V6 Engine Cylinder Pressure Mapping: Methods and Tools

SEP 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V6 Engine Pressure Mapping Background and Objectives

Cylinder pressure mapping in V6 engines has evolved significantly over the past three decades, transitioning from rudimentary mechanical measurement techniques to sophisticated digital monitoring systems. This technological progression has been driven by increasingly stringent emission regulations, performance optimization requirements, and the automotive industry's shift toward more efficient combustion processes. The fundamental objective of cylinder pressure mapping is to accurately measure and analyze the pressure variations within engine cylinders during the combustion cycle, providing critical insights into engine performance, efficiency, and emissions characteristics.

The development of cylinder pressure mapping technology can be traced back to the 1980s when basic piezoelectric sensors were first adapted for in-cylinder pressure measurement. By the 1990s, these technologies had advanced to allow for real-time data acquisition, though primarily in laboratory settings. The 2000s witnessed significant miniaturization and durability improvements, enabling more practical applications in production vehicles and field testing environments.

Current cylinder pressure mapping objectives focus on achieving high-resolution, real-time pressure data acquisition across all cylinders simultaneously, while maintaining sensor durability under extreme temperature and pressure conditions. This data serves as the foundation for advanced engine control strategies, combustion optimization, and predictive maintenance systems. The integration of pressure mapping with other engine parameters provides a comprehensive understanding of combustion dynamics, which is essential for modern engine development.

The technical goals for V6 engine pressure mapping include developing sensors capable of withstanding temperatures exceeding 2000°C and pressures up to 200 bar, while maintaining measurement accuracy within ±1%. Additionally, there is a push toward non-intrusive measurement techniques that do not require physical modification of the engine block or cylinder head, thus preserving the integrity of the combustion chamber geometry.

Another critical objective is the development of advanced signal processing algorithms capable of interpreting pressure data in real-time to enable dynamic adjustments to fuel injection timing, spark timing, and valve actuation. This closed-loop control approach represents a significant advancement over traditional open-loop engine management systems, potentially yielding substantial improvements in fuel efficiency and emissions reduction.

Looking forward, the integration of artificial intelligence and machine learning techniques with cylinder pressure mapping presents opportunities for predictive analytics, anomaly detection, and self-optimizing engine control systems. These technologies aim to continuously refine combustion parameters based on historical pressure data patterns, driving conditions, and environmental factors, ultimately pushing the boundaries of internal combustion engine efficiency and performance.

The development of cylinder pressure mapping technology can be traced back to the 1980s when basic piezoelectric sensors were first adapted for in-cylinder pressure measurement. By the 1990s, these technologies had advanced to allow for real-time data acquisition, though primarily in laboratory settings. The 2000s witnessed significant miniaturization and durability improvements, enabling more practical applications in production vehicles and field testing environments.

Current cylinder pressure mapping objectives focus on achieving high-resolution, real-time pressure data acquisition across all cylinders simultaneously, while maintaining sensor durability under extreme temperature and pressure conditions. This data serves as the foundation for advanced engine control strategies, combustion optimization, and predictive maintenance systems. The integration of pressure mapping with other engine parameters provides a comprehensive understanding of combustion dynamics, which is essential for modern engine development.

The technical goals for V6 engine pressure mapping include developing sensors capable of withstanding temperatures exceeding 2000°C and pressures up to 200 bar, while maintaining measurement accuracy within ±1%. Additionally, there is a push toward non-intrusive measurement techniques that do not require physical modification of the engine block or cylinder head, thus preserving the integrity of the combustion chamber geometry.

Another critical objective is the development of advanced signal processing algorithms capable of interpreting pressure data in real-time to enable dynamic adjustments to fuel injection timing, spark timing, and valve actuation. This closed-loop control approach represents a significant advancement over traditional open-loop engine management systems, potentially yielding substantial improvements in fuel efficiency and emissions reduction.

Looking forward, the integration of artificial intelligence and machine learning techniques with cylinder pressure mapping presents opportunities for predictive analytics, anomaly detection, and self-optimizing engine control systems. These technologies aim to continuously refine combustion parameters based on historical pressure data patterns, driving conditions, and environmental factors, ultimately pushing the boundaries of internal combustion engine efficiency and performance.

