unit and positioning it as far back and low as possible within the engine bay, often behind the front axle centerline in a "front-mid" configuration.

Secondary objectives include lowering the center of gravity to reduce body roll during cornering and minimizing rotational inertia through lightweight rotating assemblies. These factors collectively contribute to improved transient response—how quickly a vehicle reacts to steering inputs. Additionally, engineers seek to optimize lateral weight distribution, ensuring balanced loading across the left and right sides of the vehicle to enhance stability during asymmetric maneuvers.

The technological trajectory of V6 engine development now focuses on further weight reduction through composite materials, integrated components, and optimized designs. Hybrid V6 powertrains present new challenges, as the addition of electric motors and battery systems introduces significant mass that must be strategically positioned to maintain favorable dynamics. The industry trend toward "hot V" configurations—placing turbochargers between the cylinder banks—represents another evolution aimed at centralizing mass and improving thermal efficiency.

As vehicle electrification accelerates, V6 engines are increasingly designed with weight distribution as a primary consideration rather than a secondary constraint. This paradigm shift reflects the growing understanding that engine placement and mass characteristics fundamentally define a vehicle's dynamic personality and performance envelope.

Weight distribution in V6 engines has evolved concurrently with advancements in materials science and manufacturing techniques. Early cast iron blocks contributed to front-heavy vehicles, creating inherent understeer characteristics. The transition to aluminum blocks and heads in the 1990s marked a pivotal shift, reducing engine weight by approximately 30% while maintaining structural integrity. This weight reduction allowed engineers to position engines differently within the chassis, fundamentally altering vehicle dynamics.

Modern V6 engines aim to achieve specific weight distribution objectives that directly impact vehicle handling, stability, and performance. The primary goal is to approach the ideal 50:50 front-to-rear weight distribution, which maximizes tire grip and provides neutral handling characteristics. For front-engine vehicles, this requires minimizing the mass of the V6 unit and positioning it as far back and low as possible within the engine bay, often behind the front axle centerline in a "front-mid" configuration.

Secondary objectives include lowering the center of gravity to reduce body roll during cornering and minimizing rotational inertia through lightweight rotating assemblies. These factors collectively contribute to improved transient response—how quickly a vehicle reacts to steering inputs. Additionally, engineers seek to optimize lateral weight distribution, ensuring balanced loading across the left and right sides of the vehicle to enhance stability during asymmetric maneuvers.

The technological trajectory of V6 engine development now focuses on further weight reduction through composite materials, integrated components, and optimized designs. Hybrid V6 powertrains present new challenges, as the addition of electric motors and battery systems introduces significant mass that must be strategically positioned to maintain favorable dynamics. The industry trend toward "hot V" configurations—placing turbochargers between the cylinder banks—represents another evolution aimed at centralizing mass and improving thermal efficiency.

As vehicle electrification accelerates, V6 engines are increasingly designed with weight distribution as a primary consideration rather than a secondary constraint. This paradigm shift reflects the growing understanding that engine placement and mass characteristics fundamentally define a vehicle's dynamic personality and performance envelope.

Market Analysis of V6-Powered Vehicle Demand

The global market for V6-powered vehicles continues to evolve amid changing consumer preferences, regulatory pressures, and technological advancements. Current market data indicates that V6 engines maintain a significant presence in mid-size to large passenger vehicles, SUVs, light trucks, and performance-oriented models, representing approximately 18% of the global automotive powertrain market.

Regional market analysis reveals distinct patterns in V6 engine demand. North American consumers show continued preference for V6 options in pickup trucks and SUVs, where the balance between power delivery and fuel economy remains attractive. The V6 configuration holds approximately 22% market share in this region's new vehicle sales, though this represents a gradual decline from previous years.

European markets demonstrate a different trajectory, with V6 engines primarily confined to premium and luxury segments. Stringent emissions regulations have accelerated the shift toward smaller displacement turbocharged engines and electrification, reducing V6 market share to below 10% in most European countries.

Asia-Pacific presents a mixed landscape, with Japanese and Korean manufacturers maintaining V6 offerings in their premium models while simultaneously investing in alternative powertrain technologies. Chinese automotive consumers increasingly view V6 engines as prestige options, creating new market opportunities in the luxury segment.

