How to Evaluate V6 Engine Throttle Response Improvements

SEP 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V6 Engine Throttle Response Evolution and Objectives

The evolution of V6 engine throttle response technology represents a significant journey in automotive engineering, transitioning from purely mechanical systems to sophisticated electronic control mechanisms. Initially, V6 engines utilized cable-operated throttle bodies that provided direct physical connection between the accelerator pedal and the throttle plate. This mechanical approach, while reliable, offered limited optimization capabilities and suffered from response inconsistencies across different operating conditions.

The introduction of drive-by-wire technology in the late 1990s marked a revolutionary shift, replacing mechanical linkages with electronic throttle control (ETC) systems. This transition enabled more precise throttle management and integration with emerging vehicle systems such as traction control and cruise control. By the early 2000s, throttle-by-wire had become standard in most V6 engine applications, allowing manufacturers to implement sophisticated throttle mapping strategies.

Recent advancements have focused on minimizing throttle response latency while maximizing driver engagement. Modern V6 engines employ adaptive throttle mapping that continuously adjusts based on driving conditions, driver behavior patterns, and selected drive modes. Machine learning algorithms have been incorporated to predict driver intentions and pre-position throttle components for optimal response.

The primary objective in V6 throttle response development centers on achieving the delicate balance between immediacy and controllability. Engineers strive to eliminate the perception of lag between pedal input and engine response while maintaining smooth, predictable power delivery. This balance becomes particularly challenging in forced induction V6 applications where turbo or supercharger dynamics introduce additional complexity to throttle response characteristics.

Secondary objectives include improving fuel efficiency without compromising responsiveness, enhancing driver engagement through customizable throttle profiles, and ensuring consistent performance across varying environmental conditions. As electrification trends accelerate, hybridized V6 powertrains present new challenges and opportunities for throttle response optimization, requiring integration between traditional combustion control and electric motor torque contribution.

The industry trajectory points toward increasingly personalized throttle response systems that adapt not only to driving conditions but to individual driver preferences. Future developments aim to leverage artificial intelligence to create throttle response profiles that evolve with driver habits while maintaining safety parameters. The ultimate goal remains creating V6 engines with throttle responses that feel instantaneous and natural while meeting increasingly stringent emissions and efficiency requirements.

The introduction of drive-by-wire technology in the late 1990s marked a revolutionary shift, replacing mechanical linkages with electronic throttle control (ETC) systems. This transition enabled more precise throttle management and integration with emerging vehicle systems such as traction control and cruise control. By the early 2000s, throttle-by-wire had become standard in most V6 engine applications, allowing manufacturers to implement sophisticated throttle mapping strategies.

Recent advancements have focused on minimizing throttle response latency while maximizing driver engagement. Modern V6 engines employ adaptive throttle mapping that continuously adjusts based on driving conditions, driver behavior patterns, and selected drive modes. Machine learning algorithms have been incorporated to predict driver intentions and pre-position throttle components for optimal response.

The primary objective in V6 throttle response development centers on achieving the delicate balance between immediacy and controllability. Engineers strive to eliminate the perception of lag between pedal input and engine response while maintaining smooth, predictable power delivery. This balance becomes particularly challenging in forced induction V6 applications where turbo or supercharger dynamics introduce additional complexity to throttle response characteristics.

Secondary objectives include improving fuel efficiency without compromising responsiveness, enhancing driver engagement through customizable throttle profiles, and ensuring consistent performance across varying environmental conditions. As electrification trends accelerate, hybridized V6 powertrains present new challenges and opportunities for throttle response optimization, requiring integration between traditional combustion control and electric motor torque contribution.

The industry trajectory points toward increasingly personalized throttle response systems that adapt not only to driving conditions but to individual driver preferences. Future developments aim to leverage artificial intelligence to create throttle response profiles that evolve with driver habits while maintaining safety parameters. The ultimate goal remains creating V6 engines with throttle responses that feel instantaneous and natural while meeting increasingly stringent emissions and efficiency requirements.