Market Demand Analysis for Cylinder Pressure Mapping

The global market for cylinder pressure mapping technology in V6 engines has experienced significant growth over the past decade, driven primarily by increasingly stringent emission regulations and the automotive industry's pursuit of improved engine efficiency. Current market analysis indicates that the cylinder pressure mapping segment is expanding at a compound annual growth rate of approximately 7.8%, with particularly strong demand emerging from premium and performance vehicle manufacturers.

Engine manufacturers are facing mounting pressure to optimize combustion processes while reducing emissions, creating substantial market pull for advanced pressure mapping solutions. The European market leads in adoption, followed closely by North America and rapidly growing Asian markets, particularly in China and Japan where automotive technology investment continues to accelerate.

Original Equipment Manufacturers (OEMs) represent the largest customer segment, accounting for roughly 65% of market demand. These manufacturers increasingly incorporate cylinder pressure mapping as a standard development tool rather than a specialized research instrument. The aftermarket performance sector constitutes a smaller but growing segment, with specialized tuning companies utilizing pressure mapping to maximize engine output while maintaining reliability.

Market research indicates three primary demand drivers for cylinder pressure mapping technology. First, regulatory compliance requirements are becoming more stringent worldwide, with Euro 7 standards and equivalent regulations in other regions necessitating more precise combustion control. Second, consumer expectations for fuel efficiency continue to rise even in performance vehicles, creating demand for technologies that can optimize the efficiency-power balance. Third, the growing complexity of modern engine management systems requires more sophisticated calibration tools to achieve optimal performance across all operating conditions.

The market shows distinct segmentation between high-end laboratory-grade systems used in research and development environments and more cost-effective solutions designed for production testing and field diagnostics. The former segment values measurement precision and comprehensive data analysis capabilities, while the latter prioritizes durability, ease of integration, and cost-effectiveness.

Recent industry surveys reveal that manufacturers are increasingly seeking integrated solutions that combine pressure mapping with other diagnostic capabilities, creating opportunities for comprehensive engine analysis platforms. Additionally, there is growing demand for real-time pressure mapping systems that can be permanently installed in production vehicles for continuous monitoring and adaptive control, representing a potential high-growth market segment for the coming decade.

Engine manufacturers are facing mounting pressure to optimize combustion processes while reducing emissions, creating substantial market pull for advanced pressure mapping solutions. The European market leads in adoption, followed closely by North America and rapidly growing Asian markets, particularly in China and Japan where automotive technology investment continues to accelerate.

Original Equipment Manufacturers (OEMs) represent the largest customer segment, accounting for roughly 65% of market demand. These manufacturers increasingly incorporate cylinder pressure mapping as a standard development tool rather than a specialized research instrument. The aftermarket performance sector constitutes a smaller but growing segment, with specialized tuning companies utilizing pressure mapping to maximize engine output while maintaining reliability.

Market research indicates three primary demand drivers for cylinder pressure mapping technology. First, regulatory compliance requirements are becoming more stringent worldwide, with Euro 7 standards and equivalent regulations in other regions necessitating more precise combustion control. Second, consumer expectations for fuel efficiency continue to rise even in performance vehicles, creating demand for technologies that can optimize the efficiency-power balance. Third, the growing complexity of modern engine management systems requires more sophisticated calibration tools to achieve optimal performance across all operating conditions.

The market shows distinct segmentation between high-end laboratory-grade systems used in research and development environments and more cost-effective solutions designed for production testing and field diagnostics. The former segment values measurement precision and comprehensive data analysis capabilities, while the latter prioritizes durability, ease of integration, and cost-effectiveness.

Recent industry surveys reveal that manufacturers are increasingly seeking integrated solutions that combine pressure mapping with other diagnostic capabilities, creating opportunities for comprehensive engine analysis platforms. Additionally, there is growing demand for real-time pressure mapping systems that can be permanently installed in production vehicles for continuous monitoring and adaptive control, representing a potential high-growth market segment for the coming decade.

Current Pressure Mapping Technologies and Challenges

Cylinder pressure mapping in V6 engines has evolved significantly over the past decade, with several technologies currently dominating the market. Piezoelectric sensors remain the gold standard for high-precision in-cylinder pressure measurement, offering exceptional response rates and temperature stability. These sensors convert mechanical pressure into electrical signals with minimal latency, making them ideal for real-time engine monitoring. However, their high cost (typically $500-1,000 per sensor) and complex installation requirements limit widespread adoption in production vehicles.