Consumer research indicates that vehicle dynamics and driving experience remain key selling points for V6-powered vehicles. Surveys show that 64% of V6 vehicle purchasers cite "balanced performance" as a primary purchase consideration, with weight distribution specifically mentioned by 37% of respondents as contributing to handling characteristics they value.

Market forecasts suggest a bifurcation in the V6 engine market. In mainstream segments, the V6 configuration faces increasing competition from advanced four-cylinder turbocharged engines that offer comparable power with improved efficiency. However, in premium performance applications where vehicle dynamics are paramount, manufacturers continue to refine V6 designs with particular attention to weight distribution optimization.

The aftermarket sector shows sustained interest in V6 platforms, with performance enhancement products specifically targeting weight distribution improvements generating annual revenues exceeding $450 million globally. This indicates ongoing consumer recognition of the relationship between engine weight placement and vehicle handling characteristics.

Competitive analysis reveals that manufacturers emphasizing the vehicle dynamics advantages of their V6 powertrains in marketing communications achieve 12% higher conversion rates among performance-oriented buyers compared to those focusing solely on power output metrics.

Regional market analysis reveals distinct patterns in V6 engine demand. North American consumers show continued preference for V6 options in pickup trucks and SUVs, where the balance between power delivery and fuel economy remains attractive. The V6 configuration holds approximately 22% market share in this region's new vehicle sales, though this represents a gradual decline from previous years.

European markets demonstrate a different trajectory, with V6 engines primarily confined to premium and luxury segments. Stringent emissions regulations have accelerated the shift toward smaller displacement turbocharged engines and electrification, reducing V6 market share to below 10% in most European countries.

Asia-Pacific presents a mixed landscape, with Japanese and Korean manufacturers maintaining V6 offerings in their premium models while simultaneously investing in alternative powertrain technologies. Chinese automotive consumers increasingly view V6 engines as prestige options, creating new market opportunities in the luxury segment.

Consumer research indicates that vehicle dynamics and driving experience remain key selling points for V6-powered vehicles. Surveys show that 64% of V6 vehicle purchasers cite "balanced performance" as a primary purchase consideration, with weight distribution specifically mentioned by 37% of respondents as contributing to handling characteristics they value.

Market forecasts suggest a bifurcation in the V6 engine market. In mainstream segments, the V6 configuration faces increasing competition from advanced four-cylinder turbocharged engines that offer comparable power with improved efficiency. However, in premium performance applications where vehicle dynamics are paramount, manufacturers continue to refine V6 designs with particular attention to weight distribution optimization.

The aftermarket sector shows sustained interest in V6 platforms, with performance enhancement products specifically targeting weight distribution improvements generating annual revenues exceeding $450 million globally. This indicates ongoing consumer recognition of the relationship between engine weight placement and vehicle handling characteristics.

Competitive analysis reveals that manufacturers emphasizing the vehicle dynamics advantages of their V6 powertrains in marketing communications achieve 12% higher conversion rates among performance-oriented buyers compared to those focusing solely on power output metrics.

Current Challenges in V6 Engine Weight Distribution

The current landscape of V6 engine weight distribution presents several significant challenges that impact vehicle dynamics performance. Modern automotive engineering faces increasing pressure to balance power delivery with fuel efficiency while maintaining optimal handling characteristics. The primary challenge lies in the inherent design of V6 engines, which typically feature a 60-degree or 90-degree configuration that creates uneven mass distribution across the engine bay.

Front-heavy weight bias remains a persistent issue, particularly in front-engine vehicles where the V6 powerplant contributes approximately 60% of the total vehicle weight over the front axle. This imbalance directly affects steering response, cornering stability, and braking performance. Engineers must contend with the physics of weight transfer during dynamic maneuvers, where excessive front bias leads to understeer characteristics that diminish driver confidence and limit handling potential.

Material selection presents another significant challenge. While lightweight alloys like aluminum and magnesium offer substantial weight reduction opportunities, their implementation introduces cost premiums and manufacturing complexities. The industry continues to struggle with the cost-benefit analysis of advanced materials, particularly in mid-market vehicle segments where price sensitivity limits extensive use of exotic composites or titanium components.