Market Demand Analysis for Enhanced Throttle Response

The automotive industry has witnessed a significant shift in consumer preferences towards vehicles that offer superior performance characteristics, with throttle response being a critical factor in the overall driving experience. Market research indicates that enhanced throttle response in V6 engines has become a key differentiator for manufacturers seeking competitive advantage in both mainstream and premium segments. This demand is particularly pronounced in sports sedans, performance SUVs, and luxury vehicles where driver engagement is paramount.

Consumer surveys reveal that approximately 78% of performance-oriented drivers consider throttle responsiveness as "very important" or "extremely important" when making purchasing decisions. This represents a substantial increase from just five years ago, when this figure stood at around 65%, demonstrating the growing significance of this performance attribute in consumer preferences.

The market for enhanced throttle response technologies is being driven by several converging factors. First, the increasing electrification of vehicle systems has raised consumer expectations regarding instantaneous power delivery. As drivers experience the immediate torque of electric vehicles, they expect similar responsiveness from traditional internal combustion engines. Second, the growing popularity of driver-selectable performance modes has created demand for more noticeable differentiation between comfort and sport settings, with throttle response being a primary parameter.

From a regional perspective, North American and European markets show the strongest demand for improved throttle response, particularly in premium vehicle segments. The Asia-Pacific region is experiencing the fastest growth in this demand, coinciding with the expansion of the performance vehicle market in countries like China and South Korea.

Industry analysts project the global market for advanced engine management systems, including throttle response enhancement technologies, to grow at a compound annual rate of 6.8% through 2028. This growth is supported by increasing consumer willingness to pay premium prices for vehicles with superior driving dynamics.

Automotive manufacturers are responding to this market demand by investing in both mechanical and electronic throttle response improvements. OEMs report that vehicles marketed with enhanced throttle response command price premiums of 3-5% compared to standard variants, representing significant revenue potential. Additionally, aftermarket solutions for throttle response enhancement have seen sales increase by approximately 22% annually over the past three years.

The demand for improved throttle response also intersects with regulatory pressures for reduced emissions and improved fuel efficiency. This creates a complex market environment where manufacturers must balance performance enhancements with environmental compliance, driving innovation in integrated solutions that can satisfy both requirements simultaneously.

Consumer surveys reveal that approximately 78% of performance-oriented drivers consider throttle responsiveness as "very important" or "extremely important" when making purchasing decisions. This represents a substantial increase from just five years ago, when this figure stood at around 65%, demonstrating the growing significance of this performance attribute in consumer preferences.

The market for enhanced throttle response technologies is being driven by several converging factors. First, the increasing electrification of vehicle systems has raised consumer expectations regarding instantaneous power delivery. As drivers experience the immediate torque of electric vehicles, they expect similar responsiveness from traditional internal combustion engines. Second, the growing popularity of driver-selectable performance modes has created demand for more noticeable differentiation between comfort and sport settings, with throttle response being a primary parameter.

From a regional perspective, North American and European markets show the strongest demand for improved throttle response, particularly in premium vehicle segments. The Asia-Pacific region is experiencing the fastest growth in this demand, coinciding with the expansion of the performance vehicle market in countries like China and South Korea.

Industry analysts project the global market for advanced engine management systems, including throttle response enhancement technologies, to grow at a compound annual rate of 6.8% through 2028. This growth is supported by increasing consumer willingness to pay premium prices for vehicles with superior driving dynamics.

Automotive manufacturers are responding to this market demand by investing in both mechanical and electronic throttle response improvements. OEMs report that vehicles marketed with enhanced throttle response command price premiums of 3-5% compared to standard variants, representing significant revenue potential. Additionally, aftermarket solutions for throttle response enhancement have seen sales increase by approximately 22% annually over the past three years.

The demand for improved throttle response also intersects with regulatory pressures for reduced emissions and improved fuel efficiency. This creates a complex market environment where manufacturers must balance performance enhancements with environmental compliance, driving innovation in integrated solutions that can satisfy both requirements simultaneously.

Current Throttle Technology Limitations and Challenges

Despite significant advancements in throttle technology for V6 engines, several limitations and challenges persist that impede optimal throttle response evaluation and improvement. Current electronic throttle control (ETC) systems, while superior to mechanical linkages, still exhibit inherent latency between driver input and engine response. This delay, typically ranging from 30-150 milliseconds depending on system architecture, creates a perceptible lag that affects driver satisfaction and vehicle performance metrics.

