V6 Engine Oil Viscosity: Impact on Performance

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V6 Engine Oil Evolution and Performance Objectives

The evolution of engine oils for V6 engines represents a fascinating journey of technological advancement driven by increasing performance demands and environmental considerations. Since the 1980s, when V6 engines gained widespread popularity in consumer vehicles, lubricant technology has undergone significant transformation to accommodate higher operating temperatures, increased power outputs, and extended service intervals.

Early V6 engines utilized conventional mineral-based oils with relatively high viscosity ratings (typically 10W-40 or 20W-50), which provided adequate protection but limited efficiency. The introduction of multi-grade oils marked a critical advancement, allowing for temperature-adaptive viscosity characteristics that improved cold-start protection while maintaining high-temperature performance.

The 1990s witnessed a paradigm shift with the introduction of synthetic and semi-synthetic formulations specifically engineered for V6 applications. These oils delivered superior thermal stability, oxidation resistance, and film strength, enabling engines to operate more efficiently across wider temperature ranges. This period also saw the emergence of lower viscosity grades (5W-30, 5W-20) that reduced internal friction without compromising protection.

Current performance objectives for V6 engine oils center around four key parameters: fuel efficiency enhancement, emissions reduction, extended engine longevity, and protection under extreme operating conditions. Modern V6 engines, particularly those with turbocharging or direct injection systems, generate significantly higher thermal loads and mechanical stresses that demand advanced lubricant properties.

The trend toward lower viscosity oils (0W-20, 0W-16) continues to accelerate, driven by manufacturer requirements for improved fuel economy and reduced emissions. However, this presents technical challenges in maintaining adequate oil film thickness and protection, particularly in high-performance V6 applications where operating temperatures can exceed 300°F under load.

Additive technology has evolved in parallel, with modern V6 engine oils incorporating complex packages of detergents, dispersants, anti-wear agents, friction modifiers, and viscosity index improvers. These additives must perform synergistically while remaining compatible with emission control systems and catalytic converters.

The performance objectives for next-generation V6 engine oils include further reductions in internal friction, enhanced thermal stability at higher operating temperatures, improved protection against low-speed pre-ignition (LSPI), and compatibility with hybrid powertrain systems where engines may experience frequent start-stop cycles and variable load conditions.

Early V6 engines utilized conventional mineral-based oils with relatively high viscosity ratings (typically 10W-40 or 20W-50), which provided adequate protection but limited efficiency. The introduction of multi-grade oils marked a critical advancement, allowing for temperature-adaptive viscosity characteristics that improved cold-start protection while maintaining high-temperature performance.

The 1990s witnessed a paradigm shift with the introduction of synthetic and semi-synthetic formulations specifically engineered for V6 applications. These oils delivered superior thermal stability, oxidation resistance, and film strength, enabling engines to operate more efficiently across wider temperature ranges. This period also saw the emergence of lower viscosity grades (5W-30, 5W-20) that reduced internal friction without compromising protection.

Current performance objectives for V6 engine oils center around four key parameters: fuel efficiency enhancement, emissions reduction, extended engine longevity, and protection under extreme operating conditions. Modern V6 engines, particularly those with turbocharging or direct injection systems, generate significantly higher thermal loads and mechanical stresses that demand advanced lubricant properties.

The trend toward lower viscosity oils (0W-20, 0W-16) continues to accelerate, driven by manufacturer requirements for improved fuel economy and reduced emissions. However, this presents technical challenges in maintaining adequate oil film thickness and protection, particularly in high-performance V6 applications where operating temperatures can exceed 300°F under load.

Additive technology has evolved in parallel, with modern V6 engine oils incorporating complex packages of detergents, dispersants, anti-wear agents, friction modifiers, and viscosity index improvers. These additives must perform synergistically while remaining compatible with emission control systems and catalytic converters.

The performance objectives for next-generation V6 engine oils include further reductions in internal friction, enhanced thermal stability at higher operating temperatures, improved protection against low-speed pre-ignition (LSPI), and compatibility with hybrid powertrain systems where engines may experience frequent start-stop cycles and variable load conditions.