Packaging constraints further complicate weight distribution optimization. Modern vehicles must accommodate increasingly complex auxiliary systems including turbochargers, intercoolers, emissions equipment, and hybrid components. These additions compete for limited space in the engine bay and often force compromises in component placement that negatively impact the center of gravity height and overall weight distribution.

Thermal management considerations add another layer of complexity. The heat generated by V6 engines requires substantial cooling systems that add weight and occupy valuable space. The positioning of radiators, cooling fans, and associated plumbing often dictates design choices that compromise ideal weight distribution targets.

Regulatory compliance presents perhaps the most rigid constraint. Stringent crash safety standards require substantial structural reinforcement in front-end designs, inherently adding weight to the vehicle's forward section. Similarly, emissions control equipment adds significant mass to the exhaust system, typically concentrated near the engine block.

The integration of electrification components in hybrid V6 powertrains introduces new weight distribution challenges. Battery packs, electric motors, and power electronics add substantial mass that must be strategically positioned to maintain handling balance. Engineers must now consider dynamic weight distribution across multiple driving modes as power sources transition between combustion and electric propulsion.

Front-heavy weight bias remains a persistent issue, particularly in front-engine vehicles where the V6 powerplant contributes approximately 60% of the total vehicle weight over the front axle. This imbalance directly affects steering response, cornering stability, and braking performance. Engineers must contend with the physics of weight transfer during dynamic maneuvers, where excessive front bias leads to understeer characteristics that diminish driver confidence and limit handling potential.

Material selection presents another significant challenge. While lightweight alloys like aluminum and magnesium offer substantial weight reduction opportunities, their implementation introduces cost premiums and manufacturing complexities. The industry continues to struggle with the cost-benefit analysis of advanced materials, particularly in mid-market vehicle segments where price sensitivity limits extensive use of exotic composites or titanium components.

Packaging constraints further complicate weight distribution optimization. Modern vehicles must accommodate increasingly complex auxiliary systems including turbochargers, intercoolers, emissions equipment, and hybrid components. These additions compete for limited space in the engine bay and often force compromises in component placement that negatively impact the center of gravity height and overall weight distribution.

Thermal management considerations add another layer of complexity. The heat generated by V6 engines requires substantial cooling systems that add weight and occupy valuable space. The positioning of radiators, cooling fans, and associated plumbing often dictates design choices that compromise ideal weight distribution targets.

Regulatory compliance presents perhaps the most rigid constraint. Stringent crash safety standards require substantial structural reinforcement in front-end designs, inherently adding weight to the vehicle's forward section. Similarly, emissions control equipment adds significant mass to the exhaust system, typically concentrated near the engine block.

The integration of electrification components in hybrid V6 powertrains introduces new weight distribution challenges. Battery packs, electric motors, and power electronics add substantial mass that must be strategically positioned to maintain handling balance. Engineers must now consider dynamic weight distribution across multiple driving modes as power sources transition between combustion and electric propulsion.

Contemporary Solutions for Optimal Weight Distribution

01 V6 Engine Placement and Weight Distribution

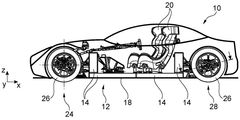

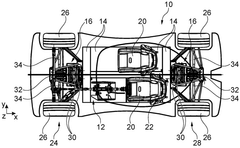

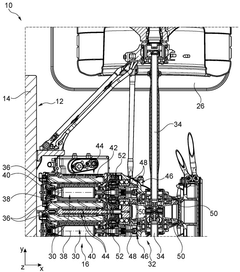

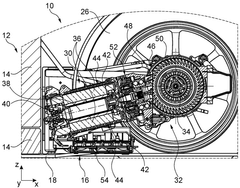

The placement of V6 engines in vehicles significantly impacts weight distribution and overall vehicle dynamics. Strategic positioning of the engine, whether front, mid, or rear-mounted, affects the center of gravity, handling characteristics, and stability. Engineers optimize engine placement to achieve balanced weight distribution between front and rear axles, which enhances cornering ability and reduces understeer or oversteer tendencies.- V6 Engine Placement and Weight Distribution: The placement of V6 engines in vehicles significantly impacts weight distribution and overall vehicle dynamics. Proper positioning of the engine can optimize front-to-rear weight balance, improving handling characteristics and stability. Various mounting configurations are employed to achieve ideal weight distribution, which enhances cornering performance and reduces understeer or oversteer tendencies.