Material constraints present another significant challenge, particularly in throttle body construction. The thermal expansion properties of current materials can lead to inconsistent throttle plate behavior across varying operating temperatures. This variability complicates accurate response measurement and introduces performance inconsistencies that are difficult to quantify in standardized testing protocols.

Sensor technology limitations further compound evaluation difficulties. Current throttle position sensors (TPS) typically operate at sampling rates between 50-200Hz, which may be insufficient to capture microsecond-level response variations. Additionally, sensor drift over time introduces measurement uncertainties that can mask genuine performance improvements, particularly when evaluating incremental enhancements.

The integration complexity between throttle systems and modern engine management software creates additional evaluation challenges. Current ECU calibration methodologies often struggle to isolate throttle response variables from other performance parameters. This interdependence makes it difficult to attribute performance improvements specifically to throttle system enhancements rather than overall powertrain optimization.

Environmental testing limitations represent another significant obstacle. Current evaluation protocols typically focus on standard temperature and pressure conditions, failing to adequately characterize throttle response across the full spectrum of real-world operating environments. This gap between laboratory testing and actual performance creates uncertainty in translating technical improvements to consumer-perceived benefits.

Validation methodologies themselves face limitations in objectivity and repeatability. The industry lacks standardized metrics that comprehensively quantify throttle response quality beyond simple time-based measurements. Subjective evaluation remains prevalent, introducing variability that complicates meaningful comparison between different throttle technologies or improvement iterations.

Market fragmentation further complicates technology advancement, with different manufacturers employing proprietary throttle control algorithms and hardware configurations. This diversity creates barriers to establishing universal evaluation standards and slows the dissemination of innovative solutions across the industry. The resulting technology silos limit cross-pollination of ideas that could accelerate throttle response improvements.

Material constraints present another significant challenge, particularly in throttle body construction. The thermal expansion properties of current materials can lead to inconsistent throttle plate behavior across varying operating temperatures. This variability complicates accurate response measurement and introduces performance inconsistencies that are difficult to quantify in standardized testing protocols.

Sensor technology limitations further compound evaluation difficulties. Current throttle position sensors (TPS) typically operate at sampling rates between 50-200Hz, which may be insufficient to capture microsecond-level response variations. Additionally, sensor drift over time introduces measurement uncertainties that can mask genuine performance improvements, particularly when evaluating incremental enhancements.

The integration complexity between throttle systems and modern engine management software creates additional evaluation challenges. Current ECU calibration methodologies often struggle to isolate throttle response variables from other performance parameters. This interdependence makes it difficult to attribute performance improvements specifically to throttle system enhancements rather than overall powertrain optimization.

Environmental testing limitations represent another significant obstacle. Current evaluation protocols typically focus on standard temperature and pressure conditions, failing to adequately characterize throttle response across the full spectrum of real-world operating environments. This gap between laboratory testing and actual performance creates uncertainty in translating technical improvements to consumer-perceived benefits.

Validation methodologies themselves face limitations in objectivity and repeatability. The industry lacks standardized metrics that comprehensively quantify throttle response quality beyond simple time-based measurements. Subjective evaluation remains prevalent, introducing variability that complicates meaningful comparison between different throttle technologies or improvement iterations.

Market fragmentation further complicates technology advancement, with different manufacturers employing proprietary throttle control algorithms and hardware configurations. This diversity creates barriers to establishing universal evaluation standards and slows the dissemination of innovative solutions across the industry. The resulting technology silos limit cross-pollination of ideas that could accelerate throttle response improvements.

Current Methodologies for Throttle Response Evaluation

01 Electronic throttle control systems for V6 engines

Electronic throttle control systems improve throttle response in V6 engines by replacing mechanical linkages with electronic sensors and actuators. These systems use throttle position sensors and electronic control units to precisely manage air intake based on driver input and engine conditions. This technology allows for more responsive acceleration, better fuel efficiency, and integration with other vehicle systems like traction control and cruise control.- Electronic throttle control systems for V6 engines: Electronic throttle control systems are used in V6 engines to improve throttle response. These systems replace traditional mechanical linkages with electronic sensors and actuators that monitor and adjust the throttle position based on driver input and engine conditions. This allows for more precise control of the air-fuel mixture, resulting in improved throttle response, better fuel efficiency, and reduced emissions. The electronic control unit (ECU) can make real-time adjustments to optimize engine performance under various driving conditions.