Market Analysis of High-Performance Engine Oils

The high-performance engine oil market has experienced substantial growth over the past decade, driven primarily by increasing consumer demand for superior vehicle performance and extended engine life. Currently valued at approximately $12.3 billion globally, this specialized segment is projected to grow at a compound annual growth rate (CAGR) of 3.8% through 2028, outpacing the standard motor oil market's growth rate of 2.5%.

The market for V6 engine-specific high-performance oils represents a significant portion of this sector, accounting for roughly 27% of total high-performance oil sales. This prominence stems from the widespread adoption of V6 engines across mid-range and premium vehicle categories, particularly in North America and Europe where they remain popular in SUVs, crossovers, and performance sedans.

Consumer behavior analysis reveals a growing willingness among vehicle owners to invest in premium lubricants, with 64% of V6 engine owners prioritizing oil quality over price. This trend is especially pronounced among owners of vehicles less than five years old, where the premium oil adoption rate reaches 78%. The average price premium consumers are willing to pay for high-performance oils stands at 35-40% above conventional options.

Distribution channels have evolved significantly, with automotive specialty retailers capturing 32% of market share, followed by authorized service centers (28%), online retailers (22%), and traditional auto parts stores (18%). The online segment has demonstrated the most rapid growth, expanding at 11.2% annually as consumers increasingly research and purchase automotive products digitally.

Regional market dynamics show notable variations, with North America leading consumption at 38% of global market share, followed by Europe (29%), Asia-Pacific (24%), and other regions (9%). Within these markets, synthetic and semi-synthetic formulations optimized for V6 engines dominate, collectively representing 83% of high-performance oil sales.

Key market drivers include increasing consumer awareness about the relationship between oil viscosity and engine performance, stricter emission regulations necessitating advanced lubricant formulations, and the growing average vehicle age in developed markets, which has reached 12.1 years in the United States. Additionally, the rise of turbocharged V6 engines, which place greater demands on lubricants, has spurred innovation in thermal stability and wear protection properties.

Market challenges include price sensitivity among certain consumer segments, counterfeit products in emerging markets, and the gradual shift toward electric vehicles in premium segments, which could potentially impact long-term growth trajectories for combustion engine lubricants.

The market for V6 engine-specific high-performance oils represents a significant portion of this sector, accounting for roughly 27% of total high-performance oil sales. This prominence stems from the widespread adoption of V6 engines across mid-range and premium vehicle categories, particularly in North America and Europe where they remain popular in SUVs, crossovers, and performance sedans.

Consumer behavior analysis reveals a growing willingness among vehicle owners to invest in premium lubricants, with 64% of V6 engine owners prioritizing oil quality over price. This trend is especially pronounced among owners of vehicles less than five years old, where the premium oil adoption rate reaches 78%. The average price premium consumers are willing to pay for high-performance oils stands at 35-40% above conventional options.

Distribution channels have evolved significantly, with automotive specialty retailers capturing 32% of market share, followed by authorized service centers (28%), online retailers (22%), and traditional auto parts stores (18%). The online segment has demonstrated the most rapid growth, expanding at 11.2% annually as consumers increasingly research and purchase automotive products digitally.

Regional market dynamics show notable variations, with North America leading consumption at 38% of global market share, followed by Europe (29%), Asia-Pacific (24%), and other regions (9%). Within these markets, synthetic and semi-synthetic formulations optimized for V6 engines dominate, collectively representing 83% of high-performance oil sales.

Key market drivers include increasing consumer awareness about the relationship between oil viscosity and engine performance, stricter emission regulations necessitating advanced lubricant formulations, and the growing average vehicle age in developed markets, which has reached 12.1 years in the United States. Additionally, the rise of turbocharged V6 engines, which place greater demands on lubricants, has spurred innovation in thermal stability and wear protection properties.

Market challenges include price sensitivity among certain consumer segments, counterfeit products in emerging markets, and the gradual shift toward electric vehicles in premium segments, which could potentially impact long-term growth trajectories for combustion engine lubricants.

Current Viscosity Technologies and Limitations

Current engine oil viscosity technologies face significant limitations when applied to V6 engines, particularly under varying performance conditions. The industry standard classification system, established by the Society of Automotive Engineers (SAE), categorizes oils based on their viscosity characteristics at different temperatures. However, this system struggles to fully address the complex demands of modern V6 engines, which operate under increasingly extreme conditions.