Piezoresistive sensors present a more cost-effective alternative, utilizing pressure-induced changes in electrical resistance. While they offer good accuracy at approximately half the cost of piezoelectric options, they suffer from temperature drift issues that necessitate sophisticated compensation algorithms, particularly in high-temperature engine environments exceeding 200°C.

Optical pressure sensors have emerged as a promising technology, using fiber optic principles to measure pressure changes without electrical components inside the combustion chamber. This provides superior electromagnetic interference immunity but requires precise optical alignment and specialized signal processing equipment.

Integration challenges persist across all sensor types. Physical installation often requires cylinder head modifications, which can compromise structural integrity if not properly engineered. Signal conditioning remains complex due to the harsh electromagnetic environment of modern engines, with noise from ignition systems and variable valve timing actuators frequently contaminating pressure signals.

Data acquisition systems present another significant challenge. Modern pressure mapping requires sampling rates of at least 100 kHz per cylinder to capture meaningful combustion events, generating substantial data volumes that strain conventional ECU processing capabilities. This necessitates dedicated hardware solutions with high-speed data buses and significant computational resources.

Calibration drift represents a persistent issue in long-term deployment scenarios. Even premium sensors exhibit sensitivity changes over time due to thermal cycling and carbon deposits, requiring periodic recalibration or sophisticated self-calibration algorithms to maintain measurement accuracy.

Cost remains perhaps the most significant barrier to widespread implementation. A complete six-cylinder pressure mapping system with sensors, signal conditioning, and data acquisition hardware typically costs $15,000-25,000, making it prohibitively expensive for production vehicles and limiting its use primarily to research and development applications.

Recent innovations focus on non-intrusive pressure estimation techniques, including torque-based reconstruction algorithms and ion-current sensing through spark plugs, which offer lower-cost alternatives with reduced accuracy but minimal hardware modifications.

Piezoresistive sensors present a more cost-effective alternative, utilizing pressure-induced changes in electrical resistance. While they offer good accuracy at approximately half the cost of piezoelectric options, they suffer from temperature drift issues that necessitate sophisticated compensation algorithms, particularly in high-temperature engine environments exceeding 200°C.

Optical pressure sensors have emerged as a promising technology, using fiber optic principles to measure pressure changes without electrical components inside the combustion chamber. This provides superior electromagnetic interference immunity but requires precise optical alignment and specialized signal processing equipment.

Integration challenges persist across all sensor types. Physical installation often requires cylinder head modifications, which can compromise structural integrity if not properly engineered. Signal conditioning remains complex due to the harsh electromagnetic environment of modern engines, with noise from ignition systems and variable valve timing actuators frequently contaminating pressure signals.

Data acquisition systems present another significant challenge. Modern pressure mapping requires sampling rates of at least 100 kHz per cylinder to capture meaningful combustion events, generating substantial data volumes that strain conventional ECU processing capabilities. This necessitates dedicated hardware solutions with high-speed data buses and significant computational resources.

Calibration drift represents a persistent issue in long-term deployment scenarios. Even premium sensors exhibit sensitivity changes over time due to thermal cycling and carbon deposits, requiring periodic recalibration or sophisticated self-calibration algorithms to maintain measurement accuracy.

Cost remains perhaps the most significant barrier to widespread implementation. A complete six-cylinder pressure mapping system with sensors, signal conditioning, and data acquisition hardware typically costs $15,000-25,000, making it prohibitively expensive for production vehicles and limiting its use primarily to research and development applications.

Recent innovations focus on non-intrusive pressure estimation techniques, including torque-based reconstruction algorithms and ion-current sensing through spark plugs, which offer lower-cost alternatives with reduced accuracy but minimal hardware modifications.