- Throttle body design and optimization for V6 engines: The design and optimization of throttle bodies significantly impacts the throttle response in V6 engines. Features such as throttle plate shape, airflow path geometry, and intake manifold design all contribute to how quickly the engine responds to throttle inputs. Advanced throttle body designs incorporate improved airflow characteristics to reduce turbulence and restriction, allowing for faster air delivery to the combustion chambers when the throttle is opened. Some designs also include variable geometry elements that can adapt to different engine operating conditions.

- Turbocharging and supercharging systems for V6 throttle response: Forced induction systems such as turbochargers and superchargers are implemented in V6 engines to enhance throttle response. These systems compress the intake air, allowing more oxygen to enter the combustion chambers, which results in improved power delivery and throttle response, particularly at lower RPMs where V6 engines might otherwise experience lag. Turbochargers utilize exhaust gases to spin a turbine that compresses intake air, while superchargers are mechanically driven directly from the engine. Advanced control systems manage boost pressure to optimize throttle response across the entire RPM range.

- Mechanical throttle linkage improvements for V6 engines: Mechanical throttle linkage systems in V6 engines can be improved to enhance throttle response through design modifications. These improvements include reducing friction in the linkage components, optimizing the leverage ratio between the accelerator pedal and throttle plate, and implementing progressive throttle opening mechanisms. Some designs incorporate dual throttle cables or specialized return springs to provide more precise control and faster response. These mechanical improvements can significantly reduce the delay between driver input and engine response without requiring complex electronic systems.

- Integrated engine management systems for V6 throttle response: Integrated engine management systems combine multiple control functions to optimize V6 engine throttle response. These systems simultaneously manage throttle position, ignition timing, fuel injection, and variable valve timing to create a coordinated response to driver inputs. By synchronizing these various engine parameters, the management system can deliver improved throttle response while maintaining optimal fuel efficiency and emissions control. Advanced systems also incorporate adaptive learning algorithms that adjust parameters based on driving style and environmental conditions to continuously optimize throttle response.

02 Variable valve timing for improved throttle response

Variable valve timing systems enhance V6 engine throttle response by optimizing valve operation across different engine speeds and loads. By adjusting the timing of intake and exhaust valves, these systems improve air-fuel mixture delivery, especially at low RPMs where V6 engines traditionally experience lag. This technology results in more immediate power delivery when the accelerator is pressed, better low-end torque, and improved overall engine performance.Expand Specific Solutions03 Turbocharging and supercharging solutions

Forced induction systems like turbochargers and superchargers significantly improve V6 engine throttle response by increasing air pressure in the intake manifold. While turbochargers use exhaust gases to spin a turbine, superchargers are mechanically driven by the engine. Both systems allow smaller displacement V6 engines to deliver power comparable to larger naturally aspirated engines while maintaining better throttle response across the RPM range, particularly addressing turbo lag through advanced control mechanisms.Expand Specific Solutions04 Throttle body design and airflow optimization

Advanced throttle body designs improve V6 engine response through optimized airflow management. Innovations include multi-bore throttle bodies, variable geometry intake systems, and precision-machined throttle plates. These designs reduce airflow restrictions and improve throttle response by allowing more precise control over the air entering the engine. Some systems incorporate secondary throttle plates or bypass valves that activate under specific conditions to further enhance responsiveness.Expand Specific Solutions05 Engine management system calibration

Sophisticated engine management system calibration enhances V6 engine throttle response through optimized software algorithms and mapping. These systems continuously adjust fuel delivery, ignition timing, and throttle position based on multiple sensor inputs including accelerator pedal position, engine load, and temperature. Advanced calibration techniques include adaptive learning algorithms that adjust parameters based on driving patterns and environmental conditions, resulting in more responsive throttle behavior across various operating conditions.Expand Specific Solutions