Multi-grade oils represent the most widely adopted viscosity technology, utilizing viscosity index improvers (VII) to maintain appropriate flow characteristics across temperature ranges. These polymeric additives expand at higher temperatures to maintain oil thickness but have demonstrated durability issues in high-performance V6 applications. Under sustained high RPM conditions typical in performance driving, these polymers can break down through mechanical shearing, leading to viscosity loss and reduced engine protection.

Synthetic oil technologies have significantly advanced viscosity stability, with fully synthetic formulations offering superior molecular uniformity compared to conventional mineral oils. This results in more predictable viscosity behavior across temperature extremes. However, even advanced synthetics face limitations in addressing the conflicting requirements of cold-start protection and high-temperature performance in V6 engines, particularly those with turbocharging or supercharging.

Recent developments in viscosity modifier technology include shear-stable polymers and PAMA (polyalkylmethacrylate) additives that demonstrate improved resistance to breakdown. Yet these technologies still represent a compromise between low-temperature flow properties and high-temperature protection. The fundamental challenge remains that optimal viscosity for cold-starting differs significantly from that required for maximum power output and efficiency at operating temperature.

Viscosity-sensitive variable valve timing systems in modern V6 engines further complicate oil requirements, as these precision components demand consistent hydraulic pressure that can be compromised by viscosity fluctuations. Additionally, the trend toward lower-viscosity oils to improve fuel economy (such as 0W-20 and even 0W-16 formulations) creates potential durability concerns for high-performance applications where engine loads generate substantial heat.

Temperature management represents another critical limitation, as oil viscosity changes approximately 10% for every 20°F temperature change. V6 engines with varied cylinder cooling characteristics often develop temperature gradients that create inconsistent oil viscosity throughout the engine, potentially leaving certain components with suboptimal protection during performance driving scenarios.

Multi-grade oils represent the most widely adopted viscosity technology, utilizing viscosity index improvers (VII) to maintain appropriate flow characteristics across temperature ranges. These polymeric additives expand at higher temperatures to maintain oil thickness but have demonstrated durability issues in high-performance V6 applications. Under sustained high RPM conditions typical in performance driving, these polymers can break down through mechanical shearing, leading to viscosity loss and reduced engine protection.

Synthetic oil technologies have significantly advanced viscosity stability, with fully synthetic formulations offering superior molecular uniformity compared to conventional mineral oils. This results in more predictable viscosity behavior across temperature extremes. However, even advanced synthetics face limitations in addressing the conflicting requirements of cold-start protection and high-temperature performance in V6 engines, particularly those with turbocharging or supercharging.

Recent developments in viscosity modifier technology include shear-stable polymers and PAMA (polyalkylmethacrylate) additives that demonstrate improved resistance to breakdown. Yet these technologies still represent a compromise between low-temperature flow properties and high-temperature protection. The fundamental challenge remains that optimal viscosity for cold-starting differs significantly from that required for maximum power output and efficiency at operating temperature.

Viscosity-sensitive variable valve timing systems in modern V6 engines further complicate oil requirements, as these precision components demand consistent hydraulic pressure that can be compromised by viscosity fluctuations. Additionally, the trend toward lower-viscosity oils to improve fuel economy (such as 0W-20 and even 0W-16 formulations) creates potential durability concerns for high-performance applications where engine loads generate substantial heat.

Temperature management represents another critical limitation, as oil viscosity changes approximately 10% for every 20°F temperature change. V6 engines with varied cylinder cooling characteristics often develop temperature gradients that create inconsistent oil viscosity throughout the engine, potentially leaving certain components with suboptimal protection during performance driving scenarios.

Contemporary Viscosity Solutions for V6 Engines

01 Optimal viscosity ranges for V6 engine oils

Specific viscosity ranges are recommended for V6 engines to ensure proper lubrication and performance. These ranges typically include SAE grades such as 5W-30, 10W-40, and 0W-20, depending on operating conditions. The optimal viscosity ensures adequate oil flow at startup while maintaining sufficient film thickness at operating temperatures, which is crucial for V6 engines that may generate more heat than smaller engines.- Optimal viscosity ranges for V6 engine oils: Specific viscosity ranges are recommended for V6 engines to ensure proper lubrication and engine protection. These ranges typically include SAE grades such as 5W-30, 10W-30, and 10W-40, which provide adequate flow at cold startup temperatures while maintaining sufficient film thickness at operating temperatures. The optimal viscosity selection depends on factors such as engine design, operating conditions, and ambient temperature ranges to balance fuel efficiency with engine protection.