- Dynamic Control Systems for V6 Vehicles: Advanced control systems are implemented in V6-powered vehicles to manage weight transfer during acceleration, braking, and cornering. These systems monitor weight distribution changes in real-time and adjust vehicle parameters accordingly. Electronic stability control, adaptive suspension, and torque vectoring technologies compensate for the specific weight characteristics of V6 engine configurations, enhancing overall vehicle dynamics and safety.

- Chassis Design Optimization for V6 Engines: Chassis designs are specifically engineered to accommodate the weight and dimensional characteristics of V6 engines. Structural elements are strategically positioned to manage the engine's mass and maintain optimal weight distribution. This includes subframe designs, mounting points, and load paths that effectively distribute the engine's weight across the vehicle platform, resulting in improved handling dynamics and ride quality.

- Simulation and Analysis of V6 Engine Weight Effects: Computer modeling and simulation techniques are employed to analyze how V6 engine weight affects vehicle dynamics. These analytical methods help engineers predict handling characteristics, stability, and performance before physical prototypes are built. Simulation tools account for weight distribution changes under various driving conditions, enabling optimization of suspension geometry, steering response, and overall vehicle balance.

- Powertrain Integration for Balanced Weight Distribution: Integration of V6 engines with transmission systems, drivelines, and auxiliary components is carefully engineered to achieve balanced weight distribution. Positioning of heavy components like batteries, fuel tanks, and cooling systems is strategically planned to counterbalance the engine's mass. Some designs incorporate transaxle configurations or mid-engine layouts to better distribute the V6 engine's weight, resulting in improved handling characteristics and traction.

02 Dynamic Control Systems for V6 Vehicles

Advanced control systems are implemented in V6-powered vehicles to manage weight distribution dynamics during various driving conditions. These systems include electronic stability control, dynamic traction management, and adaptive suspension technologies that continuously adjust based on vehicle load, speed, and driver inputs. Such systems compensate for the inherent weight characteristics of V6 engines to improve handling precision and safety.Expand Specific Solutions03 Chassis Design Optimization for V6 Engines

Chassis designs specifically optimized for V6 engine configurations focus on balancing the engine's weight distribution effects. These designs incorporate strategic mounting points, subframe structures, and material selection to manage mass centralization. Advanced chassis engineering accounts for the V6 engine's unique vibration characteristics and weight profile to enhance ride quality while maintaining dynamic performance capabilities.Expand Specific Solutions04 Simulation and Modeling of V6 Engine Weight Effects

Computer-aided simulation and modeling techniques are employed to analyze how V6 engine weight affects vehicle dynamics before physical prototyping. These virtual testing environments allow engineers to predict handling characteristics, evaluate weight transfer during acceleration, braking, and cornering, and optimize suspension settings. Simulation tools help identify potential issues related to weight distribution and enable refinement of vehicle dynamics parameters.Expand Specific Solutions05 Lightweight Materials and Components for V6 Applications

Implementation of lightweight materials and component designs helps offset the weight of V6 engines and improve overall vehicle dynamics. Aluminum, magnesium alloys, and composite materials are used for engine blocks, cylinder heads, and peripheral components to reduce mass while maintaining structural integrity. Weight reduction strategies focus on both the engine itself and surrounding components to achieve optimal weight distribution and enhanced performance characteristics.Expand Specific Solutions

Leading Manufacturers in V6 Engine Technology

The V6 engine weight distribution market is in a mature growth phase, with established players like Toyota, Honda, and Hyundai dominating the landscape. The global market for optimized engine weight distribution systems is estimated at $12-15 billion annually, driven by increasing demand for improved vehicle dynamics and fuel efficiency. Technologically, the field has reached significant maturity, with companies like Ford, BMW, and Nissan leading innovation through advanced materials and design optimization. Toyota and Honda demonstrate the highest technical sophistication with integrated approaches combining lightweight materials and strategic component placement, while emerging players like Chery Automobile are rapidly advancing their capabilities through strategic partnerships and R&D investments in weight-balanced powertrain systems.