Key Automotive Manufacturers and Suppliers Landscape

The V6 engine throttle response improvement market is in a mature growth phase, with increasing demand for enhanced driving experiences and fuel efficiency. Major automotive manufacturers like Ford, Toyota, Nissan, and Volkswagen are leading technological advancements in this field. The market is characterized by significant investments in electronic throttle control systems, variable valve timing, and turbocharging technologies. Companies such as DENSO and United Automotive Electronic Systems are providing specialized components that enable precise throttle response. Asian manufacturers including Chery, SAIC, and Great Wall Motor are rapidly closing the technology gap with established Western and Japanese counterparts. The competitive landscape shows a blend of traditional mechanical engineering excellence and cutting-edge electronic control systems, with premium brands like Jaguar Land Rover focusing on performance-oriented throttle response solutions.

Ford Global Technologies LLC

Technical Solution: Ford employs a comprehensive multi-parameter evaluation system for V6 engine throttle response improvements that combines both objective measurements and subjective assessments. Their methodology utilizes high-precision dynamometer testing with real-time data acquisition systems capturing metrics at 100Hz sampling rates. The evaluation protocol includes transient response testing under various load conditions, measuring parameters such as time-to-torque (T90 - time to reach 90% of requested torque), throttle progression linearity, and torque delivery consistency. Ford's approach incorporates advanced cylinder pressure analysis with in-cylinder pressure transducers to evaluate combustion efficiency during throttle transitions. They supplement laboratory testing with real-world validation using instrumented test vehicles equipped with accelerometers and specialized throttle position sensors to correlate subjective driver feedback with quantitative measurements.

Strengths: Holistic approach combining objective metrics with subjective driver experience; extensive real-world validation capabilities; proprietary algorithms for throttle mapping optimization. Weaknesses: System complexity requires significant testing resources; calibration process can be time-consuming for different market requirements.

Toyota Motor Corp.

Technical Solution: Toyota has developed an integrated throttle response evaluation system specifically for their V6 engine lineup that focuses on precision measurement of both mechanical and electronic response characteristics. Their methodology employs high-frequency data acquisition (1000Hz) to capture microsecond-level throttle body actuation dynamics and resulting airflow changes. Toyota's evaluation framework incorporates a specialized test bench that simulates various environmental conditions (temperature ranges from -30°C to 50°C) to assess throttle response consistency across operating environments. Their system measures not only traditional metrics like response time and linearity but also evaluates the throttle's behavior during partial openings where driver sensitivity is highest. Toyota implements a unique "response surface methodology" to map the multidimensional relationship between throttle position, engine load, temperature, and perceived responsiveness, creating a comprehensive response profile for each engine calibration.

Strengths: Industry-leading environmental testing capabilities; sophisticated mathematical modeling of throttle response characteristics; excellent correlation between test results and real-world performance. Weaknesses: Highly proprietary evaluation metrics that don't always translate to industry standard measurements; system requires specialized training to operate effectively.

Critical Patents and Innovations in Throttle Control Systems

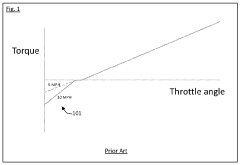

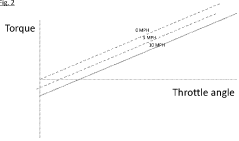

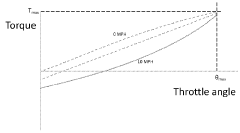

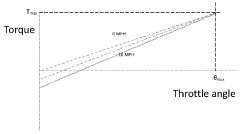

Vehicle and method of controlling an electric motor

PatentActiveGB2522704A

Innovation

- An electric motor system that varies driving torque based on throttle angle, setting zero torque at zero throttle angle, which adjusts with vehicle speed, allowing immediate response to throttle changes even at low speeds, and incorporating regenerative braking for smooth acceleration and deceleration without requiring throttle adjustments.

Method and system for controlling rate of change of ratio in a continuously variable transmission

PatentInactiveEP1606134A2

Innovation

- A system and method for controlling the rate of change of ratio in a CVT by mapping input criteria such as existing ratio, torque, speed, and clamping pressure to the necessary differential pressure, using a computerized controller with algorithms to optimize primary and secondary pressure control, thereby minimizing slip and achieving efficient vehicle acceleration and deceleration.