- Viscosity modifiers for V6 engine oils: Viscosity modifiers are additives incorporated into V6 engine oils to improve their viscosity-temperature relationship. These polymeric compounds help maintain appropriate oil viscosity across a wide temperature range, reducing viscosity loss at high temperatures while ensuring adequate flow at low temperatures. Common viscosity modifiers include polymethacrylates, olefin copolymers, and hydrogenated styrene-diene copolymers, which enhance the oil's performance in V6 engines under varying operating conditions.

- Viscosity monitoring systems for V6 engines: Advanced monitoring systems have been developed to continuously assess oil viscosity in V6 engines during operation. These systems utilize sensors to measure oil properties in real-time, providing feedback on viscosity changes due to factors such as oxidation, contamination, or shear thinning. The monitoring data helps determine optimal oil change intervals and alerts drivers to potential lubrication issues before they cause engine damage, enhancing overall engine reliability and longevity.

- Temperature effects on V6 engine oil viscosity: Temperature significantly impacts oil viscosity in V6 engines, with viscosity decreasing as temperature rises and increasing as temperature falls. This relationship is particularly important for V6 engines that may operate in extreme temperature conditions. Multigrade oils with appropriate viscosity indices are formulated to provide adequate lubrication at cold startup while maintaining sufficient film strength at high operating temperatures, helping to protect critical engine components throughout the temperature range experienced during normal operation.

- Synthetic oils for V6 engine viscosity optimization: Synthetic oils offer enhanced viscosity characteristics for V6 engines compared to conventional mineral oils. These engineered lubricants provide more stable viscosity across a wider temperature range, improved resistance to thermal breakdown, and better low-temperature flow properties. Synthetic formulations typically include carefully selected base stocks and advanced additive packages that maintain optimal viscosity under high-stress conditions, extending engine life and improving performance in modern V6 engines with demanding lubrication requirements.

02 Temperature-dependent viscosity control systems

Advanced systems have been developed to monitor and adjust oil viscosity based on engine temperature in V6 engines. These systems use sensors to detect engine operating conditions and can modify oil flow or properties accordingly. This technology helps maintain optimal viscosity across varying operating conditions, from cold starts to high-temperature highway driving, extending engine life and improving fuel efficiency in V6 engines.Expand Specific Solutions03 Viscosity modifiers and additives for V6 engines

Specialized additives and viscosity modifiers are formulated specifically for V6 engine oils to maintain optimal performance. These include polymeric viscosity improvers, pour point depressants, and friction modifiers that help maintain viscosity stability across temperature ranges. The additives are designed to reduce wear on critical engine components, improve cold-start performance, and enhance fuel efficiency in V6 engines that may experience higher thermal stress.Expand Specific Solutions04 Viscosity monitoring and measurement systems

Various systems have been developed to monitor oil viscosity in real-time for V6 engines. These include sensors and diagnostic tools that can detect changes in oil viscosity during operation, alerting drivers to potential issues before they cause damage. The monitoring systems can be integrated with engine management systems to optimize performance based on current oil conditions, which is particularly important for high-performance V6 engines.Expand Specific Solutions05 Impact of viscosity on V6 engine performance and efficiency

Research has shown that oil viscosity significantly affects V6 engine performance, fuel efficiency, and emissions. Using the correct viscosity oil can improve fuel economy by reducing internal friction, enhance power output by ensuring proper lubrication of moving parts, and reduce emissions by promoting more complete combustion. Studies have demonstrated that optimizing oil viscosity for specific V6 engine designs can lead to measurable improvements in overall engine performance and longevity.Expand Specific Solutions

Leading Engine Oil Manufacturers and Formulation Experts

The V6 engine oil viscosity market is in a mature growth phase, characterized by established technologies and steady demand. The global market size for high-performance engine oils is estimated at $9-10 billion annually, with consistent 3-5% growth. From a technological maturity perspective, major players demonstrate varying levels of innovation: ExxonMobil, Shell, and Infineum lead with advanced synthetic formulations optimized for V6 performance; GM, Ford, and Rolls-Royce focus on OEM-specific solutions; while emerging players like Afton Chemical and Chevron Oronite are developing specialized additives to enhance viscosity stability under extreme conditions. Chinese manufacturers including Sinopec and Weichai Power are rapidly advancing their technical capabilities, particularly in cost-effective formulations for diverse operating environments.