Current Pressure Mapping Solutions and Implementation

01 Cylinder pressure measurement techniques

Various techniques are employed to measure cylinder pressure in V6 engines. These include the use of pressure sensors installed directly in the cylinder, piezoelectric sensors that convert pressure to electrical signals, and optical sensors that detect pressure changes through light intensity variations. These measurement techniques provide accurate real-time data on cylinder pressure during engine operation, which is essential for engine performance analysis and optimization.- Cylinder pressure measurement techniques: Various techniques are employed to measure cylinder pressure in V6 engines. These include using pressure sensors installed directly in the cylinder, piezoelectric transducers that convert pressure into electrical signals, and optical sensors that detect pressure changes through light intensity variations. These measurement techniques provide accurate real-time data on combustion processes, enabling precise engine performance monitoring and optimization.

- Pressure mapping systems for engine diagnostics: Pressure mapping systems collect and analyze cylinder pressure data to diagnose engine conditions. These systems create visual representations of pressure distribution across all cylinders, allowing engineers to identify anomalies, combustion inefficiencies, or mechanical issues. Advanced mapping systems incorporate multiple data points throughout the combustion cycle to generate comprehensive pressure profiles that help optimize engine performance and identify potential failures before they occur.

- Real-time cylinder pressure monitoring: Real-time monitoring systems continuously track cylinder pressure during engine operation. These systems use high-speed data acquisition hardware and specialized software to process pressure signals instantaneously. Real-time monitoring enables immediate detection of combustion anomalies, misfires, or detonation events in V6 engines. This capability is particularly valuable for performance tuning, emissions control, and preventing catastrophic engine damage through early intervention when abnormal pressure patterns are detected.

- Cylinder pressure-based engine control strategies: Advanced engine management systems utilize cylinder pressure data to optimize various engine parameters. By analyzing pressure curves, these systems can dynamically adjust fuel injection timing, ignition timing, valve timing, and air-fuel ratios. This closed-loop control approach based on actual combustion pressure rather than inferred parameters allows for more precise engine operation across varying conditions, resulting in improved fuel efficiency, reduced emissions, and enhanced performance in V6 engines.

- Cylinder pressure balancing and harmonization: Techniques for balancing cylinder pressure across all six cylinders in V6 engines ensure smooth operation and prevent vibration. These methods involve analyzing pressure data from each cylinder and making adjustments to equalize combustion forces. Pressure harmonization systems can compensate for manufacturing variations, wear patterns, or fuel quality differences by fine-tuning individual cylinder parameters. This balancing improves engine longevity, reduces noise and vibration, and maintains optimal performance throughout the engine's operational range.

02 Pressure mapping systems for engine diagnostics

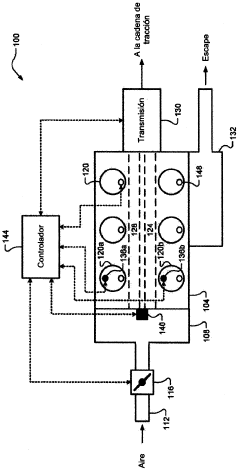

Pressure mapping systems collect and analyze cylinder pressure data across all cylinders of a V6 engine to identify performance issues. These systems create visual representations of pressure distribution, allowing engineers to detect anomalies such as misfires, valve leakage, or combustion irregularities. Advanced mapping systems can correlate pressure data with other engine parameters to provide comprehensive diagnostics and troubleshooting capabilities.Expand Specific Solutions03 Real-time cylinder pressure monitoring and control

Real-time monitoring systems continuously track cylinder pressure in V6 engines and use this data to make immediate adjustments to engine parameters. These systems integrate pressure sensors with engine control units to optimize fuel injection timing, ignition timing, and air-fuel ratios based on actual cylinder pressure. This approach enables dynamic engine management that can adapt to changing operating conditions and maintain optimal performance and efficiency.Expand Specific Solutions04 Pressure-based combustion analysis for V6 engines

Cylinder pressure data is used to analyze combustion processes in V6 engines. By examining pressure curves, engineers can evaluate combustion efficiency, heat release rates, and energy conversion. Advanced analysis techniques include cycle-to-cycle variation assessment, combustion stability evaluation, and thermal efficiency calculations. These analyses help in optimizing engine design, improving fuel economy, and reducing emissions through better understanding of the combustion process.Expand Specific Solutions05 Integration of pressure data with engine management systems