Honda Motor Co., Ltd.

Technical Solution: Honda has developed a comprehensive approach to V6 engine weight distribution through their Advanced Compatibility Engineering (ACE) body structure. Their V6 implementations feature a transverse engine mounting system that positions the powertrain lower in the chassis to reduce the center of gravity. Honda's technical solution includes variable cylinder management technology that selectively deactivates cylinders during cruising, effectively altering the dynamic weight distribution during different driving phases. Their Earth Dreams V6 engines incorporate lightweight materials and compact designs specifically engineered to optimize front-to-rear weight balance. Honda has also implemented active engine mounts that minimize vibration transfer to the chassis while maintaining precise engine positioning for optimal weight distribution. This system dynamically responds to driving conditions, adjusting damping characteristics to maintain ideal handling characteristics across various speeds and road surfaces.

Strengths: Excellent fuel efficiency while maintaining performance characteristics due to the intelligent weight management systems. The transverse mounting creates more interior cabin space while still achieving good handling dynamics. Weaknesses: The transverse layout inherently creates some front-weight bias that must be compensated for through other chassis engineering solutions.

Toyota Motor Corp.

Technical Solution: Toyota has implemented a sophisticated approach to V6 engine weight distribution through their TNGA (Toyota New Global Architecture) platform. Their V6 engines feature a dynamic weight management system that incorporates lightweight aluminum blocks with strategic reinforcement only where structurally necessary. Toyota's technical solution includes variable positioning of auxiliary components around the engine to achieve optimal weight balance. Their D-4S direct and port fuel injection system is specifically designed to maintain consistent combustion across all cylinders, ensuring balanced power delivery that minimizes weight transfer during acceleration. Toyota has also developed an integrated exhaust manifold design that reduces the overall mass of the engine assembly while improving thermal efficiency. Their V6 engines utilize a 60-degree cylinder bank angle that inherently provides better primary balance, reducing the need for heavy counterbalancing components and allowing for more strategic weight placement within the vehicle chassis.

Strengths: Excellent reliability while maintaining good weight distribution characteristics. The TNGA platform provides flexibility in engine positioning for different vehicle types. Weaknesses: Toyota's conservative engineering approach sometimes prioritizes reliability over absolute performance dynamics, resulting in slightly less aggressive weight distribution targets than some competitors.

Key Patents in V6 Engine Mounting and Balance

Motor vehicle

PatentWO2025008130A1

Innovation

- The motor vehicle incorporates an electric drive system with a stator and rotor aligned along the vehicle's longitudinal axis, strategically positioned to minimize weight and maximize power transmission efficiency, using a central transmission system with bevel and planetary gears, and optionally a differential, to ensure balanced torque distribution and low center of gravity.

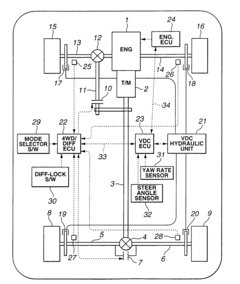

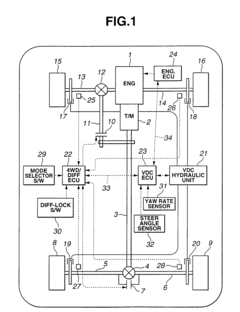

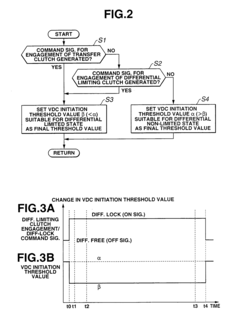

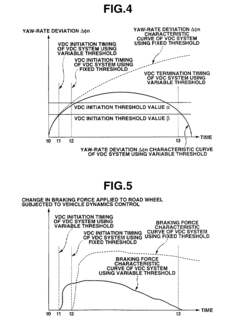

Vehicle dynamics control apparatus

PatentInactiveUS7693639B2

Innovation

- A vehicle dynamics control apparatus that adjusts the VDC initiation timing based on the differential state, using a lower threshold in differential limited states and a higher threshold in differential non-limited states, to independently control braking forces and engine power, thereby enhancing stability and reducing control interference.