GM Global Technology Operations LLC

Technical Solution: GM has developed dexos® oil specification technology specifically optimized for their V6 engine platforms, with precise viscosity requirements tailored to their engine designs. Their approach focuses on maintaining optimal viscosity across the wide temperature ranges experienced in modern V6 engines while providing enhanced protection against low-speed pre-ignition (LSPI). GM's research has demonstrated that properly formulated oils with specific viscosity characteristics can extend timing chain life by up to 20% in their V6 applications. Their technology incorporates specialized friction modifiers designed to work with specific bearing materials used in GM V6 engines, optimizing both protection and efficiency. GM has also developed specific viscosity requirements for their turbocharged V6 engines that balance the need for high-temperature protection with fuel economy benefits, resulting in formulations that maintain viscosity stability under the most demanding conditions while reducing internal friction.

Strengths: Precisely tailored to GM V6 engine designs; excellent protection against specific wear mechanisms in GM engines; optimized for emissions system compatibility. Weaknesses: Less versatile for non-GM applications; may prioritize GM-specific concerns over general performance metrics.

Shell Internationale Research Maatschappij BV

Technical Solution: Shell has developed advanced synthetic oil formulations specifically engineered for V6 engines that utilize their proprietary PurePlus Technology. This technology converts natural gas into crystal-clear base oil with virtually none of the impurities found in crude oil. For V6 engines, Shell's formulations focus on optimizing viscosity across a wide temperature range, maintaining optimal viscosity at high temperatures while ensuring sufficient flow at cold starts. Their research has demonstrated that proper viscosity management can improve fuel efficiency by up to 2.6% in V6 engines while reducing engine wear by maintaining a consistent protective film between moving parts. Shell's technology also incorporates adaptive viscosity modifiers that respond to temperature changes, providing thicker oil films under high-load conditions and thinner films for reduced friction during normal operation.

Strengths: Superior temperature stability across extreme operating conditions; reduced oil degradation leading to extended drain intervals; excellent protection against wear in high-performance V6 engines. Weaknesses: Premium pricing compared to conventional oils; may be overengineered for older V6 engines with less demanding requirements.

Key Patents in Engine Oil Viscosity Enhancement

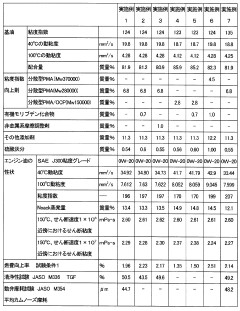

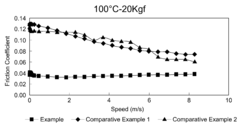

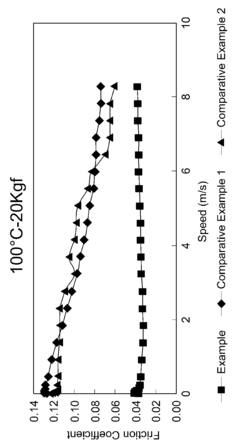

Engine oil

PatentActiveJP2010095664A

Innovation

- The engine oil is formulated with specific shear viscosities at 150°C and targeted shear rates, incorporating a shear viscosity of 2.5 mPa·s or less at 1×10⁷ sec⁻¹ and 2.6 mPa·s or more at 1×10⁶ sec⁻¹, along with additives like organic molybdenum compounds and ashless friction modifiers, to enhance fuel efficiency in both fluid and boundary lubrication regions.