Modern V6 engine management systems integrate cylinder pressure data with other sensor inputs to create comprehensive control strategies. These integrated systems use pressure information alongside temperature, airflow, and exhaust gas composition data to optimize engine performance. Machine learning algorithms can be employed to analyze pressure patterns and predict potential issues before they cause failures. This integration enables more sophisticated engine control strategies that balance power, efficiency, and emissions.Expand Specific Solutions

Key Industry Players in Engine Diagnostics

The V6 Engine Cylinder Pressure Mapping technology market is currently in a growth phase, with an estimated global market size of $2-3 billion and projected annual growth of 8-10%. Major automotive manufacturers including Toyota, Ford, Volkswagen, and GM are competing alongside specialized technology providers like Robert Bosch GmbH and Delphi Technology. The technology has reached moderate maturity, with established players like Scania CV AB and BorgWarner implementing advanced pressure mapping solutions in production engines. Asian manufacturers including Mitsubishi Electric, DENSO, and Great Wall Motor are rapidly advancing their capabilities, while European companies maintain technological leadership through sophisticated integration with engine management systems. The competitive landscape is characterized by increasing focus on precision diagnostics and real-time monitoring capabilities.

GM Global Technology Operations LLC

Technical Solution: GM has developed a comprehensive cylinder pressure mapping system for V6 engines called Dynamic Skip Fire (DSF) with Pressure Sensing. This technology combines cylinder deactivation capabilities with advanced pressure monitoring to optimize engine performance. GM's approach utilizes miniaturized pressure transducers with high temperature resistance (up to 900°C) and response rates exceeding 100kHz. Their system features dedicated signal processing hardware that performs real-time combustion analysis, including pressure peak detection, IMEP calculation, and heat release analysis. GM's implementation includes sophisticated algorithms that detect combustion anomalies such as pre-ignition, misfire, and knock events with high accuracy. The pressure data is integrated with GM's proprietary engine control architecture to enable cylinder-specific fuel and spark control, allowing for precise combustion phasing optimization across varying operating conditions.

Strengths: Seamless integration with cylinder deactivation technology; exceptional diagnostic capabilities for combustion anomalies; enables ultra-lean combustion strategies for improved efficiency. Weaknesses: System complexity increases maintenance requirements; higher initial cost compared to conventional systems; requires specialized technician training for service operations.

Toyota Motor Corp.

Technical Solution: Toyota has developed an innovative cylinder pressure mapping system for their V6 engines called D-4S Pressure-Based Combustion Control. Their approach utilizes high-precision piezoelectric pressure sensors with temperature compensation capabilities, allowing accurate measurements across the entire engine operating range. Toyota's system features a dedicated high-speed data acquisition module that samples pressure signals at up to 720 samples per engine cycle (0.5° crank angle resolution). Their technology incorporates advanced signal processing algorithms that perform real-time combustion analysis, including heat release calculations, combustion stability metrics, and knock detection. Toyota's implementation integrates pressure data with their dual injection system (port and direct injection), enabling sophisticated combustion mode switching based on actual in-cylinder conditions rather than pre-programmed maps. The system also features self-calibration capabilities that compensate for sensor aging and drift over time.

Strengths: Exceptional integration with Toyota's dual injection technology; highly refined signal processing algorithms; enables sophisticated combustion mode switching strategies. Weaknesses: Proprietary sensor technology increases replacement costs; system complexity requires specialized diagnostic equipment; calibration process is time-intensive.

Core Pressure Sensor Technologies and Patents

Method of cylinder pressure sensor data/angle capture for low and high resolution

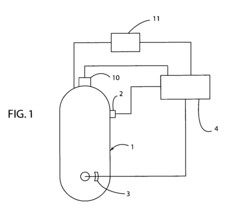

PatentActiveUS7320308B1

Innovation

- A method that utilizes a low-resolution position sensor to generate high-resolution cylinder pressure measurements by taking additional time-based readings within a user-selected angular window during the combustion event, allowing for precise calculation of combustion-related parameters without the need for high-resolution crank angle sensors.

Systems and methods for real-time angle-domain measurement of filtered cylinder pressure.