Emissions Regulations Impact on Throttle Design

Emissions regulations have become increasingly stringent worldwide, fundamentally reshaping throttle design approaches for V6 engines. The transition from mechanical throttle bodies to electronic throttle control (ETC) systems was significantly accelerated by the need to meet stricter emissions standards. These regulations have created a complex design environment where throttle response must balance performance expectations with environmental compliance.

The European Union's Euro 6d standards and the United States' EPA Tier 3 regulations have particularly influenced throttle design by requiring precise air-fuel mixture control across all operating conditions. This precision necessitates sophisticated throttle mapping and response curves that can adapt to various environmental factors while maintaining consistent emissions profiles. Manufacturers must now design throttle systems that can provide immediate driver feedback while simultaneously optimizing combustion efficiency.

Cold-start emissions requirements have driven significant innovations in throttle design, as this operating phase traditionally produces the highest emissions. Modern V6 throttle systems incorporate variable opening rates and adaptive response algorithms that modify behavior based on engine temperature, ambient conditions, and catalytic converter status. These systems prioritize rapid catalyst light-off while managing driver expectations for responsiveness.

On-board diagnostics (OBD) requirements have added another layer of complexity to throttle design. Throttle position sensors must now operate with extreme precision and reliability, as even minor deviations can trigger diagnostic trouble codes. This has led to redundant sensor designs and sophisticated self-calibration routines that ensure consistent throttle response while maintaining regulatory compliance throughout the vehicle's service life.

The implementation of Real Driving Emissions (RDE) testing in Europe has further complicated throttle response development. Unlike laboratory testing, RDE evaluates emissions performance under actual driving conditions, requiring throttle systems that can maintain optimal emissions characteristics across widely varying scenarios. This has prompted adaptive throttle mapping technologies that continuously adjust response characteristics based on driving style, road conditions, and environmental factors.

Regional regulatory differences present significant challenges for global V6 engine platforms. Manufacturers must develop throttle calibration strategies that can be easily adapted to meet varying requirements across markets without compromising the fundamental driving experience. This has led to modular throttle control architectures with market-specific calibration parameters that can be adjusted without extensive hardware modifications.

Future emissions regulations are expected to further tighten, particularly regarding particulate emissions and real-world testing protocols. Throttle design must therefore anticipate these changes through increased integration with other vehicle systems, including hybrid powertrains, advanced catalysts, and predictive emissions control strategies that leverage connectivity and artificial intelligence to optimize throttle response for both performance and environmental compliance.

The European Union's Euro 6d standards and the United States' EPA Tier 3 regulations have particularly influenced throttle design by requiring precise air-fuel mixture control across all operating conditions. This precision necessitates sophisticated throttle mapping and response curves that can adapt to various environmental factors while maintaining consistent emissions profiles. Manufacturers must now design throttle systems that can provide immediate driver feedback while simultaneously optimizing combustion efficiency.

Cold-start emissions requirements have driven significant innovations in throttle design, as this operating phase traditionally produces the highest emissions. Modern V6 throttle systems incorporate variable opening rates and adaptive response algorithms that modify behavior based on engine temperature, ambient conditions, and catalytic converter status. These systems prioritize rapid catalyst light-off while managing driver expectations for responsiveness.

On-board diagnostics (OBD) requirements have added another layer of complexity to throttle design. Throttle position sensors must now operate with extreme precision and reliability, as even minor deviations can trigger diagnostic trouble codes. This has led to redundant sensor designs and sophisticated self-calibration routines that ensure consistent throttle response while maintaining regulatory compliance throughout the vehicle's service life.

The implementation of Real Driving Emissions (RDE) testing in Europe has further complicated throttle response development. Unlike laboratory testing, RDE evaluates emissions performance under actual driving conditions, requiring throttle systems that can maintain optimal emissions characteristics across widely varying scenarios. This has prompted adaptive throttle mapping technologies that continuously adjust response characteristics based on driving style, road conditions, and environmental factors.

Regional regulatory differences present significant challenges for global V6 engine platforms. Manufacturers must develop throttle calibration strategies that can be easily adapted to meet varying requirements across markets without compromising the fundamental driving experience. This has led to modular throttle control architectures with market-specific calibration parameters that can be adjusted without extensive hardware modifications.