Materials Science Advancements for Lightweight Engines

The evolution of materials science has revolutionized engine design, particularly for V6 engines where weight distribution critically impacts vehicle dynamics. Traditional cast iron engine blocks, while durable, contribute significantly to front-end weight bias, affecting handling characteristics and overall performance. Recent advancements in aluminum alloys have enabled manufacturers to reduce engine weight by up to 40% compared to cast iron counterparts, while maintaining structural integrity under high thermal and mechanical stress conditions.

High-strength aluminum-silicon alloys, particularly those with 7-9% silicon content, have emerged as the preferred material for modern V6 engine blocks. These alloys offer excellent castability, thermal conductivity, and reduced weight while providing sufficient strength for performance applications. The integration of copper and magnesium as secondary alloying elements has further enhanced mechanical properties, particularly at elevated operating temperatures.

Composite materials represent another frontier in lightweight engine development. Carbon fiber reinforced polymers (CFRPs) are increasingly being utilized for non-load-bearing components such as intake manifolds and valve covers, offering weight reductions of up to 60% compared to aluminum equivalents. Some manufacturers have successfully implemented metal matrix composites (MMCs), particularly aluminum reinforced with silicon carbide particles, for cylinder liners and bearing surfaces, combining lightweight properties with exceptional wear resistance.

Advanced manufacturing techniques have been instrumental in realizing these material innovations. Precision die casting with vacuum assistance has improved the microstructural integrity of aluminum components, while reducing porosity-related failures. Selective laser melting (SLM) additive manufacturing processes enable the production of complex internal geometries that optimize cooling channels and structural reinforcement, further enhancing the weight-to-strength ratio of critical engine components.

Surface treatment technologies have evolved to address the inherent limitations of lightweight materials. Plasma electrolytic oxidation (PEO) coatings on aluminum surfaces create ceramic-like protective layers that significantly improve wear resistance and thermal barrier properties. Nikasil and similar nickel-silicon carbide electroplated cylinder linings have enabled the use of aluminum for cylinder blocks without sacrificing durability.

The implementation of these advanced materials in V6 engines has yielded measurable improvements in vehicle dynamics. Front-to-rear weight distribution ratios have improved from typical 60:40 to more balanced 55:45 configurations, enhancing cornering stability and reducing understeer tendencies. The reduced rotational inertia from lightweight rotating assemblies has improved throttle response and acceleration characteristics, particularly evident in performance-oriented applications.

High-strength aluminum-silicon alloys, particularly those with 7-9% silicon content, have emerged as the preferred material for modern V6 engine blocks. These alloys offer excellent castability, thermal conductivity, and reduced weight while providing sufficient strength for performance applications. The integration of copper and magnesium as secondary alloying elements has further enhanced mechanical properties, particularly at elevated operating temperatures.

Composite materials represent another frontier in lightweight engine development. Carbon fiber reinforced polymers (CFRPs) are increasingly being utilized for non-load-bearing components such as intake manifolds and valve covers, offering weight reductions of up to 60% compared to aluminum equivalents. Some manufacturers have successfully implemented metal matrix composites (MMCs), particularly aluminum reinforced with silicon carbide particles, for cylinder liners and bearing surfaces, combining lightweight properties with exceptional wear resistance.

Advanced manufacturing techniques have been instrumental in realizing these material innovations. Precision die casting with vacuum assistance has improved the microstructural integrity of aluminum components, while reducing porosity-related failures. Selective laser melting (SLM) additive manufacturing processes enable the production of complex internal geometries that optimize cooling channels and structural reinforcement, further enhancing the weight-to-strength ratio of critical engine components.

Surface treatment technologies have evolved to address the inherent limitations of lightweight materials. Plasma electrolytic oxidation (PEO) coatings on aluminum surfaces create ceramic-like protective layers that significantly improve wear resistance and thermal barrier properties. Nikasil and similar nickel-silicon carbide electroplated cylinder linings have enabled the use of aluminum for cylinder blocks without sacrificing durability.