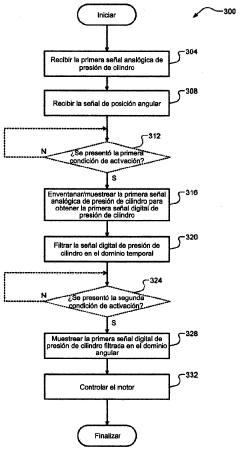

PatentActiveMX2017014461A

Innovation

- Convert analog cylinder pressure signals to digital signals in the angular domain, perform digital filtering in the time domain, and sample the filtered signals in the angular domain to obtain measured pressures, reducing processing and memory needs.

Environmental Impact and Emissions Regulations

The evolving landscape of environmental regulations has significantly impacted V6 engine development, particularly in the area of cylinder pressure mapping technologies. Stringent emissions standards, including Euro 7, China 7, and US EPA Tier 3, have necessitated more precise control over combustion processes to reduce harmful pollutants such as NOx, particulate matter, and CO2. These regulations have accelerated the adoption of advanced cylinder pressure mapping tools as essential components in engine development and calibration.

Real-time cylinder pressure monitoring has become crucial for meeting these regulatory requirements while maintaining performance standards. Engine manufacturers must now demonstrate compliance through detailed emissions testing protocols that rely heavily on accurate pressure data across various operating conditions. The integration of cylinder pressure mapping into engine control systems enables dynamic adjustments to fuel injection timing and quantity, directly contributing to emissions reduction strategies.

The carbon footprint associated with V6 engine production and operation has prompted regulatory bodies to implement lifecycle assessment requirements. Manufacturers must now document environmental impacts from raw material extraction through to end-of-life disposal. This holistic approach has elevated the importance of cylinder pressure mapping technologies that can optimize combustion efficiency throughout the engine's operational lifespan, reducing overall environmental impact.

Regional variations in emissions regulations present significant challenges for global engine platforms. European regulations emphasize CO2 reduction, while North American standards focus more heavily on NOx and particulate emissions. This regulatory divergence has driven the development of adaptable cylinder pressure mapping systems capable of supporting region-specific calibration strategies while maintaining a common hardware architecture.

The transition toward real-world driving emissions (RDE) testing protocols has further emphasized the need for robust cylinder pressure mapping technologies. Unlike laboratory testing, RDE evaluations expose engines to variable conditions that can significantly affect combustion characteristics. Advanced pressure mapping tools provide critical data for developing control strategies that maintain emissions compliance across this broader operational envelope.

Looking forward, upcoming regulations are expected to impose even stricter limits on previously unregulated emissions components and require longer compliance periods under more diverse operating conditions. This regulatory trajectory will likely accelerate innovation in cylinder pressure mapping technologies, particularly in areas of sensor durability, data processing capabilities, and integration with predictive control algorithms.

Real-time cylinder pressure monitoring has become crucial for meeting these regulatory requirements while maintaining performance standards. Engine manufacturers must now demonstrate compliance through detailed emissions testing protocols that rely heavily on accurate pressure data across various operating conditions. The integration of cylinder pressure mapping into engine control systems enables dynamic adjustments to fuel injection timing and quantity, directly contributing to emissions reduction strategies.

The carbon footprint associated with V6 engine production and operation has prompted regulatory bodies to implement lifecycle assessment requirements. Manufacturers must now document environmental impacts from raw material extraction through to end-of-life disposal. This holistic approach has elevated the importance of cylinder pressure mapping technologies that can optimize combustion efficiency throughout the engine's operational lifespan, reducing overall environmental impact.

Regional variations in emissions regulations present significant challenges for global engine platforms. European regulations emphasize CO2 reduction, while North American standards focus more heavily on NOx and particulate emissions. This regulatory divergence has driven the development of adaptable cylinder pressure mapping systems capable of supporting region-specific calibration strategies while maintaining a common hardware architecture.

The transition toward real-world driving emissions (RDE) testing protocols has further emphasized the need for robust cylinder pressure mapping technologies. Unlike laboratory testing, RDE evaluations expose engines to variable conditions that can significantly affect combustion characteristics. Advanced pressure mapping tools provide critical data for developing control strategies that maintain emissions compliance across this broader operational envelope.

Looking forward, upcoming regulations are expected to impose even stricter limits on previously unregulated emissions components and require longer compliance periods under more diverse operating conditions. This regulatory trajectory will likely accelerate innovation in cylinder pressure mapping technologies, particularly in areas of sensor durability, data processing capabilities, and integration with predictive control algorithms.