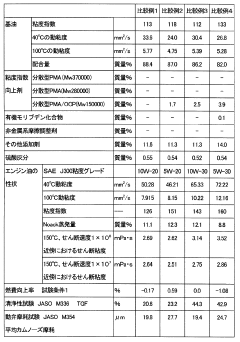

Low viscosity diesel engine oil composition with improved fuel efficiency

PatentActiveUS9085743B2

Innovation

- A diesel engine oil composition incorporating polymethylacrylate as a viscosity index improver, zinc alkyldithiophosphate as an anti-wear agent, molybdenum dithiocarbamate for friction reduction, and a hindered phenol antioxidant, along with a fixed mineral oil, optimized to maintain high-temperature viscosity and improve oxidative stability and wear resistance.

Environmental Impact of Engine Oil Formulations

The environmental implications of engine oil formulations, particularly for V6 engines, extend far beyond the immediate performance considerations. Modern engine oils contain various additives and base stocks that directly impact their ecological footprint throughout their lifecycle.

The production phase of engine oils involves significant environmental considerations. Conventional mineral-based oils require extensive petroleum refining processes that contribute to greenhouse gas emissions and energy consumption. Synthetic oils, while offering better performance characteristics for V6 engines, often require more energy-intensive manufacturing processes, though their extended service life may offset this initial environmental cost.

During vehicle operation, oil viscosity plays a crucial environmental role. Higher viscosity oils can increase fuel consumption in V6 engines by creating greater internal resistance, particularly during cold starts. This translates to increased carbon emissions per mile driven. Studies indicate that properly formulated lower viscosity oils can improve fuel economy by 1-2% in modern V6 engines, representing significant emission reductions across vehicle fleets.

Oil degradation and disposal present substantial environmental challenges. V6 engines operating with improper viscosity oils may experience accelerated wear, leading to increased particulate matter in emissions. Additionally, used engine oil contains heavy metals, combustion byproducts, and other contaminants that pose serious environmental hazards if improperly disposed of. One quart of used oil can contaminate up to 250,000 gallons of groundwater.

Biodegradability and toxicity profiles vary significantly among oil formulations. Conventional mineral oils typically degrade slowly and may contain toxic compounds. Advanced synthetic formulations for V6 engines often incorporate more environmentally friendly additives with reduced heavy metal content and improved biodegradability characteristics, though they remain far from benign environmental substances.

Recent regulatory trends have pushed manufacturers toward developing more environmentally sustainable engine oil formulations. These include bio-based lubricants derived from renewable resources and formulations designed specifically to reduce emissions in modern V6 engines. While these alternatives currently represent a small market segment, they signal an important direction for future development in response to increasingly stringent environmental regulations.

The environmental impact assessment of engine oils must consider their complete lifecycle, from raw material extraction through disposal. Optimizing viscosity for V6 engine performance must be balanced with environmental considerations to achieve truly sustainable lubrication solutions.

The production phase of engine oils involves significant environmental considerations. Conventional mineral-based oils require extensive petroleum refining processes that contribute to greenhouse gas emissions and energy consumption. Synthetic oils, while offering better performance characteristics for V6 engines, often require more energy-intensive manufacturing processes, though their extended service life may offset this initial environmental cost.

During vehicle operation, oil viscosity plays a crucial environmental role. Higher viscosity oils can increase fuel consumption in V6 engines by creating greater internal resistance, particularly during cold starts. This translates to increased carbon emissions per mile driven. Studies indicate that properly formulated lower viscosity oils can improve fuel economy by 1-2% in modern V6 engines, representing significant emission reductions across vehicle fleets.

Oil degradation and disposal present substantial environmental challenges. V6 engines operating with improper viscosity oils may experience accelerated wear, leading to increased particulate matter in emissions. Additionally, used engine oil contains heavy metals, combustion byproducts, and other contaminants that pose serious environmental hazards if improperly disposed of. One quart of used oil can contaminate up to 250,000 gallons of groundwater.

Biodegradability and toxicity profiles vary significantly among oil formulations. Conventional mineral oils typically degrade slowly and may contain toxic compounds. Advanced synthetic formulations for V6 engines often incorporate more environmentally friendly additives with reduced heavy metal content and improved biodegradability characteristics, though they remain far from benign environmental substances.

Recent regulatory trends have pushed manufacturers toward developing more environmentally sustainable engine oil formulations. These include bio-based lubricants derived from renewable resources and formulations designed specifically to reduce emissions in modern V6 engines. While these alternatives currently represent a small market segment, they signal an important direction for future development in response to increasingly stringent environmental regulations.