Future emissions regulations are expected to further tighten, particularly regarding particulate emissions and real-world testing protocols. Throttle design must therefore anticipate these changes through increased integration with other vehicle systems, including hybrid powertrains, advanced catalysts, and predictive emissions control strategies that leverage connectivity and artificial intelligence to optimize throttle response for both performance and environmental compliance.

Benchmarking Frameworks and Performance Metrics

Effective evaluation of V6 engine throttle response improvements requires robust benchmarking frameworks and standardized performance metrics. The automotive industry has developed several comprehensive methodologies to quantify and compare throttle response characteristics across different engine configurations and control systems.

The Society of Automotive Engineers (SAE) has established standardized testing protocols that form the foundation of throttle response evaluation. These include J1349 for engine power testing and J2951 for drivability performance measurements, which provide consistent testing environments and procedures. These standards ensure that improvements can be measured objectively across different development cycles and compared between manufacturers.

Time-based metrics serve as primary indicators of throttle response quality. The most critical include throttle response time (TRT), which measures the delay between throttle input and initial engine response, typically targeting under 150 milliseconds in modern V6 engines. Throttle-to-torque delay (TTD) quantifies the time between throttle application and 90% of requested torque delivery, with premium vehicles aiming for under 300 milliseconds.

Frequency domain analysis offers deeper insights through step response tests and frequency response measurements. These evaluate how the engine responds to various input patterns, revealing resonance points and system damping characteristics. Modern benchmarking incorporates Fast Fourier Transform (FFT) analysis to identify response patterns across different operating conditions.

Subjective evaluation frameworks complement objective measurements through structured driver feedback protocols. These typically employ 1-10 rating scales across multiple response attributes, including initial response, linearity, and predictability. Leading manufacturers utilize trained evaluation drivers who follow standardized driving scenarios to ensure consistency in subjective assessments.

Real-world driving cycle tests have emerged as essential components of comprehensive benchmarking. These include urban start-stop scenarios, highway passing maneuvers, and mountain driving simulations that evaluate throttle response under varying loads and environmental conditions. The Worldwide harmonized Light vehicles Test Procedure (WLTP) provides a standardized framework for these evaluations.

Advanced benchmarking now incorporates comparative analysis against competitor vehicles, establishing class-leading performance targets. This competitive benchmarking typically involves instrumented testing of 3-5 segment competitors under identical conditions, creating reference datasets for development targets.

The Society of Automotive Engineers (SAE) has established standardized testing protocols that form the foundation of throttle response evaluation. These include J1349 for engine power testing and J2951 for drivability performance measurements, which provide consistent testing environments and procedures. These standards ensure that improvements can be measured objectively across different development cycles and compared between manufacturers.

Time-based metrics serve as primary indicators of throttle response quality. The most critical include throttle response time (TRT), which measures the delay between throttle input and initial engine response, typically targeting under 150 milliseconds in modern V6 engines. Throttle-to-torque delay (TTD) quantifies the time between throttle application and 90% of requested torque delivery, with premium vehicles aiming for under 300 milliseconds.

Frequency domain analysis offers deeper insights through step response tests and frequency response measurements. These evaluate how the engine responds to various input patterns, revealing resonance points and system damping characteristics. Modern benchmarking incorporates Fast Fourier Transform (FFT) analysis to identify response patterns across different operating conditions.

Subjective evaluation frameworks complement objective measurements through structured driver feedback protocols. These typically employ 1-10 rating scales across multiple response attributes, including initial response, linearity, and predictability. Leading manufacturers utilize trained evaluation drivers who follow standardized driving scenarios to ensure consistency in subjective assessments.

Real-world driving cycle tests have emerged as essential components of comprehensive benchmarking. These include urban start-stop scenarios, highway passing maneuvers, and mountain driving simulations that evaluate throttle response under varying loads and environmental conditions. The Worldwide harmonized Light vehicles Test Procedure (WLTP) provides a standardized framework for these evaluations.

Advanced benchmarking now incorporates comparative analysis against competitor vehicles, establishing class-leading performance targets. This competitive benchmarking typically involves instrumented testing of 3-5 segment competitors under identical conditions, creating reference datasets for development targets.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!