Real-time Monitoring and Data Analysis Methods

Real-time monitoring of cylinder pressure in V6 engines has evolved significantly with advancements in sensor technology and data processing capabilities. Modern systems employ piezoelectric or piezoresistive pressure sensors installed directly in each cylinder, capable of sampling rates exceeding 1 MHz to capture the rapid pressure changes during combustion cycles. These high-frequency measurements enable precise tracking of pressure variations throughout the entire four-stroke cycle, providing critical insights into combustion efficiency and engine performance.

Data acquisition systems for cylinder pressure mapping typically incorporate specialized hardware with multi-channel capabilities, allowing simultaneous monitoring across all six cylinders. Signal conditioning circuits filter noise and amplify sensor outputs before analog-to-digital conversion, with resolution typically ranging from 12 to 16 bits to ensure measurement accuracy within 0.1-0.5% of full scale. Engine control units (ECUs) increasingly integrate these monitoring capabilities, enabling real-time adjustments based on pressure data.

Advanced data analysis methods employ both time-domain and frequency-domain techniques to extract meaningful information from pressure signals. Peak pressure detection algorithms identify maximum pressure values and their crank angle positions, while heat release calculations derive combustion characteristics through thermodynamic models. Cycle-to-cycle variation analysis quantifies combustion stability by examining statistical distributions of key parameters across hundreds of consecutive cycles.

Machine learning approaches have recently enhanced cylinder pressure analysis capabilities. Supervised learning models trained on extensive datasets can detect anomalies indicating potential mechanical issues before they manifest as performance problems. Neural networks and pattern recognition algorithms identify subtle pressure signature changes that might escape traditional threshold-based detection methods, enabling predictive maintenance strategies.

Visualization tools transform complex pressure data into actionable insights through intuitive interfaces. Real-time pressure-volume (P-V) diagrams display the thermodynamic cycle graphically, while cylinder-specific dashboards highlight performance metrics across the engine. Heat maps and 3D surface plots reveal spatial pressure distribution patterns, particularly valuable for identifying cylinder-specific issues in V6 configurations where bank-to-bank variations may occur.

Integration with broader engine management systems allows correlation of pressure data with other parameters such as air-fuel ratios, ignition timing, and emissions measurements. This holistic approach enables comprehensive engine performance optimization, supporting both development activities and production quality control processes.

Data acquisition systems for cylinder pressure mapping typically incorporate specialized hardware with multi-channel capabilities, allowing simultaneous monitoring across all six cylinders. Signal conditioning circuits filter noise and amplify sensor outputs before analog-to-digital conversion, with resolution typically ranging from 12 to 16 bits to ensure measurement accuracy within 0.1-0.5% of full scale. Engine control units (ECUs) increasingly integrate these monitoring capabilities, enabling real-time adjustments based on pressure data.

Advanced data analysis methods employ both time-domain and frequency-domain techniques to extract meaningful information from pressure signals. Peak pressure detection algorithms identify maximum pressure values and their crank angle positions, while heat release calculations derive combustion characteristics through thermodynamic models. Cycle-to-cycle variation analysis quantifies combustion stability by examining statistical distributions of key parameters across hundreds of consecutive cycles.

Machine learning approaches have recently enhanced cylinder pressure analysis capabilities. Supervised learning models trained on extensive datasets can detect anomalies indicating potential mechanical issues before they manifest as performance problems. Neural networks and pattern recognition algorithms identify subtle pressure signature changes that might escape traditional threshold-based detection methods, enabling predictive maintenance strategies.

Visualization tools transform complex pressure data into actionable insights through intuitive interfaces. Real-time pressure-volume (P-V) diagrams display the thermodynamic cycle graphically, while cylinder-specific dashboards highlight performance metrics across the engine. Heat maps and 3D surface plots reveal spatial pressure distribution patterns, particularly valuable for identifying cylinder-specific issues in V6 configurations where bank-to-bank variations may occur.

Integration with broader engine management systems allows correlation of pressure data with other parameters such as air-fuel ratios, ignition timing, and emissions measurements. This holistic approach enables comprehensive engine performance optimization, supporting both development activities and production quality control processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!