The environmental impact assessment of engine oils must consider their complete lifecycle, from raw material extraction through disposal. Optimizing viscosity for V6 engine performance must be balanced with environmental considerations to achieve truly sustainable lubrication solutions.

Temperature Effects on V6 Engine Oil Performance

Temperature plays a critical role in determining the performance characteristics of engine oils in V6 engines. At low temperatures, typically below 0°C, engine oil viscosity increases significantly, creating a condition known as "cold start resistance." This phenomenon results in reduced oil flow rates, potentially leading to inadequate lubrication during engine startup and increased wear on critical engine components. Studies have shown that during cold starts, oil pressure buildup can be delayed by up to 15 seconds in extreme conditions, creating a window of vulnerability for engine bearings and other friction surfaces.

Conversely, at high operating temperatures exceeding 100°C, engine oil undergoes thermal thinning, where viscosity decreases substantially. This reduction in viscosity can compromise the oil film strength between moving parts, potentially leading to boundary lubrication conditions rather than the preferred hydrodynamic lubrication. V6 engines, particularly those with turbocharging or high-performance tuning, can generate localized hot spots where oil temperatures may exceed 150°C, approaching the thermal breakdown threshold of conventional oils.

The viscosity index (VI) of engine oil quantifies its resistance to viscosity change across temperature variations. Modern synthetic oils formulated specifically for V6 engines typically feature VI values exceeding 150, compared to conventional mineral oils with VI ratings of 95-100. This improved temperature stability translates to more consistent protection across the operating temperature spectrum, particularly beneficial for V6 engines that may experience rapid temperature fluctuations during variable load conditions.

Temperature cycling effects present another significant challenge for V6 engine oils. The repeated heating and cooling cycles experienced in stop-start driving conditions can accelerate oxidation processes within the oil, leading to viscosity increase over time. Research indicates that oils operating in severe temperature cycling environments may experience up to 30% faster viscosity increase compared to those in steady-state temperature conditions, directly impacting long-term engine protection and efficiency.

Multi-grade oils, such as 5W-30 or 0W-40, are engineered with viscosity modifiers (VMs) that expand at higher temperatures to maintain adequate viscosity. However, these VM polymers are susceptible to mechanical shearing in high-stress areas of V6 engines, such as valve trains and bearings. This shearing effect becomes more pronounced at elevated temperatures, potentially leading to permanent viscosity loss and reduced protection in critical engine areas over extended service intervals.

Conversely, at high operating temperatures exceeding 100°C, engine oil undergoes thermal thinning, where viscosity decreases substantially. This reduction in viscosity can compromise the oil film strength between moving parts, potentially leading to boundary lubrication conditions rather than the preferred hydrodynamic lubrication. V6 engines, particularly those with turbocharging or high-performance tuning, can generate localized hot spots where oil temperatures may exceed 150°C, approaching the thermal breakdown threshold of conventional oils.

The viscosity index (VI) of engine oil quantifies its resistance to viscosity change across temperature variations. Modern synthetic oils formulated specifically for V6 engines typically feature VI values exceeding 150, compared to conventional mineral oils with VI ratings of 95-100. This improved temperature stability translates to more consistent protection across the operating temperature spectrum, particularly beneficial for V6 engines that may experience rapid temperature fluctuations during variable load conditions.

Temperature cycling effects present another significant challenge for V6 engine oils. The repeated heating and cooling cycles experienced in stop-start driving conditions can accelerate oxidation processes within the oil, leading to viscosity increase over time. Research indicates that oils operating in severe temperature cycling environments may experience up to 30% faster viscosity increase compared to those in steady-state temperature conditions, directly impacting long-term engine protection and efficiency.

Multi-grade oils, such as 5W-30 or 0W-40, are engineered with viscosity modifiers (VMs) that expand at higher temperatures to maintain adequate viscosity. However, these VM polymers are susceptible to mechanical shearing in high-stress areas of V6 engines, such as valve trains and bearings. This shearing effect becomes more pronounced at elevated temperatures, potentially leading to permanent viscosity loss and reduced protection in critical engine areas over extended service intervals.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!