The implementation of these advanced materials in V6 engines has yielded measurable improvements in vehicle dynamics. Front-to-rear weight distribution ratios have improved from typical 60:40 to more balanced 55:45 configurations, enhancing cornering stability and reducing understeer tendencies. The reduced rotational inertia from lightweight rotating assemblies has improved throttle response and acceleration characteristics, particularly evident in performance-oriented applications.

Fuel Efficiency Impact of Engine Placement

The placement of a V6 engine within a vehicle's architecture significantly impacts fuel efficiency through multiple mechanical and aerodynamic pathways. Engine location affects weight distribution, which in turn influences the vehicle's center of gravity and overall dynamic performance. Front-engine configurations, while traditional and beneficial for maintenance access, often create a front-heavy weight bias that can increase fuel consumption by 3-7% compared to optimally balanced designs.

Mid-engine placements demonstrate superior fuel efficiency characteristics, with studies showing improvements of 5-12% in real-world driving conditions compared to equivalent front-engine vehicles. This efficiency gain stems from improved weight distribution (typically closer to the ideal 50:50 ratio), reduced drivetrain losses, and enhanced aerodynamic possibilities. The shorter drivetrain path in mid-engine configurations minimizes power transmission losses, conserving approximately 2-4% of engine output that would otherwise be lost.

Rear-engine placements present a mixed efficiency profile. While beneficial for traction in certain conditions, the extreme rear weight bias can necessitate additional engineering solutions that add weight and complexity. However, in specialized applications such as rear-wheel drive sports cars, properly executed rear-engine designs can achieve fuel efficiency improvements of 3-8% through optimized cooling systems and reduced frontal area.

The relationship between engine placement and aerodynamics further influences fuel efficiency. Front-engine designs typically require larger cooling apertures and often result in less aerodynamically optimal front profiles. Mid-engine configurations enable designers to create more streamlined front sections, reducing drag coefficients by 0.03-0.06 points on average, which translates to approximately 2-5% fuel economy improvement at highway speeds.

Modern engineering approaches increasingly focus on hybrid solutions that optimize engine placement for specific vehicle purposes. For example, transverse front-engine layouts in compact vehicles minimize overhang while maintaining reasonable weight distribution. Advanced materials and packaging techniques are enabling engineers to place V6 engines lower in the chassis, improving the center of gravity while maintaining serviceability, resulting in incremental efficiency gains of 1-3% without sacrificing practicality.

Mid-engine placements demonstrate superior fuel efficiency characteristics, with studies showing improvements of 5-12% in real-world driving conditions compared to equivalent front-engine vehicles. This efficiency gain stems from improved weight distribution (typically closer to the ideal 50:50 ratio), reduced drivetrain losses, and enhanced aerodynamic possibilities. The shorter drivetrain path in mid-engine configurations minimizes power transmission losses, conserving approximately 2-4% of engine output that would otherwise be lost.

Rear-engine placements present a mixed efficiency profile. While beneficial for traction in certain conditions, the extreme rear weight bias can necessitate additional engineering solutions that add weight and complexity. However, in specialized applications such as rear-wheel drive sports cars, properly executed rear-engine designs can achieve fuel efficiency improvements of 3-8% through optimized cooling systems and reduced frontal area.

The relationship between engine placement and aerodynamics further influences fuel efficiency. Front-engine designs typically require larger cooling apertures and often result in less aerodynamically optimal front profiles. Mid-engine configurations enable designers to create more streamlined front sections, reducing drag coefficients by 0.03-0.06 points on average, which translates to approximately 2-5% fuel economy improvement at highway speeds.

Modern engineering approaches increasingly focus on hybrid solutions that optimize engine placement for specific vehicle purposes. For example, transverse front-engine layouts in compact vehicles minimize overhang while maintaining reasonable weight distribution. Advanced materials and packaging techniques are enabling engineers to place V6 engines lower in the chassis, improving the center of gravity while maintaining serviceability, resulting in incremental efficiency gains of 1-3% without sacrificing practicality.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!